IEC 62620:2014

(Main)Secondary cells and batteries containing alkaline or other non-acid electrolytes - Secondary lithium cells and batteries for use in industrial applications

Secondary cells and batteries containing alkaline or other non-acid electrolytes - Secondary lithium cells and batteries for use in industrial applications

IEC 62620:2014 specifies marking, tests and requirements for lithium secondary cells and batteries used in industrial applications including stationary applications. When there exists an IEC standard specifying test conditions and requirements for cells used in special applications and which is in conflict with this standard, the former takes precedence. (e.g. IEC 62660 series on road vehicles). The following are some examples of applications that utilize the cells and batteries under the scope of this standard.

- Stationary applications: telecom, uninterruptible power supplies (UPS), electrical energy storage system, utility switching, emergency power and similar applications.

- Motive applications: fork-lift truck, golf cart, AGV, railway, and marine, excluding road vehicles.

This standard applies to cells and batteries. If the battery is divided into smaller units, the smaller unit can be tested as the representative of the battery. The manufacturer clearly declares the tested unit. The manufacturer may add functions, which are present in the final battery, to the tested unit.

Accumulateurs alcalins et autres accumulateurs à électrolyte non acide - Eléments et batteries d'accumulateurs au lithium pour utilisation dans les applications industrielles

L'IEC 62620:2014 spécifie le marquage, les essais et les exigences pour les éléments et les batteries d accumulateurs au lithium utilisés dans les applications industrielles, y compris les applications stationnaires. En cas d'existence d'une norme IEC spécifiant des conditions d'essai et des exigences pour des éléments destinés à des applications particulières, et qui serait en contradiction avec la présente norme, la publication particulière est appliquée en priorité (par exemple, la série IEC 62660 sur les véhicules routiers). Ci-après figurent des exemples d'applications utilisant les éléments et les batteries inclus dans le domaine d'application de la présente norme.

- Applications stationnaires: télécommunications, alimentation sans interruption (ASI), système de stockage de l'énergie électrique, sélecteur de service, alimentation d'urgence et applications analogues.

- Applications mobiles: chariot élévateur, voiturette de golf, AGV, ferroviaire, et marine, à l'exception des véhicules routiers.

La présente norme s'applique aux éléments et aux batteries. Si la batterie est divisée en unités plus petites, l'unité plus petite peut être soumise aux essais pour représenter l'ensemble de la batterie. Le fabricant déclare clairement l'unité soumise aux essais. Le fabricant peut ajouter des fonctions, qui sont présentes dans la batterie finale, à l'unité soumise aux essais.

General Information

- Status

- Published

- Publication Date

- 11-May-2023

- Technical Committee

- SC 21A - Secondary cells and batteries containing alkaline or other non-acid electrolytes

- Drafting Committee

- WG 5 - TC 21/SC 21A/WG 5

- Current Stage

- PPUB - Publication issued

- Start Date

- 25-Nov-2014

- Completion Date

- 31-Dec-2014

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62620:2014 is an international standard developed by the International Electrotechnical Commission (IEC) that specifies the marking, testing, and performance requirements for secondary lithium cells and batteries containing alkaline or other non-acid electrolytes used in industrial applications. This standard covers lithium secondary cells and batteries primarily for industrial and stationary uses, such as telecom, uninterruptible power supplies (UPS), electrical energy storage systems, and utility switching, as well as motive applications like fork-lift trucks, golf carts, automated guided vehicles (AGVs), railway, and marine equipment-excluding road vehicles. IEC 62620 ensures consistency, safety, and reliability in the design and operation of industrial lithium batteries, supporting end users and manufacturers globally.

Key Topics

Scope and Applicability

IEC 62620 applies to secondary lithium cells and batteries designed for industrial applications. When conflicting with a specialized IEC standard (e.g., IEC 62660 series for road vehicles), the more specific standard prevails. The document addresses cells, entire batteries, and smaller units representing a whole battery, provided the manufacturer clearly declares the tested unit and its functions.Marking and Designation

The standard details requirements for clear marking of cells and batteries to ensure traceability, safety information, capacity, and voltage specifications. It defines how cells and battery modules should be designated, including structured formulations for battery configurations.Electrical Testing

IEC 62620 outlines comprehensive electrical tests to evaluate discharge performance at standard (+25 °C) and low temperatures, charge retention, internal resistance (both AC and DC), and endurance under cyclic use or constant voltage storage. These tests guarantee batteries meet minimum operational and safety standards required by industrial users.Type Testing and Approval

The document specifies conditions for type testing, including sample size, testing sequences, dimensional requirements, and electrical performance assessments. This framework enables certification and quality control for manufacturers and regulatory bodies.

Applications

IEC 62620 batteries are designed for a wide range of industrial uses that demand high reliability, safety, and consistent energy delivery:

Stationary Energy Storage

Batteries compliant with IEC 62620 are widely used in telecom infrastructure, UPS systems, and electrical energy storage systems, providing backup power and grid stabilization.Motive Power Solutions

Industrial motive applications such as fork-lift trucks, golf carts, AGVs, railway systems, and marine vessels benefit from the standard's requirements to ensure operational efficiency and safety in harsh or demanding environments.Emergency and Utility Power

The standard supports use in emergency power supply systems and utility switching applications where dependable battery performance is critical.

Related Standards

IEC 62660 Series – Lithium-ion cells and batteries for road vehicles, which take precedence over IEC 62620 when applicable.

IEC 62133 – Safety requirements for portable sealed secondary cells and batteries, applicable to a broader range of nickel and lithium chemistry batteries.

ISO/IEC Directives Part 2 – Guidelines for the preparation of international standards, under which IEC 62620 was drafted.

IEC 61960 – Secondary lithium-ion cells and batteries for portable applications, complementary to industrial battery standards.

Practical Value

Adoption of IEC 62620:2014 enables manufacturers and end-users in industrial sectors to:

- Guarantee battery safety and compliance with internationally recognized test methods.

- Enhance product interoperability and global market acceptance.

- Facilitate reliable performance in critical industrial applications such as backup power and motive operations.

- Reduce risks related to battery failure through standardized endurance and electrical performance testing.

- Ensure accurate product information through mandated marking and designation conventions.

By adhering to IEC 62620, stakeholders can efficiently manage the design, testing, and deployment of industrial lithium secondary cells and batteries, driving innovation while maintaining high industry standards.

IEC 62620:2014 - Secondary cells and batteries containing alkaline or other non-acid electrolytes - Secondary lithium cells and batteries for use in industrial applications

IEC 62620:2014+AMD1:2023 CSV - Secondary cells and batteries containing alkaline or other non-acid electrolytes - Secondary lithium cells and batteries for use in industrial applications Released:5/12/2023

Frequently Asked Questions

IEC 62620:2014 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Secondary cells and batteries containing alkaline or other non-acid electrolytes - Secondary lithium cells and batteries for use in industrial applications". This standard covers: IEC 62620:2014 specifies marking, tests and requirements for lithium secondary cells and batteries used in industrial applications including stationary applications. When there exists an IEC standard specifying test conditions and requirements for cells used in special applications and which is in conflict with this standard, the former takes precedence. (e.g. IEC 62660 series on road vehicles). The following are some examples of applications that utilize the cells and batteries under the scope of this standard. - Stationary applications: telecom, uninterruptible power supplies (UPS), electrical energy storage system, utility switching, emergency power and similar applications. - Motive applications: fork-lift truck, golf cart, AGV, railway, and marine, excluding road vehicles. This standard applies to cells and batteries. If the battery is divided into smaller units, the smaller unit can be tested as the representative of the battery. The manufacturer clearly declares the tested unit. The manufacturer may add functions, which are present in the final battery, to the tested unit.

