ASTM D3481-06

(Test Method)Standard Test Method for Manual Shelling Two-Piece Child-Resistant Closures That Are Activated by Two Simultaneous Dissimilar Motions

Standard Test Method for Manual Shelling Two-Piece Child-Resistant Closures That Are Activated by Two Simultaneous Dissimilar Motions

SIGNIFICANCE AND USE

This test method of applying force may be used as a standard test to compare the characteristics of a given design of container/child-resistant closure system with a standard or to compare the characteristics of container/child-resistant closure systems differing in construction.

It may be used to simulate certain manipulations that may be expected to occur in protocol testing4 (such as, prying with the teeth or objects in the room, biting, and pulling with the teeth).

This test method may be used to establish performance specifications.

SCOPE

1.1 This test method covers the measurement of the force required to separate (or "shell") the snap-fitted outer cap from the inner cap of Type IA, IB, or IC child-resistant closures.

1.2 This test method does not measure the force required to separate parts of a child-resistant closure system that were originally "screwed-on" instead of "snapped-on" (for example, pull a cap over or through continuous or multi-start threads when the cap was originally screwed on).

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3481–06

Standard Test Method for

Manual Shelling Two-Piece Child-Resistant Closures That

1

Are Activated by Two Simultaneous Dissimilar Motions

This standard is issued under the fixed designation D3481; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology (see Classification D3475)

1.1 This test method covers the measurement of the force 3.1 Definitions:

required to separate (or “shell”) the snap-fitted outer cap from 3.1.1 Type IA child-resistant closure—a two-piece continu-

the inner cap of Type IA, IB, or IC child-resistant closures. ous thread closure requiring a random push down while

1.2 This test method does not measure the force required to turning; no orientation of the push down force is necessary.

separate parts of a child-resistant closure system that were 3.1.2 Type IB child-resistant closure—a two-piece continu-

originally “screwed-on” instead of “snapped-on” (for example, ous thread closure requiring a localized squeeze force while

pull a cap over or through continuous or multi-start threads turning; the force must be applied to a designated location on

when the cap was originally screwed on). the closure skirt.

1.3 The values stated in SI units are to be regarded as the 3.1.3 Type IC child-resistant closure—a two-piece continu-

standard. The inch-pound units given in parentheses are for ous thread closure requiring a random squeeze while turning;

information only. no orientation of the squeeze force is necessary.

1.4 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

4.1 This test method measures the force required to pry the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- outercapofftheinnercapusingafixturehavingacontactpoint

under the tip of the skirt of the outer cap and leverage being

bility of regulatory limitations prior to use.

placed on that point and the top of the cap. This procedure is

2. Referenced Documents

used where a pivotal prying force can be successfully used to

2

2.1 ASTM Standards: separate the components of the closure system. Either a torque

D3474 Practice for Calibration and Use of Torque Meters wrench or a torque meter can be used as a measuring device.

Used in Packaging Applications

5. Significance and Use

D3475 Classification of Child-Resistant Packages

E105 Practice for Probability Sampling Of Materials 5.1 This test method of applying force may be used as a

standardtesttocomparethecharacteristicsofagivendesignof

E122 Practice for Calculating Sample Size to Estimate,

With Specified Precision, the Average for a Characteristic container/child-resistant closure system with a standard or to

compare the characteristics of container/child-resistant closure

of a Lot or Process

2.2 Other Documents: systems differing in construction.

5.2 It may be used to simulate certain manipulations that

ISO Bulletin 2233 Packaging—Complete, Filled, Transport

4

3

Packages—Part 2: Conditioning for Testing may be expected to occur in protocol testing (such as, prying

with the teeth or objects in the room, biting, and pulling with

the teeth).

1

This test method is under the jurisdiction of ASTM Committee D10 on

5.3 This test method may be used to establish performance

Packaging and is the direct responsibility of Subcommittee D10.32 on Consumer,

specifications.

Pharmaceutical and Medical Packaging.

Current edition approved April 1, 2006. Published April 2006. Originally

approved in 1976. Last previous edition approved in 2002 as D3481 – 97 (2002). 6. Apparatus

DOI: 10.1520/D3481-06.

2 6.1 Testing Machine(s):

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., Consumer Product Safety Commission’s Poison Prevention Packaging Act,

4th Floor, New York, NY 10036. 1970.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3481–06

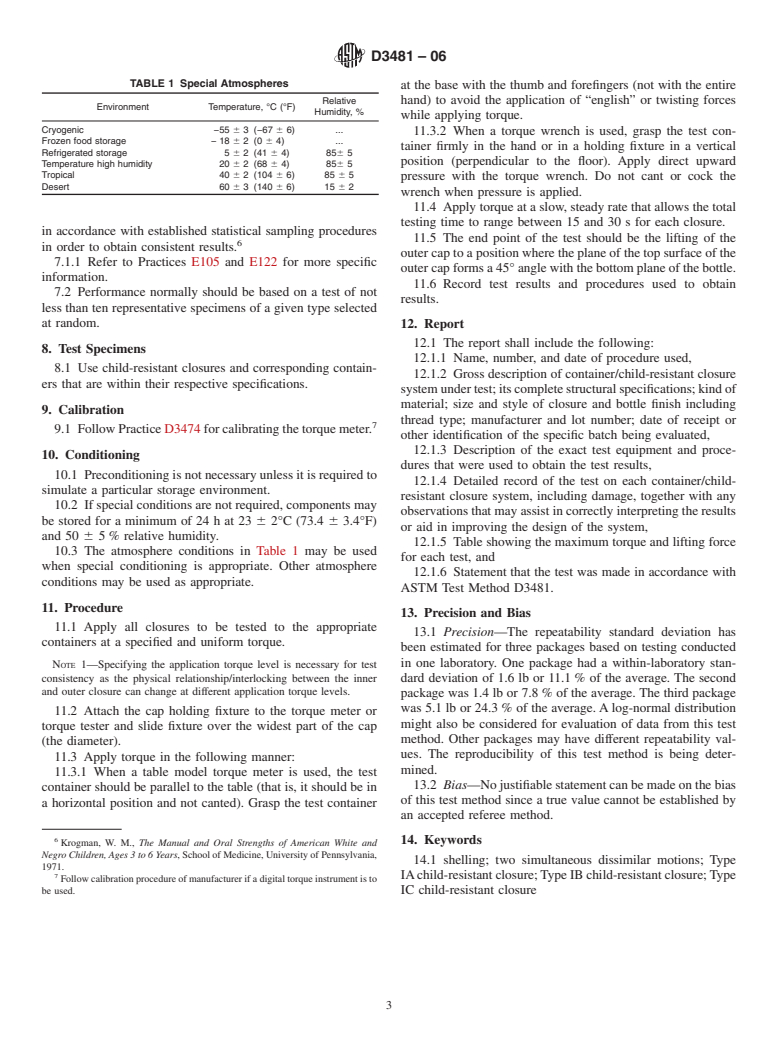

Metric Equivalents

in. mm

3.00 76.2

1.00 25.4

1.70 43.2

0.50 12.7

0.22 5.6

0.04 1.0

0.07 1.8

0.88 22.4

0.38 9.7

0.60 15.2

0.85 21.6

2.10 53.3

Note A—0.040 in. (1.0 mm) or outer shell thickness.

3

Note B—Maximum 1 ⁄4 in. (34 mm)

Note C—Height adjusted with cap screw shown.

1 1 3

Note 1—

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.