EN 13329:2016+A1:2017

(Main)Laminate floor coverings - Elements with a surface layer based on aminoplastic thermosetting resins - Specifications, requirements and test methods

Laminate floor coverings - Elements with a surface layer based on aminoplastic thermosetting resins - Specifications, requirements and test methods

This European Standard specifies characteristics, requirements and test methods for laminate floor coverings with a surface layer based on aminoplastic thermosetting resins as defined in 3.1 and 3.2. It also specifies requirements for marking and packaging.

It includes a classification system, based on EN ISO 10874, giving practical requirements for areas of use and levels of use, to indicate where laminate floor coverings will give satisfactory service and to encourage the consumer to make an informed choice.

Laminate floor coverings are considered for domestic and commercial levels of use, including domestic kitchens. This standard does not specify requirements relating to areas which are subjected to frequent wetting, such as bathrooms, laundry rooms or saunas.

Laminatböden - Elemente mit einer Deckschicht auf Basis aminoplastischer, wärmehärtbarer Harze - Spezifikationen, Anforderungen und Prüfverfahren

Revêtements de sol stratifiés - Éléments dont la surface est à base de résines aminoplastes thermodurcissables - Spécifications, exigences et méthodes d'essai

La présente Norme européenne spécifie les caractéristiques, les exigences et les méthodes d’essai pour les revêtements de sol stratifiés dont le parement est à base de résines aminoplastes thermodurcissables, tels que définis en 3.1 et 3.2. Elle spécifie également les exigences relatives au marquage et à l’emballage.

Elle comporte un système de classification fondé sur l’EN ISO 10874, qui donne les exigences pratiques relatives aux zones et niveaux d’utilisation, afin d’indiquer les cas où les revêtements de sol stratifiés peuvent être utilisés de manière satisfaisante et favoriser ainsi un choix avisé du consommateur.

Les revêtements de sol stratifiés sont destinés à des usages domestiques et commerciaux, notamment dans les cuisines domestiques. La présente norme ne spécifie pas les exigences relatives aux zones présentant un risque d’humidification fréquente comme les salles de bains, les buanderies ou les saunas.

Laminatne talne obloge - Elementi z zunanjo plastjo na osnovi aminoplastičnih termostabilnih smol - Specifikacije, zahteve in preskusne metode

Ta evropski standard določa lastnosti, zahteve in preskusne metode za laminatne talne

obloge s površinsko plastjo na osnovi aminoplastičnih duromernih smol, kot je določeno v točkah 3.1 in 3.2. Določa tudi zahteve za označevanje in pakiranje.

Vključuje sistem razvrščanja na podlagi standarda EN ISO 10874 ter podaja praktične zahteve za območja in ravni uporabe z namenom opredelitve področij zadovoljive uporabe laminatnih talnih oblog ter spodbude potrošnikov k sprejemanju utemeljenih odločitev.

Laminatne talne obloge so primerne za domačo in komercialno uporabo, kar vključuje domače kuhinje. Ta standard ne določa zahtev v zvezi z območji, ki se lahko zmočijo (npr. kopalnice, pralnice ali savne).

General Information

- Status

- Withdrawn

- Publication Date

- 10-Oct-2017

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 134 - Resilient and textile floor coverings

- Drafting Committee

- CEN/TC 134/WG 9 - Laminate floor coverings

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 22-Sep-2021

- Completion Date

- 14-Apr-2025

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 11-Dec-2019

Frequently Asked Questions

EN 13329:2016+A1:2017 is a standard published by the European Committee for Standardization (CEN). Its full title is "Laminate floor coverings - Elements with a surface layer based on aminoplastic thermosetting resins - Specifications, requirements and test methods". This standard covers: This European Standard specifies characteristics, requirements and test methods for laminate floor coverings with a surface layer based on aminoplastic thermosetting resins as defined in 3.1 and 3.2. It also specifies requirements for marking and packaging. It includes a classification system, based on EN ISO 10874, giving practical requirements for areas of use and levels of use, to indicate where laminate floor coverings will give satisfactory service and to encourage the consumer to make an informed choice. Laminate floor coverings are considered for domestic and commercial levels of use, including domestic kitchens. This standard does not specify requirements relating to areas which are subjected to frequent wetting, such as bathrooms, laundry rooms or saunas.

This European Standard specifies characteristics, requirements and test methods for laminate floor coverings with a surface layer based on aminoplastic thermosetting resins as defined in 3.1 and 3.2. It also specifies requirements for marking and packaging. It includes a classification system, based on EN ISO 10874, giving practical requirements for areas of use and levels of use, to indicate where laminate floor coverings will give satisfactory service and to encourage the consumer to make an informed choice. Laminate floor coverings are considered for domestic and commercial levels of use, including domestic kitchens. This standard does not specify requirements relating to areas which are subjected to frequent wetting, such as bathrooms, laundry rooms or saunas.

