ASTM D5507-21

(Test Method)Standard Test Method for Determination of Trace Organic Impurities in Monomer Grade Vinyl Chloride by Capillary Column/Multidimensional Gas Chromatography

Standard Test Method for Determination of Trace Organic Impurities in Monomer Grade Vinyl Chloride by Capillary Column/Multidimensional Gas Chromatography

SIGNIFICANCE AND USE

5.1 The multidimensional approach permits all of the trace impurities to be well separated from the main vinyl chloride peak, thereby improving quantitative accuracy over established packed column methods.

5.2 The minimum detection limit (MDL) for all components of interest has been shown to be well below 500 ppb for this test method.

SCOPE

1.1 This is a general-purpose capillary-based test method for the determination of trace level impurities in high-purity vinyl chloride. This test method uses serially coupled capillary PLOT columns in conjunction with the multidimensional techniques of column switching and cryogenic trapping to permit the complete separation of the 11 key vinyl chloride impurities in a single 25-min run.

Note 1: There is no known ISO equivalent to this standard.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 8.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5507 − 21

Standard Test Method for

Determination of Trace Organic Impurities in Monomer

Grade Vinyl Chloride by Capillary Column/Multidimensional

1

Gas Chromatography

This standard is issued under the fixed designation D5507; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Summary of Test Method

1.1 This is a general-purpose capillary-based test method 4.1 The liquid vinyl chloride sample or calibration standard

for the determination of trace level impurities in high-purity

is injected either directly using a high-pressure liquid sampling

vinyl chloride. This test method uses serially coupled capillary valveoralternatelyasanexpandedgas.Anappropriatevolume

PLOT columns in conjunction with the multidimensional

of the liquid or gas sample is injected to enable the required

techniques of column switching and cryogenic trapping to

detection limits to be achieved.Apreliminary GC separation is

permit the complete separation of the 11 key vinyl chloride

achieved on a 6-m pre-column, the purpose of which is to

impurities in a single 25-min run.

removethebulkofthevinylchloridepeakfromthetracepeaks

of interest. Two heart-cut transfers are made from this pre-

NOTE 1—There is no known ISO equivalent to this standard.

column separation, which sends selected portions to a second

1.2 This standard does not purport to address all of the

column for additional separation. These two cuts incorporate

safety concerns, if any, associated with its use. It is the

10 of the 11 trace impurities of interest, but they exclude 1,2

responsibility of the user of this standard to establish appro-

ethylenedichlorideandthebulkofthevinylchloridepeak.The

priate safety, health, and environmental practices and deter-

1,2 EDC peak is eluted from the 6-m pre-column and detected

mine the applicability of regulatory limitations prior to use.

at the first FID after the two cuts are made.

Specific hazards statements are given in Section 8.

1.3 This international standard was developed in accor- 4.2 The components eluting to the two FID detectors are

dance with internationally recognized principles on standard- identified and quantitated by comparing their retention times

ization established in the Decision on Principles for the and area counts to those obtained previously from a calibration

Development of International Standards, Guides and Recom- standard run under identical conditions.

mendations issued by the World Trade Organization Technical

5. Significance and Use

Barriers to Trade (TBT) Committee.

5.1 The multidimensional approach permits all of the trace

2. Referenced Documents

impurities to be well separated from the main vinyl chloride

2

2.1 ASTM Standards:

peak,therebyimprovingquantitativeaccuracyoverestablished

D883 Terminology Relating to Plastics

packed column methods.

D1600 Terminology forAbbreviatedTerms Relating to Plas-

5.2 Theminimumdetectionlimit(MDL)forallcomponents

tics

of interest has been shown to be well below 500 ppb for this

F307 Practice for Sampling Pressurized Gas for Gas Analy-

test method.

sis

3. Terminology

6. Apparatus

3.1 Definitions—Terminology is in accordance with Termi-

6.1 Instrumentation:

nologies D883 and D1600 unless otherwise indicated.

6.1.1 Capillary Column/Multidirectional Gas

Chromatograph, equipped as follows:

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

6.1.1.1 Split/Splitless Injector System—Must be demon-

and is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

strated to be free of discrimination effects induced by vapor

Current edition approved Jan. 15, 2021. Published January 2021. Originally

viscosity differences if helium- or nitrogen-based gas standards

approved in 1994. Last previous edition approved in 2012 as D5507 – 99(2012).

