EN 10371:2021

(Main)Metallic materials - Small punch test method

Metallic materials - Small punch test method

This document specifies the small punch method of testing metallic materials and the estimation of tensile, creep and fracture mechanical material properties from cryogenic up to high temperatures.

Metallische Werkstoffe - Small-Punch-Test

Dieses Dokument legt das Small-Punch-Prüfverfahren für metallische Werkstoffe und die Abschätzung der mechanischen Werkstoffeigenschaften in Bezug auf Zug, Kriechen und Bruch bei sehr tiefen bis hohen Temperaturen fest.

Matériaux métalliques - Méthode d’essai de micro-emboutissage

Le présent document spécifie la méthode d’essai de micro-emboutissage des matériaux métalliques et l’estimation des propriétés de traction, de fluage et de mécanique de la rupture depuis les températures cryogéniques jusqu’aux hautes températures.

Kovinski materiali - Preskusna metoda z uporabo majhnega bata

General Information

- Status

- Published

- Publication Date

- 13-Apr-2021

- Withdrawal Date

- 30-Oct-2021

- Technical Committee

- ECISS/TC 101 - Test methods for steel (other than chemical analysis)

- Drafting Committee

- ECISS/TC 101 - Test methods for steel (other than chemical analysis)

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 14-Apr-2021

- Completion Date

- 14-Apr-2021

Relations

- Effective Date

- 02-Mar-2016

Overview

EN 10371:2021 - Metallic materials - Small punch test method is the CEN standard that specifies the small punch (SP) and small punch creep (SPC) testing techniques for metallic materials across temperatures from cryogenic up to high temperatures. The standard defines the test pieces, apparatus, test procedures and the interpretation of force–deflection and creep–deflection data to estimate tensile, creep and fracture-related material properties when only small amounts of material are available.

Key topics and technical requirements

- Scope and purpose: Standardizes the SP and SPC methods for estimating tensile strength, proof strength, ductile–brittle transition (DBTT), fracture toughness and creep properties from small disc-shaped specimens.

- Specimens: Defines a circular, disc-shaped test piece and permits other geometries only when the active cylindrical area and clamped zone are equivalent.

- Apparatus: Requirements for the testing machine, punch (hemispherical tip or ball), specimen holder, force application and measurement, displacement/deflection measurement and accurate test temperature control.

- Test methods:

- Small punch (SP) test: constant crosshead displacement rate; records force–deflection (F(u) or F(v)) curves.

- Small punch creep (SPC) test: constant applied force; records deflection-time (u(t)) or displacement-time (v(t)) curves.

- Characteristic outputs: Maximum force, small punch energy (integral up to um), normalized energy, pop-in detection (brittle events), creep rupture time tr.

- Data quality and calibration: Addresses machine compliance, displacement measurement (Annex A), and temperature measurement/control procedures (Annex B).

- Interpretation & estimations: Informative annexes provide methods to estimate uniaxial tensile strength (Rm), proof strength (Rp0.2), DBTT (TSP), fracture toughness, and creep properties from SP/SPC results.

- Reporting: Defines required test report contents and post-test examination (Annex H).

Applications and users

- When to use: Ideal for material batches with limited volume, assessment of aged or irradiated components, weld zone characterization and R&D material screening.

- Who uses it: Materials testing laboratories, metallurgists, nuclear and aerospace engineers, failure analysis teams, research institutes and manufacturers needing mechanical property estimates from small specimens.

- Benefits: Minimizes material consumption, reduces handling of hazardous (irradiated) samples, and enables localized property assessment (e.g., in-service components or welds).

Related standards

Normative and related references in EN 10371:2021 include:

- EN ISO 6892-1 / EN ISO 6892-2 (tensile testing)

- EN ISO 204 (uniaxial creep testing)

- EN ISO 148-1 (Charpy)

- EN ISO 7500-1 / EN ISO 7500-2 (machine calibration/verification)

- EN 60584-1 (thermocouples)

- EN ISO 9513, EN ISO 286-2, ISO 2768-1

EN 10371:2021 is essential for anyone performing or interpreting small punch testing of metallic materials and for bridging small-specimen results to conventional mechanical property metrics.

Frequently Asked Questions

EN 10371:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Metallic materials - Small punch test method". This standard covers: This document specifies the small punch method of testing metallic materials and the estimation of tensile, creep and fracture mechanical material properties from cryogenic up to high temperatures.

This document specifies the small punch method of testing metallic materials and the estimation of tensile, creep and fracture mechanical material properties from cryogenic up to high temperatures.

EN 10371:2021 is classified under the following ICS (International Classification for Standards) categories: 77.040.10 - Mechanical testing of metals. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10371:2021 has the following relationships with other standards: It is inter standard links to CWA 15627:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase EN 10371:2021 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2021

Kovinski materiali - Preskusna metoda z uporabo majhnega bata

Metallic materials - Small punch test method

Small punch test für metallische Werkstoffe

Matériaux métalliques - Méthode d’essai de micro-emboutissage

Ta slovenski standard je istoveten z: EN 10371:2021

ICS:

77.040.10 Mehansko preskušanje kovin Mechanical testing of metals

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 10371

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2021

EUROPÄISCHE NORM

ICS 77.040.10

English Version

Metallic materials - Small punch test method

Matériaux métalliques - Méthode d'essai de micro- Metallische Werkstoffe - Small-Punch-Test

emboutissage

This European Standard was approved by CEN on 11 January 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 10371:2021 E

worldwide for CEN national Members.