EN 13329:2016+A1:2017 is classified under the following ICS (International Classification for Standards) categories: 97.150 - Floor coverings. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13329:2016+A1:2017 has the following relationships with other standards: It is inter standard links to EN 13329:2016+A2:2021, EN 13329:2016, EN 13329:2016/prA1, EN 13329:2016+A1:2017/FprA2. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase EN 13329:2016+A1:2017 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.QRSODVWLþQLKLaminatböden - Elemente mit einer Deckschicht auf Basis aminoplastischer, wärmehärtbarer Harze - Spezifikationen, Anforderungen und PrüfverfahrenRevêtements de sol stratifiés - Éléments dont la surface est à base de résines aminoplastes thermodurcissables - Spécifications, exigences et méthodes d'essaiLaminate floor coverings - Elements with a surface layer based on aminoplastic thermosetting resins - Specifications, requirements and test methods97.150Talne oblogeFloor coveringsICS:Ta slovenski standard je istoveten z:EN 13329:2016+A1:2017SIST EN 13329:2016+A1:2017en,fr,de01-december-2017SIST EN 13329:2016+A1:2017SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13329:2016+A1

October

t r s y ICS

{ yä s w r Supersedes EN

s u u t {ã t r s xEnglish Version

Laminate floor coverings æ Elements with a surface layer based on aminoplastic thermosetting resins æ Specificationsá requirements and test methods Revêtements de sol stratifiés æ Éléments dont la surface est à base de résines aminoplastes thermodurcissables æ Spécificationsá exigences et méthodes d 5essai

Laminatböden æ Elemente mit einer Deckschicht auf Basis aminoplastischerá wärmehärtbarer Harze æ Spezifikationená Anforderungen und Prüfverfahren This European Standard was approved by CEN on

t y November

t r s w and includes Amendment

s approved by CEN on

s July

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s y CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s u u t {ã t r s x ªA sã t r s y ESIST EN 13329:2016+A1:2017

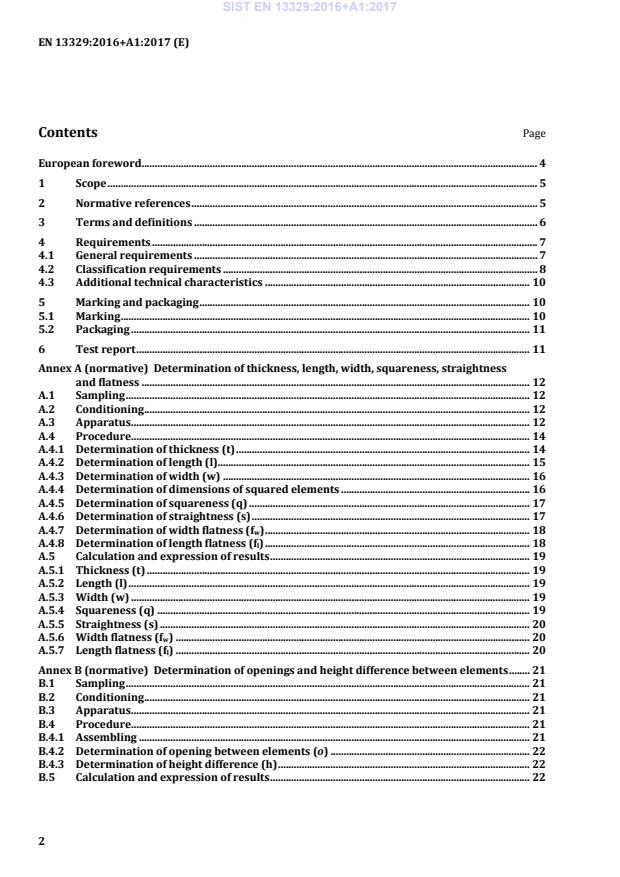

Determination of thickness, length, width, squareness, straightness and flatness . 12 A.1 Sampling . 12 A.2 Conditioning . 12 A.3 Apparatus . 12 A.4 Procedure. 14 A.4.1 Determination of thickness (t) . 14 A.4.2 Determination of length (l). 15 A.4.3 Determination of width (w) . 16 A.4.4 Determination of dimensions of squared elements . 16 A.4.5 Determination of squareness (q) . 17 A.4.6 Determination of straightness (s) . 17 A.4.7 Determination of width flatness (fw) . 18 A.4.8 Determination of length flatness (fl) . 18 A.5 Calculation and expression of results . 19 A.5.1 Thickness (t) . 19 A.5.2 Length (l) . 19 A.5.3 Width (w) . 19 A.5.4 Squareness (q) . 19 A.5.5 Straightness (s) . 20 A.5.6 Width flatness (fw) . 20 A.5.7 Length flatness (fl) . 20 Annex B (normative)