DOI: 10.1520/D5507-21.

are to be used for instrument calibration.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1.1.2 Dual Flame-Ionization Detectors.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.1.1.3 Column Switching Device A pneumatics control

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. system.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5507 − 21

concentrations of the various components in this standard

should also represent typical values expected for the particular

proce

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5507 − 99 (Reapproved 2012) D5507 − 21

Standard Test Method for

Determination of Trace Organic Impurities in Monomer

Grade Vinyl Chloride by Capillary Column/Multidimensional

1

Gas Chromatography

This standard is issued under the fixed designation D5507; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This is a general-purpose capillary-based test method for the determination of trace level impurities in high-purity vinyl

chloride. This test method uses serially coupled capillary PLOT columns in conjunction with the multidimensional techniques of

column switching and cryogenic trapping to permit the complete separation of the 11 key vinyl chloride impurities in a single

25-min run.

NOTE 1—There is no known ISO equivalent to this standard.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 8.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

F307 Practice for Sampling Pressurized Gas for Gas Analysis

3. Terminology

3.1 Definitions—Terminology is in accordance with Terminologies D883 and D1600 unless otherwise indicated.

4. Summary of Test Method

4.1 The liquid vinyl chloride sample or calibration standard is injected either directly using a high-pressure liquid sampling valve

or alternately as an expanded gas. An appropriate volume of the liquid or gas sample is injected to enable the required detection

limits to be achieved. A preliminary GC separation is achieved on a 6-m pre-column, the purpose of which is to remove the bulk

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.70 on Analytical Methods.

Current edition approved Oct. 10, 2012Jan. 15, 2021. Published November 2012January 2021. Originally approved in 1994. Last previous edition approved in 20082012

ε1

as D5507 – 99D5507 - 99 (2008)(2012). . DOI: 10.1520/D5507-99R12.10.1520/D5507-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5507 − 21

