EN 13136:2013+A1:2018

(Main)Refrigerating systems and heat pumps - Pressure relief devices and their associated piping - Methods for calculation

Refrigerating systems and heat pumps - Pressure relief devices and their associated piping - Methods for calculation

1.1 This European Standard describes the calculation of mass flow for sizing pressure relief devices for components of refrigerating systems.

NOTE The term "refrigerating system" used in this European Standard includes heat pumps.

1.2 This European Standard describes the calculation of discharge capacities for pressure relief valves and other pressure relief devices in refrigerating systems including the necessary data for sizing these when relieving to atmosphere or to components within the system at lower pressure.

1.3 This European Standard specifies the requirements for selection of pressure relief devices to prevent excessive pressure due to internal and external heat sources, the sources of increasing pressure (e.g. compressor, heaters, etc.) and thermal expansion of trapped liquid.

1.4 This European Standard describes the calculation of the pressure loss in the upstream and downstream line of pressure relief valves and other pressure relief devices and includes the necessary data.

1.5 This European Standard refers to other relevant standards in Clause 5.

Kälteanlagen und Wärmepumpen - Druckentlastungseinrichtungen und zugehörige Leitungen - Berechnungsverfahren

1.1 Diese Europäische Norm beschreibt die Berechnung der Massenströme zur Größenbestimmung von Druckentlastungseinrichtungen für Teile von Kälteanlagen.

ANMERKUNG Der in dieser Europäischen Norm verwendete Begriff „Kälteanlage“ schließt Wärmepumpen mit ein.

1.2 Diese Europäische Norm beschreibt die Berechnung der Abblaseleistungen von Druckentlastungsventilen und anderen Druckentlastungseinrichtungen in Kälteanlagen einschließlich der hierzu erforderlichen Daten zur Größenbestimmung dieser Einrichtungen, wenn sie ins Freie oder in Bauteile der Kälteanlage mit niedrigerem Druck abblasen.

1.3 Diese Europäische Norm legt die Anforderungen an die Auswahl von Druckentlastungseinrichtungen zur Vermeidung von unzulässigen Drücken, hervorgerufen durch innere und äußere Wärmequellen, Druckerzeuger (z. B. Verdichter, Erhitzer usw.) und die Wärmeausdehnung eingesperrter Flüssigkeit fest.

1.4 Diese Europäische Norm beschreibt die Berechnung des Druckabfalls in den zu und abführenden Leitungen von Druckentlastungsventilen und anderen Druckentlastungseinrichtungen einschließlich der erforderlichen Daten.

1.5 Diese Europäische Norm verweist in Abschnitt 5 auf weitere einschlägige Normen.

Systèmes frigorifiques et pompes à chaleur - Dispositifs de limitation de pression et tuyauteries associées - Méthodes de calcul

1.1 La présente Norme européenne décrit le calcul du débit-masse pour le dimensionnement des dispositifs de limitation de pression pour les composants des systèmes frigorifiques.

NOTE Le terme « système frigorifique » utilisé dans la présente Norme européenne inclut les pompes à chaleur.

1.2 La présente Norme européenne décrit le calcul des capacités de décharge des soupapes de sûreté et autres dispositifs de limitation de pression des systèmes frigorifique, y compris les données nécessaires à leur dimensionnement lors de leur décharge dans l’atmosphère ou dans les composants du système à basse pression.

1.3 La présente Norme européenne spécifie les exigences relatives à la sélection des dispositifs de limitation de pression pour éviter une pression excessive due aux sources de chaleur internes et externes, aux autres sources de génération de pression (par exemple compresseurs, chauffages, etc.) et à la dilatation du fluide piégé.

1.4 La présente Norme européenne décrit le calcul de la perte de charge dans la tubulure en amont et en aval des soupapes de sûreté et autres dispositifs de limitation de pression, et inclut les données nécessaires.

1.5 La présente Norme européenne renvoie à d’autres normes pertinentes à l’Article 5.

Hladilni sistemi in toplotne črpalke - Tlačne varnostne naprave in njihove napeljave - Metode za izračun

1.1 Ta evropski standard opisuje izračun masnega pretoka za tlačne varnostne naprave komponent hladilnih sistemov.

OPOMBA: Pojem »hladilni sistem« v tem evropskem standardu zajema tudi toplotne črpalke.