IEC 62620:2014 specifies marking, tests and requirements for lithium secondary cells and batteries used in industrial applications including stationary applications. When there exists an IEC standard specifying test conditions and requirements for cells used in special applications and which is in conflict with this standard, the former takes precedence. (e.g. IEC 62660 series on road vehicles). The following are some examples of applications that utilize the cells and batteries under the scope of this standard. - Stationary applications: telecom, uninterruptible power supplies (UPS), electrical energy storage system, utility switching, emergency power and similar applications. - Motive applications: fork-lift truck, golf cart, AGV, railway, and marine, excluding road vehicles. This standard applies to cells and batteries. If the battery is divided into smaller units, the smaller unit can be tested as the representative of the battery. The manufacturer clearly declares the tested unit. The manufacturer may add functions, which are present in the final battery, to the tested unit.

IEC 62620:2014 is classified under the following ICS (International Classification for Standards) categories: 29.220.30 - Alkaline secondary cells and batteries. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62620:2014 has the following relationships with other standards: It is inter standard links to IEC 62620:2014/AMD1:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase IEC 62620:2014 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of IEC standards.

Standards Content (Sample)

IEC 62620 ®

Edition 1.0 2014-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Secondary cells and batteries containing alkaline or other non-acid

electrolytes – Secondary lithium cells and batteries for use in industrial

applications

Accumulateurs alcalins et autres accumulateurs à électrolyte non acide –

Éléments et batteries d'accumulateurs au lithium pour utilisation dans les

applications industrielles

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite

ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie

et les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Central Office Tel.: +41 22 919 02 11

3, rue de Varembé Fax: +41 22 919 03 00

CH-1211 Geneva 20 info@iec.ch

Switzerland www.iec.ch

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigenda or an amendment might have been published.

IEC Catalogue - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

The stand-alone application for consulting the entire The world's leading online dictionary of electronic and

bibliographical information on IEC International Standards, electrical terms containing more than 30 000 terms and

Technical Specifications, Technical Reports and other definitions in English and French, with equivalent terms in 14

documents. Available for PC, Mac OS, Android Tablets and additional languages. Also known as the International

iPad. Electrotechnical Vocabulary (IEV) online.

IEC publications search - www.iec.ch/searchpub IEC Glossary - std.iec.ch/glossary

The advanced search enables to find IEC publications by a More than 55 000 electrotechnical terminology entries in

variety of criteria (reference number, text, technical English and French extracted from the Terms and Definitions

committee,…). It also gives information on projects, replaced clause of IEC publications issued since 2002. Some entries

and withdrawn publications. have been collected from earlier publications of IEC TC 37,

77, 86 and CISPR.

IEC Just Published - webstore.iec.ch/justpublished

Stay up to date on all new IEC publications. Just Published IEC Customer Service Centre - webstore.iec.ch/csc

details all new publications released. Available online and If you wish to give us your feedback on this publication or

also once a month by email. need further assistance, please contact the Customer Service

Centre: csc@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Catalogue IEC - webstore.iec.ch/catalogue Electropedia - www.electropedia.org

Application autonome pour consulter tous les renseignements

Le premier dictionnaire en ligne de termes électroniques et

bibliographiques sur les Normes internationales,

électriques. Il contient plus de 30 000 termes et définitions en

Spécifications techniques, Rapports techniques et autres

anglais et en français, ainsi que les termes équivalents dans

documents de l'IEC. Disponible pour PC, Mac OS, tablettes

14 langues additionnelles. Egalement appelé Vocabulaire

Android et iPad.

Electrotechnique International (IEV) en ligne.

Recherche de publications IEC - www.iec.ch/searchpub

Glossaire IEC - std.iec.ch/glossary

Plus de 55 000 entrées terminologiques électrotechniques, en

La recherche avancée permet de trouver des publications IEC

en utilisant différents critères (numéro de référence, texte, anglais et en français, extraites des articles Termes et

comité d’études,…). Elle donne aussi des informations sur les Définitions des publications IEC parues depuis 2002. Plus

projets et les publications remplacées ou retirées. certaines entrées antérieures extraites des publications des

CE 37, 77, 86 et CISPR de l'IEC.

IEC Just Published - webstore.iec.ch/justpublished

Service Clients - webstore.iec.ch/csc

Restez informé sur les nouvelles publications IEC. Just

Published détaille les nouvelles publications parues. Si vous désirez nous donner des commentaires sur cette

Disponible en ligne et aussi une fois par mois par email. publication ou si vous avez des questions contactez-nous:

csc@iec.ch.

IEC 62620 ®

Edition 1.0 2014-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

Secondary cells and batteries containing alkaline or other non-acid

electrolytes – Secondary lithium cells and batteries for use in industrial

applications

Accumulateurs alcalins et autres accumulateurs à électrolyte non acide –

Éléments et batteries d'accumulateurs au lithium pour utilisation dans les

applications industrielles

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

PRICE CODE

INTERNATIONALE

CODE PRIX U

ICS 29.220.30 ISBN 978-2-8322-1958-4

– 2 – IEC 62620:2014 © IEC 2014

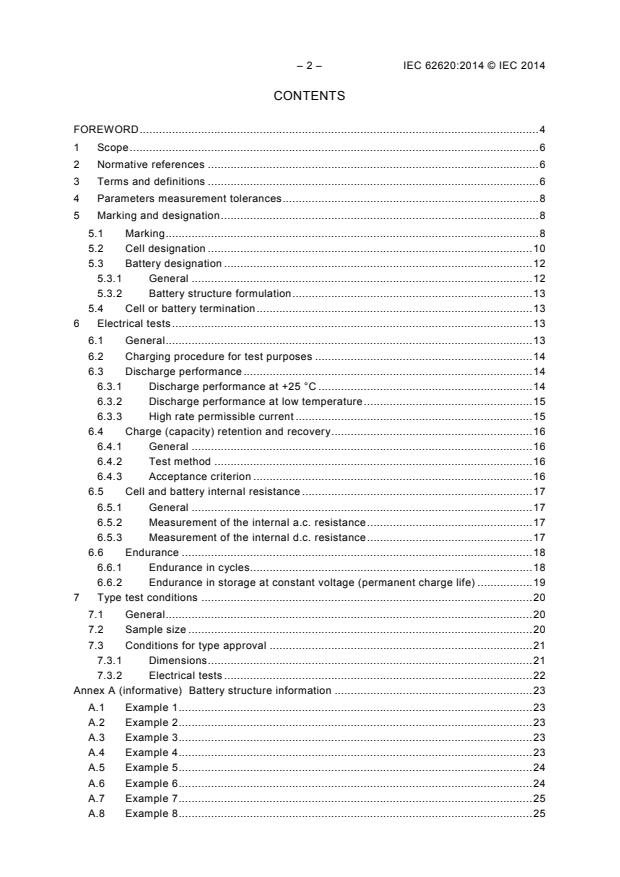

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Parameters measurement tolerances . 8

