ASTM B824-09

(Specification)Standard Specification for General Requirements for Copper Alloy Castings

Standard Specification for General Requirements for Copper Alloy Castings

ABSTRACT

This specification establishes the general requirements common to copper alloy castings of UNS Nos. C94700, C95300, C95400, C95410, C95500, C95520, and C96800. Materials shall be sampled and prepared, then tested accordingly to examine their conformance to mechanical (tensile and yield strength, hardness, and elongation), electrical (resistivity and conductivity), dimensional, chemical composition, and grain size requirements. In the event of conflict between this specification and the individual casting product specifications, the requirements of the casting specification shall take precedence.

SIGNIFICANCE AND USE

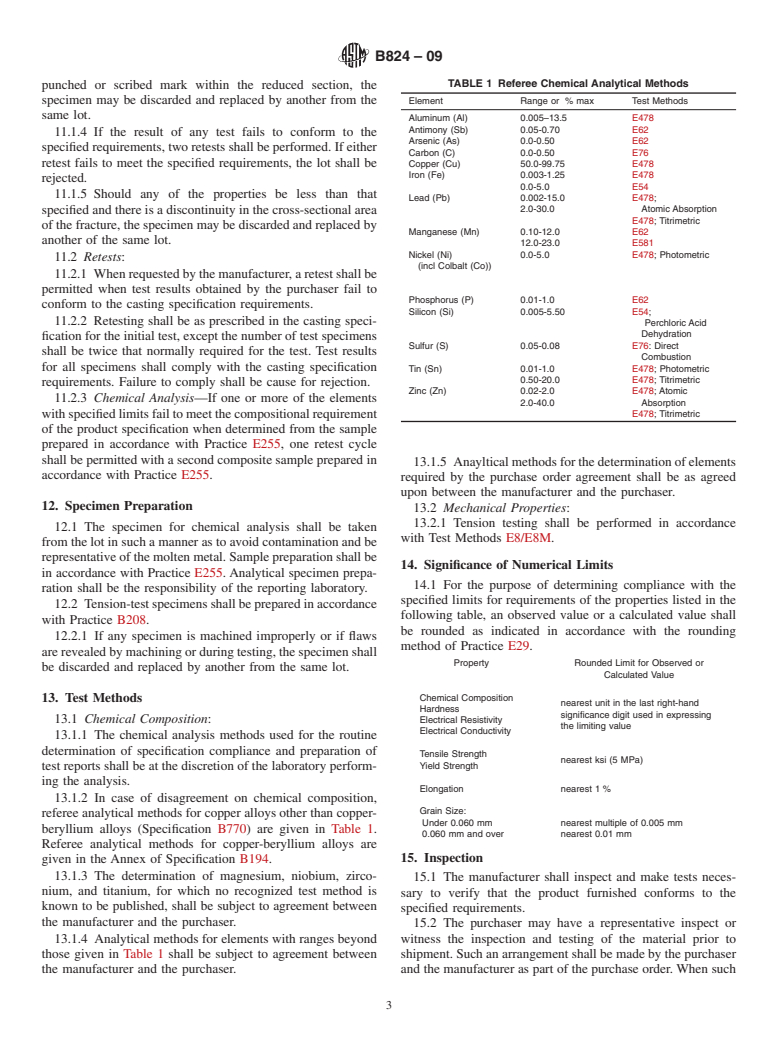

For the purpose of determining compliance with the specified limits for requirements of the properties listed in the following table, an observed value or a calculated value shall be rounded as indicated in accordance with the rounding method of Practice E 29.

PropertyRounded Limit for Observed or

Calculated Value Chemical Composition

Hardness

Electrical Resistivity

Electrical Conductivitynearest unit in the last right-hand significance digit used in expressing the limiting value Tensile Strengthnearest ksi (5 MPa) Yield Strength Elongation nearest 1 % Grain Size: Under 0.060 mmnearest multiple of 0.005 mm 0.060 mm and overnearest 0.01 mm

SCOPE

1.1 This specification establishes general requirements common to ASTM copper alloy casting specifications B 22, B 61, B 62, B 66, B 67, B 148, B 176, B 271, B 369, B 427, B 505, B 584, B 763, B 770, and B 806. These requirements apply to the casting specifications to the extent referenced therein.

1.1.1 In the event of conflict between this specification and a casting specification, the requirements of the casting specification shall take precedence.

1.2 The chemical composition and other requirements not included in this specification shall be prescribed in the casting product specifications.

1.3 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 No precise quantitative relationship can be stated between the properties of the metal in various locations of the same casting or between the properties of castings and those of a test bar casting from the same metal. (See Appendix X1.)