Determination of openings and height difference between elements . 21 B.1 Sampling . 21 B.2 Conditioning . 21 B.3 Apparatus . 21 B.4 Procedure. 21 B.4.1 Assembling . 21 B.4.2 Determination of opening between elements (o) . 22 B.4.3 Determination of height difference (h) . 22 B.5 Calculation and expression of results . 22 SIST EN 13329:2016+A1:2017

Determination of dimensional variations after changes in relative humidity . 23 C.1 General . 23 C.2 Sampling . 23 C.3 Conditioning . 23 C.4 Calculation and expression of results . 24 Annex D (normative)

Determination of surface soundness . 25 D.1 General . 25 D.2 Sampling . 25 D.3 Conditioning . 25 D.4 Procedure . 25 D.4.1 Preparing the test specimen . 25 D.4.2 Bonding the steel pad to the surface. 26 D.4.3 Determination of force at fracture . 26 D.5 Calculation and expression of results . 26 Annex E (normative)

Determination of abrasion resistance and abrasion classification . 27 E.1 Sampling . 27 E.2 Conditioning . 27 E.3 Apparatus . 28 E.3.1 Testing machine . 28 E.3.2 Additional material or equipment . 30 E.4 Procedure . 31 E.4.1 General . 31 E.4.2 Preparation of test specimens and abrasive papers . 31 E.4.3 Preparation of abrasive wheels . 31 E.4.4 Determination of the abrasion rate of abrasive paper . 31 E.4.5 Abrasion of test specimen . 31 E.4.6 Expression of results . 32 E.4.7 Test report . 33 Annex F (normative)

Calibration and Maintenance of Abrasion equipment . 34 F.1 General . 34 F.2 Apparatus . 34 F.3 Procedure . 34 F.3.1 Bearing Wear. 34 F.3.2 Shaft Wear . 34 F.3.3 Alignment . 35 Annex G (normative)

Measurement of shore A hardness . 37 Annex H (normative)

Determination of impact resistance and impact classification . 38 H.1 General . 38 H.2 Sampling . 38 H.3 Apparatus . 38 H.4 Procedure . 38 H.4.1 Large-diameter ball test . 38 H.4.2 Small-diameter ball test . 39 Bibliography . 42

· 800 kg/m3. 3.4 backer layer opposite to the surface layer used to balance and stabilize the product Note 1 to entry: The backer is generally made of impregnated papers. 3.5 underlay layer placed between the laminate floor covering and the subfloor to impart specific properties SIST EN 13329:2016+A1:2017

See Figure 1.

Key 1 surface layer 2 substrate 3 backer 4 underlay (optional) Figure 1— Laminate floor-covering element 4 Requirements 4.1 General requirements All laminate floor coverings shall conform to the general requirements given in Table 1, when tested by the methods specified therein. SIST EN 13329:2016+A1:2017

¶ 0,50 mm, relative to nominal value tmax.- tmin.

¶ 0,50 mm Annex A With pre-attached underlay average

¶ 0,50 mm, relative to nominal value tmax.- tmin.

¶ 0,80 mm Annex A Length of the surface layer, (l) For the nominal values given, no measured value shall exceed: l

¶ 1 500 mm:

¶ 0,5 mm l > 1 500 mm:

¶ 0,3 mm/m Annex A Width of the surface layer, (w) average

¶ 0,10 mm, relative to nominal value wmax. – wmin.

¶ 0,20 mm Annex A Length and width of squared elements,

(l = w) average

¶ 0,10 mm relative to nominal value average

¶ 0,10 mm, relative to nominal value lmax. – lmin.

¶ 0,20 mm w max. – w min.

¶ 0,20 mm Annex A Squareness of the element, (q) q max.

¶ 0,20 mm Annex A Straightness of the surface layer, (s) s max.

¶ 0,30 mm/m Annex A Flatness of the element, (f) Maximum single values: f w, concave

¶ 0,15 %

f w, convex

¶ 0,20 % f l, concave

¶ 0,50 %

f l, convex

¶ 1,00 % Annex A Openings between elements, (o) o average

¶ 0,15 mm o max.

¶ 0,20 mm Annex B Height difference between elements, (h) h average

¶ 0,10 mm h max.