5 Marking and designation . 8

5.1 Marking . 8

5.2 Cell designation . 10

5.3 Battery designation . 12

5.3.1 General . 12

5.3.2 Battery structure formulation . 13

5.4 Cell or battery termination . 13

6 Electrical tests . 13

6.1 General . 13

6.2 Charging procedure for test purposes . 14

6.3 Discharge performance . 14

6.3.1 Discharge performance at +25 °C . 14

6.3.2 Discharge performance at low temperature . 15

6.3.3 High rate permissible current . 15

6.4 Charge (capacity) retention and recovery . 16

6.4.1 General . 16

6.4.2 Test method . 16

6.4.3 Acceptance criterion . 16

6.5 Cell and battery internal resistance . 17

6.5.1 General . 17

6.5.2 Measurement of the internal a.c. resistance . 17

6.5.3 Measurement of the internal d.c. resistance . 17

6.6 Endurance . 18

6.6.1 Endurance in cycles. 18

6.6.2 Endurance in storage at constant voltage (permanent charge life) . 19

7 Type test conditions . 20

7.1 General . 20

7.2 Sample size . 20

7.3 Conditions for type approval . 21

7.3.1 Dimensions . 21

7.3.2 Electrical tests . 22

Annex A (informative) Battery structure information . 23

A.1 Example 1 . 23

A.2 Example 2 . 23

A.3 Example 3 . 23

A.4 Example 4 . 23

A.5 Example 5 . 24

A.6 Example 6 . 24

A.7 Example 7 . 25

A.8 Example 8 . 25

A.9 Example 9 . 26

Bibliography . 27

Figure 1 – Test sequence . 21

Figure A.1 – Structure 3S . 23

Figure A.2 – Structure 2P . 23

Figure A.3 – Structure 3S2P . 23

Figure A.4 – Structure 2P4S . 24

Figure A.5 – Structure 2P4S3P . 24

Figure A.6 – Structure (2P4S)3P . 25

Figure A.7 – Structure (3S2P)3P . 25

Figure A.8 – Structure (5S)4S . 26

Figure A.9 – Structure ((3S2P)3P)2S . 26

Table 1 – Marking . 10

Table 2 – Discharge performance at +25 °C ± 5 °C . 14

Table 3 – Discharge performance at low temperature . 15

Table 4 – Discharge current values for high rate permissible test . 16

Table 5 – Constant discharge current used for measurement of the internal d.c.

resistance . 18

Table 6 – Type test . 20

Table 7 – Severe conditions . 22

– 4 – IEC 62620:2014 © IEC 2014

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SECONDARY CELLS AND BATTERIES CONTAINING

ALKALINE OR OTHER NON-ACID ELECTROLYTES –

SECONDARY LITHIUM CELLS AND BATTERIES

FOR USE IN INDUSTRIAL APPLICATIONS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

International Standard IEC 62620 has been prepared by subcommittee 21A: Secondary cells

and batteries containing alkaline or other non-acid electrolytes, of IEC technical committee 21:

Secondary cells and batteries.

The text of this standard is based on the following documents:

FDIS Report on voting

21A/561/FDIS 21A/572/RVD

Full information on the voting for the approval of this standard can be found in the report on

voting indicated in the above table.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of this publication will remain unchanged until

the stability date indicated on the IEC web site under "http://webstore.iec.ch" in the data

related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

– 6 – IEC 62620:2014 © IEC 2014

SECONDARY CELLS AND BATTERIES CONTAINING

ALKALINE OR OTHER NON-ACID ELECTROLYTES –

SECONDARY LITHIUM CELLS AND BATTERIES

FOR USE IN INDUSTRIAL APPLICATIONS

1 Scope

This International Standard specifies marking, tests and requirements for lithium secondary

cells and batteries used in industrial applications including stationary applications.

When there exists an IEC standard specifying test conditions and requirements for cells used

in special applications and which is in conflict with this standard, the former takes precedence.

(e.g. IEC 62660 series on road vehicles).

The following are some examples of applications that utilize the cells and batteries under the

scope of this standard.

• Stationary applications: telecom, uninterruptible power supplies (UPS), electrical energy

storage system, utility switching, emergency power and similar applications.

• Motive applications: fork-lift truck, golf cart, AGV, railway, and marine, excluding road

vehicles.

Since this standard covers batteries for various industrial applications, it includes those

requirements, which are common and minimum to the various applications.

This standard applies to cells and batteries. If the battery is divided into smaller units, the

smaller unit can be tested as the representative of the battery. The manufacturer clearly

declares the tested unit. The manufacturer may add functions, which are present in the final

battery, to the tested unit.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050-482:2004, International Electrotechnical Vocabulary (IEV) – Part 482: Primary and

secondary cells and batteries

ISO/IEC Guide 51, Safety aspects – Guidelines for their inclusion in standards

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-482 and

ISO/IEC Guide 51 as well as the following apply.

3.1

charge recovery

capacity recovery

capacity that a cell or battery can deliver after the charge following the charge retention test

Note 1 to entry: Charge retention is defined in 3.2.

3.2

charge retention

capacity retention

capacity that a cell or battery can deliver after storage, at a specific temperature, for a

specific time without subsequent recharge as a percentage of the rated capacity

3.3

final voltage

end-of-discharge voltage

specified closed circuit voltage at which the discharge of a cell or battery is terminated

3.4

nominal voltage

suitable approximate value of the voltage used to designate or identify a cell or a battery

Note 1 to entry: The cell or battery manufacturer may provide the nominal voltage.

Note 2 to entry: The nominal voltage of a battery of n series connected cells is equal to n times the nominal

voltage of a single cell.

[SOURCE: IEC 60050-482:2004, 482-03-31, modified – Addition of Notes 1 and 2 to entry.]

3.5

rated capacity

capacity value of a cell or battery determined under specified conditions and declared by the

manufacturer

Note 1 to entry: The rated capacity is the quantity of electricity Cn Ah (ampere-hours) declared by the

manufacturer which a single cell or battery can deliver during a n h period when charging, storing and discharging

under the conditions specified in 6.3.1. n is 5 for an E, M and H discharge rate type cell or battery. n is 8, 10, 20 or

240 for an S discharge rate type battery.

[SOURCE: IEC 60050-482:2004, 482-03-15, modified – Addition of Note 1 to entry.]

3.6

cell

secondary lithium cell

secondary cell where electrical energy is derived from the insertion/extraction reactions of

lithium ions or oxidation/reduction reaction of lithium between the negative electrode and the

positive electrode

Note 1 to entry: The cell typically has an electrolyte that consists of a lithium salt and organic solvent compound

in liquid, gel or solid form and has a metal or a laminate film casing. It is not ready for use in an application

because it is not yet fitted with its final housing, terminal arrangement and electronic control device.

