ASTM D5476-99

(Classification)Standard Classification System for Thermoplastic Polyurethane Materials (TPU) (Withdrawn 2005)

Standard Classification System for Thermoplastic Polyurethane Materials (TPU) (Withdrawn 2005)

SCOPE

1.1 This classification system covers thermoplastic polyurethane materials suitable for injection molding, extrusion, compression molding, melt processing, or other applicable methods. Recycled thermoplastic polyurethanes meeting the classification requirements may be used interchangeably with virgin resin.

1.2 The properties included in this classification system are those required to identify the compositions covered. There may be other requirements necessary to identify particular characteristics important to specialized applications, which may be designated by using the suffixes as given in Section 5.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-There are no ISO standards covering the primary subject matter of this ASTM classification system.

WITHDRAWN RATIONALE

This classification system covers thermoplastic polyurethane materials suitable for injection molding, extrusion, compression molding, melt processing, or other applicable methods. Recycled thermoplastic polyurethanes meeting the classification requirements may be used interchangeably with virgin resin.

Formerly under the jurisdiction of Committee D20 on Plastics, this classification was withdrawn in July 2005 due to its limited use in industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5476 – 99

Standard Classification System for

Thermoplastic Polyurethane Materials (TPU)

This standard is issued under the fixed designation D 5476; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This classification system and subsequent line callout is intended to be a means of calling out

thermoplastic polyurethane materials used in the fabrication of end items or parts. It is not intended

for the selection of materials. Material selection should be made by those having expertise in the

plastics field after careful consideration of the design and performance required of the part,

environment to which it will be exposed, fabrication processes to be used, and inherent properties of

the material other than those covered by this classification.

1. Scope D 618 Practice for Conditioning Plastics and Electrical

Insulating Materials for Testing

1.1 This classification system covers thermoplastic polyure-

D 638 Test Method for Tensile Properties of Plastics

thane materials suitable for injection molding, extrusion, com-

D 648 Test Method for Deflection Temperature of Plastics

pression molding, melt processing, or other applicable meth-

Under Flexural Load

ods. Recycled thermoplastic polyurethanes meeting the

D 696 Test Method for Coefficient of Linear Thermal Ex-

classification requirements may be used interchangeably with

pansion of Plastics

virgin resin.

D 790 TestMethodsforFlexuralPropertiesofUnreinforced

1.2 The properties included in this classification system are

and Reinforced Plastics and Electrical Insulating Materi-

thoserequiredtoidentifythecompositionscovered.Theremay

als

be other requirements necessary to identify particular charac-

D 792 Test Method for Specific Gravity (Relative Density)

teristics important to specialized applications, which may be

and Density of Plastics by Displacement

designated by using the suffixes as given in Section 5.

D 883 Terminology Relating to Plastics

1.3 The values stated in SI units are to be regarded as the

D 1600 Terminology for Abbreviated Terms Relating to

standard.

Plastics

1.4 This standard does not purport to address all of the

D 1897 Practice for Injection Molding Test Specimens of

safety concerns, if any, associated with its use. It is the

Thermoplastic Molding and Extrusion Materials

responsibility of the user of this standard to establish appro-

D 2240 Test Method for Rubber Property—Durometer

priate safety and health practices and determine the applica-

Hardness

bility of regulatory limitations prior to use.

D 3892 Practice for Packaging/Packing of Plastics

NOTE 1—There are no ISO standards covering the primary subject

D 4000 Classification System for Specifying Plastic Mate-

matter of this ASTM classification.

rials

D 5033 GuidefortheDevelopmentofStandardsRelatingto

2. Referenced Documents

the Proper Use of Recycled Plastics

2.1 ASTM Standards:

E 29 Practice for Using Significant Digits in Test Data to

D 256 Test Methods for Impact Resistance of Plastics and

Determine Conformance with Specifications

Electrical Insulating Materials

D 412 Test Methods for Rubber Properties in Tension

3. Terminology

3.1 Definitions—For definitions of technical terms pertain-

ing to plastics used in this classification, see Terminologies

This classification system is under the jurisdiction of ASTM Committee D-20

D 883 and D 1600 and Guide D 5033.

on Plastics and is the direct responsibility of Subcommittee D20.15 on Thermo-

plastic Materials.