1.2 Ta evropski standard opisuje izračun zmogljivosti za praznjenje tlačnih varnostnih ventilov in drugih tlačnih varnostnih naprav v hladilnih sistemih, vključno s potrebnimi podatki za določanje njihove količine pri razbremenitvi v ozračje ali v komponente znotraj sistema, ki imajo nižji tlak.

1.3 Ta evropski standard določa zahteve za izbiro tlačnih varnostnih naprav za preprečevanje prekomernega tlaka, ki nastane zaradi notranjih in zunanjih virov toplote, virov naraščajočega tlaka (npr. kompresor, grelniki itd.) ter toplotnega raztezanja ujete tekočine.

1.4 Ta evropski standard opisuje izračun izgube tlaka na vhodni in izhodni liniji tlačnih varnostnih ventilov in drugih tlačnih varnostnih naprav ter vključuje potrebne podatke.

1.5 Ta evropski standard se nanaša na druge ustrezne standarde iz točke 5.

General Information

- Status

- Withdrawn

- Publication Date

- 27-Nov-2018

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 182 - Refrigerating systems, safety and environmental requirements

- Drafting Committee

- CEN/TC 182/WG 2 - Design and testing

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 18-Dec-2024

- Completion Date

- 14-Apr-2025

Relations

- Effective Date

- 24-Oct-2018

- Effective Date

- 24-Oct-2018

- Effective Date

- 09-Dec-2020

Frequently Asked Questions

EN 13136:2013+A1:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Refrigerating systems and heat pumps - Pressure relief devices and their associated piping - Methods for calculation". This standard covers: 1.1 This European Standard describes the calculation of mass flow for sizing pressure relief devices for components of refrigerating systems. NOTE The term "refrigerating system" used in this European Standard includes heat pumps. 1.2 This European Standard describes the calculation of discharge capacities for pressure relief valves and other pressure relief devices in refrigerating systems including the necessary data for sizing these when relieving to atmosphere or to components within the system at lower pressure. 1.3 This European Standard specifies the requirements for selection of pressure relief devices to prevent excessive pressure due to internal and external heat sources, the sources of increasing pressure (e.g. compressor, heaters, etc.) and thermal expansion of trapped liquid. 1.4 This European Standard describes the calculation of the pressure loss in the upstream and downstream line of pressure relief valves and other pressure relief devices and includes the necessary data. 1.5 This European Standard refers to other relevant standards in Clause 5.

1.1 This European Standard describes the calculation of mass flow for sizing pressure relief devices for components of refrigerating systems. NOTE The term "refrigerating system" used in this European Standard includes heat pumps. 1.2 This European Standard describes the calculation of discharge capacities for pressure relief valves and other pressure relief devices in refrigerating systems including the necessary data for sizing these when relieving to atmosphere or to components within the system at lower pressure. 1.3 This European Standard specifies the requirements for selection of pressure relief devices to prevent excessive pressure due to internal and external heat sources, the sources of increasing pressure (e.g. compressor, heaters, etc.) and thermal expansion of trapped liquid. 1.4 This European Standard describes the calculation of the pressure loss in the upstream and downstream line of pressure relief valves and other pressure relief devices and includes the necessary data. 1.5 This European Standard refers to other relevant standards in Clause 5.

EN 13136:2013+A1:2018 is classified under the following ICS (International Classification for Standards) categories: 27.080 - Heat pumps; 27.200 - Refrigerating technology. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13136:2013+A1:2018 has the following relationships with other standards: It is inter standard links to EN 13136:2013/prA1:2017, EN 13136:2013, EN ISO 24664:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13136:2013+A1:2018 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 13136:2013+A1:2018 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kälteanlagen und Wärmepumpen - Druckentlastungseinrichtungen und zugehörige Leitungen - BerechnungsverfahrenSystèmes frigorifiques et pompes à chaleur - Dispositifs de limitation de pression et tuyauteries associées - Méthodes de calculRefrigerating systems and heat pumps - Pressure relief devices and their associated piping - Methods for calculation27.200Hladilna tehnologijaRefrigerating technology27.080Heat pumpsICS:Ta slovenski standard je istoveten z:EN 13136:2013+A1:2018SIST EN 13136:2014+A1:2019en,fr,de01-februar-2019SIST EN 13136:2014+A1:2019SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13136:2013+A1

November

t r s z ICS

t yä r z râ

t yä t r r Supersedes EN

s u s u xã t r s uEnglish Version

Refrigerating systems and heat pumps æ Pressure relief devices and their associated piping æ Methods for calculation Systèmes frigorifiques et pompes à chaleur æ Dispositifsde limitation de pression et tuyauteries associées æ Méthodes de calcul