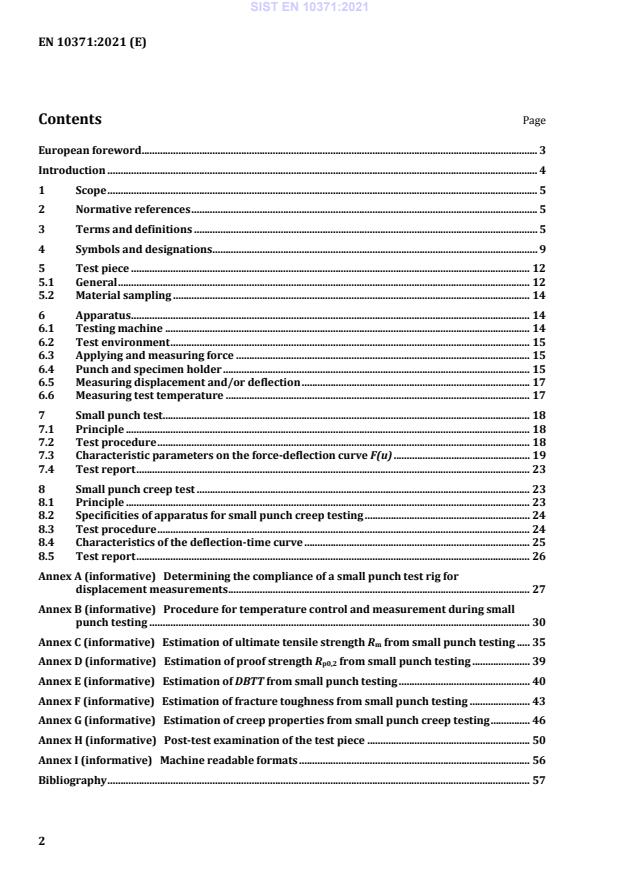

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Symbols and designations . 9

5 Test piece . 12

5.1 General . 12

5.2 Material sampling . 14

6 Apparatus . 14

6.1 Testing machine . 14

6.2 Test environment . 15

6.3 Applying and measuring force . 15

6.4 Punch and specimen holder . 15

6.5 Measuring displacement and/or deflection . 17

6.6 Measuring test temperature . 17

7 Small punch test. 18

7.1 Principle . 18

7.2 Test procedure . 18

7.3 Characteristic parameters on the force-deflection curve F(u) . 19

7.4 Test report . 23

8 Small punch creep test . 23

8.1 Principle . 23

8.2 Specificities of apparatus for small punch creep testing . 24

8.3 Test procedure . 24

8.4 Characteristics of the deflection-time curve . 25

8.5 Test report . 26

Annex A (informative) Determining the compliance of a small punch test rig for

displacement measurements . 27

Annex B (informative) Procedure for temperature control and measurement during small

punch testing . 30

from small punch testing . 35

Annex C (informative) Estimation of ultimate tensile strength Rm

Annex D (informative) Estimation of proof strength R from small punch testing . 39

p0,2

Annex E (informative) Estimation of DBTT from small punch testing . 40

Annex F (informative) Estimation of fracture toughness from small punch testing . 43

Annex G (informative) Estimation of creep properties from small punch creep testing . 46

Annex H (informative) Post-test examination of the test piece . 50

Annex I (informative) Machine readable formats . 56

Bibliography . 57

European foreword

This document (EN 10371:2021) has been prepared by Technical Committee CEN/TC 459/SC 1 “Test

methods for steel (other than chemical analysis)”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2021, and conflicting national standards shall

be withdrawn at the latest by October 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document describes small punch testing of metallic materials.

While it is recognized that the small punch test technique is not equivalent to uniaxial testing and cannot

currently replace uniaxial and fracture mechanics tests with larger specimens, it allows estimation of the

values normally obtained using classical standard size uniaxial or fracture mechanics specimens.

The small punch technique is especially useful when only small amounts of material are available as in

the case of experimental material batches, or for assessing aging of components where the extraction of

classical specimen types would require expensive repairs. Other areas of interest for small punch testing

are the characterization of irradiated materials, where small specimens minimize laboratory staff

exposure to radiation or the investigation of different zones in welds.

1 Scope

This document specifies the small punch method of testing metallic materials and the estimation of

tensile, creep and fracture mechanical material properties from cryogenic up to high temperatures.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 60584-1, Thermocouples - Part 1: EMF specifications and tolerances (IEC 60584 1)

EN ISO 148-1, Metallic materials - Charpy pendulum impact test - Part 1: Test method (ISO 148-1)

EN ISO 204, Metallic materials - Uniaxial creep testing in tension - Method of test (ISO 204)

EN ISO 286-2, Geometrical product specifications (GPS) - ISO code system for tolerances on linear sizes -

Part 2: Tables of standard tolerance classes and limit deviations for holes and shafts (ISO 286-2)

EN ISO 6892-1, Metallic materials - Tensile testing - Part 1: Method of test at room temperature

(ISO 6892-1)

EN ISO 6892-2, Metallic materials - Tensile testing - Part 2: Method of test at elevated temperature

(ISO 6892-2)

EN ISO 7500-1, Metallic materials - Calibration and verification of static uniaxial testing machines - Part 1:

Tension/compression testing machines - Calibration and verification of the force-measuring system

(ISO 7500-1)

EN ISO 7500-2, Metallic materials - Verification of static uniaxial testing machines - Part 2: Tension creep

testing machines - Verification of the applied force (ISO 7500-2)

EN ISO 9513, Metallic materials - Calibration of extensometer systems used in uniaxial testing (ISO 9513)

ISO 2768-1, General tolerances - Part 1: Tolerances for linear and angular dimensions without individual

tolerance indications

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

punch

single solid rod with a hemispherical tip or a cylindrical rod combined with a ball is used to punch through

the centre of the disc shaped test piece

Note 1 to entry: The hemispherical portion of the punch or the ball shall have a sufficient hardness to ensure

rigidity so as not to be deformed during the test. Ultra-hard ball-bearing balls can be used for that application. The

compliance of the punch will affect the displacement measurement (see 3.5).