Current edition approved March 10, 1999. Published June 1999. Originally

published as D 5476–93. Last previous edition D 5476–93. Annual Book of ASTM Standards, Vol 08.02.

2 5

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 08.03.

3 6

Annual Book of ASTM Standards, Vol 09.01. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5476

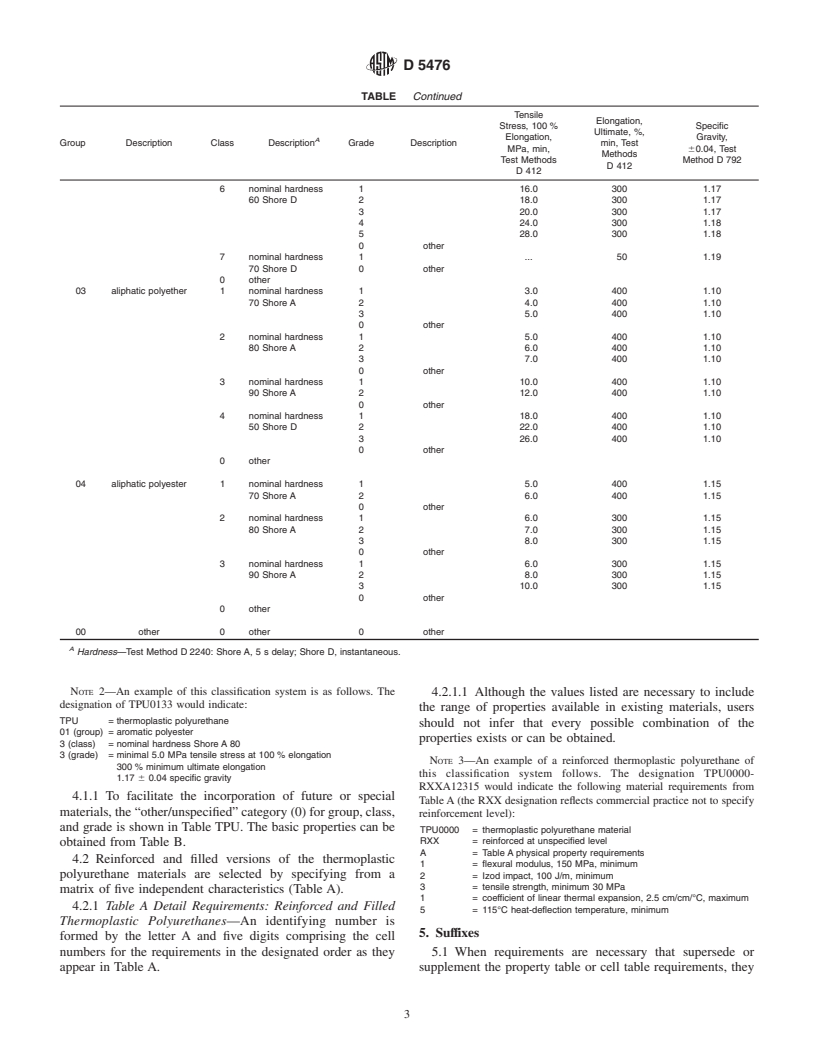

4. Classification These groups are subdivided into classes and grades as shown

in the basic property table (Table TPU).

4.1 Unreinforced thermoplastic polyurethane materials are

classified into groups according to their chemical composition.