¶ 0,15 mm Annex B Dimensional variations after changes in relative humidity,

average

¶ 0,9 mm

average

¶ 0,9 mm Annex C Light fastness Colour contrast between unexposed and exposed sample part

· 4 of grey scale according to EN 20105—A02 EN ISO 4892-2:2006/A1:2009 procedure B – cycle 5 (50 % rel. hum.) a b Static indentation residual indentation

¶ 0,05 mm EN ISO 24343-1 a Test until blue wool scale No. 6 according to EN ISO 105-B02 (= colour contrast 4 on the grey scale according to EN 20105-A02 between exposed and unexposed part of blue wool scale). b Allow sample (24 ± 1 h) recovery time without light exposure at 23 °C and 50 % rel. humidity before taking final assessment. 4.2 Classification requirements All laminate floor coverings shall be classified as suitable for different levels of use according to the requirements specified in Table 2, when tested by the methods given therein. Classification shall conform to the scheme specified in EN ISO 10874. The large ball impact test and the castor chair test of class 34 products shall be carried out with the pre-attached underlays or with an underlay specified by the manufacturer. For the large ball impact test of SIST EN 13329:2016+A1:2017

Levels of use

Domestic Commercial

Moderate General Heavy Moderate General Heavy Very Heavy

Class:

21 22 23 31 32 33 34 Test method Abrasion resistance AC1 AC2 AC3 AC4 AC5 AC 6 Annex E Impact resistance Small ball

· 8 N

· 12 N

· 15 N

· 20 N Annex H Big ball

· 500 mm

· 750 mm

· 1 000 mm

·

s 600 mm Resistance to staining 4, (groups 1 and 2) 3, (group 3) 5, (groups 1 and 2) 4, (group 3) 5, (groups 1, 2 and 3) EN 438 series Effect of a furniture leg _ No damage shall be visible, when tested with foot type 0 EN 424 Effect of a castor chaira _ 25 000 cycles, No damagea 25 000 cycles No damagea with type H wheels EN 425:2002 b Thickness swelling

¶ 20 %

¶ 18 %

¶ 15 %

¶ 8 % ISO 24336 Locking strength - fl0,2

· 1 kN/m (length) fs0,2

· 2 kN/m (width)

fl0,2

· 3,5 kN/m (length) fs0,2

· 3,5 kN/m (width) ISO 24334 Surface soundness

· 1,0 N/mm2

· 1,25 N/mm2

· 1,50 N/mm2 Annex D Dimensional stability _ w avg,

l avg:

¶ 0,15 % - 0,20 %

¶ Cavg c

¶ 0,25 % JL avg,

JS avg:

¶ 0,15 mm hL avg, hS avg:

¶ 0,15 mm ISO 24339 a

No visible damage on the surface of the assembled test area caused by detachment of layers, opening of joints, or crazing. Ignore any flattening or change in appearance, e.g. change in gloss. b

Using soft castor wheels W PU (95 ± 5) Shore A except for class 34 wheels H PA (95 ± 5) Shore A. c

Take the maximum of Cavg from wet climate (23°C, 85 % rel. hum) and the minimum of Cavg from dry climate (23°C, 30 % rel. hum.) for the evaluation.

1 The product “Selitflex 1,6 mm” made by Selit Dämmtechnik GmbH is an example of a suitable product commercially available. This information is given for the convenience of users of this European Standard and does not constitute an endorsement by CEN of this product. Equivalent products may be used if they can be shown to lead to the same results. SIST EN 13329:2016+A1:2017

¶ 3 % EN 322 Appearance, surface defects Minor surface defects as defined in the EN 438 series are permitted. EN 438–2 Micro-scratch resistance Can be declared as micro-scratch resistance classes according to procedure A and/or B EN 16094 5 Marking and packaging 5.1 Marking NOTE For CE-Marking see EN 14041. Laminate floor coverings which comply with the requirements of this standard shall have the following information clearly marked by the manufacturer, either on their packaging, or on a label or information sheet included in the packaging: a) a reference to this European Standard; b) manufacturer’s and/or supplier’s identification; c) product name; d) colour/pattern and batch number; e) level of use symbols appropriate to EN ISO 10874 and in accordance with Table 4; f) nominal dimensions of one floor covering element in millimetres; if relevant: nominal thickness of pre-attached underlay, nominal thickness of products with pre-attached underlay e.g. 10 (8 + 2) mm; g) number of elements contained in a package; h) area contained in a package in square metres. SIST EN 13329:2016+A1:2017

General

Heavy

Very Heavy -

5.2 Packaging Laminate floor coverings shall be delivered in packages designed to protect the corners, edges and surfaces of the product, under normal conditions of transport and handling. Installation, cleaning and maintenance instructions shall be delivered together with the product. 6 Test report The test report shall include at least the following information: a) the name and address of the test laboratory; b) date of test report; c) a reference to this standard; d) full description of the product tested; e) sampling information; f) test results; g) all deviations from this standard. SIST EN 13329:2016+A1:2017