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B824 – 09

Standard Specification for

1

General Requirements for Copper Alloy Castings

This standard is issued under the fixed designation B824; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B62 Specification for Composition Bronze or Ounce Metal

Castings

1.1 Thisspecificationestablishesgeneralrequirementscom-

B66 Specification for Bronze Castings for Steam Locomo-

mon to ASTM copper alloy casting specifications B22, B61,

tive Wearing Parts

B62, B66, B67, B148, B176, B271, B369, B427, B505/

B67 Specification for Car and Tender Journal Bearings,

B505M, B584, B763, B770, and B806. These requirements

Lined

apply to the casting specifications to the extent referenced

B148 Specification for Aluminum-Bronze Sand Castings

therein.

B176 Specification for Copper-Alloy Die Castings

1.1.1 In the event of conflict between this specification and

B194 Specification for Copper-Beryllium Alloy Plate,

a casting specification, the requirements of the casting speci-

Sheet, Strip, and Rolled Bar

fication shall take precedence.

B208 Practice for Preparing Tension Test Specimens for

1.2 The chemical composition and other requirements not

Copper Alloy Sand, Permanent Mold, Centrifugal, and

included in this specification shall be prescribed in the casting

Continuous Castings

product specifications.

B271 Specification for Copper-Base Alloy Centrifugal

1.3 Units—The values stated in inch-pound units are to be

Castings

regarded as standard. The values given in parentheses are

B369 Specification for Copper-Nickel Alloy Castings

mathematical conversions to SI units that are provided for

B427 Specification for Gear Bronze Alloy Castings

information only and are not considered standard.

B505/B505M Specification for Copper Alloy Continuous

1.4 No precise quantitative relationship can be stated be-

Castings

tween the properties of the metal in various locations of the

B584 Specification for Copper Alloy Sand Castings for

same casting or between the properties of castings and those of

2 General Applications

a test bar casting from the same metal. (See Appendix X1.)

B763 Specification for Copper Alloy Sand Castings for

2. Referenced Documents Valve Applications

B770 Specification for Copper-Beryllium Alloy Sand Cast-

2.1 The following documents, of the issue in effect on date

ings for General Applications

ofcastingpurchase,form,partofthisspecificationtotheextent

B806 Specification for CopperAlloy Permanent Mold Cast-

referenced herein:

3

ings for General Applications

2.2 ASTM Standards:

B846 Terminology for Copper and Copper Alloys

B22 Specification for Bronze Castings for Bridges and

E8/E8M Test Methods for Tension Testing of Metallic

Turntables

Materials

B61 Specification for Steam or Valve Bronze Castings

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

E54 Test Methods for ChemicalAnalysis of Special Brasses

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper 4

and Bronzes

and Copper Alloys and is the direct responsibility of Subcommittee B05.05 on

E62 Test Methods for Chemical Analysis of Copper and

Castings and Ingots for Remelting.

Current edition approved April 1, 2009. Published May 2009. Originally Copper Alloys (Photometric Methods)

approved in 1992. Last previous edition approved in 2004 as B824 – 04. DOI:

E76 Test Methods for ChemicalAnalysis of Nickel-Copper

10.1520/B0824-09.

4

Alloys

2

For ASME Boiler and Pressure Vessel Codeapplicationseerelatedspecification

in Section II of that code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B824 – 09

E255 Practice for Sampling Copper and Copper Alloys for visual acceptance standards agreed upon between the manu-

the Determination of Chemical Composition facturer and the purchaser.

E478 TestMethodsforChemicalAnalysisofCopperAlloys

E581 Test Methods for Chemical Analysis of Manganese- 10. Sampling

Copper Alloys

10.1 Lot—A lot shall consist of: (1) all of the metal poured

from a single furnace or crucible mel

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B824–04 Designation: B 824 – 09

Standard Specification for

1

General Requirements for Copper Alloy Castings

This standard is issued under the fixed designation B 824; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification establishes general requirements common toASTM copper alloy casting specifications B 22, B 61, B 62,

B 66, B 67, B 148, B 176, B 271, B 369, B 427, B 505, B 584, B 763, B 770, and B 806. These requirements apply to the casting

specifications to the extent referenced therein.

1.1.1 In the event of conflict between this specification and a casting specification, the requirements of the casting specification

shall take precedence.

1.2 Thechemicalcompositionandotherrequirementsnotincludedinthisspecificationshallbeprescribedinthecastingproduct

specifications.

1.3 Units—The values stated in inch-pound units are the to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units, whichunits that are provided for information only and are not considered standard.

1.4 Noprecisequantitativerelationshipcanbestatedbetweenthepropertiesofthemetalinvariouslocationsofthesamecasting

2

or between the properties of castings and those of a test bar casting from the same metal. (See Appendix X1.)