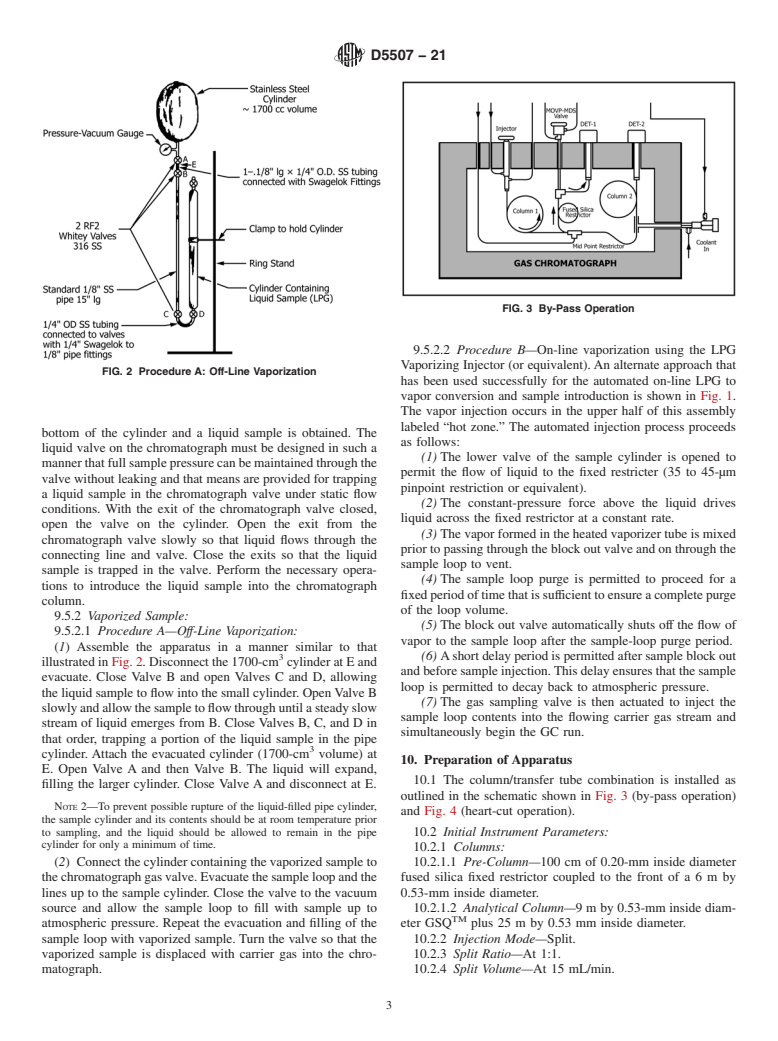

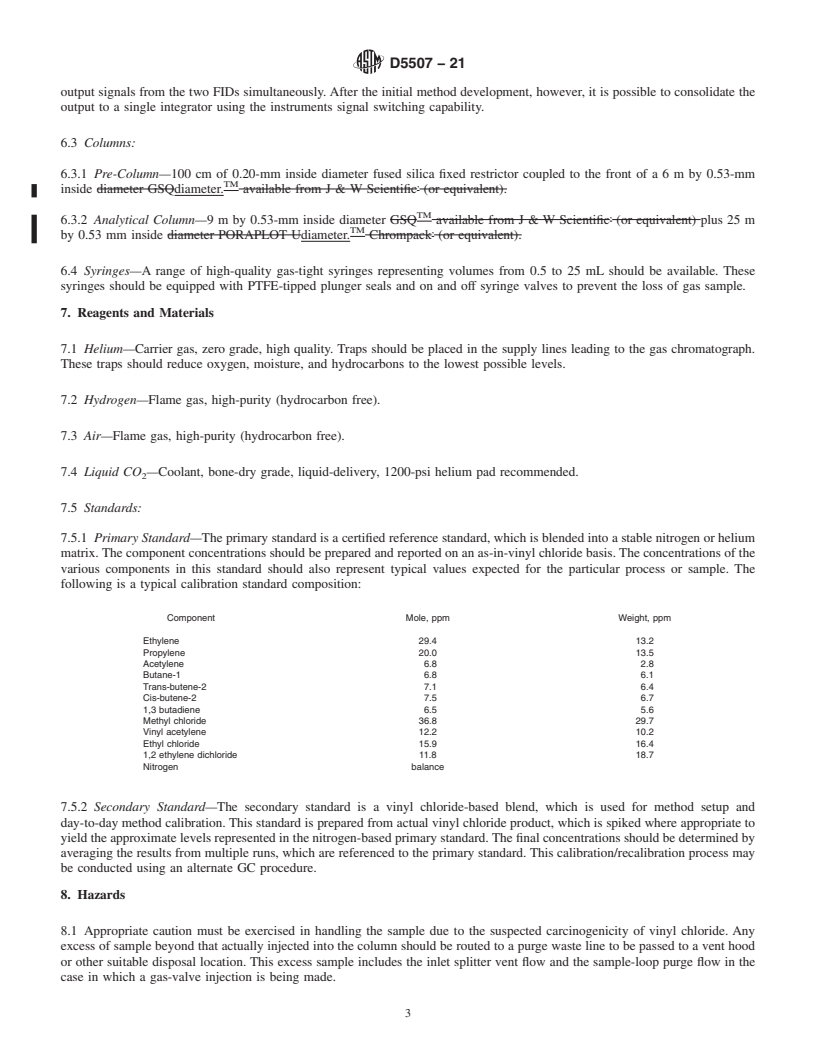

FIG. 1 Procedure B: On-Line Vaporization Using the LPG Vaporizing Injector

of the vinyl chloride peak from the trace peaks of interest. Two heart-cut transfers are made from this pre-column separation, which

sends selected portions to a second column for additional separation. These two cuts incorporate 10 of the 11 trace impurities of

interest, but they exclude 1,2 ethylene dichloride and the bulk of the vinyl chloride peak. The 1,2 EDC peak is eluted from the

6-m pre-column and detected at the first FID after the two cuts are made.

4.2 The components eluting to the two FID detectors are identified and quantitated by comparing their retention times and area

counts to those obtained previously from a calibration standard run under identical conditions.

5. Significance and Use

5.1 The multidimensional approach permits all of the trace impurities to be well separated from the main vinyl chloride peak,

thereby improving quantitative accuracy over established packed column methods.

5.2 The minimum detection limit (MDL) for all components of interest has been shown to be well below 500 ppb for this test

method.

6. Apparatus

6.1 Instrumentation:

,

6.1.1 HP 5890ACapillary Colu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.