3.2

test piece

circular, disc shaped piece of the material under investigation

Note 1 to entry: The testing of other geometries is admissible according to this document if the active part of the

specimen has a flat cylindrical shape and the clamped area is equal to or larger than that of the specimens included

in this document.

3.3

small punch (SP) test

when the punch tip/ball is pushed through the specimen with constant displacement rate of the cross

head, ẇ and the force, F is measured as a function of deflection, u / displacement, v

Note 1 to entry: The test can be used for estimating tensile and fracture material properties. If displacement is

used, consideration of machine compliance is necessary (Annex A).

3.4

small punch creep (SPC) test

when the punch tip/ball is pushed through the specimen under constant force, F and the deflection, u /

displacement, v is measured as a function of time

Note 1 to entry: The test can be used for estimating uniaxial creep properties.

3.5

displacement, v of the punch tip

distance by which the punch tip has moved after initial contact with the specimen surface

3.6

crosshead displacement

w

distance by which the cross head has moved after initial contact of the punch tip with the specimen

surface

3.7

deflection

u

distance by which the point at the centre of the specimen on the surface opposite to the point of contact

between the punch and the specimen has moved after initial contact of the punch tip with the test piece

3.8

creep-deflection curve

u(t)

data record of deflection, u as a function of time, t for a given applied force, F from a small punch creep

test

Note 1 to entry: The loading period is part of the creep deflection curve. t = 0, F = 0 (or F = preload) refers to the

point in time when loading is started.

3.9

creep-displacement curve

v(t)

data record of displacement, v as a function of time, t for a given applied force, F from a small punch creep

test

Note 1 to entry: The loading period is part of the creep displacement curve. t=0, F=0 (or F=preload) refers to the

point in time when loading is started.

3.10

force-deflection curve

F(u)

record of the force, F required to keep the punch moving at constant crosshead displacement rate, ẇ as a

function of the deflection

3.11

force-displacement curve

F(v)

record of the force, F required to keep the punch moving at constant crosshead displacement rate, ẇ as a

function of the displacement of the punch tip

Note 1 to entry: If the displacement is not measured at the punch tip, but derived from the displacement of the

crosshead or at another point along the force line, the displacement signal needs to be corrected for compliance.

For details, refer to Annex A.

3.12

ductile to brittle transition temperature

DBTT

temperature where the fracture behaviour of a given material changes from brittle to ductile as defined

in EN ISO 148-1

3.13

small punch ductile to brittle transition temperature

T

SP

characteristic temperature at which the fracture behaviour in a small punch test changes from brittle to

ductile (Annex E)

3.14

small punch energy

E

SP

integral of the force-deflection curve up to the deflection at maximum force, u

m

Note 1 to entry: This energy is used for determining TSP. In the case of pop-ins, the integration is carried out up

to the first significant pop-in (Annex E).

Note 2 to entry: Instead of deflection, displacement is allowed to be used.

Note 3 to entry: In the case of ductile materials, failure has not yet occurred when the maximum force, Fm is

reached. However, limiting the integration to deflection at maximum force, um allows harmonized treatment of

ductile and brittle failure.

3.15

normalized small punch energy

E

n

E normalized by the maximum force F

SP m

3.16

upper shelf energy

E

US

some materials like ferritic/martensitic steels show a distinct transition of E (T) from a lower to a higher

SP

level at a given temperature, T , the higher level of E (T) is called upper shelf energy, E

SP SP US

3.17

lower shelf energy

E

LS

some materials like ferritic/martensitic steels show a distinct transition of E (T) from a lower to a higher

SP

level at a given temperature, T , the lower level of E (T) is called lower shelf energy, E

SP SP LS

3.18

pop-in significant for E calculation

SP

event during a SP test where the force in the F(u) or F(v) curves drops quasi instantaneously and rises

again

Note 1 to entry: A pop-in is indicative for brittle failure.

Note 2 to entry: For calculating E a significant pop-in is defined as a drop of the force by 10% of the maximum

SP,

force, F in the test at any point (Annex E).

m

3.19

creep rupture time from uniaxial testing

t

u

time to rupture for a test piece maintained at the specified temperature, T and initial stress, R as defined

in EN ISO 204

Note 1 to entry: The symbol t in a uniaxial creep test may have as superscript the specified temperature in

u

degrees Celsius and as subscript the initial stress, R in mega pascals.

3.20

creep rupture time from small punch testing

t

r

time to rupture for a test piece maintained at the specified temperature, T and constant force F in a small

punch creep test

Note 1 to entry: The symbol t in a uniaxial creep test may have as superscript the specified temperature in

r

degrees Celsius and as subscript the force, F in newtons.

3.21

proof strength

R

p

proof strength determined from uniaxial tensile testing as defined in EN ISO 6892-1 and EN ISO 6892-2

or estimated from small punch testing (Annex D)

Note 1 to entry: The symbol is followed by a suffix giving the prescribed percentage of strain, for example R .

p0,2

3.22

yield strength

R R

eL, eH

lower and higher yield strength determined from uniaxial tensile testing as defined in EN ISO 6892-1 and

EN ISO 6892-2 or estimated from small punch testing (Annex D)

3.23

tensile strength

R

m

stress corresponding to maximum force in uniaxial tensile testing as defined in EN ISO 6892-1 and

EN ISO 6892-2 or estimated from small punch testing (Annex C)

3.24

plane strain fracture toughness

K

Ic

crack-extension resistance under conditions of crack-tip plane-strain, expressed as a critical value of

stress intensity factor

3.25

plane strain J-integral fracture toughness

J

Ic

crack-extension resistance under conditions of crack-tip plane strain, expressed as a critical value of J-

integral, J

Ic

3.26

effective fracture strain

ε

f

natural logarithm of the ratio from the initial specimen thickness h and the thickness after testing close

to the fracture surface, h (Annex H)

f

4 Symbols and designations

For the purposes of this document, the following symbols and designations apply.