Kälteanlagen und Wärmepumpen æ Druckentlastungseinrichtungen und zugehörige Leitungen æ Berechnungsverfahren This European Standard was approved by CEN on

t v August

t r s u and includes Amendment

s approved by CEN on

w November

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s u s u xã t r s u ªA sã t r s z ESIST EN 13136:2014+A1:2019

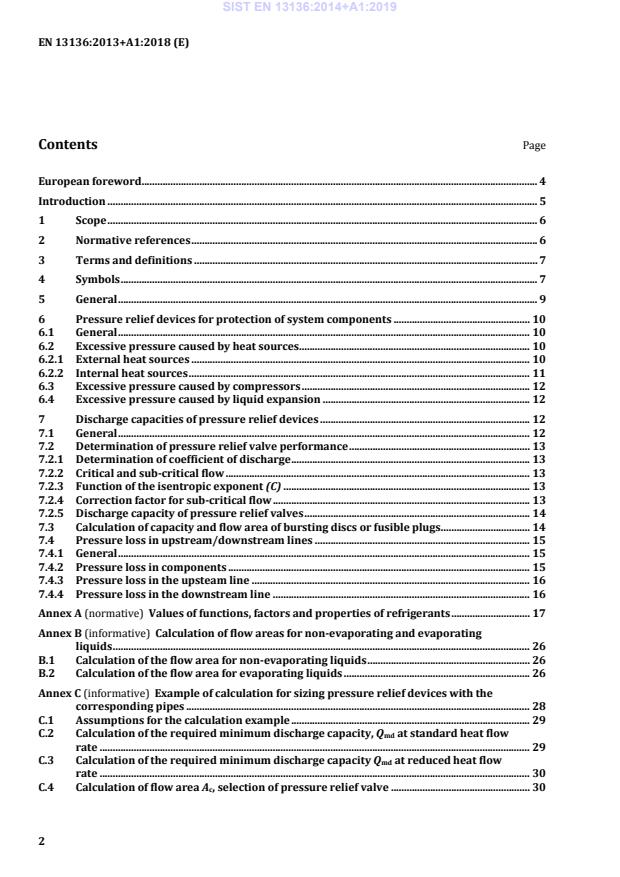

Values of functions, factors and properties of refrigerants . 17 Annex B (informative)

Calculation of flow areas for non-evaporating and evaporating liquids . 26 B.1 Calculation of the flow area for non-evaporating liquids . 26 B.2 Calculation of the flow area for evaporating liquids . 26 Annex C (informative)

Example of calculation for sizing pressure relief devices with the corresponding pipes . 28 C.1 Assumptions for the calculation example . 29 C.2 Calculation of the required minimum discharge capacity, Qmd at standard heat flow rate . 29 C.3 Calculation of the required minimum discharge capacity Qmd at reduced heat flow rate . 30 C.4 Calculation of flow area Ac, selection of pressure relief valve . 30 SIST EN 13136:2014+A1:2019

Relationship between this European Standard and the essential requirements of Directive 2014/68/EU (Pressure equipment Directive) aimed to be covered . 34 Bibliography . 35

IEC Electropedia: available at http://www.electropedia.org/

ISO Online browsing platform: available at http://www.iso.org/obp " 4 Symbols For the purposes of this document, the symbols given in EN 764-2:2012 and the following apply: Symbol Designation Unit A Flow area of the pressure relief valve π×=24dA mm2 Ac Calculated flow area mm2 ADN Valve cross section related to DN mm2 Ain Inside area of inlet tube mm2 Aliq Calculated flow area of liquid after expansion mm2 Aout Inside area of outlet tube mm2 AR Inside area of tube mm2 Asurf External surface area of the vessel m2 Avap Calculated flow area of vapour after expansion mm2 C Function of the isentropic exponents (Table A.2) – DN Nominal size (see EN ISO 6708:1995) – d Actual most narrow flow diameter of the pressure relief valve mm dc Calculated flow diameter of the pressure relief valve mm din Inside diameter of inlet tube mm dout Inside diameter of outlet tube mm DR Outside diameter of tube (Table A.4) mm dR Inside diameter of tube mm hvap Heat of vaporisation calculated at 1,1 times the set pressure of the pressure relief device (for super critical or superheated conditions, see 6.1) kJ/kg Kb Theoretical capacity correction factor for sub-critical flow (Table A.3) – Kd Certified coefficient of discharge taking into account the backpressure ratio pb/po and the possible reduced stroke of the pressure relief valve – SIST EN 13136:2014+A1:2019

