ASTM C522-03(2009)

(Test Method)Standard Test Method for Airflow Resistance of Acoustical Materials

Standard Test Method for Airflow Resistance of Acoustical Materials

SIGNIFICANCE AND USE

The specific airflow resistance of an acoustical material is one of the properties that determine its sound-absorptive and sound-transmitting properties. Measurement of specific airflow resistance is useful during product development, for quality control during manufacture, and for specification purposes.

Valid measurements are made only in the region of laminar airflow where, aside from random measurement errors, the airflow resistance (R = P/U) is constant. When the airflow is turbulent, the apparent airflow resistance increases with an increase of volume velocity and the term “airflow resistance” does not apply.

The specific airflow resistance measured by this test method may differ from the specific resistance measured by the impedance tube method in Test Method E384 for two reasons. In the presence of sound, the particle velocity inside a porous material is alternating while in this test method, the velocity is constant and in one direction only. Also, the particle velocity inside a porous material is not the same as the linear velocity measured outside the specimen.

SCOPE

1.1 This test method covers the measurement of airflow resistance and the related measurements of specific airflow resistance and airflow resistivity of porous materials that can be used for the absorption and attenuation of sound. Materials cover a range from thick boards or blankets to thin mats, fabrics, papers, and screens. When the material is anisotropic, provision is made for measurements along different axes of the specimen.

1.2 This test method is designed for the measurement of values of specific airflow resistance ranging from 100 to 10 000 mks rayls (Pa·s/m) with linear airflow velocities ranging from 0.5 to 50 mm/s and pressure differences across the specimen ranging from 0.1 to 250 Pa. The upper limit of this range of linear airflow velocities is a point at which the airflow through most porous materials is in partial or complete transition from laminar to turbulent flow.

1.3 A procedure for accrediting a laboratory for the purposes of this test method is given in Annex A1.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C522 – 03 (Reapproved 2009)

Standard Test Method for

1

Airflow Resistance of Acoustical Materials

This standard is issued under the fixed designation C522; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the measurement of airflow

resistance and the related measurements of specific airflow

3. Terminology

resistanceandairflowresistivityofporousmaterialsthatcanbe

3.1 Definitions: The definitions used in this test method are

used for the absorption and attenuation of sound. Materials

contained in Terminology C634.

cover a range from thick boards or blankets to thin mats,

3.2 Definitions of Terms Specific to This Standard: The

fabrics, papers, and screens. When the material is anisotropic,

following items have been modified to exclude alternating

provision is made for measurements along different axes of the

flow.

specimen.

3.2.1 airflow resistance, R; mks acoustic ohm

1.2 This test method is designed for the measurement of

3

(Pa·s/m )—the quotient of the air pressure difference across a

values of specific airflow resistance ranging from 100 to

specimendividedbythevolumevelocityofairflowthroughthe

10 000 mks rayls (Pa·s/m) with linear airflow velocities rang-

specimen.

ing from 0.5 to 50 mm/s and pressure differences across the

2

3.2.2 airflow resistivity, r ; mks rayl/m (Pa·s/m )— of a

0

specimen ranging from 0.1 to 250 Pa. The upper limit of this

homogeneous material, the quotient of its specific airflow

range of linear airflow velocities is a point at which the airflow

resistance divided by its thickness.

through most porous materials is in partial or complete

3.2.3 lateral airflow resistivity— of an anisotropic homoge-

transition from laminar to turbulent flow.

neous material, the airflow resistivity when the direction of

1.3 A procedure for accrediting a laboratory for the pur-

airflowisparalleltothefaceofthematerialfromwhichthetest

poses of this test method is given in Annex A1.

specimen is taken.

1.4 The values stated in SI units are to be regarded as

3.2.4 specific airflow resistance, r; mks rayl (Pa·s/m)—the

standard. No other units of measurement are included in this

product of the airflow resistance of a specimen and its area.

standard.