3.7

cell block

group of cells connected together in parallel configuration with or without protective devices

(e.g. fuse or PTC) and monitoring circuitry

Note 1 to entry: It is not ready for use in an application because it is not yet fitted with its final housing, terminal

arrangement and electronic control device.

3.8

module

group of cells connected together either in a series and/or parallel configuration with or

without protective devices (e.g. fuse or PTC) and monitoring circuitry

– 8 – IEC 62620:2014 © IEC 2014

3.9

battery pack

energy storage device, which is comprised of one or more cells or modules electrically

connected

Note 1 to entry: It may incorporate a protective housing and be provided with terminals or other interconnection

arrangement. It may include protective devices and control and monitoring, which provides information (e.g. cell

voltage) to a battery system.

3.10

battery system

battery

system which incorporates one or more cells, modules or battery packs; it has a battery

management system

Note 1 to entry: It may have cooling or heating units.

3.11

battery management system

BMS

electronic system associated with a battery which monitors and/or manages its state,

calculates secondary data, reports that data and/or controls its environment to influence the

battery’s safety, performance and/or service life and has the functions to cut off in case of

over charging, over current and over heating

Note 1 to entry: The function of the BMS can be assigned to the battery pack or to equipment that uses the

battery.

Note 2 to entry: A BMS is sometimes also referred to as a BMU (battery management unit).

4 Parameters measurement tolerances

The overall accuracy of controlled or measured values, relative to the specified or actual

values, shall be within the following tolerances:

a) ±0,5 % for voltage;

b) ±1 % for current;

c) ±2 °C for temperature;

d) ±0,1 % for time;

e) ±1 % for dimensions.

These tolerances comprise the combined accuracy of the measuring instruments, the

measurement techniques used, and all other sources of error in the test procedure.

The details of the instrumentation used shall be provided in any report of results.

5 Marking and designation

5.1 Marking

The marking items shown in Table 1 are indicated on the cell, battery system or instruction

manual. When marked on the cell or battery system, each cell or battery system that is

installed or maintained shall carry clear and durable markings giving the information.

The following options are allowed:

• if there are designations on a battery system, designations are not necessary on the

battery pack, module or cell;

• if there are designations on a battery pack, designations are not necessary on the module

and cell;

• if there are designations on a module, designations are not necessary on the cell.

However, for a transportable unit (i.e. a unit that is being shipped), it is necessary to provide

the marking information on the main transportable unit or in its instruction manual.

Furthermore, if there is a marking matter of arrangement between the purchaser and the

manufacturer, it shall comply with the agreement.

See Table 1.

Each cell or battery that is installed or maintained shall carry clear and durable markings

giving the following information:

• secondary (rechargeable) Li or Li-ion;

• polarity (can be deleted if there is an agreement between cell and pack manufacturer);

• date of manufacture (which may be in code);

• name or identification of manufacturer or supplier;

• rated capacity;

• nominal voltage;

• appropriate caution statement.

The model name and manufacturing traceability shall be marked on the cell and battery

surface. The other items listed above can be marked on the smallest package or supplied with

the cell or the battery.

The following information shall be marked on or supplied with the cell or the battery:

• disposal instructions;

• recommended charge instructions.

The following information shall be marked on the cell or when there is no marking place on

the cell, it shall be marked in the manual.

• cell designation as specified in 5.2.

– 10 – IEC 62620:2014 © IEC 2014

Table 1 – Marking

Cell block Battery system

Marking information Cell Module or

Battery pack

Secondary (rechargeable) Li or Li-ion R R R

Polarity (see NOTE 1) R R R

Date of manufacture (which may be in code)* (see NOTE 2) R R R

a

Name or identification of manufacturer or supplier R R R

b

Rated capacity R R R

c

Calculated rated capacity* -- -- R

c

Method for calculating rated capacity* -- -- R

Nominal voltage R R R

Watt-hour* (see NOTE 3) V V V

Appropriate caution statement (Including disposal R R R

instructions)

Cell designation as specified in 5.2 R -- --

Battery designation as specified in 5.4 - R R

Recommended charge instructions R R R

“R” = required; “V“ = voluntary, “--“ = unnecessary or not applicable

a It is necessary to mark designations on the main battery system.

b Tested by main battery system; shall be indicated on the main battery system.

c If evaluated by testing the split unit of a battery system; it shall be indicated as the rated capacity and shall be the

amount calculated by a reasonable method.

For example:

Measured rated capacity of module: 10 Ah

Number of modules connected in parallel: 5

Calculated rated capacity (Ah) = 10 Ah × 5 = 50 Ah

NOTE 1 There is an exception, see 5.1.

NOTE 2 The date can be in the form of a code.

NOTE 3 Watt-hour (Wh) designation on cell, module, battery pack or battery system is the rated capacity (Ah) or

c

calculated rated capacity (Ah) as defined in table footnote multiplied by the nominal voltage of the cell, module,

battery pack or battery system according to the following formula:

Watt-hour (Wh) =Rated capacity (Ah) or Calculated rated capacity (Ah) × Nominal voltage(V)

5.2 Cell designation

Cells shall be designated with following form:

A A A /N /N /N /A /T T /N

1 2 3 2 3 4 4 L H C

where

A designates the negative electrode basis in which:

I is carbon;

T is titanium;

X is other material.

A designates the positive electrode basis in which:

C is cobalt;

F is iron;

Fp is iron phosphate;

N is nickel;

M is manganese;

Mp is manganese phosphate;

V is vanadium;

X is other material.

A designates the shape of the cell in which:

R is cylindrical;

P is prismatic (including cell with laminate film case).

A designates the rate capability of the cell in which:

E is low rate long-time discharge type;

M is medium rate discharge type;

H is high rate discharge type.

NOTE 1 These types of cells are typically but not exclusively used for the following discharge rates at + 25 °C:

• E up to 0,5 I A,

t

• M up to 3,5 I A,

t

• H up to and above 7,0 I A.

t

NOTE 2 These currents are expressed as multiples of I A, where I A = C Ah/1 h (IEC 61434).

t t 5

T is the low temperature grade defined in 6.3.2. The information shall be indicated by the

L

sign + or – followed by the temperature value in °C (e.g. -30, 0, +10);

T is the high temperature grade defined in 6.6.2. The information shall be indicated by the

H

sign + or – followed by the temperature value in °C (e.g. +40, +50). If a cell is designed

only for cycle application, T should be mentioned as “NA”;

H

N is the percentage (rounded down to every 5 % step) obtained by the ratio of capacity at

C

500 cycles by the rated capacity. Refer to 6.6.1 and 6.3.1. If a cell is designed only for

stand-by application, N should be mentioned as “NA”;

C

N is the maximum diameter (if R) or the maximum thickness (if P) in mm rounded up to the

next whole number;

N is the maximum width (if P) in mm rounded up to the next whole number

(N not shown if R);

N is the maximum overall height in mm rounded up to the next whole number.

NOTE 3 If any dimension is less than 1 mm, the units used are tenths of millimetres and the single number is

written tN such as ”t1” for 0,1 mm.