Differential pressure bar in Pressure loss in the upstream line of pressure relief valve bar out Pressure loss in the downstream line of pressure relief valve bar Qh Rate of heat production, internal heat source kW Qliq Flow of liquid after expansion kg/h Qm Calculated refrigerant mass flow rate of the pressure relief device kg/h qm Theoretical discharge capacity

mm2 q’m Actual discharge capacity determined by tests kg/h Cb mm2 Qmd Minimum required discharge capacity, of refrigerant, of the pressure relief device kg/h Qmd’ Adjusted discharge capacity of refrigerant, of the pressure relief device, used for pressure drop calculation kg/h Qvap Flow of vapour after expansion kg/h R Bending radius of tube (Table A.4) mm SIST EN 13136:2014+A1:2019

Flush connection angle (Table A.4) °

Pressure loss coefficient ζζ==∑1nnn – DN Pressure loss coefficient related to DN – n Pressure loss coefficient of a single component – v Volumetric efficiency estimated at suction pressure and discharge pressure equivalent to the pressure relief device setting –

³ 0,02) –

Kinematic viscosity m2/s

= 1/vo) kg/m3 10 Vapour density at refrigerant saturation pressure/dew point at 10 °C kg/m3

Density of heat flow rate kW/m2 red Reduced density of heat flow rate kW/m2 a The Pressure Equipment Directive 97/23/EC identifies the maximum allowable pressure by the symbol "PS". 5 General Requirements for protection against excessive pressure in refrigeration systems and heat pumps are given in EN 378-2. For design and manufacturing of bodies, bonnets and bolts for pressure relief devices — safety valves and bursting discs — specification of strength pressure test, EN 12284 applies. For other aspects, the requirements of EN ISO 4126-1:2013 Safety Valves, Clause 3, Terms and definitions, Clause 5, Design, Clause 7, Type tests and Clause 10, Marking and sealing and EN ISO 4126-2:2003 Bursting Disc Safety Devices, Clause 17 Marking, 17.2 Bursting discs/bursting disc assemblies and 17.3 Bursting disc holders apply. NOTE Calculations for flow areas for non-evaporating and evaporating liquids are given in Annex B. Calculations for a pressure relief device with the corresponding pipes are given in Annex C. SIST EN 13136:2014+A1:2019

but a higher value shall be used if necessary. Where the thickness(s) of the insulation of the pressure vessel is bigger than 0,04 [m] and the insulation is tested according to reaction of fire as described in EN 13501-1 and classified better than class C, a reduced density of heat flow rate can be used and determined as follows: φφ=×2red004kW/m,[]s (3) The sizing of the pressure relief device and calculating of pressure loss are carried out in accordance with Clause 7. For pressure vessels the total external surface area of the vessel shall be taken as Asurf. SIST EN 13136:2014+A1:2019

Figure 1 — Plate Heat Exchanger (PHE) Figure 2 — Plate and Shell Heat Exchanger (PSHE) surfA of Plate Heat Exchanger will be calculated as follows: 1surf2()ALLLLLL=××+×+×22313 [m2] (4) surfA for Plate and Shell Heat Exchanger will be calculated as follows: ()1dsurfAππ=××+××21124(/)dL [m2] (5) Heat exchangers are generally considered to be vessels. Due to its unique design, some fin and tube heat exchangers in refrigeration systems may be classified according to Article 1 paragraph 2.1.2 last sentence. For further details, see guideline 2/4 of PED 97/23/EC. Higher values for density of heat flow rate than 10 kW/m2 may be necessary where in case of fire full engulfment for the pressure vessel is to be expected and/or in the case the pressure vessel is insulated with a flammable insulation. Other calculation methods could be necessary in case of heat radiation with a higher heat flow directed to one side of the vessel. Where pressure vessels of a refrigerating system are protected against excessive pressure according to EN 378-2:2008+A2:2012, 6.2 and monitored according to EN 378-3:2008+A1:2012, Clause 7 and installed in special machinery rooms as specified in EN 378-3:2008+A1:2012, Clause 5, no external heat sources for sizing the pressure relief devices used for those vessels themselves may be considered. But, nevertheless, for the sizing of those pressure relief devices on the low pressure side of the refrigerating system all connected pressure vessels, compressors and pumps should be taken into account (EN 378-2:2008+A2:2012, 6.2.6.3). Combustion heat potential of insulations in case of fire is not part of the calculations in this European Standard. Care should be taken at welding activities near insulated vessels and pipes. Electric equipment inside of the flammable insulation should be carried out according to EN 60204-1. 6.2.2 Internal heat sources The minimum required discharge capacity of the pressure relief device for conditions which arise due to an internal source of excessive heat shall be determined by the following: hmdvap×=3600QQh [kg/h] (6) The sizing of the pressure relief device and calculating of pressure loss are carried out in accordance with Clause 7. SIST EN 13136:2014+A1:2019