NOTE This list only includes the most pertinent symbols. Less important symbols that are only used in a

specific context are not listed.

Symbol Unit Designation Reference

A % Total uniform elongation of the uniaxial tensile test Annex C

gt

A, B mm Parameters in the tanh fit of E (T) Annex E

n

A , B - Parameters in the tanh-fit of ε (T) Annex E

ε ε f

α - Transfer factor between Τ and Τ : Τ = α Τ Annex E

SP CVN SP CVN

α - Transfer factor between Τ and Τ : Τ = α Τ Annex E

ε SP,ε CVN SP,ε ε CVN

β - Correlation factor for estimation of R Annex C

Rm m

C K Parameter in the tanh fit of E (T) Annex E

n

C K Parameter in the tanh-fit of ε (T) Annex E

ε f

CP mm/N Compliance of punch and push rod Annex A

d mm Diameter of the punch tip Clause 6

D mm Diameter of the receiving hole (lower die) Clause 6

DBTT °C, K Ductile to brittle transition temperature Annex E

Symbol Unit Designation Reference

D mm Diameter of the test piece Clause 5

S

E mJ Lower shelf energy Annex E

LS

EMF - Electromotive force Annex B

E mm E normalised by F Annex E

n SP m

E mJ Small punch energy Annex E

SP

E mJ Upper shelf energy Annex E

US

ELS mJ Lower shelf energy Annex E

E GPa Young's modulus Annex A

Y

ε - Effective fracture strain ε = ln(h /h ) Annex E

f f 0 f

ε - Effective fracture strain in the lower shelf Annex E

LS

Estimated uniaxial minimum strain rate corresponding to

ε min 1/h Annex G

minimum deflection rate in a SPC test

ε - Effective fracture strain in the upper shelf Annex E

US

F N Force applied to the specimen Clause 7,

Clause 8

F N Elastic-plastic transition force in a small punch test Clause 7,

e

Annex D

F N Maximum of F during the test Annex C,

m

Annex E

F N Force at deflection u or displacement v used for estimating Annex C

i i i,

R

m

h mm Thickness of the test piece Clause 5

h mm Initial thickness of the test piece (at the beginning of the Clause 5

test)

h mm Final thickness of the test piece adjacent to the fracture area Annex E,

f

Annex H

J N/mm Plane strain J-integral fracture toughness Annex F

Ic

0,5

K MPa m Plane strain fracture toughness Annex F

Ic

L mm Length of the chamfer in the receiving hole Clause 6

Ψ N/MPa Force to stress ratio in SPC Annex G

r mm Radius of the punch tip Clause 6

R mm Radius of the receiving hole (lower die) Clause 6

R MPa Initial stress in a uniaxial creep test Annex G

Symbol Unit Designation Reference

R μm Surface roughness (of the test piece) Clause 5

a

R MPa Ultimate tensile strength Annex C

m

R MPa Proof strength Annex D

p

σ MPa Equivalent stress Annex G

T °C, K Test temperature Clause 6,

Clause 7,

Clause 8,

Annex B

T °C, K Charpy transition temperature defined at 50 % of upper Annex E

CVN

shelf energy (see EN ISO 148-1)

t h Rupture time of SPC test Annex G

r

Τ °C, K Ductile to brittle transition temperature as determined from Annex E

SP

SP testing

T °C, K T determined from fracture strain Annex E

SP,ε SP

t h Rupture time in uniaxial creep testing Annex G

u

u mm Deflection of the specimen Clause 7,

Clause 8

u mm Deflection at F Annex D

e e

u mm Characteristic deflection used for estimating R Annex C

i m

u mm Deflection at F Annex C,

m m

Annex E

u mm Annex G

min Deflection at minimum deflection rate in a SPC test

u

min

mm/h Deflection rate Annex G

u

mm/h Minimum deflection rate in a SPC test Annex G

u

min

u mm Deflection at first significant pop-in Annex E

p1

v mm Displacement of the ball/punch tip Clause 7,

Clause 8

v mm Characteristic displacement used for estimating R Annex C

i m

v mm Displacement at first significant pop-in Annex E

p1

v mm Displacement at rupture Annex G

r

w mm Displacement of the crosshead Annex A

5 Test piece

5.1 General

The test pieces that should be used are circular discs with a diameter of D = 8 mm and an initial thickness

S

of h = 0,5 mm. The use of other specimen shapes is admissible according to this document provided the

thickness and surface finish requirements are met and they can be properly clamped.

The use of smaller test pieces (D = 3 mm, h = 0,25 mm) is also admissible according to this document.

S 0

This allows the use of specimens adapted to the size of a TEM specimen holder.

For obtaining macroscopic material properties a representative volume element shall be contained in the

specimen thickness. The specimen should contain at least 5 grains in thickness cross-section, but some

exceptions can be accepted for coarse-grain, directionally solidified or single crystal materials.

These cases shall be reported accordingly; the recommended correlations for tensile and fracture

estimations might not apply.