Determination of thickness, length, width, squareness, straightness and flatness A.1 Sampling Take five laminate floor-covering elements as test specimens. A.2 Conditioning Test specimens are measured in the received state. For type approval or verification purposes, the test specimens shall be stabilized to a constant mass in an atmosphere of (23 ± 2) °C and (50 ± 5) % relative humidity. Constant mass is considered to be reached when the results of two successive weighing operations, carried out at an interval of 24 h, do not differ by more than 0,1 % of the mass of the test specimens. A.3 Apparatus A.3.1 Micrometre, calliper gauge or any other equivalent tool, having flat and parallel circular measuring surfaces of at least 16 mm diameter and an operating force of (4 ± 1) N, with an accuracy of ± 0,05 mm, for thickness measurements. A.3.2 Calliper gauge or any other equivalent tools with an accuracy of ± 0,05 mm for width measurements, and ± 0,1 mm for length measurements. A.3.3 Square with arms of at least 300 mm and having a maximum angular deviation of 0,02 mm over 300 mm. A.3.4 Set of thickness gauges ranging from 0,05 mm to 0,10 mm in steps of 0,01 mm, and from 0,10 mm to 0,50 mm in steps of 0,05 mm. A.3.5 Steel ruler of length at least equal to the length of the test specimen, and having a maximum straightness deviation of 0,05 mm over 1 000 mm. A.3.6 Apparatus for measuring width flatness consisting of a dial gauge accurate to ± 0,01 mm with a rounded tip of radius

¶ 5,5 mm, installed centrally in relation to three rounded supports with radii

· 5 mm. The supports shall be adjustable along a T-shaped assembly of bars to provide the required gauge length. The measurement d shall not be less than the width w of the test specimen minus 10 mm. The tip of the gauge in contact with the face of the test specimen shall apply a force of (1,0 ± 0,5) N. The mass of the apparatus shall not affect the flatness of the test specimen beyond the limit of the accuracy of the gauge. See Figure A.1 for illustration. The instrument shall be set to zero against a suitable reference plate. SIST EN 13329:2016+A1:2017

Key 1 dial gauge 2 T-groove 3 adjustable bridge 4 adjustable pin Figure A.1 — Instrument for measuring width flatness A.3.7 Apparatus for measuring the thickness of an element with pre-attached underlay as shown in Figure A.2. The pressure foot shall have a circular plane foot parallel to the baseplate with a diameter of 10 mm and applying force between (0,5 and 2) N. SIST EN 13329:2016+A1:2017

Key 1 rigid frame 2 dial gauge 3 circular pressure foot 4 floor covering element with pre-attached underlay (downward) 5 flat rigid baseplate Figure A.2 — Instrument for measuring thickness of an element with pre-attached underlay A.4 Procedure A.4.1 Determination of thickness (t) A.4.1.1 Determination of thickness (t) of an element without pre-attached underlay Using the micrometre, calliper gauge or any other equivalent tool, measure the thickness t at a distance of 20 mm from the edges of the surface layer, at points located in each corner and in the middle of each long side (only four corner points if length < 600 mm) (see Figure A.3). SIST EN 13329:2016+A1:2017

Figure A.3 — Measuring points for determination of thickness (t) A.4.1.2 Determination of thickness (t) of an element with pre-attached underlay Take one laminate floor-covering element. Take from this element three test specimens measuring approximately 100 mm x 100 mm, two centred 10 mm in from the short edges and one exactly in the centre of the element (see Figure A.4). If the elements measure less than 100 mm, cut a square sample with the actual width of the element. Measure in the middle of each sample with an apparatus according to A.3.7 (see Figure A.2) and calculate the average of the three samples.

Figure A.4 — Sampling from one floor covering element A.4.2 Determination of length (l) Using the appropriate calliper gauge or any other equivalent tool, measure the length l of the surface layer along two lines parallel to the axis of the test specimen, at a distance of 20 mm from the long sides (see Figure A.5). SIST EN 13329:2016+A1:2017

Figure A.5 — Measuring points for determination of length (l) A.4.3 Determination of width (w) Using the appropriate calliper gauge or any other equivalent tool, measure the width w, along two lines parallel to the sides of the surface layer, at a distance of 20 mm from the sides, and in the middle for elements with a length greater than 600 mm (see Figure A.6). Dimensions in millimetres

Figure A.6 — Measuring points for determination of width (w) A.4.4 Determination of dimensions of squared elements Using the appropriate calliper gauge or any other equivalent tool, measure the width w, and the length l along two lines parallel to the sides of the surface layer, at a distance of 20 mm from the sides (see Figure A.7). SIST EN 13329:2016+A1:2017

Figure A.7 — Measuring points for determination of width (w) and length (l) of squared elements A.4.5 Determination of squareness (q) Place one side of the square against one long side of the surface layer of the element. Using the thickness gauges, determine the maximum deviation from square q max. at the small side. Repeat the procedure on the diagonally opposite corner (see Figure A.8).

