IEC 61215-2:2016/COR1:2018

(Corrigendum)Corrigendum 1 - Terrestrial photovoltaic (PV) modules - Design qualification and type approval - Part 2: Test procedures

Corrigendum 1 - Terrestrial photovoltaic (PV) modules - Design qualification and type approval - Part 2: Test procedures

Corrigendum 1 - Modules photovoltaïques (PV) pour applications terrestres - Qualification de la conception et homologation - Partie 2: Procédures d'essai

General Information

Relations

Standards Content (Sample)

IEC 2018

INTERNATIONAL ELECTROTECHNICAL COMMISSION

COMMISSION ÉLECTROTECHNIQUE INTERNATIONALE

____________

IEC 61215-2 IEC 61215-2

Edition 1.0 2016-03 Édition 1.0 2016-03

TERRESTRIAL PHOTOVOLTAIC (PV) MODULES – MODULES PHOTOVOLTAÏQUES (PV) POUR

DESIGN QUALIFICATION AND TYPE APPROVAL APPLICATIONS TERRESTRES – QUALIFICATION

DE LA CONCEPTION ET HOMOLOGATION

Part 2: Test procedures

Partie 2: Procédures d'essai

CO RRI G E NDUM 1

Corrections to the French version appear after the English text.

Les corrections à la version française sont données après le texte anglais.

4.9.4 Apparatus

Replace:

a) “Radiant source: Natural sunlight, or a class BBB (or better) steady-state solar simulator conforming

to IEC 60904-9 with an irradiance of (1 000 ± 100) W/m².”

By:

a) “Radiant source: Natural sunlight, or a class BBB (or better) steady-state solar simulator conforming

to IEC 60904-9 with an irradiance of 800 W/m² to 1 100 W/m².”

4.9.5.3.1 General

Replace:

2 2

"The hot-spot test is performed with the module exposed to 800 W/m to 1 000 W/m ."

By:

"The hot-spot test is performed with the module exposed to (1 000 ± 100) W/m²."

IEC 61215-2:2016-03/COR1:2018-03(en-fr)

– 2 – IEC 61215-2:2016/COR1:2018

IEC 2018

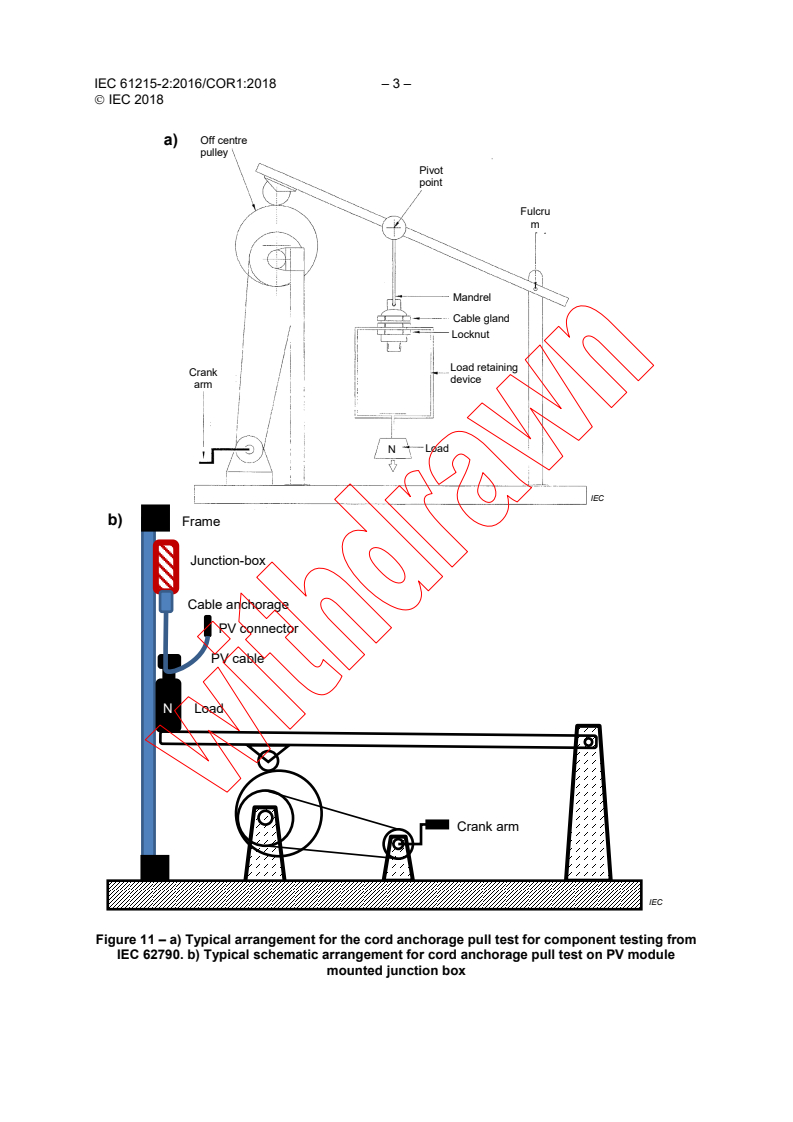

4.14.3 Test of cord anchorage (MQT 14.2)

Replace:

Off centre

pulley

Pivot

point

Fulcrum

point

Mandrel

Cable gland

Locknut

Load retaining

Crank

device

arm

N Load

IEC

NOTE For module testing setup depends on the module construction.

Figure 11 – Typical arrangement for the cord anchorage pull test for component testing

By:

IEC 2018

Off centre

a)

pulley

Pivot

point

Fulcru

m

it

Mandrel

Cable gland

Locknut

Load retaining

Crank

device

arm

N Load

IEC

b)

Frame

Junction-box

Cable anchorage

PV connector

PV cable

N

Load

Crank arm

IEC

Figure 11 – a) Typical arrangement for the cord anchorage pull test for component testing from

IEC 62790. b) Typical schematic arrangement for cord anchorage pull test on PV module

mounted junction box

– 4 – IEC 61215-2:2016/COR1:2018

IEC 2018

Replace:

Device for securing

test mandrel

Bearings enabling

Test

Fixed rotational

easy rotation

mandrel Sample

indicator

Sample securing plate

(interchangeable)

Direction of

rotation

Rotating

indicator

Radius

N Load Load N

IEC

Figure 12 – Typical arrangement for torsion test

By:

Device for securing

test mandrel

Test

Bearings enabling

mandrel

Fixed rotational

easy rotation

or cable Sample

indicator

Sample securing plate

(interchangeable)

Direction of

rotation

Rotating

indicator

Radius

N Load Load N

IEC

If the test is performed with the manufacturer's cable, the fixture for securing the cable shall be as close as possible to the cable

securing plate of the junction box.

Figure 12 – Typical arrangement for torsion test

IEC 2018

4.17.3 Procedure

Table 4 – Impact locations

Replace:

3, 4 Over edges of the circuit (e.g. individual cells).

5, 6 Over the circuit near interconnects (i.e. cell interconnects and bus ribbons).

By:

3, 4 Over the circuit near interconnects (i.e. cell interconnects and bus ribbons).

5, 6 Over edges of the circuit (e.g. individual cells).

---------------------- Page

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.