To eliminate the influence of surface damage, the specimen should be machined to a minimal thickness

of h +0,1 mm and then should be ground from both sides on abrasive paper with a recommended

abrasive grit size designation P320 followed by fine grinding (P1200) to reach the final thickness with a

tolerance of no more than 1 %. Grinding on both faces shall be done with minimal 0,03 mm material

removal from each side of the test piece. Since the test piece is clamped during test, the tolerance of its

diameter, D is not critical, but it shall not be less than the value indicated in Table 1 to ensure sufficient

S

clamping. The thickness of the test disc specimen shall be measured at four positions around the

perimeter at 90° intervals from each other and in the centre. Each measurement shall be within the

specifications. The diameter shall be measured in two positions at 90° from each other.

Table 1 — Required test piece dimensions, tolerances and surface roughness

D [mm] h [mm] Ra [µm]

S 0

Ø 8 0 0,50 +0,005 < 0,25

−0,1 −0,005

Ø 3 0 0,25 +0,0025 < 0,25

−0,025 −0,0025

Orientation of the test piece shall be defined by Figure 1 in the test report.

Key

L longitudinal direction (i.e. rolling direction)

T transverse direction

S short transverse direction

C circumferential direction

R radial direction

NOTE The specimens are classified so that the letter designating the axis falls together with the axis along

which the force is applied. Because of the multiaxial stress state, the directions tested in a SP test do not coincide

with the force axis.

Figure 1 — Orientation of SP specimen

5.2 Material sampling

A major benefit of the small punch test method is that it enables estimation of actual mechanical

properties of operating components or structural materials without affecting their integrity and

operational performance. Sampling of the material can be done by a minimally invasive, virtually non-

destructive manner. It means that testing material is removed from the component without requirements

for its repair due to the small volume of the extracted material that is necessary for the small punch

specimen manufacture. Current standardized mechanical tests, on the other hand, require relatively large

volumes of material that cannot be extracted from in-service equipment without repair after the material

removal.

For the material sampling, existing mechanical or electric discharge machining (EDM) extraction

techniques can be used. As a universal system for the sampling of different devices without any significant

impact on the component surface and without necessity to repair or modify the component, a Scoop

Cutter Sampling technique can be used. The unique hemispherical liquid cooled cutter used in the scoop

sampler is able to remove sufficient volume of material without mechanical distortion or thermal

degradation of the component. The principle of the sampling by this machine is schematically shown in

Figure 2 [1]-[3].

Figure 2 — Schematic view of abrasive-edged spinning cutter [2]

6 Apparatus

6.1 Testing machine

Universal testing machines are often used for SP testing (Clause 7) whereas SPC tests are mainly

conducted on test specific dead-weight machines (Clause 8). In both test types, a disc-shaped test piece

is clamped between an upper and a lower part of the specimen holder. A hemispherical punch or ball

deforms the disc specimen until fracture is indicated by force drop (SP) or sudden rise in

deflection/displacement (SPC).

For both test types, the testing machine shall apply a force perpendicular to the surface of the test piece

while preventing inadvertent tilting of the punch and misalignment of the specimen. Prior to the test, the

machine should be visually examined to ensure that the punch, specimen holder, universal joints and

associated equipment are in a good state of repair.

6.2 Test environment

6.2.1 General

When oxidation of the specimen becomes an issue for a given temperature and expected test duration,

testing needs to be carried out in inert environment or vacuum.

6.2.2 Heating/cooling system

Small punch tests can be performed in a wide temperature range, i.e. cryogenic to high temperature. In

all cases, the measurement of the true test temperature is of great importance (Annex B and Annex G).

At cryogenic temperatures attention should be paid to ensure that the deflection/displacement

measurement and the true applied force are not affected by ice forming.

6.3 Applying and measuring force

In a SP and SPC test, the force shall be applied smoothly and without shock.

In SP testing (and SPC with force measurement), the force measuring system shall comply with the

requirements given in EN ISO 7500-1 class 1 or better. For static dead-weight machines (without force

measurement), the requirements are given in EN ISO 7500-2.

It is important to ensure the true force applied on the specimen is known, i.e. the friction losses and

similar effects of lead-throughs, pulleys and levers shall be accounted for.

6.4 Punch and specimen holder

Two different types of punching solutions can be used. Both a punch with a hemispherical tip or a ball

can be used as shown in Figure 3. The test setup dimensions for the specimen holder that comply with

the standard specimen (Table 1) are given in Table 2.

The general tolerance for the manufacture of the specimen holder is tolerance class “f” (fine) in

accordance with ISO 2768-1. The receiving hole, the chamfer and the hemispherical punch / balls have a

tolerance requirement of H6 according to EN ISO 286-2. An example of a specimen holder is shown in

Figure 4.

The specimen holder surfaces shall be plane and perpendicular to the force direction. The surfaces

affecting the specimen position and clamping shall be clean and free from oxide build-up, corrosion and

dirt. The working surfaces of the upper and lower part of the specimen holder shall have a good oxidation

resistance at the test temperatures. The specimen holder itself or a separate fixture shall ensure sufficient

clamping, i.e. ensure that the specimen cannot bend upwards. In the case of clamping fixtures with several

tightening bolts, it is important to alternate the tightening on opposing sides to avoid uneven clamping.

Over-clamping shall be avoided since initial plastic deformation might influence the test result. For better

repeatability of clamping a torque wrench should be used to ensure a consistent torsional load.

In high temperature SPC testing oxidation and wear of the punch is a concern, especially if metallic

punches are used. It is recommended to frequently check hemispherical punches to ensure that wear has

not affected the required tolerances.

