ASTM F1472-00

(Specification)Standard Specification for Wrought Titanium -6Aluminum -4Vanadium Alloy (UNS R56400) for Surgical Implant Applications

Standard Specification for Wrought Titanium -6Aluminum -4Vanadium Alloy (UNS R56400) for Surgical Implant Applications

SCOPE

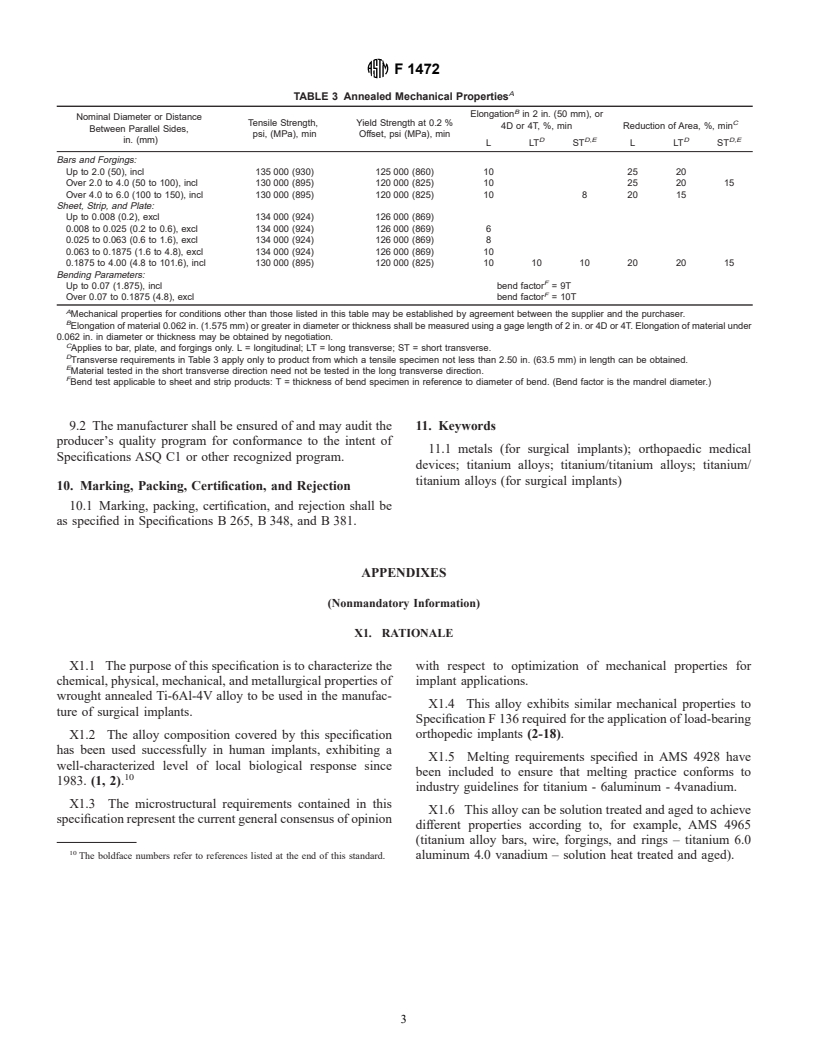

1.1 This specification covers the chemical, mechanical, and metallurgical requirements for wrought annealed titanium-6aluminum-4vanadium alloy (UNS R56400) to be used in the manufacture of surgical implants.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

Designation: F 1472 – 00

Standard Specification for

Wrought Titanium-6Aluminum-4Vanadium Alloy (UNS

1

R56400) for Surgical Implant Applications

This standard is issued under the fixed designation F 1472; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Vanadium ELI (Extra Low Interstitial) Alloy (UNS

7

R56401) for Surgical Implant Applications

1.1 This specification covers the chemical, mechanical, and

2.2 Other Standard:

metallurgical requirements for wrought annealed titanium-

ASQ C1 Specifications of General Requirements for a

6aluminum-4vanadium alloy (UNS R56400) to be used in the

8

Quality Program

manufacture of surgical implants.

2.3 Aerospace Material Specifications:

1.2 The values stated in inch-pound units are to be regarded

AMS 2249 Chemical Check Analysis Limits, Titanium and

as the standard. The values given in parentheses are provided

9

Titanium Alloys

for information only.

