ASTM D5400-15(2021)

(Test Method)Standard Test Methods for Hydroxypropylcellulose

Standard Test Methods for Hydroxypropylcellulose

SIGNIFICANCE AND USE

5.1 The results of this test are used for calculating the total solids in the sample; and, by common usage, all materials volatile at this test temperature are designated as moisture.

5.2 Moisture analysis (along with residue on ignition) is a measure of the amount of active polymer in the material and must be considered when determining the amount of hydroxypropylcellulose to use in various formulations.

SCOPE

1.1 These test methods cover the testing of hydroxypropylcellulose.

1.2 The test procedures appear in the following order:

Sections

Moisture

4 – 9

Viscosity

10 – 16

pH

17 – 21

Residue on Ignition

22 – 28

Hydroxypropoxy Content

29 – 36

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 26.6.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5400 − 15 (Reapproved 2021)

Standard Test Methods for

1

Hydroxypropylcellulose

This standard is issued under the fixed designation D5400; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Reagents

1.1 These test methods cover the testing of hydroxypropy- 3.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

lcellulose.

all reagents shall conform to the specifications of the Commit-

1.2 The test procedures appear in the following order:

tee onAnalytical Reagents of theAmerican Chemical Society,

3

Sections

where such specifications are available. Other grades may be

Moisture 4–9

used, provided it is first ascertained that the reagent is of

Viscosity 10–16

pH 17–21

sufficiently high purity to permit its use without lessening the

Residue on Ignition 22–28

accuracy of the determination.

Hydroxypropoxy Content 29–36

3.2 Purity of Water—Unless otherwise indicated, references

1.3 The values stated in SI units are to be regarded as the

to water shall be understood to mean distilled water.

standard. The values given in parentheses are for information

only.

MOISTURE

1.4 This standard does not purport to address all of the

4. Scope

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4.1 Thistestmethodcoversthedeterminationofthevolatile

priate safety, health, and environmental practices and deter- content of hydroxypropylcellulose.

mine the applicability of regulatory limitations prior to use.

5. Significance and Use

For specific hazard statements, see 26.6.

5.1 The results of this test are used for calculating the total

1.5 This international standard was developed in accor-

solids in the sample; and, by common usage, all materials

dance with internationally recognized principles on standard-

volatile at this test temperature are designated as moisture.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5.2 Moisture analysis (along with residue on ignition) is a

mendations issued by the World Trade Organization Technical

measure of the amount of active polymer in the material and

Barriers to Trade (TBT) Committee.

must be considered when determining the amount of hydroxy-

propylcellulose to use in various formulations.

2. Referenced Documents

6. Apparatus

2

2.1 ASTM Standards:

6.1 Oven, gravity convection, capable of maintaining a

D3876Test Method for Methoxyl and Hydroxypropyl Sub-

temperature of 105 6 3°C.

stitution in Cellulose Ether Products by Gas Chromatog-

raphy 6.2 Weighing Dish, glass or aluminum, with cover, 50 mm

E70Test Method for pH of Aqueous Solutions With the

in diameter, 25 mm in height, or equivalent.

Glass Electrode

6.3 Analytical Balance.

7. Procedure

1

These test methods are under the jurisdiction of ASTM Committee D01 on 7.1 Weigh about5gof sample to the nearest 0.001 g in a

Paint and Related Coatings, Materials, and Applications and are the direct

tared and covered weighing dish.

responsibility of Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

Current edition approved June 1, 2021. Published June 2021. Originally

3

approved in 1993. Last previous edition approved in 2015 as D5400–15. DOI: ACS Reagent Chemicals, Specifications and Procedures for Reagents and

10.1520/D5400-15R21. Standard-Grade Reference Materials, American Chemical Society, Washington,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or DC. For suggestions on the testing of reagents not listed by theAmerican Chemical

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

Standards volume information, refer to the standard’s Document Summary page on U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

the ASTM website. copeial Convention, Inc. (USPC), Rockville, MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

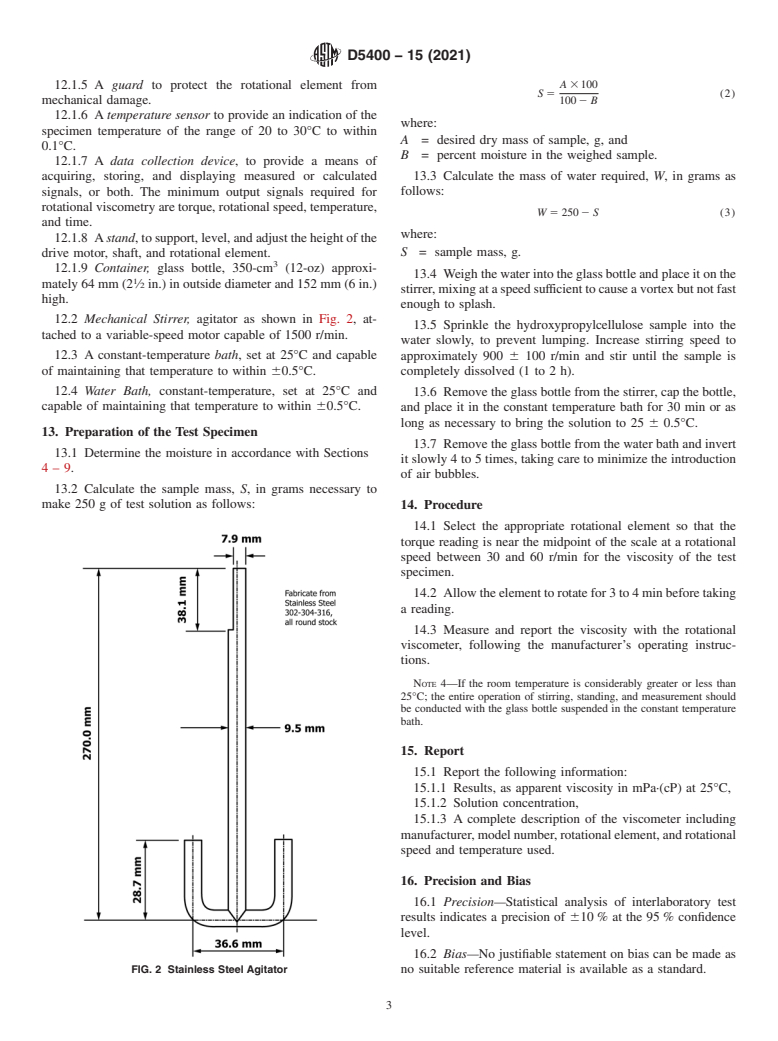

D5400 − 15 (2021)

7.2 Place it in an oven at 105 6 1°C for 3 h with the cover

removed.

7.3 Removethedishfromtheoven,immediatelyreplacethe

cover, cool in a desiccator, and weigh.

8. Calculation

8.1 Calculate the percent moisture, M, as follows:

M 5 ~A/B! 3100 (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.