Key

A the punch

B the specimen

C the punch-ball

D a ceramic rod for deflection measurement (and temperature E)

E the location where a thermocouple can be integrated into the ceramic deflection rod

Figure 3 — Test set-up and specimen

Table 2 — Required test set-up dimensions

Required test set-up Punch radius Chamfer length

dimensions for the

diameter of the

receiving hole

Test piece D [mm] r [mm] L [mm]

Standard 4 1,25 0,2

Miniature 1,75 0,5 0,2

NOTE Other punch radiuses have historically been used (e.g. 1,0 mm). The use of a differing punch size is

acceptable for ensuring consistency during prolonged test campaigns. However, the evaluation of material

behaviour in these cases cannot be performed with the correlations given in this document. The use of other punch

sizes is discouraged to ensure future comparability of SP and SPC test results.

It is recommended that the material used for the specimen holder should have a similar coefficient of

thermal expansion to the test specimen as to minimize stresses from thermal expansion. If there is a

marked difference in the thermal expansion coefficient between the punch, disc and specimen holder

materials, any effect of thermal loading shall be carefully evaluated.

The shallow recess for fixing the specimen position shall allow for the tolerance of the specimen

( 8 see Clause 5) to ensure that the specimen will lie flat and not in a tilted position, e.g. ∅8G6 (see

−01,

Figure 4b).

(a) (b)

Figure 4 — Example of specimen holder (a) and drawing (b)

6.5 Measuring displacement and/or deflection

In SP and SPC tests, the displacement (or deflection) shall be measured using an extensometer, which

meets the performance requirements of class 1 or better of EN ISO 9513 or by other means which ensure

the same accuracy. The extensometer can be directly in contact with the bottom of the test piece

(deflection) and/or attached to the loading rod/punch (displacement). Also, non-contact methods like

optical or laser extensometers can be used.

The extensometer shall be calibrated over an appropriate range depending on the expected failure

displacement/deflection, for instance 0 mm to 5 mm.

The extensometer shall be calibrated at intervals not exceeding 1 year. If the predicted test duration

exceeds the date of the expiry of the calibration certificate, then the extensometer shall be recalibrated

prior to commencement of the test.

6.6 Measuring test temperature

The thermocouple(s) defining the test temperature is recommended to be in contact with the specimen.

The preferred location is underneath the specimen in the clamped region or measured from below with

a thermocouple integrated into the ceramic rod employed for deflection measurement. It is also allowed

to have the test temperature sensor located elsewhere in close proximity of the specimen as long as the

true specimen temperature can be derived within tolerances. In all cases the temperature should be

calibrated against an instrumented SP test specimen as described in Annex B. If a large temperature

gradient across the specimen or through the thickness is found, correcting action shall be taken.

The permitted deviations between the indicated temperature, T and the specified test temperature, T

i

during a test are given in Table 3.

Table 3 — Permitted deviations between T and T

i

Specified test temperature, Permitted deviation between T and

i

T

T

°C

°C

T < 600 ±2

600 < T ≤ 800 ±3

800 < T ≤ 1 000 ±4

1 000 < T ≤ 1 100 ±5

For temperatures greater than 1 100°C, the permitted values shall be defined according to target

application and in agreement between the parties concerned.

7 Small punch test

7.1 Principle

The test methods of this part of the standard cover the SP test of metallic materials. According to the

definition of Clause 3, the SP test shall be performed at a constant displacement rate of the crosshead, ẇ,

of the testing machine. The direct output of the test is the force-deflection curve, F(u) or alternatively the

force-displacement curve F(v). Several characteristic parameters can be derived from these curves.

Specifically, the elastic-plastic transition force, F , the deflection at F , u (or alternatively the punch tip

e e e

displacement at F , v ), the maximum force during the test F , the deflection at F , u (or alternatively the

e e m m m

punch tip displacement at F , v ), the deflection/displacement at the onset of plastic instability u /v , the

m m i i

force at the onset of plastic instability, Fi the force at ui or vi and the energy up to Fm, ESP, can be obtained

from test curves. These parameters, together with post-test examinations of the test pieces (Annex H) are

the basis of the correlations that allow the ultimate tensile strength, R (Annex C), the proof strength, R

m p

(Annex D), the ductile to brittle transition temperature, T (Annex E) and fracture toughness (Annex F)

SP

to be estimated.

7.2 Test procedure

7.2.1 Test piece placement

The test piece shall be clean and be clamped between the upper and lower die of the specimen holder in

the testing device following the requirements of 6.4. If the testing temperature is different from room

temperature, the test shall be kept at the target temperature at least for 10 min or longer if required by

the soaking of the test equipment before starting the test. Temperature should be controlled according

to Annex B.

7.2.2 Preload

The SP test starts when the force applied to the specimen increases. From a practical point of view the

application of a preload may be useful. The maximum allowable value for this preload is 10 % of F .

e

7.2.3 Displacement rate

The SP test shall be performed by applying a constant displacement rate of the cross head of the testing

machine, ẇ. A displacement rate, ẇ, of 0,2 mm/min to 2,0 mm/min should be used.

NOTE 0,5 mm/min has been used for testing and establishing material correlations for steels in this document.

7.2.4 Test monitoring

During the test, both force, F and deflection, u, shall be measured following Clause 6. Alternatively, the

displacement of the punch tip v can be used. This displacement of the punch tip, v, can be derived from

the displacement of the cross head of the testing machine, w, by correcting this value for the compliance

of the device in the force line (Annex A). The frequency of data sampling should be adapted to obtain at

least 500 data points per test.

7.2.5 Test termination

The test is considered to be finished after a drop of the force to less than 0,8 F .

m

NOTE Force fluctuations in the excess of 20 % can occur at the lowest load levels in the very beginning of a test

that could affect automatically programmed test termination. To avoid premature test termination, a small preload

can be applied (see 7.2.2).