AMS 4928 Titanium Alloy Bars, Wire, Forgings and Rings

1.3 This standard does not purport to address all of the

9

6Al-4V

safety concerns, if any, associated with its use. It is the

AMS 4965 Titanium Alloy, Bars, Wire, Forgings, and Rings

responsibility of the user of this standard to establish appro-

9

6.0Al-4.0V Solution Heat Treated and Aged

priate safety and health practices and to determine the

applicability of regulatory limitations prior to use.

3. Classification

2. Referenced Documents 3.1 Strip—Any product under 0.1875 in. (4.76 mm) in

thickness and under 24 in. (610 mm) wide.

2.1 ASTM Standards:

3.2 Sheet—Any product under 0.1875 in. (4.76 mm) in

B 265 Specification for Titanium and Titanium Alloy Strip,

2 thickness and 24 in. (610 mm) or more in width.

Sheet, and Plate

3.3 Plate—Any product 0.1875 in. (4.76 mm) thick and

B 348 Specification for Titanium and Titanium Alloy Bars

2

over and 10 in. (254 mm) wide and over, with widths greater

and Billets

than five times the thickness. Plate up to 4.00 in. (101.60 mm)

B 381 Specification for Titanium and Titanium Alloy Forg-

2

thick, inclusive, is covered by this specification.

ings

3

3.4 Bar—Round bars and flats from 0.1875 in. (4.75 mm) to

E 8 Test Methods for Tension Testing of Metallic Materials

4.00 in. (101.60 mm) in diameter or thickness (other sizes and

E 120 Test Methods for Chemical Analysis of Titanium and

4

shapes by special order).

Titanium Alloys

3.5 Forging Bar—Bar as described in 3.4, used for produc-

E 290 Test Method for Semi-Guided Bend Test for Ductility

3

tion of forgings, may be furnished in the hot-rolled condition.

of Metallic Materials

5

3.6 Wire—Rounds less than 0.1875 in. (4.76 mm) in diam-

E 527 Practice for Numbering Metals and Alloys (UNS)

eter.

E 1409 Test Method for Determination of Oxygen in Tita-

nium and Titanium Alloys by the Inert Gas Fusion Tech-

4. Ordering Information

4

nique

4.1 Inquiries and orders for material under this specification

E 1447 Test Method for Determination of Hydrogen in

shall include the following information:

Titanium and Titanium Alloys by the Inert Gas Fusion

6 4.1.1 Quantity (weight or number of pieces),

Thermal Conductivity Method

4.1.2 Applicable ASTM designation,

F 136 Specification for Wrought Titanium-6 Aluminum-4

4.1.3 Form (sheet, strip, plate, wire, bar, or forging bar),

4.1.4 Condition (see 5.1),

1

This specification is under the jurisdiction of ASTM Committee F04 on

4.1.5 Mechanical properties (if applicable, for special con-

Medical and Surgical Materials and Devices and is the direct responsibility of

ditions),

Subcommittee F04.02 on Resources.

Current edition approved Nov. 10, 2000. Published March 2001. Originally

published as F 1472 – 93. Last previous edition F 1472 – 99.

2 7

Annual Book of ASTM Standards, Vol 02.04. Annual Book of ASTM Standards, Vol 13.01.

3 8

Annual Book of ASTM Standards, Vol 03.01. Available from American Society for Quality, 611 E. Wisconsin Ave., PO Box

4

Annual Book of ASTM Standards, Vol 03.05. 3005, Milwaukee, WI 53201–3005.

5 9

Annual Book of ASTM Standards, Vol 01.01. Available from the SAE World Headquarters, 400 Commonwealth Dr., War-

6

Annual Book of ASTM Standards, Vol 03.06. rendale, PA 15096–0001.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F 1472

4.1.6 Finish (see 5.2), 6.2.2 Product analysis tolerances do not broaden the speci-

4.1.7 Applicable dimensions including size, thickness, fied heat analysis requirements but cover variation between

width, or drawing number, laboratories in the measurement of chemical content. Product

4.1.8 Special tests, and analysis limits shall be as specified in Table 2.

4.1.9 Special requirements. 6.3 For referee purposes, Test Methods E 120, E 1409, and

E 1447 shall be used.

5. M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.