TABLE TPU Requirements for Thermoplastic Polyurethanes

Tensile

Elongation,

Stress, 100 % Specific

Ultimate, %,

Elongation, Gravity,

A

Group Description Class Description Grade Description min, Test

MPa, min, 60.04, Test

Methods

Test Methods Method D 792

D 412

D 412

01 aromatic polyester 1 nominal hardness 1 1.4 600 1.10

60 Shore A 2 2.0 700 1.10

0 other

2 nominal hardness 1 2.0 700 1.10

70 Shore A 2 3.0 500 1.10

0 other

3 nominal hardness 1 3.0 300 1.15

80 Shore A 2 4.0 300 1.17

3 5.0 300 1.17

4 6.0 300 1.17

0 other

4 nominal hardness 1 4.0 300 1.22

90 Shore A 2 6.0 300 1.22

3 8.0 300 1.22

4 10.0 300 1.22

5 12.0 300 1.22

0 other

5 nominal hardness 1 8.0 400 1.22

50 Shore D 2 10.0 400 1.22

3 12.0 400 1.22

4 14.0 300 1.22

5 16.0 300 1.22

6 18.0 300 1.22

0 other

6 nominal hardness 1 12.0 250 1.22

60 Shore D 2 16.0 250 1.22

3 20.0 250 1.22

4 24.0 250 1.22

5 28.0 250 1.22

0 other

7 nominal hardness 1 18.0 200 1.23

70 Shore D 2 22.0 200 1.23

3 26.0 200 1.23

4 30.0 200 1.23

5 34.0 200 1.23

0 other

8 nominal hardness 1 30.0 100 1.24

80 Shore D 2 34.0 100 1.24

3 38.0 100 1.24

0 other

0 other

02 aromatic polyether 1 nominal hardness 1 2.0 700 1.03

60 Shore A 0 other

2 nominal hardness 1 2.0 700 1.03

70 Shore A 2 2.5 700 1.06

3 3.0 500 1.06

4 3.5 500 1.06

0 other

3 nominal hardness 1 3.5 500 1.06

80 Shore A 2 4.5 400 1.10

3 5.5 350 1.11

4 6.5 300 1.12

0 other

4 nominal hardness 1 4.5 400 1.12

90 Shore A 2 6.5 400 1.12

3 8.5 400 1.13

4 10.5 400 1.13

0 other

5 nominal hardness 1 10.0 400 1.13

50 Shore D 2 14.0 300 1.14

3 18.0 300 1.15

0 other

D 5476

TABLE Continued

Tensile

Elongation,

Stress, 100 % Specific

Ultimate, %,

Elongation, Gravity,

A

Group Description Class Description Grade Description min, Test

MPa, min, 60.04, Test

Methods

Test Methods Method D 792

D 412

D 412

6 nominal hardness 1 16.0 300 1.17

60 Shore D 2 18.0 300 1.17

3 20.0 300 1.17

4 24.0 300 1.18

5 28.0 300 1.18

0 other

7 nominal hardness 1 . 50 1.19

70 Shore D 0 other

0 other

03 aliphatic polyether 1 nominal hardness 1 3.0 400 1.10

70 Shore A 2 4.0 400 1.10

3 5.0 400 1.10

0 other

2 nominal hardness 1 5.0 400 1.10

80 Shore A 2 6.0 400 1.10

3 7.0 400 1.10

0 other

3 nominal hardness 1 10.0 400 1.10

90 Shore A 2 12.0 400 1.10

0 other

4 nominal hardness 1 18.0 400 1.10

50 Shore D 2 22.0 400 1.10

3 26.0 400 1.10

0 other

0 other

04 aliphatic polyester 1 nominal hardness 1 5.0 400 1.15

70 Shore A 2 6.0 400 1.15

0 other

2 nominal hardness 1 6.0 300 1.15

80 Shore A 2 7.0 300 1.15

3 8.0 300 1.15

0 other

3 nominal hardness 1 6.0 300 1.15

90 Shore A 2 8.0 300 1.15

3 10.0 300 1.15

0 other

0 other

00 other 0 other 0 other

A

Hardness—Test Method D 2240: Shore A, 5 s delay; Shore D, instantaneous.

NOTE 2—An example of this classification system is as follows. The

4.2.1.1 Although the values listed are necessary to include

designation of TPU0133 would indicate:

the range of properties available in existing materials, users

TPU = thermoplastic polyurethane

should not infer that every possible combination of the

01 (group) = aromatic polyester

properties exists or can be obtained.

3 (class) = nominal hardness Shore A 80

3 (grade) = minimal 5.0 MPa tensile stress at 100 % elongation

NOTE 3—An example of a reinforced thermoplastic polyurethane of

300 % minimum ultimate elongation

this classification system follows. The designation TPU0000-

1.17 6 0.04 specific gravity

RXXA12315 would indicate the following material requirements from

4.1.1 To facilitate the incorporation of future or special

TableA(the RXX designation reflects commercial practice not to specify

materials, the “other/uns

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.