This is equivalent to the air pressure difference across the

1.5 This standard does not purport to address all of the

specimen divided by the linear velocity of airflow measured

safety concerns, if any, associated with its use. It is the

outside the specimen.

responsibility of the user of this standard to establish appro-

3.2.5 transverse airflow resistivity— of an anisotropic ho-

priate safety and health practices and determine the applica-

mogeneous material, the airflow resistivity when the direction

bility of regulatory limitations prior to use.

of airflow is perpendicular to the face of the material from

2. Referenced Documents which the test specimen is taken.

2 3.3 Application of Terms:

2.1 ASTM Standards:

3.3.1 The term airflow resistance can be applied to speci-

E384 Test Method for Microindentation Hardness of Mate-

mens of any kind.

rials

3.3.2 The term specific airflow resistance has meaning only

C634 Terminology Relating to Building and Environmental

when applied to a specimen of uniform thickness that is

Acoustics

homogeneous in directions parallel to its surface but not

necessarily homogeneous in the direction of airflow perpen-

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE33onBuilding

dicular to its surface.

and Environmental Acoustics and is the direct responsibility of Subcommittee

3.3.3 The term airflow resistivity has meaning only when

E33.01 on Sound Absorption.

applied to a specimen that is homogeneous in directions

Current edition approved Oct. 1, 2009. Published February 2010. Originally

approved in 1963. Last previous edition approved in 2003 as C522 – 03. DOI:

parallel to a and perpendicular to its surface but not necessarily

10.1520/C0522-03R09.

isotropic.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.4 Symbols:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.4.1 P = air pressure difference across test specimen, Pa.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

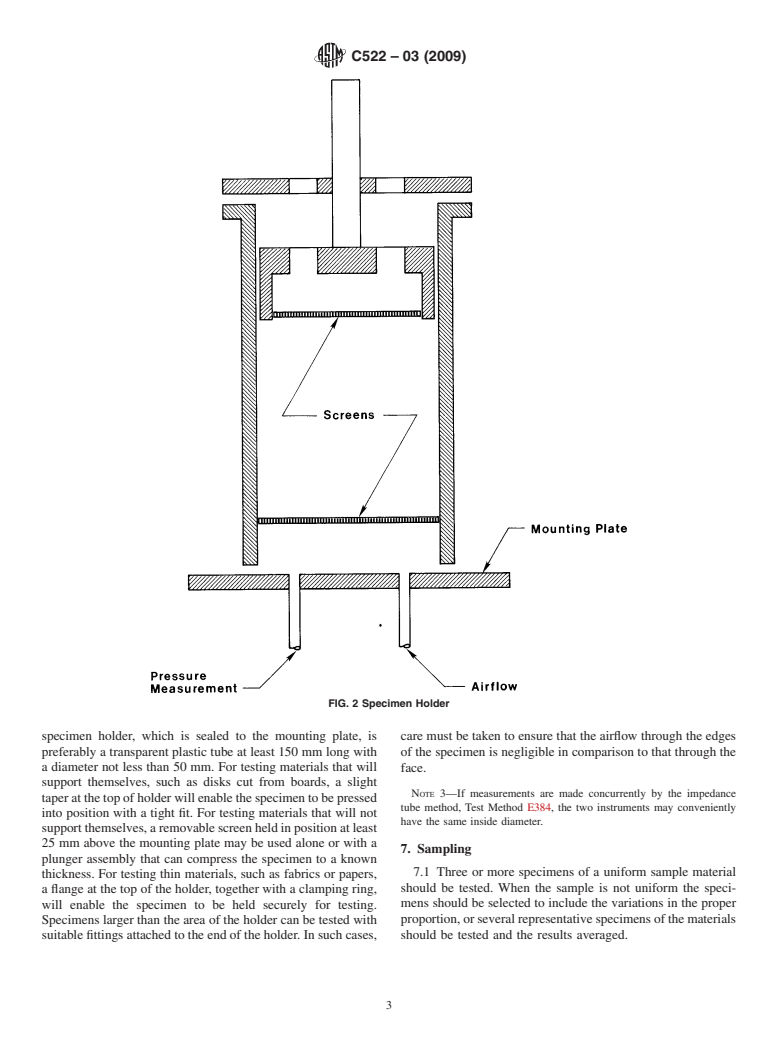

---------------------- Page: 1 ----------------------

C522 – 03 (2009)

3.4.2 U = volume velocity of airflow through the specime

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.