Figure A.8 — Determination of squareness (q) A.4.6 Determination of straightness (s) Place the steel ruler against one long side of the surface layer. Using the thickness gauges, determine the maximum deviation s max. from the ruler. Measure only the concave or cupped side (see Figure A.9). SIST EN 13329:2016+A1:2017

Figure A.9 — Determination of straightness (s) A.4.7 Determination of width flatness (fw) Adjust the supports along the T-shaped assembly of bars according to the width of the test specimen to evaluate (see Figure A.10). Determine the maximum deviation fw for each element. The measurement d shall not be less than the width w of the test specimen minus 10 mm.

Figure A.10 — Determination of width flatness (fw) A.4.8 Determination of length flatness (fl) Place the test specimen against the steel ruler as shown in Figure A.11. Using the thickness gauges or the calliper gauge, determine the maximum deviation f l from the ruler for each element. The measured value shall be expressed as concave when the surface layer is facing towards the ruler and as convex when the surface layer is facing away from the ruler. SIST EN 13329:2016+A1:2017

Key 1 test specimen 2 steel ruler Figure A.11 — Determination of length flatness (fl) A.5 Calculation and expression of results A.5.1 Thickness (t) A.5.1.1 Thickness (average) Using all the measurements taken, calculate the mean value taverage, and also record the single maximum value t max. and the single minimum value t min. Calculate average = |tnominal - taverage| and tmax. - tmin. and express the results in millimetres to the nearest 0,05 mm. A.5.1.2 Thickness (t) Using all the measurements taken, calculate the mean value t average and express the results in millimetres to the nearest 0,05 mm. A.5.2 Length (l) Record all measured values lmeasured. Calculate for all measured values

= |lnominal - lmeasured | and express the results in millimetres to the nearest 0,1 mm. If lnominal > 1500 mm divide

by lnominal and express the results in millimetres to the nearest 0,1 mm/m. A.5.3 Width (w) Using all the measurements taken, calculate the mean value w average, and also record the single maximum value wmax. and the single minimum value w min. Calculate average = |wnominal - waverage | and wmax. - wmin. and express the results in millimetres to the nearest 0,05 mm. A.5.4 Squareness (q) Record all measured values q and take the largest value qmax. of the deviation from square to the nearest 0,05 mm as the result. SIST EN 13329:2016+A1:2017

Determination of openings and height difference between elements B.1 Sampling Take 8 laminate floor-covering elements as test specimens. B.2 Conditioning Test specimens are measured in the received state. For type approval or verification purposes, the test specimens shall be stabilized to a constant mass in an atmosphere of (23 ± 2) °C and (50 ± 5) % relative humidity. Constant mass is considered to be reached when the results of two successive weighing operations, carried out at an interval of 24 h, do not differ by more than 0,1 % of the mass of the test specimens. B.3 Apparatus B.3.1 Set of thickness gauges ranging from 0,05 mm to 0,10 mm in steps of 0,01 mm, and from 0,10 mm to 0,50 mm in steps of 0,05 mm. B.3.2

Calliper gauge or a depth gauge with a scale interval of 0,01 mm. B.3.3

Test surface of appropriate size that is rigid, horizontal and flat. B.3.4

Ruler or any other device, by which the first strip row shall be aligned and whose length is

· 2,50 m. B.4 Procedure B.4.1 Assembling By hand force, firmly assemble the test specimens on the test surface without using any glue, as in Figure B.1, using the ruler as a guide. The Ï-symbol indicates the 13 measuring points.

Key 1 steel ruler 2 measuring point 3 test specimen Figure B.1 — Test specimens assembled, with the 13 measuring points indicated by Ï SIST EN 13329:2016+A1:2017

Determination of dimensional variations after changes in relative humidity C.1 General Test in accordance with EN 318, with the following modifications. C.2 Sampling Take from each of three laminate floor-covering elements one test specimen in the length direction and another in the width direction. The test specimens may be taken from any part of the element as long as the length direction and width direction is maintained (see Figure C.1). The dimension of a test specimen shall be (180 ± 1) mm x (20 ± 1) mm. If the nominal width of the element is less than 180 mm, no test specimen in the width direction shall be taken.

