ASTM D5793-95

(Test Method)Standard Test Method for Binding Sites Per Unit Length or Width of Pile Yarn Floor Coverings

Standard Test Method for Binding Sites Per Unit Length or Width of Pile Yarn Floor Coverings

SCOPE

1.1 This test method describes the measurement of the number of binding sites per unit length or width of machine-made, woven, knitted and tufted pile yarn covering both before and after adhesive backing application.

1.2 The values stated in SI units are to be regarded as the standard for all measurements. The inch-pound values are provided for information purposes only.

1.3 Determination of the number of binding sites per unit length or width of pile yarn floor covering previously was contained within Test Methods D 418. For user convenience Subcommittee D13.21 has subdivided Test Methods D 418 into separate standards, of which this test method is one.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5793 – 95

Standard Test Method for

Binding Sites Per Unit Length or Width of Pile Yarn Floor

Coverings

This standard is issued under the fixed designation D 5793; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope array at uniform intervals in both lengthwise and widthwise

directions of the floor covering. Among woven, knitted and

1.1 This test method describes the measurement of the

tufted floor coverings, binding sites differ. For example, the

number of binding sites per unit length or width of machine-

binding site of a woven floor covering consists of one or more

made, woven, knitted and tufted pile yarn covering both before

filling shots under which the face yarn passes, while the

and after adhesive backing application.

binding site of a tufted floor covering consists of the section of

1.2 The values stated in SI units are to be regarded as the

backing fabric between two adjacent needle holes in the

standard for all measurements. The inch-pound values are

lengthwise direction. The number of pile yarn strands that can

provided for information purposes only.

be fastened at one binding site can vary from one to several,

1.3 Determination of the number of binding sites per unit

according to design.

length or width of pile yarn floor covering previously was

contained within Test Methods D 418. For user convenience

Subcommittee D13.21 has subdivided Test Methods D 418 into

separate standards, of which this test method is one.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