(8) 7 Discharge capacities of pressure relief devices 7.1 General When the operational characteristics have been satisfactorily established, it is acceptable to use steam, air or other gas of known characteristics as the fluid for flow characteristics tests except for valves SIST EN 13136:2014+A1:2019

(10) 7.2.2 Critical and sub-critical flow The flow of a gas or vapour through an orifice, such as the flow areas of a pressure relief valve, increases as the outlet pressure is decreased until critical flow is achieved. Further decrease in outlet pressure will not result in any further increase in flow. Critical flow occurs when boκκκ−≤+121/()pp [–]

(11) and sub-critical flow occurs when boκκκ−>+121/()pp [–] (12) assuming the validity of Rankine's law. If the flow is critical Kb = 1, and if the flow is sub-critical, the correction factor shall be calculated according to Formula (14) in 7.2.4 or taken from Table A.3. 7.2.3 Function of the isentropic exponent (C) The function (C) of the isentropic exponent is calculated from

...

기사 제목: EN 13136:2013+A1:2018 - 냉동 시스템 및 열펌프 - 압력 해방 장치 및 관련 파이프 - 계산 방법 기사 내용: 1.1 이 유럽 표준은 냉동 시스템 구성 요소용 압력 해방 장치의 사이징을 위한 질량 흐름 계산에 대해 설명한다. 주의 사항: 이 유럽 표준에서 사용되는 "냉동 시스템"이라는 용어에는 열펌프도 포함된다. 1.2 이 유럽 표준은 냉동 시스템의 압력 해방 밸브 및 기타 압력 해방 장치의 배출 능력을 계산하는 방법에 대해 설명하며, 이를 해방시킬 때 대기 압력이거나 시스템 내의 낮은 압력 요소로 제어하기 위해 필요한 데이터를 포함한다. 1.3 이 유럽 표준은 내부 및 외부 열원, 압력 증가 원인 (예: 압축기, 히터 등) 및 가두어진 액체의 열 팽창 때문에 발생하는 과도한 압력을 방지하기 위한 압력 해방 장치의 선택 요구 사항을 명시한다. 1.4 이 유럽 표준은 압력 해방 밸브 및 기타 압력 해방 장치 앞뒤의 압력 손실 계산을 설명하며, 필요한 데이터를 포함한다. 1.5 이 유럽 표준은 5절에서 관련 표준을 참조한다.

記事のタイトル:EN 13136:2013+A1:2018 - 冷凍システムおよびヒートポンプ - 安全弁および関連パイピング - 計算方法 記事の内容:この記事では、EN 13136:2013+A1:2018というヨーロッパ規格について説明しています。これは、冷凍システムおよびヒートポンプで使用される安全弁および関連パイピングのサイジングのための計算方法を提供しています。この規格には、質量フローの計算方法、安全弁およびその他の安全装置の放出能力の計算方法が含まれています。これらは、大気に対して圧力を開放する場合やシステム内のより低い圧力のコンポーネントに対して圧力を開放する場合に必要なデータも含まれています。また、内部および外部の熱源、圧力の上昇原因(例:コンプレッサー、ヒーターなど)、閉じ込められた液体の熱膨張による過剰な圧力を防ぐための安全弁の選択要件も規定しています。規格では安全弁およびその他の安全装置の上流および下流ラインの圧力損失の計算方法も説明しており、関連する規格についても言及しています。(Translated from English to Japanese)

This article discusses the European Standard EN 13136:2013+A1:2018, which provides methods for calculating the size and capacity of pressure relief devices used in refrigerating systems and heat pumps. The standard includes calculations for mass flow, discharge capacities, and pressure loss in the piping of these devices. It also specifies the requirements for selecting pressure relief devices to prevent excessive pressure in the system. The standard refers to other relevant standards in Clause 5.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...