EXAMPLE 1 ----INR54/222/H/-20+50/70 would designate a cylindrical Li-ion secondary cell, with a nickel-based

positive electrode. Its maximum diameter is between 53 mm and 54 mm, and its overall height is between 221 mm

and 222 mm. It is designed for high discharge rate. Its low temperature grade is -20 °C. Its high temperature grade

is 50 °C. It applies for both cycle and stand-by application. Its capacity retention after 500 cycles to rated capacity

is between 70 % and 74 %.

EXAMPLE 2 ---ICP25/150/150/E/0+60/60 would designate a prismatic Li-ion secondary cell, with a cobalt-based

positive electrode. Its maximum thickness is between 24 mm and 25 mm, its maximum width is between 149 mm

and 150 mm, and its overall height is between 149 mm and 150 mm. It is designed for low discharge rate over a

long period. Its low temperature grade is 0 °C. Its high temperature grade is 60 °C. It applies for both cycle and

stand-by application. Its capacity after 500 cycles to rated capacity is between 60 % and 64 %.

EXAMPLE 3 ---INR50/150/M/-30NA/75 would designate a cylindrical Li-ion secondary cell, with a nickel-based

positive electrode. Its maximum diameter is between 49 mm and 50 mm, and its overall height is between 149 mm

and 150 mm. It is designed for medium discharge rate. Its low temperature grade is -30 °C. Its high temperature

grade is NA. It applies for cycle application only. Its capacity retention after 500 cycles to rated capacity is between

75 % and 79 %.

– 12 – IEC 62620:2014 © IEC 2014

EXAMPLE 4 ---IMP50/240/150/M/-30+10/NA would designate a prismatic Li-ion secondary cell, with a

manganese-based positive electrode. Its maximum thickness is between 49 mm and 50 mm, its maximum width is

between 239 mm and 240 mm, and its overall height is between 149 mm and 150 mm. It is designed for a medium

discharge rate. Its low temperature grade is -30 °C. Its high temperature grade is 10 °C. It applies for stand-by

application only.

5.3 Battery designation

5.3.1 General

Batteries shall be designated with following form:

A A A /N /N /N /[S ]A /T T /N

1 2 3 2 3 4 1 4 L H C

where

A designates the negative electrode basis in which:

I is carbon;

T is titanium;

X is other materials.

A designates the positive electrode basis in which:

C is cobalt;

F is iron;

Fp is iron phosphate

N is nickel;

M is manganese;

Mp is manganese phosphate;

V is vanadium;

X is other materials.

A designates the shape of the cell in which:

R is cylindrical;

P is prismatic (including cell with laminate film case).

A designates the rate capability of the battery in which

S is very low rate long-time discharge type;

E is low rate long-time discharge type;

M is medium rate discharge type;

H is high rate discharge type.

NOTE 1 These types of cells are typically but not exclusively used for the following discharge rates at +25 °C.

• S up to 0,125 I A,

t

• E up to 0,5 I A,

t

• M up to 3,5 I A,

t

• H up to and above 7,0 I A.

t

T is the low temperature grade defined in 6.3.2. The information shall be indicated by

L

the sign + or − followed by the temperature value in °C (e.g. -30, 0, +10);

T is the high temperature grade defined in 6.6.2. The information shall be indicated by the

H

sign + or − followed by the temperature value in °C (e.g. +40, +50). If a battery is

designed only for cycle application, T should be mentioned as “NA”.

H

N is the percentage (rounded down to every 5 % step) obtained by the ratio of capacity at

C

500 cycles by the rated capacity. Refer to 6.6.1 and 6.3.1. If a battery is designed only for

stand-by application, N should be mentioned as “NA”.

C

N is the maximum diameter (if R) or the maximum thickness (if P) in mm rounded up to the

next whole number;

N is the maximum width (if P) in mm rounded up to the next whole number (N not shown

3 3

if R);

N is the maximum overall height in mm rounded up to the next whole number;

NOTE 2 If any dimension is less than 1 mm, the units used are tenths of millimetres and the single number is

written tN such as ”t1” for 0,1 mm.

S is the battery structure formulation shown in 5.3.2.

EXAMPLE 1 ---ICP200/150/150/[7S]E/0+50/75 would designate a battery composed of 7S connected prismatic Li-

ion secondary cells, with a cobalt-based positive electrode. Its cell maximum thickness is between 199 mm and 200

mm, its cell maximum width is between 149 mm and 150 mm, and its cell overall height is between 149 mm and

150 mm. It is designed for low discharge rate over long period. Its low temperature grade is 0 °C. Its high

temperature grade is +50 °C. Its capacity after 500 cycles to rated capacity is between 75 % and 79 %.

EXAMPLE 2 ----INR54/222[4P3S]H/-20+50/80 would designate a battery composed of 4P-3S connected

cylindrical Li-ion secondary cells, with a nickel-based positive electrode. Its cell maximum diameter is between 53

mm and 54 mm, and its cell overall height is between 221 mm and 222 mm. It is designed for high discharge rate.

Its low temperature grade is -20 °C. Its high temperature grade is +50 °C. Its capacity after 500 cycles to rated

capacity is between 80 % and 84 %.

5.3.2 Battery structure formulation

The battery designation should include the breakdown structure of the battery. The descriptive

path followed to formulate the battery is from the smallest entity to the largest one.

a) It describes the number of cells in the minimum constitutive entity and on the right side of

the number describes their connection mode in series (S) or in parallel (P).

See Figures A.1 and A.2.

b) In case that the minimum constitutive entities are connected in series or in parallel, it

describes the number of the minimum constitutive entities, and on the right side of the

number describes their connection mode in series (S) or in parallel (P).

See Figures A.3 and A.4.

c) In case of the larger constitutive entities, it describes the symbols on the right side in the

same way as mentioned above.

When some constitutive entities can be divided for ease of handling or transportation, these

entities can be distinguished from other entities by bracketing.

Some examples are shown in Figure A.5 through Figure A.9.

5.4 Cell or battery termination

This standard does not specify cell or battery termination.

6 Electrical tests

6.1 General

Electrical tests are applied to cells and/or batteries. If the battery is divided in smaller units,

the unit can be tested as the representative of the battery. The manufacturer shall clearly

declare the tested unit. The manufacturer may add, to the tested unit, functions which are

present in the final battery.

The manufacturer can use “cell block(s)” instead of “cell(s)” at any test that specifies “cell(s)”

as the test unit in this document. The cell manufacturer shall clearly declare the test unit for

each test.

– 14 – IEC 62620:2014 © IEC 2014

Charge and discharge currents for the tests shall be based on the value of the rated capacity

(C Ah). These currents are expressed as a multiple of I A, where: I A = C Ah/1 h.

n t t n

C is the rated capacity declared by the manufacturer in ampere hours (Ah), and n is the time

n

base in hours (h) for which the rated capacity is declared. n is 5 for E, M and H discharge rate

type cells or batteries, n is 8, 10, 20 or 240 for S discharge rate type batteries.

See Table 2.

6.2 Charging procedure for test purposes

Prior to charging, the cell or battery shall be discharged at 25 °C ± 5 °C at a constant current

of 1/n I A, down to a specified final voltage.

t

Unless otherwise stated in this standard, cells or batteries shall be charged, in an ambient

temperature of 25 °C ± 5 °C, using the method declared by the manufacturer.

