ASTM D7454-08

(Test Method)Standard Test Method for Determination of Vibrated Bulk Density of Calcined Petroleum Coke using a Semi-Automated Apparatus

Standard Test Method for Determination of Vibrated Bulk Density of Calcined Petroleum Coke using a Semi-Automated Apparatus

SIGNIFICANCE AND USE

Vibrated bulk density (VBD) is an indicator of calcined petroleum coke porosity, which affects its suitability for use in pitch-bonded carbon applications. (Warning—Vibrated bulk density for a sample of calcined petroleum coke is strongly dependent upon average particle size and particle size range. Bulk density tends to increase with decreasing coke size. A narrow particle size range for this test minimizes the possibility for variation due to skewing of the test sample toward either screen defining the sample.)

SCOPE

1.1 This test method covers the determination of bulk density of a representative 2-kg sample of calcined petroleum coke, after vibration to increase compaction, using a semi-automatic apparatus.

1.2 The procedure is applied, but not limited, to particles passing through a 4.75-mm opening sieve and retained on a 1.18-mm opening sieve. Further, the procedure is applied, but not limited, to a specific test sample having particles passing through a 0.85-mm opening sieve and retained on a 0.425-mm opening sieve. This procedure could also be applied to other sieve fractions being agreed on in the aluminum industry as specified in Annex A1.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7454 − 08

StandardTest Method for

Determination of Vibrated Bulk Density of Calcined

Petroleum Coke using a Semi-Automated Apparatus

This standard is issued under the fixed designation D7454; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 bulk density, n—of coke, the ratio of the mass of a

collection of particles of a specified particle size range to the

1.1 This test method covers the determination of bulk

volume occupied.

density of a representative 2-kg sample of calcined petroleum

coke, after vibration to increase compaction, using a semi- 3.1.3 laboratory crushed particles, n—of coke, those par-

automatic apparatus. ticles of petroleum coke that have been crushed in the

laboratory.

1.2 The procedure is applied, but not limited, to particles

passing through a 4.75-mm opening sieve and retained on a

4. Summary of Test Method

1.18-mm opening sieve. Further, the procedure is applied, but

not limited, to a specific test sample having particles passing

4.1 The natural 4.75 by 1.18-mm fraction of the original

through a 0.85-mm opening sieve and retained on a 0.425-mm

cokeisseparatedfromthesamplebymanualscreening,ground

opening sieve. This procedure could also be applied to other

to 0.85 by 0.425 mm, and fed at a controlled rate into a

sieve fractions being agreed on in the aluminum industry as

graduated cylinder on a vibrating table until the coke reaches

specified in Annex A1.

the 50-mL mark. The collected coke is weighed and the bulk

density is calculated and reported in g/mL.

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

4.2 The procedure is empirical; close adherence to the

standard.

technique and apparatus is necessary to ensure reproducible

1.4 This standard does not purport to address all of the results. To provide comparable results in different locations,

exact adjustments of operating parameters are required using

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- reference samples.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 5. Significance and Use

5.1 Vibrated bulk density (VBD) is an indicator of calcined

2. Referenced Documents

petroleum coke porosity, which affects its suitability for use in

2.1 ASTM Standards:

pitch-bonded carbon applications. (Warning—Vibrated bulk

E11 Specification for Woven Wire Test Sieve Cloth and Test

density for a sample of calcined petroleum coke is strongly

Sieves

dependent upon average particle size and particle size range.

Bulk density tends to increase with decreasing coke size. A

3. Terminology narrowparticlesizerangeforthistestminimizesthepossibility

for variation due to skewing of the test sample toward either

3.1 Definitions:

screen defining the sample.)

3.1.1 as-calcined particles, n—of coke, those particles that

have not been subject to laboratory crushing.

6. Apparatus

6.1 Pan Balance—Accurate to 0.1 g, with a capacity of

1 2.0 kg.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

6.2 Riffle Sampler—Enclosed drawer, approximately 380 by

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

Current edition approved Oct. 15, 2008. Published October 2008. DOI: 10.1520/ 290 by 360 mm, 24-slot.

D7454-08.