2. Referenced Documents

2.1 The following documents, of the issue in effect on date of casting purchase, form, part of this specification to the extent

referenced herein:

3

2.2 ASTM Standards:

B22 Specification for Bronze Castings for Bridges and Turntables

B61 Specification for Steam or Valve Bronze Castings

B62 Specification for Composition Bronze or Ounce Metal Castings

B66 Specification for Bronze Castings for Steam Locomotive Wearing Parts

B67 Specification for Car and Tender Journal Bearings, Lined

B 148 Specification for Aluminum-Bronze Sand Castings

B 176 Specification for Copper-Alloy Die Castings

B 194 Specification for Copper-Beryllium Alloy Plate, Sheet, Strip, and Rolled Bar

B 208 Practice for Preparing Tension Test Specimens for Copper-Base Alloys forCopper Alloy Sand, Permanent Mold,

Centrifugal, and Continuous Castings

B 271 Specification for Copper-Base Alloy Centrifugal Castings

B 369 Specification for Copper-Nickel Alloy Castings

B 427 Specification for Gear Bronze Alloy Castings

B 505/B 505M Specification for Copper Alloy Continuous Castings

B 584 Specification for Copper Alloy Sand Castings for General Applications

B 763 Specification for Copper Alloy Sand Castings for Valve Applications

B 770 Specification for Copper-Beryllium Alloy Sand Castings for General Applications

B 806 Specification for Copper Alloy Permanent Mold Castings for General Applications

B 846 Terminology for Copper and Copper Alloys

E8 8/E 8M Test Methods for Tension Testing of Metallic Materials

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.05 on Castings

and Ingots for Remelting.

Current edition approved MayApril 1, 2004.2009. Published June 2004.May 2009. Originally approved in 1992. Last previous edition approved in 20022004 as

B 824 – 024.

2

For ASME Boiler and Pressure Vessel Code application see related specification in Section II of that code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B824–09

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E54 Test Methods for Chemical Analysis of Special Brasses and Bronzes

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods)

E76 Test Methods for Chemical Analysis of Nickel-Copper Alloys

E 255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E 478 Test Methods for Chemical Analysis of Copper Alloys

E 581 Test Metho

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B 824–04 Designation: B824 – 09

Standard Specification for

1

General Requirements for Copper Alloy Castings

This standard is issued under the fixed designation B824; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1This specification establishes general requirements common to ASTM copper alloy casting specifications B 22, B 61, B 62,

B 66, B 67, B 148, B 176, B 271, B 369, B 427, B 505, B 584, B 763, B 770, and B 806B 22B 61B 62B 66B 67B 148B 176B

271B 369B 427B 505/B 505MB 584B 763B 770B 806

1.1 This specification establishes general requirements common to ASTM copper alloy casting specifications B22, B61, B62,

B66, B67, B148, B176, B271, B369, B427, B505/B505M, B584, B763, B770, and B806. These requirements apply to the casting

specifications to the extent referenced therein.

1.1.1 In the event of conflict between this specification and a casting specification, the requirements of the casting specification

shall take precedence.

1.2 Thechemicalcompositionandotherrequirementsnotincludedinthisspecificationshallbeprescribedinthecastingproduct

specifications.

1.3 Units—The values stated in inch-pound units are the to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units, whichunits that are provided for information only and are not considered standard.

1.4 Noprecisequantitativerelationshipcanbestatedbetweenthepropertiesofthemetalinvariouslocationsofthesamecasting

2

or between the properties of castings and those of a test bar casting from the same metal. (See Appendix X1.)

2. Referenced Documents

2.1 The following documents, of the issue in effect on date of casting purchase, form, part of this specification to the extent

referenced herein:

3

2.2 ASTM Standards:

B22 Specification for Bronze Castings for Bridges and Turntables

B61 Specification for Steam or Valve Bronze Castings

B62 Specification for Composition Bronze or Ounce Metal Castings

B66 Specification for Bronze Castings for Steam Locomotive Wearing Parts

B67 Specification for Car and Tender Journal Bearings, Lined

B148 Specification for Aluminum-Bronze Sand Castings

B176 Specification for Copper-Alloy Die Castings

B194 Specification for Copper-Beryllium Alloy Plate, Sheet, Strip, and Rolled Bar

B208 Practice for Preparing Tension Test Specimens for Copper-Base Alloys forCopper Alloy Sand, Permanent Mold,

Centrifugal, and Continuous Castings

B271 Specification for Copper-Base Alloy Centrifugal Castings

B369 Specification for Copper-Nickel Alloy Castings

B427 Specification for Gear Bronze Alloy Castings

B505/B505M Specification for Copper Alloy Continuous Castings

B584 Specification for Copper Alloy Sand Castings for General Applications

B763 Specification for Copper Alloy Sand Castings for Valve Applications

B770 Specification for Copper-Beryllium Alloy Sand Castings for General Applications

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.05 on Castings

and Ingots for Remelting.

Current edition approved May 1, 2004. Published June 2004. Originally approved in 1992. Last previous edition approved in 2002 as B 824–02.

Current edition approvedApril 1, 2009. Published May 2009. Originally approved in 1992. Last previous edition approved in 2004 as B824 – 04. DOI: 10.1520/B0824-09.

2

For ASME Boiler and Pressure Vessel Code application see related specification in Section II of that code.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B824 – 09

B806 Specification for Copper Alloy Permanent Mold Castings for General Applications

B846 Terminology for Copper and Copper Alloys

E88/E8M Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specificati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.