NOTE The final voltage in discharge tests is declared by the manufacturer. All tests are performed with the same

final voltage value. For example, the manufacturer cannot use different final voltage values for discharge

performance tests at 25 °C ± 5 °C, at low temperature, for the endurance tests, etc.

6.3 Discharge performance

6.3.1 Discharge performance at +25 °C

This test verifies the rated capacity of a cell or battery.

Step 1 – The cell or battery shall be fully charged in accordance with 6.2.

Step 2 – The cell or battery shall be stored in an ambient temperature of 25 °C ± 5 °C, for not

less than 1 h and not more than 4 h.

Step 3 – The cell or battery shall then be discharged in the same ambient temperature and as

specified in Table 2 to the final voltage specified by the manufacturer in 6.2.

Step 4 – The capacity (Ah), delivered during step 3, shall not be less than that specified for

this characteristic in Table 2.

Table 2 – Discharge performance at +25 °C ± 5 °C

Discharge conditions Minimum discharge capacity

Rate of Final voltage declared Discharge rate type

constant current by the manufacturer

A V S E M H

(1/n) I Refer to 6.2 100 % Cn Ah

t

a

0,2 I Refer to 6.2 100 % C Ah 100 % C Ah 100 % C Ah

t

5 5 5

1,0 I 95 % C Ah 95 % C Ah

Refer to 6.2 –

t 5 5

b

5,0 I Refer to 6.2 – – 90 % C Ah

t

a

Five cycles are permitted for this test which shall be terminated at the end of the first cycle which meets the

requirement

b

Prior to the 5 I A discharge tests, a conditioning cycle may be included if necessary. This cycle shall consist of

t

charging and discharging in accordance with 6.2.

6.3.2 Discharge performance at low temperature

This test identifies the temperature at which a capacity of not less than 70 % of the rated

capacity can be achieved.

This test verifies the discharge performance at low temperature of the cell or battery. It shall

be measured in accordance with the following steps.

Step 1 – The cell or battery shall be fully charged in accordance with 6.2.

Step 2 – The cell or battery shall be stored for not less than 16 h and not more than 24 h at

an ambient “target” test temperature which is specified by the manufacturer.

Step 3 – The cell or battery shall then be discharged at the same target test temperature and

at the discharge rates specified in Table 3 to the manufacturer’s declared final voltage as

defined in 6.2.

Step 4 – The capacity (Ah), delivered during step 3 shall be not less than that specified for the

cell type and discharge currents in Table 3.

The cell or battery’s low temperature discharge performance can be declared at 10 °C

intervals, such as +10 °C, 0 °C, -10 °C and -20 °C. The declared temperature should be in

the range of the target test temperature and target test temperature plus 10 °C. For example if

the test is performed at -27 °C, the declared temperature should be –20 °C. The temperature

grade is the highest temperature among the tests for discharge rate type M and H. For

example if an “H” type cell has a discharge capacity higher than 70 % of the rated capacity:

at –30 °C with 0,2 I A, at –20 °C, with 1,0 I A and at –10 °C with 5,0 I A, the temperature

t t t

grade is judged as “–10 °C”.

Table 3 – Discharge performance at low temperature

Discharge conditions Minimum discharge capacity

Rate of Final voltage declared

Discharge rate type

constant current by the manufacturer

A V S E M H

(1/n) I 70 % Cn Ah

Refer to 6.2 – – –

t

0,2 It Refer to 6.2 70 % C Ah 70 % C Ah 70 % C Ah

5 5 5

1,0 It Refer to 6.2 – 70 % C Ah 70 % C Ah

5 5

5,0 It Refer to 6.2 – – 70 % C Ah

6.3.3 High rate permissible current

6.3.3.1 General

This test is to evaluate the ability of an “H” or “M” type cell or battery to withstand high

currents.

6.3.3.2 Test method

Step 1 – The cell or battery shall be fully charged in accordance with 6.2.

Step 2 – The cell or battery shall be stored for not less than 1 h and not more than 4 h in an

ambient temperature of 25 °C ± 5 °C.

– 16 – IEC 62620:2014 © IEC 2014

Step 3 – It shall then be discharged for 5 ± 0,1 s at 25 °C ± 5 °C and at the currents specified

in Table 4. During the d

...

IEC 62620 ®

Edition 1.1 2023-05

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Secondary cells and batteries containing alkaline or other non-acid

electrolytes – Secondary lithium cells and batteries for use in industrial

applications

Accumulateurs alcalins et autres accumulateurs à électrolyte non acide –

Eléments et batteries d'accumulateurs au lithium pour utilisation dans les

applications industrielles

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - Découvrez notre puissant moteur de recherche et consultez

webstore.iec.ch/advsearchform gratuitement tous les aperçus des publications. Avec un

La recherche avancée permet de trouver des publications IEC abonnement, vous aurez toujours accès à un contenu à jour

en utilisant différents critères (numéro de référence, texte, adapté à vos besoins.

comité d’études, …). Elle donne aussi des informations sur les

projets et les publications remplacées ou retirées. Electropedia - www.electropedia.org

Le premier dictionnaire d'électrotechnologie en ligne au monde,

IEC Just Published - webstore.iec.ch/justpublished

avec plus de 22 300 articles terminologiques en anglais et en

Restez informé sur les nouvelles publications IEC. Just

français, ainsi que les termes équivalents dans 19 langues

Published détaille les nouvelles publications parues.

additionnelles. Egalement appelé Vocabulaire

Disponible en ligne et une fois par mois par email.

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC Products & Services Portal - products.iec.ch

IEC 62620 ®

Edition 1.1 2023-05

CONSOLIDATED VERSION

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Secondary cells and batteries containing alkaline or other non-acid

electrolytes – Secondary lithium cells and batteries for use in industrial

applications

Accumulateurs alcalins et autres accumulateurs à électrolyte non acide –

Eléments et batteries d'accumulateurs au lithium pour utilisation dans les

applications industrielles

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.220.30 ISBN 978-2-8322-7030-1

IEC 62620 ®

Edition 1.1 2023-05

CONSOLIDATED VERSION

REDLINE VERSION

VERSION REDLINE

colour

inside

Secondary cells and batteries containing alkaline or other non-acid

electrolytes – Secondary lithium cells and batteries for use in industrial

applications

Accumulateurs alcalins et autres accumulateurs à électrolyte non acide –

Eléments et batteries d'accumulateurs au lithium pour utilisation dans les

applications industrielles

– 2 – IEC 62620:2014+AMD1:2023 CSV

© IEC 2023

CONTENTS

FOREWORD . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Parameters measurement tolerances . 8