6.3 Sieves—Meeting Specification E11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.4 Sieve Shaker—Electrical drive with an automatic timer;

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. should have a rotating and tapping action.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7454 − 08

6.5 Roller Crusher—Laboratory type; glass hardened rolls; 6.7.11 Round Level.

roll diameter of approximately 150 mm; roll width of approxi- 6.7.12 Balance—0 to 300 g and sensitive to 0.01 g.

mately 150 mm; gap range from 0 to 12.7 mm.

7. Hazards

6.6 Thickness Gauges (leaf-type)—0.4, 1.0, 1.5, and 4.0

mm.

7.1 Exercise care in the operation of the roll crusher.

7.1.1 Wear safety glasses and keep hands clear when feed-

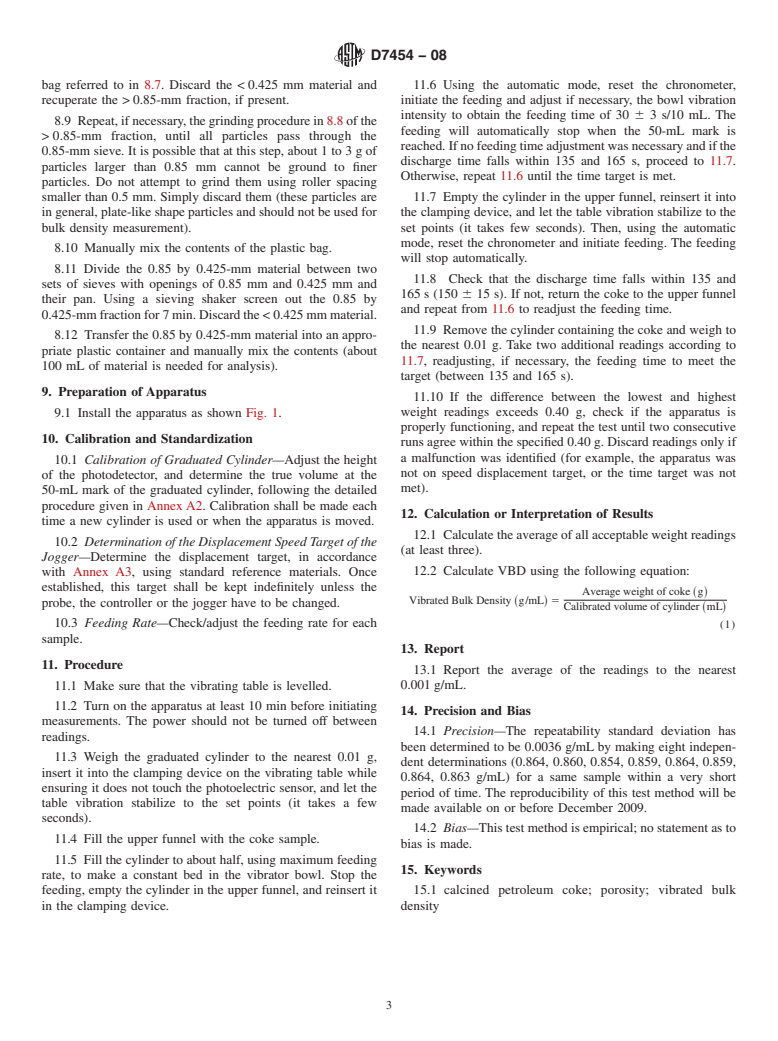

6.7 Semi-Automated VBD Apparatus, As shown in Fig. 1.

ing material.

See also comments about installation in Annex A1.

7.1.2 Turn power off at the source when equipment is

6.7.1 Borosilicate Glass Powder Funnels—8-cm diameter

opened for cleaning after the grinding operation.

funnels with 1-cm internal diameter and stems about 3.5 cm

long. Tips of funnels should be cut at a right (not oblique)

8. Sample Preparation

angles (see Fig. 1). The distance between the tip of the upper

funnel and the bottom of the vibrating bowl should be around

8.1 Reduce the original sample volume to about 1 kg.

6 mm.

8.2 Manually screen out the natural to 4.75 by 1.18 mm and

6.7.2 Electromagnetic Jogger—With approximately 175- by

< 1.18 mm.

250-mm deck, and shall be capable of vibrating at a frequency

of 60 Hz.