Key 1 test specimen taken in the width direction 2 test specimen taken in the length direction 3 laminate floor covering element Figure C.1 — Example of sampling C.3 Conditioning Test specimens are measured in the received state. For type approval or verification purposes, the test specimens shall be stabilized to a constant mass in an atmosphere of (23 ± 2) °C and (50 ± 5) % relative humidity. Constant mass is considered to be reached when the results of two successive weighing operations, carried out at an interval of 24 h, do not differ by more than 0,1 % of the mass of the test specimens. SIST EN 13329:2016+A1:2017

and

for each test specimen, see Figure C.2, between 30 % relative humidity and 90 % relative humidity. Calculate the average length variation average and average width variation average respectively. Express the results in millimetres to the nearest 0,1 mm.

Key 1 dimensional variation

2 test specimen taken in the width direction 3 test specimen taken in the length direction 4 dimensional variation

Figure C.2 —

The small size of test specimen in this test method has been chosen in order to obtain reliable results in a reasonably short period of time. The achieved results cannot be scaled-up to large flooring elements, and should never be used as a basis for calculation of the dimensional changes of a laminate floor covering in service. SIST EN 13329:2016+A1:2017

Determination of surface soundness D.1 General Test in accordance with EN 311, with the following modifications. D.2 Sampling From three laminate floor covering elements, take from each element three test specimens of (50 × 50) mm, two centred 10 mm in from the short edges and one exactly in the centre of the element (see Figure D.1). Dimensions in millimetres

Figure D.1 — Sampling from one of the floor covering elements D.3 Conditioning Test specimens are measured in the received state. For type approval or verification purposes, the specimens shall be stabilized to a constant mass in an atmosphere of (23 ± 2) °C and (50 ± 5) % relative humidity. Constant mass is considered to be reached when the results of two successive weighing operations, carried

...

La norme EN 13329:2016+A1:2017 offre une approche exhaustive pour la spécification, les exigences et les méthodes d'essai des revêtements de sol stratifiés. Cette norme européenne se concentre sur les éléments ayant une couche de surface basée sur des résines thermodurcissables aminoplatiques, définissant clairement les caractéristiques essentielles nécessaires pour garantir la performance des produits sur le marché. L'un des points forts de cette norme réside dans son système de classification, basé sur la norme EN ISO 10874, qui fournit des exigences pratiques pour les zones d'utilisation et les niveaux d'utilisation. Cela permet aux consommateurs de faire des choix éclairés concernant les revêtements de sol stratifiés, en leur indiquant où ces produits peuvent offrir un service satisfaisant. Cela contribue non seulement à la satisfaction du client, mais également à une utilisation optimale du matériau, garantissant ainsi une durabilité et une fonctionnalité à long terme. En outre, la norme prend en compte les usages domestiques et commerciaux, y compris les cuisines domestiques, ce qui renforce sa pertinence sur le marché. Toutefois, il est important de noter que la norme ne couvre pas les exigences pour les zones soumises à un mouillage fréquent, comme les salles de bains, les buanderies ou les saunas, ce qui pourrait limiter son application dans certains environnements. La norme EN 13329:2016+A1:2017 est, par conséquent, un document fondamental pour les fabricants, les distributeurs et les consommateurs de revêtements de sol stratifiés. Son cadre détaillé et ses exigences spécifiques assurent que chaque produit respecte des standards de qualité élevés, favorisant ainsi la confiance des consommateurs dans leur choix de revêtements de sol.

표준 EN 13329:2016+A1:2017은 아미노플라스틱 열경화 수지를基로 한 표면층을 갖춘 라미네이트 바닥재에 대한 특성, 요구사항 및 시험 방법을 지정합니다. 이 표준은 바닥재의 마킹 및 포장 요구 사항도 명시하며, 사용자들이 정보에 기반한 선택을 할 수 있도록 돕는 분류 시스템을 제공합니다. 이 표준의 범위는 가정용 및 상업용 수준의 사용을 포함하며, 가정용 주방에서의 사용도 고려됩니다. 이는 사용자들에게 라미네이트 바닥재가 만족스러운 서비스를 제공할 수 있는 곳과 사용 수준을 명시함으로써, 소비자에게 유용한 정보를 제공합니다. 그러나, 이 표준은 욕실, 세탁실, 사우나 등 자주 젖는 지역에 대한 요구 사항은 포함하고 있지 않다는 점에서 특정 사용 조건에 대한 명확함을 제공합니다. EN 13329는 라미네이트 바닥재의 품질과 내구성에 대한 엄격한 기준을 설정하여, 제조업체와 소비자 모두에게 이점이 됩니다. 이 표준은 또한 시험 방법을 명확하게 정의하여 제품의 성능을 객관적으로 평가할 수 있도록 하며, 이는 사용자의 만족도를 높이는 데 기여합니다. 결과적으로, EN 13329는 라미네이트 바닥재의 안전성과 신뢰성을 보장하는데 중요한 역할을 하며, 시장에서의 경쟁력을 확보하는 데 도움을 줍니다.