7.3 Characteristic parameters on the force-deflection curve F(u)

7.3.1 Elastic-plastic transition force, F

e

The transition between elastic and plastic conditions in a SP test can be characterized by means of the

force, F . This force can be used for estimating yield strength, R of the material (Annex D). The methods

e p

for F determination are described below. When reporting F values, the method used for its

e e

determination shall always be indicated.

can be obtained as the force, f (Figure 5). This f , can be determined by fitting a

Bilinear method- Fe A A

bilinear function f(u) from the origin of the curve through the points A and B as follows:

f

A

u for 0≤

A

u

A

f u = (1)

( )

ff−

B A

uu− + f for u ≤≤u u

( )

AA A B

uu−

BA

This bilinear function can be easily adjusted by varying f , f and u parameters and minimizing the error

A B A

as follows:

u

B

err F u− f u du (2)

( ) ( )

∫

For u , a fixed value equal to h is recommended (Table 1).

B 0

Trilinear method- Alternatively, when recording displacement, v instead of deflection, u, F can be

e

obtained as the force, f (Figure 6). This f , can be determined by fitting a trilinear function f(v) from the

A A

origin of the curve though the points, 0, A and B as follows:

0 for 0≤

f

A

(3)

fv v− v for v≤

( ) ( )

0 0 A

vv−

A0

ff−

B A

vv− + f for v ≤≤v v

( )

AA A B

vv−

BA

=

=

This trilinear function can be easily adjusted by varying f , f , v and v parameters and minimizing the

A B 0 A

error as follows:

v

B

(4)

err F v− f v dv

( ) ( )

∫

For v , a fixed value equal to h is recommended (Table 1).

B 0

Figure 5 — Determination of F and u by means of the bilinear method

e e

=

Figure 6 — Determination of F and v by means of the trilinear method (Force-displacement

e e

curves)

Figure 7 — Determination of F , u , F , u and E

m m i i SP

7.3.2 Deflection at F , u

e e

u is defined as the deflection corresponding to F (Figure 5).

e e

NOTE If displacement, v is recorded instead of deflection, u, v values can be obtained (Figure 6). v values

e e

cannot be interchanged with ue values.

7.3.3 Force at the onset of plastic instability, F

i

F is the force at the onset of plastic instability at displacement, v or deflection, u (C.3, Figure C.2).

i i i

7.3.4 Maximum force during the test, F

m

F can be directly obtained as the maximum force measured during the test (Figure 7). F is used in some

m m

of the available correlations for the estimation of ultimate tensile strength, R (Annex C).

m

7.3.5 Deflection at Fm, um

u is defined as the deflection corresponding to F (Figure 7). u is used in some of the available

m m m

correlations for ultimate tensile strength estimation R (Annex C).

m

NOTE If displacement, v is recorded instead of deflection, u, vm values can be obtained. vm values cannot be

interchanged with um values.

7.3.6 Small punch energy, ESP

E , is the area under the force-deflection curve, F(u) (Figure 7). E values are used for the determination

SP SP

of T (Annex E). E values can also be used as a qualitative estimation of the fracture resistance of the

SP SP

material.

NOTE If displacement, v is recorded instead of deflection, u, ESP values can be calculated in a similar way, but

cannot be interchanged with those obtained from F(u) curves.

7.4 Test report

The test report shall contain the following requirements:

— Reference to document EN 10371;

— Material and specimen identification;

— Test piece description, including: initial dimensions, orientation, preparation, surface condition and

special features if any;

— Description of the test setup (chamfer; radius; machine identifier);

— Test conditions, including: testing temperature, preload, displacement rate and environment;

— Force-deflection curve, F(u). Alternatively, force-displacement curve, F(v) can be reported;

— F and u , (or v ) indicating the method(s) used for their determination;

e e e

— F and u (or v );

m m m

— E ;

SP

— Post-test examination results (Annex H);

— Any other aspect of interest or incidence during the test.

NOTE Standard data formats are available (see Annex I).

8 Small punch creep test

8.1 Principle

This procedure is specific to tests performed on small disc specimens (Clause 5) employing a punch and

ball or a solid rod with a hemispherical tip under constant force conditions. Two main forms of data can

be generated in the form of i) deflection vs. time, u(t) from each individual test and ii) equivalent stress

) from a collection of tests. Additional analysis may then be performed to calculate

v

...

Die EN 10371:2021, auch bekannt als SIST EN 10371:2021, beschreibt ein standardisiertes Verfahren zur Durchführung des kleinen Punch-Tests für metallische Materialien. Der Umfang dieses Dokuments umfasst die Ermittlung mechanischer Eigenschaften wie Zugfestigkeit, Kriechverhalten und Bruchmechanik von Metallen, und das über einen breiten Temperaturbereich, der von kryogenen Bedingungen bis hin zu hohen Temperaturen reicht. Ein wesentlicher Stärke der EN 10371:2021 liegt in der präzisen Methodik zur Bewertung der Materialeigenschaften. Diese Norm gewährt Forschern und Industrievertretern eine verlässliche Grundlage zur Beurteilung der Verformungseigenschaften und der strukturellen Integrität von metallischen Werkstoffen. Insbesondere die Möglichkeit, sowohl unter extremen als auch unter normalen Temperaturen zu testen, macht diese Norm besonders relevant für zahlreiche industrielle Anwendungen. Die Relevanz der EN 10371:2021 wird durch die steigenden Anforderungen in der Materialforschung und -prüfung deutlich. Da metallische Materialien in vielen kritischen Anwendungen verwendet werden, von der Luft- und Raumfahrt bis hin zur Energietechnik, ist ein genaues Verständnis ihrer mechanischen Eigenschaften unerlässlich. Die Norm stellt sicher, dass die Testergebnisse reproduzierbar und vergleichbar sind, was für die Qualitätssicherung von Produkten entscheidend ist. Zusammenfassend bietet die EN 10371:2021 eine umfassende und sorgfältig strukturierte Methodik, die sowohl für die Forschung als auch für industrielle Anwendungen von großer Bedeutung ist. Die Einführung dieser Norm in die Praxis wird erwartet, um die Sicherheit und Effizienz in der Verarbeitung und Anwendung metallischer Materialien entscheidend zu verbessern.