8.3 Transfer the 4.75 by 1.18-mm fraction into a suitable

6.7.3 Acrylic Clamp—To hold cylinder. plastic bag and homogenize manually.

6.7.4 Vibrating Bowl—Having a diameter of approximately

8.4 Weigh 180 to 200 g of 4.75 by 1.18 mm material.

7.5 cm and a height of 4.0 mm, such as that being used with

8.5 UsingtheStarrettthicknessgauges,adjustrollerspacing

rotary micro riffler.

to 4.0 mm. Slowly feed the roller crusher with the 4.75 by

6.7.5 Displacement Probe and Reading Device—Permitting

1.18-mm fraction by spreading the material all over the rollers.

continuous monitoring of amplitude vibration.

6.7.6 Graduated Cylinder—50 mL, with inside diameter

8.6 Adjust the spacing between rollers to 1.5 mm to regrind

approximately 23 mm and height approximately 19 cm.

the material. Set the spacing between the rollers to 1.0 mm and

6.7.7 Photoelectric Sensor Switch.

regrind the material a second time.

6.7.8 Control Device—Permitting real-time adjustment of

8.7 Manually screen out the 0.85 by 0.425-mm fraction and

the vibration amplitude and automatic stopping of the feeding

transfer it into a plastic bag. Discard the < 0.425-mm fraction

device when the coke level reaches the 50-mL mark.

and keep the > 0.85-mm fraction.

6.7.9 Automatic Timer, Clock, or Watch—With a second

indicator. 8.8 Adjust the roller spacing to 0.5 mm and grind the

> 0.85-mm fraction. Manually screen out the 0.85 by

6.7.10 Line Stabilizer (Optional)—Use if the noise on the

power line is significant and affects the apparatus performance. 0.425-mm fraction and add this fraction into the same plastic

FIG. 1 Example of Semi-Automated Apparatus Set-Up

D7454 − 08

bag referred to in 8.7. Discard the < 0.425 mm material and 11.6 Using the automatic mode, reset the chronometer,

recuperate the > 0.85-mm fraction, if present. initiate the feeding and adjust if necessary, the bowl vibration

intensity to obtain the feeding time of 30 6 3 s/10 mL. The

8.9 Repeat,ifnecessary,thegrindingprocedurein8.8ofthe

feeding will automatically stop when the 50-mL mark is

> 0.85-mm fraction, until all particles pass through the

reached.Ifnofeedingtimeadjustmentwasnecessaryandifthe

0.85-mm sieve. It is possible that at this step, about 1 to3gof

discharge time falls within 135 and 165 s, proceed to 11.7.

particles larger than 0.85 mm cannot be ground to finer

Otherwise, repeat 11.6 until the time target is met.

particles. Do not attempt to grind them using roller spacing

smaller than 0.5 mm. Simply discard them (these particles are 11.7 Empty the cylinder in the upper funnel, reinsert it into

in general, plate-like shape particles and should not be used for the clamping device, and let the table vibration stabilize to the

bulk density measurement). set points (it takes few seconds). Then, using the automatic

mode, reset the chronometer and initiate feeding. The feeding

8.10 Manually mix the contents of the plastic bag.

will stop automatically.

8.11 Divide the 0.85 by 0.425-mm material between two

11.8 Check that the discharge time falls within 135 and

sets of sieves with openings of 0.85 mm and 0.425 mm and

165 s (150 6 15 s). If not, return the coke to the upper funnel

their pan. Using a sieving shaker screen out the 0.85 by

and repeat from 11.6 to readjust the feeding time.

0.425-mmfractionfor7min.Discardthe< 0.425mmmaterial.

11.9 Remove the cylinder containing the coke and weigh to

8.12 Transfer the 0.85 by 0.425-mm material into an appro-

the nearest 0.01 g. Take two additional readings according to

priate plastic container and manually mix the contents (about

11.7, readjusting, if necessary, the feeding time to meet the

100 mL of material is needed for analysis).

target (between 135 and 165 s).

9. Preparation of Apparatus

11.10 If the difference between the lowest and highest

weight readings exceeds 0.40 g, check if the apparatus is

9.1 Install the apparatus as shown Fig. 1.

properly functioning, and repeat the test until two consecutive

10. Calibration and Standardization

runs agree within the specified 0.40 g. Discard readings only if

a malfunction was identified (for example, the apparatus was

10.1 Calibration of Graduated Cylinder—Adjust the height

not on speed displacement targ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.