5 Marking and designation . 8

5.1 Marking . 8

5.2 Cell designation . 10

5.3 Battery designation . 12

5.3.1 General . 12

5.3.2 Battery structure formulation . 13

5.4 Cell or battery termination . 13

6 Electrical tests . 13

6.1 General . 13

6.2 Charging procedure for test purposes . 14

6.3 Discharge performance . 14

6.3.1 Discharge performance at +25 °C . 14

6.3.2 Discharge performance at low temperature . 15

6.3.3 High rate permissible current . 15

6.4 Charge (capacity) retention and recovery . 16

6.4.1 General . 16

6.4.2 Test method . 16

6.4.3 Acceptance criterion . 16

6.5 Cell and battery internal resistance . 17

6.5.1 General . 17

6.5.2 Measurement of the internal a.c. resistance . 17

6.5.3 Measurement of the internal d.c. resistance . 17

6.6 Endurance . 18

6.6.1 Endurance in cycles. 18

6.6.2 Endurance in storage at constant voltage (permanent charge life) . 19

7 Type test conditions . 20

7.1 General . 20

7.2 Sample size . 20

7.3 Conditions for type approval . 21

7.3.1 Dimensions . 21

7.3.2 Electrical tests . 22

Annex A (informative) Battery structure information . 23

A.1 Example 1 . 23

A.2 Example 2 . 23

A.3 Example 3 . 23

A.4 Example 4 . 23

A.5 Example 5 . 24

A.6 Example 6 . 24

A.7 Example 7 . 25

A.8 Example 8 . 25

A.9 Example 9 . 26

© IEC 2023

Bibliography . 27

Figure 1 – Test sequence . 21

Figure A.1 – Structure 3S . 23

Figure A.2 – Structure 2P . 23

Figure A.3 – Structure 3S2P . 23

Figure A.4 – Structure 2P4S . 24

Figure A.5 – Structure 2P4S3P . 24

Figure A.6 – Structure (2P4S)3P . 25

Figure A.7 – Structure (3S2P)3P . 25

Figure A.8 – Structure (5S)4S . 26

Figure A.9 – Structure ((3S2P)3P)2S . 26

Table 1 – Marking . 10

Table 2 – Discharge performance at +25 °C ± 5 °C . 14

Table 3 – Discharge performance at low temperature . 15

Table 4 – Discharge current values for high rate permissible test . 16

Table 5 – Constant discharge current used for measurement of the internal d.c.

resistance . 18

Table 6 – Type test . 20

Table 7 – Severe conditions . 22

– 4 – IEC 62620:2014+AMD1:2023 CSV

© IEC 2023

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

SECONDARY CELLS AND BATTERIES CONTAINING

ALKALINE OR OTHER NON-ACID ELECTROLYTES –

SECONDARY LITHIUM CELLS AND BATTERIES

FOR USE IN INDUSTRIAL APPLICATIONS

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote

international co-operation on all questions concerning standardization in the electrical and electronic fields. To

this end and in addition to other activities, IEC publishes International Standards, Technical Specifications,

Technical Reports, Publicly Available Specifications (PAS) and Guides (hereafter referred to as “IEC

Publication(s)”). Their preparation is entrusted to technical committees; any IEC National Committee interested

in the subject dealt with may participate in this preparatory work. International, governmental and non-

governmental organizations liaising with the IEC also participate in this preparation. IEC collaborates closely

with the International Organization for Standardization (ISO) in accordance with conditions determined by

agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence

between any IEC Publication and the corresponding national or regional publication shall be clearly indicated in

the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of

patent rights. IEC shall not be held responsible for identifying any or all such patent rights.

This consolidated version of the official IEC Standard and its amendment has been

prepared for user convenience.

IEC 62620 edition 1.1 contains the first edition (2014-11) [documents 21A/561/FDIS and

21A/572/RVD] and its amendment 1 (2023-05) [documents 21A/795/CDV and

21A/812/RVC].

In this Redline version, a vertical line in the margin shows where the technical content

is modified by amendment 1. Additions are in green text, deletions are in strikethrough

red text. A separate Final version with all changes accepted is available in this

publication.

© IEC 2023

International Standard IEC 62620 has been prepared by subcommittee 21A: Secondary cells

and batteries containing alkaline or other non-acid electrolytes, of IEC technical committee 21:

Secondary cells and batteries.

This publication has been drafted in accordance with the ISO/IEC Directives, Part 2.

The committee has decided that the contents of the base publication and its amendment will

remain unchanged until the stability date indicated on the IEC web site under webstore.iec.ch

in the data related to the specific publication. At this date, the publication will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The 'colour inside' logo on the cover page of this publication indicates

that it contains colours which are considered to be useful for the correct

understanding of its contents. Users should therefore print this document using a

colour printer.

– 6 – IEC 62620:2014+AMD1:2023 CSV

© IEC 2023

SECONDARY CELLS AND BATTERIES CONTAINING

ALKALINE OR OTHER NON-ACID ELECTROLYTES –

SECONDARY LITHIUM CELLS AND BATTERIES

FOR USE IN INDUSTRIAL APPLICATIONS

1 Scope

This International Standard specifies marking, tests and requirements for lithium secondary

cells and batteries used in industrial applications including stationary applications.

When there exists an IEC standard specifying test conditions and requirements for cells used

in special applications and which is in conflict with this standard, the former takes precedence.

(e.g. IEC 62660 series on road vehicles).

The following are some examples of applications that utilize the cells and batteries under the

scope of this standard.

• Stationary applications: telecom, uninterruptible power supplies (UPS), electrical energy

storage system, utility switching, emergency power and similar applications.

• Motive applications: fork-lift truck, golf cart, AGV, railway, and marine, excluding road

vehicles.

Since this standard covers batteries for various industrial applications, it includes those

requirements, which are common and minimum to the various applications.

This standard applies to cells and batteries. If the battery is divided into smaller units, the

smaller unit can be tested as the representative of the battery. The manufacturer clearly

declares the tested unit. The manufacturer may add functions, which are present in the final

battery, to the tested unit.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and

are indispensable for its application. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60050-482:2004, International Electrotechnical Vocabulary (IEV) – Part 482: Primary and

secondary cells and batteries

ISO/IEC Guide 51, Safety aspects – Guidelines for their inclusion in standards

3 Terms and definitions

For the purposes of this document, the terms and definitions given in IEC 60050-482 and

ISO/IEC Guide 51 as well as the following apply.

3.1

charge recovery

capacity recovery

capacity that a cell or battery can deliver after the charge following the charge retention test

© IEC 2023

Note 1 to entry: Charge retention is defined in 3.2.

3.2

charge retention

capacity retention

capacity that a cell or battery can deliver after storage, at a specific temperature, for a

specific time without subsequent recharge as a percentage of the rated capacity

3.3

final voltage

end-of-discharge voltage

specified closed circuit voltage at which the discharge of a cell or battery is terminated

3.4

nominal voltage

suitable approximate value of the voltage used to designate or identify a cell or a battery

Note 1 to entry: The cell or battery manufacturer may provide the nominal voltage.

Note 2 to entry: The nominal voltage of a battery of n series connected cells is equal to n times the nominal

voltage of a single cell.

[SOURCE: IEC 60050-482:2004, 482-03-31, modified – Addition of Notes 1 and 2 to entry.]

3.5

rated capacity

capacity value of a cell or battery determined under specified conditions and declared by the

manufacturer

Note 1 to entry: The rated capacity is the quantity of electricity Cn Ah (ampere-hours) declared by the

manufacturer which a single cell or battery can deliver during a n h period when charging, storing and discharging

under the conditions specified in 6.3.1. n is 5 for an E, M and H discharge rate type cell or battery. n is 8, 10, 20 or

240 for an S discharge rate type battery.