La norme EN 10371:2021, intitulée "Métalliques matériels - Méthode de test de petit punch", présente des spécificités essentielles pour l'évaluation des propriétés mécaniques des matériaux métalliques. Son champ d'application est particulièrement vaste, englobant des tests à différentes températures, ce qui la rend pertinente dans divers secteurs industriels, notamment ceux soumis à des conditions extrêmes. Une des forces de cette norme réside dans sa capacité à fournir une méthode fiable et précise pour l'estimation des propriétés de résistance à la traction, de fluage et de fracture. Cela permet aux ingénieurs et aux chercheurs d'obtenir des données cruciales sur le comportement des matériaux, allant des températures cryogéniques jusqu'aux températures élevées. Ce facteur est primordial pour les industries de l'aéronautique, de l'énergie et de la métallurgie, où la performance et la sécurité des matériaux sont primordiales. De plus, le document SIST EN 10371:2021 propose une approche standardisée qui facilite la comparabilité des résultats entre différents laboratoires, renforçant ainsi la confiance dans les données expérimentales obtenues. La norme inclut également des directives claires sur la préparation des échantillons et la conduite des essais, assurant une uniformité dans l'exécution des tests. Enfin, la norme EN 10371:2021 répond à un besoin croissant de méthodes de test efficaces et adaptées pour les matériaux métalliques, ce qui la rend d'une grande pertinence dans la recherche et le développement de nouveaux alliages et produits. Sa mise en œuvre est un atout indéniable pour les acteurs du secteur, permettant d'optimiser les processus de fabrication et d'améliorer les performances des produits finaux.

SIST EN 10371:2021は、金属材料の小型パンチ試験法を規定する文書であり、その範囲は広範囲にわたります。この標準は、低温から高温までの範囲で金属材料の引張、クリープ、そして破壊力学的特性を推定するための方法を提供しています。この小型パンチ試験法は、従来の試験法に比べて少量の試料で高精度の測定を可能にし、特に試料の使用効率を向上させる点において、その強みを発揮します。 さらに、この標準は、金属材料の評価において重要な特性を包括的にカバーしており、さまざまな産業や研究分野での応用性が高いことから、実用的かつ適切な方法論として評価されています。また、EN 10371:2021は、試験条件や手順が明確に記載されているため、作業者にとっても実施しやすく、結果の再現性が高いという利点があります。 加えて、この標準は、金属材料の特性評価に関する一般的な合意を提供し、国際的な規範と整合性を持たせることで、研究者や技術者が互いに信頼性のあるデータを共有しやすくしています。このような点から、SIST EN 10371:2021は、金属材料の特性評価における重要な基準として、非常に関連性の高い文書であると言えるでしょう。

SIST EN 10371:2021 표준은 금속 재료의 특성 평가를 위한 소형 펀치 시험 방법을 규정하고 있습니다. 이 표준은 저온부터 고온까지의 범위에서 인장, 크리프 및 파괴 기계적 물성을 측정하는 데 필요한 절차와 기술적인 측면을 제공합니다. 이 표준의 강점은 그 범위가 넓다는 것입니다. 다양한 온도 조건에서 금속 재료의 성능을 평가할 수 있는 능력은 산업 전반에 걸쳐 중요한 의미를 지니며, 특히 항공, 우주 및 에너지 분야에서의 응용 가능성이 큽니다. SIST EN 10371:2021은 금속 재료의 성능을 진단하는 데 있어 실험적 데이터의 신뢰성을 높이는 데 기여하는 동시에, 재료 개발 및 품질 관리를 위한 필수 가이드라인을 제공합니다. 또한, 다양한 환경 조건에서의 실험을 통해 얻은 데이터는 신뢰할 수 있는 결과로 이어지며, 이는 산업별 맞춤형 솔루션 개발에 있어서 중요한 기준이 될 것입니다. 더불어 이 표준은 국제적인 기준으로 자리 잡고 있으며, 연구 및 개발, 제조 공정 개선 등 다양한 분야에서의 적용이 가능합니다. 따라서 SIST EN 10371:2021은 금속 재료에 대한 신뢰성 높은 평가를 원하는 모든 산업 분야에서 반드시 참조해야 할 중요한 표준입니다.

The EN 10371:2021 standard provides a comprehensive framework for the small punch test method applied to metallic materials. This standard is crucial as it details the testing procedures necessary for evaluating critical material properties such as tensile, creep, and fracture mechanics, enabling a deeper understanding of performance across a range of temperatures, from cryogenic to high heat scenarios. One of the strengths of EN 10371:2021 lies in its rigorous approach to standardization within the materials testing domain. By establishing a defined methodology for the small punch test, the standard fosters consistency and reliability in the assessment of metallic materials. This consistency is particularly valuable for industries where material performance may have significant safety and reliability implications. Moreover, the relevance of this standard extends to its application in various sectors, including aerospace, nuclear, and automotive industries, where materials are often subjected to extreme conditions. By employing the small punch test method outlined in EN 10371:2021, professionals can ensure that they are accurately characterizing the mechanical behavior of materials, which is vital for the design and integrity of critical components. In summary, the EN 10371:2021 standard is an essential document that expertly outlines the standardized procedures for small punch testing of metallic materials, ensuring that tensile and mechanical properties are accurately assessed across a broad temperature spectrum. Its strengths in fostering reliability and its wide applicability across industries underscore its importance in the field of metallic materials testing.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...