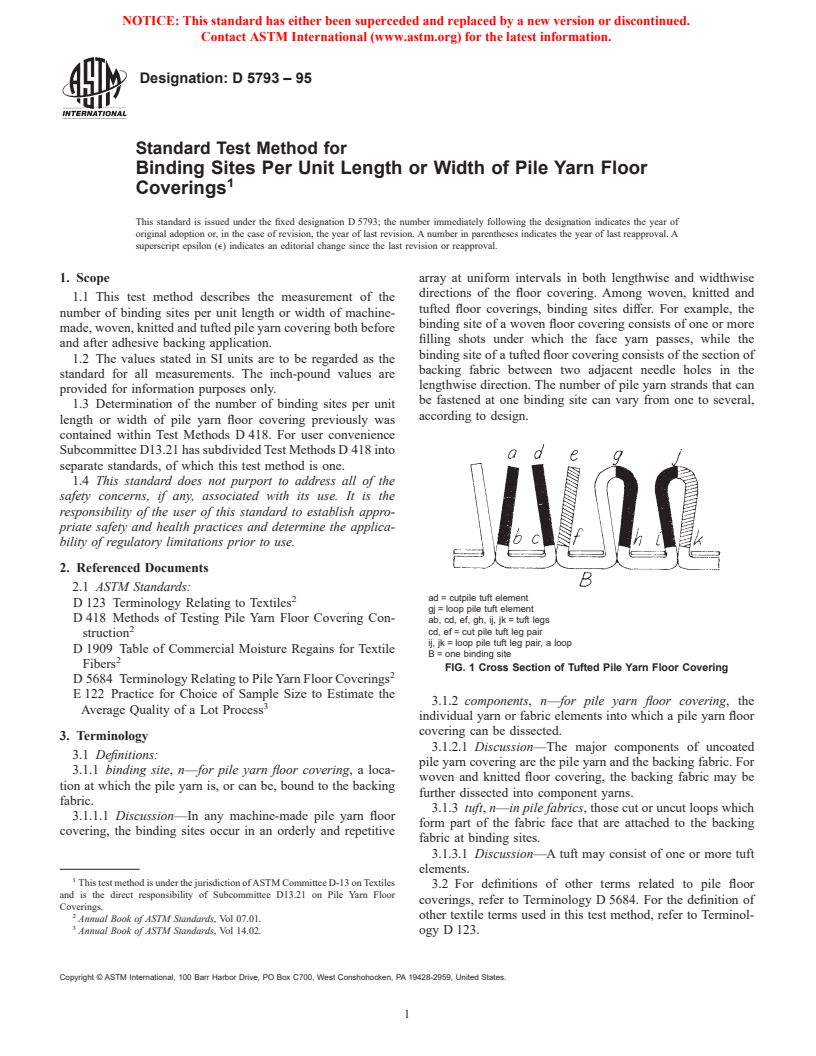

ad = cutpile tuft element

D 123 Terminology Relating to Textiles

gj = loop pile tuft element

D 418 Methods of Testing Pile Yarn Floor Covering Con-

ab, cd, ef, gh, ij, jk = tuft legs

cd, ef = cut pile tuft leg pair

struction

ij, jk = loop pile tuft leg pair, a loop

D 1909 Table of Commercial Moisture Regains for Textile

B = one binding site

Fibers

FIG. 1 Cross Section of Tufted Pile Yarn Floor Covering

D 5684 Terminology Relating to Pile Yarn Floor Coverings

E 122 Practice for Choice of Sample Size to Estimate the

3.1.2 components, n—for pile yarn floor covering, the

Average Quality of a Lot Process

individual yarn or fabric elements into which a pile yarn floor

covering can be dissected.

3. Terminology

3.1.2.1 Discussion—The major components of uncoated

3.1 Definitions:

pile yarn covering are the pile yarn and the backing fabric. For

3.1.1 binding site, n—for pile yarn floor covering, a loca-

woven and knitted floor covering, the backing fabric may be

tion at which the pile yarn is, or can be, bound to the backing

further dissected into component yarns.

fabric.

3.1.3 tuft, n—in pile fabrics, those cut or uncut loops which

3.1.1.1 Discussion—In any machine-made pile yarn floor

form part of the fabric face that are attached to the backing

covering, the binding sites occur in an orderly and repetitive

fabric at binding sites.

3.1.3.1 Discussion—A tuft may consist of one or more tuft

elements.

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles

3.2 For definitions of other terms related to pile floor

and is the direct responsibility of Subcommittee D13.21 on Pile Yarn Floor

coverings, refer to Terminology D 5684. For the definition of

Coverings.

other textile terms used in this test method, refer to Terminol-

Annual Book of ASTM Standards, Vol 07.01.

Annual Book of ASTM Standards, Vol 14.02. ogy D 123.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D5793–95

4. Summary of Test Method shall be in accordance with the manufacturer’s quality control

program or with the specification agreed to by the purchaser

4.1 The length of pile floor covering containing 40 binding

and the supplier.

sites is measured in either the lengthwise or the widthwise

7.3 A test sample shall consist of a full width section of floor

direction as required and the number of binding sites per unit

covering cut from one end of each roll in the lot sample and

length is calculated.

shall be at least 100 mm (4 in.) longer than the specimens

required for the tests being conducted. Do not cut a test sample

5. Significance and Use

of coated floor covering from a seam end of a production roll.

5.1 This test method is useful in quality and cost control

7.4 Test Specimens:

during manufacture. Both appearance and performance of pile

7.4.1 The test specimens shall be large enough to include 44

yarn floor coverings can be affected by changes in bindings

binding sites in each direction.

sites per unit length or width.

7.4.2 This test method may be nondestructive since the

5.2 Although this test method is useful for acceptance

measurements may be made on the test specimens without

testing of commercial shipments as the best available method,

cutting the test specimens from the test sample.

between-laboratory precision has not yet been determined.

7.4.3 A test specimen is a designated area of a test sample

5.2.1 In case of a dispute from differences in reported test

that may be marked on or cut from the test sample as directed

results when using this test method the purchaser and the

in the test method. For test samples 3000 mm (118 in.) wide or

supplier should conduct comparative tests to determine if there

wider, three test specimens are required, one at each edge no

is statistical bias between their laboratories. Competent statis-

nearer to the edge than 5 % of the total floor covering width

tical assistance is recommended for the investigation of bias.

and one in the middle portion of the test sample. For test

As a minimum, the two parties should take a group of test

samples at least 1500 mm (60 in.) wide but less 3000 mm (118

specimens which are as homogeneous as possible and which

in.), take two test specimens, one at each edge no nearer to the

are from a lot of material of the type in question. The test

edge than 5 % of the total floor covering width. For test

specimens should then be randomly assigned in equal numbers

samples less than 1500 mm wide (60 in.), take one specimen,

to each laboratory for testing. The average results from the two

from the middle.

laboratories would be compared using Student’s t-test for

7.4.4 Where it is known that systematic variations in a floor

unpaired data and an acceptable probability level chosen by the

covering characteristic may occur in bands 460 mm (18 in.) or

two parties before testing is begun. If a bias is f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.