[SOURCE: IEC 60050-482:2004, 482-03-15, modified – Addition of Note 1 to entry.]

3.6

cell

secondary lithium cell

secondary cell where electrical energy is derived from the insertion/extraction reactions of

lithium ions or oxidation/reduction reaction of lithium between the negative electrode and the

positive electrode

Note 1 to entry: The cell typically has an electrolyte that consists of a lithium salt and organic solvent compound

in liquid, gel or solid form and has a metal or a laminate film casing. It is not ready for use in an application

because it is not yet fitted with its final housing, terminal arrangement and electronic control device.

3.7

cell block

group of cells connected together in parallel configuration with or without protective devices

(e.g. fuse or PTC) and monitoring circuitry

Note 1 to entry: It is not ready for use in an application because it is not yet fitted with its final housing, terminal

arrangement and electronic control device.

3.8

module

group of cells connected together either in a series and/or parallel configuration with or

without protective devices (e.g. fuse or PTC) and monitoring circuitry

– 8 – IEC 62620:2014+AMD1:2023 CSV

© IEC 2023

3.9

battery pack

energy storage device, which is comprised of one or more cells or modules electrically

connected

Note 1 to entry: It may incorporate a protective housing and be provided with terminals or other interconnection

arrangement. It may include protective devices and control and monitoring, which provides information (e.g. cell

voltage) to a battery system.

3.10

battery system

battery

system which incorporates one or more cells, modules or battery packs; it has a battery

management system

Note 1 to entry: It may have cooling or heating units.

3.11

battery management system

BMS

electronic system associated with a battery which monitors and/or manages its state,

calculates secondary data, reports that data and/or controls its environment to influence the

battery’s safety, performance and/or service life and has the functions to cut off in case of

over charging, over current and over heating

Note 1 to entry: The function of the BMS can be assigned to the battery pack or to equipment that uses the

battery.

Note 2 to entry: A BMS is sometimes also referred to as a BMU (battery management unit).

4 Parameters measurement tolerances

The overall accuracy of controlled or measured values, relative to the specified or actual

values, shall be within the following tolerances:

a) ±0,5 % for voltage;

b) ±1 % for current;

c) ±2 °C for temperature;

d) ±0,1 % for time;

e) ±1 % for dimensions.

These tolerances comprise the combined accuracy of the measuring instruments, the

measurement techniques used, and all other sources of error in the test procedure.

The details of the instrumentation used shall be provided in any report of results.

5 Marking and designation

5.1 Marking

The marking items shown in Table 1 are indicated on the cell, battery system or instruction

manual. When marked on the cell or battery system, each cell or battery system that is

installed or maintained shall carry clear and durable markings giving the information.

The following options are allowed:

• if there are designations on a battery system, designations are not necessary on the

battery pack, module or cell;

© IEC 2023

• if there are designations on a battery pack, designations are not necessary on the module

and cell;

• if there are designations on a module, designations are not necessary on the cell.

However, for a transportable unit (i.e. a unit that is being shipped), it is necessary to provide

the marking information on the main transportable unit or in its instruction manual.

Furthermore, if there is a marking matter of arrangement between the purchaser and the

manufacturer, it shall comply with the agreement.

See Table 1.

Each cell or battery that is installed or maintained shall carry clear and durable markings

giving the following information:

• secondary (rechargeable) Li or Li-ion;

• polarity (can be deleted if there is an agreement between cell and pack manufacturer);

• date of manufacture (which may be in code);

• name or identification of manufacturer or supplier;

• rated capacity;

• nominal voltage;

• appropriate caution statement.

The model name and manufacturing traceability shall be marked on the cell and battery

surface. The other items listed above can be marked on the smallest package or supplied with

the cell or the battery.

The following information shall be marked on or supplied with the cell or the battery:

• disposal instructions;

• recommended charge instructions.

The following information shall be marked on the cell or when there is no marking place on

the cell, it shall be marked in the manual.

• cell designation as specified in 5.2.

– 10 – IEC 62620:2014+AMD1:2023 CSV

© IEC 2023

Table 1 – Marking

Cell block Battery system

Marking information Cell Module or

Battery pack

Secondary (rechargeable) Li or Li-ion R R R

Polarity (see NOTE 1) R R R

Date of manufacture (which may be in code)* (see NOTE 2) R R R

a

Name or identification of manufacturer or supplier R R R

b

Rated capacity R R R

c

Calculated rated capacity* -- -- R

c

Method for calculating rated capacity* -- -- R

Nominal voltage R R R

Watt-hour* (see NOTE 3) V V V

Appropriate caution statement (Including disposal R R R

instructions)

Cell designation as specified in 5.2 R -- --

Battery designation as specified in 5.4 - R R

Recommended charge instructions R R R

“R” = required; “V“ = voluntary, “--“ = unnecessary or not applicable

a It is necessary to mark designations on the main battery system.

b Tested by main battery system; shall be indicated on the main battery system.

c If evaluated by testing the split unit of a battery system; it shall be indicated as the rated capacity and shall be the

amount calculated by a reasonable method.

For example:

Measured rated capacity of module: 10 Ah

Number of modules connected in parallel: 5

Calculated rated capacity (Ah) = 10 Ah × 5 = 50 Ah

NOTE 1 There is an exception, see 5.1.

NOTE 2 The date can be in the form of a code.

NOTE 3 Watt-hour (Wh) designation on cell, module, battery pack or battery system is the rated capacity (Ah) or

c

calculated rated capacity (Ah) as defined in table footnote multiplied by the nominal voltage of the cell, module,

battery pack or battery system according to the following formula:

Watt-hour (Wh) =Rated capacity (Ah) or Calculated rated capacity (Ah) × Nominal voltage(V)

5.2 Cell designation

Cells shall be designated with following form:

A A A /N /N /N /A /T T /N

1 2 3 2 3 4 4 L H C

A A A N /N /N /A /T T /N

1 2 3 2 3 4 4 L H C

where

A designates the negative electrode basis in which:

I is carbon;

T is titanium;

X is other material.

© IEC 2023

A designates the positive electrode basis in which:

C is cobalt;

F is iron;

Fp is iron phosphate;

N is nickel;

M is manganese;

Mp is manganese phosphate;

V is vanadium;

X is other material.

A designates the shape of the cell in which:

R is cylindrical;

P is prismatic (including cell with laminate film case).

A designates the rate capability of the cell in which:

E is low rate long-time discharge type;

M is medium rate discharge type;

H is high rate discharge type.

NOTE 1 These types of cells are typically but not exclusively used for the following discharge rates at +25 °C:

• E up to 0,5 I A,

t

• M up to 3,5 I A,

t

• H up to and above 7,0 3,5 I A.

t

NOTE 2 These currents are expressed as multiples of I A, where I A = C Ah/1 h (IEC 61434).

t t 5

T is the low temperature grade defined in 6.3.2. The information shall be indicated by the

L

sign + or – followed by the temperature value in °C (e.g. -30, 0, +10);

T is the high temperature grade defined in 6.6.2. The information shall be indicated by the

H

sign + or – followed by the temperature value in °C (e.g. +40, +50). If a cell is designed