EN 13329:2016+A1:2017に関するレビューはその特性、要件、試験方法を明確に定義しており、特にアミノプラスチック熱硬化性樹脂を基にした表面層を持つラミネートフローリングに関する要件を詳述しています。この標準規格は、ラミネートフローリングの性能を確保するために重要な基準となり得るものであり、消費者が適切な選択を行うための情報を提供します。 この規格の強みは、実用的な使用区域と使用レベルを示す分類システムが含まれている点です。このシステムは、EN ISO 10874に基づいており、ラミネートフローリングの使用において十分なサービスを提供する場所を明確に示すことができます。これにより、消費者は自身のニーズに適した製品を選択する際の指針を得ることができます。 また、家庭用及び商業レベルの使用を考慮に入れているため、特に家庭のキッチンなどでも利用可能な仕様が含まれており、幅広いニーズに応えるものとなっています。ただし、本規格は頻繁な湿気にさらされる場所(バスルーム、ランドリールーム、サウナなど)に関する要件を規定していないことに留意する必要があります。 全体として、EN 13329:2016+A1:2017は、ラミネートフローリングの品質、安全性、及び消費者の選択を促進するための堅牢な基準を提供しており、業界における信頼性の向上に寄与しています。

Die Norm EN 13329:2016+A1:2017 bietet umfassende Richtlinien für Laminatfußbodenbeläge mit einer Oberflächenbeschichtung auf der Basis von aminoplastischen, hitzefestigen Harzen. Sie definiert klar die Eigenschaften, Anforderungen und Prüfmethoden, die für diese Art von Fußbodenbelag relevant sind. Besonders hervorgehoben wird das Klassifizierungssystem, das auf EN ISO 10874 basiert und praktische Anforderungen für verschiedene Nutzungsbereiche sowie Nutzungsstufen bereitstellt. Diese Einteilung ermöglicht es Verbrauchern, fundierte Entscheidungen zu treffen und sicherzustellen, dass der ausgewählte Laminatfußbodenbelag in dem vorgesehenen Einsatzbereich zufriedenstellende Leistungen erbringt. Ein wesentlicher Vorteil dieser Norm ist ihre Relevanz sowohl für den privaten als auch für den gewerblichen Gebrauch, was die Anwendbarkeit auf verschiedensten Ebenen unterstreicht. Dabei wird auch der Gebrauch in privaten Küchen berücksichtigt, was den praktischen Nutzen der Norm weiter erhöht. Zusätzlich stellt die Norm Anforderungen an die Kennzeichnung und Verpackung der Produkte, was die Transparenz und Nachvollziehbarkeit für den Endverbraucher verbessert. Es ist wichtig zu beachten, dass die Norm keine Anforderungen für Bereiche festlegt, die häufigem Nassen ausgesetzt sind, wie Badezimmer, Waschküchen oder Saunen. Diese Einschränkung ist klar definiert und ermöglicht es den Nutzern, geeignete Laminatfußbodenbeläge für spezifische Umgebungen auszuwählen, ohne Fehlentscheidungen zu riskieren. Insgesamt ist die EN 13329:2016+A1:2017 eine bedeutende Norm, die eine hohe Qualität und Langlebigkeit von Laminatfußbodenbelägen fördert, während sie gleichzeitig die Bedürfnisse der Verbraucher in verschiedenen Anwendungen berücksichtigt.

The standard EN 13329:2016+A1:2017 is a comprehensive document that delineates the specifications, requirements, and test methods for laminate floor coverings featuring a surface layer based on aminoplastic thermosetting resins. Its scope is particularly significant as it not only addresses the technical characteristics of laminate flooring but also emphasizes a classification system aligned with EN ISO 10874. This system serves to inform users about the appropriate areas and levels of use, thus enhancing consumer awareness and facilitating informed decisions when selecting laminate floor coverings. One of the key strengths of this standard lies in its detailed specifications surrounding performance criteria, which encompass durability, wear resistance, and aesthetic qualities. By establishing concrete benchmarks, EN 13329 assists manufacturers in producing high-quality laminate floor coverings that meet rigorous market needs. Furthermore, it outlines marking and packaging requirements, ensuring that consumers can easily identify compliant products, thus enhancing transparency within the market. The relevance of EN 13329 extends to both residential and commercial applications, making it suitable for various environments, including domestic kitchens. However, it is crucial to note that this standard specifically excludes areas prone to frequent wetting, such as bathrooms and laundry rooms, which is an important consideration for consumers seeking laminate options in diverse settings. Overall, EN 13329:2016+A1:2017 plays an essential role in guiding both manufacturers and consumers in the laminate flooring industry, promoting quality assurance and enabling effective product selection that aligns with practical use scenarios.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...