ISO 12580:2007

(Main)Timber structures — Glued laminated timber — Methods of test for glue-line delamination

Timber structures — Glued laminated timber — Methods of test for glue-line delamination

ISO 12580:2007 specifies five delamination methods for factory quality assurance of the glue line of glued laminated timber.

Structures en bois — Bois lamellé-collé — Méthodes d'essai de décollement des plans de collage

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 12580

First edition

2007-10-01

Timber structures — Glued laminated

timber — Methods of test for glue-line

delamination

Structures en bois — Bois lamellé-collé — Méthodes d'essai de

décollement des plans de collage

Reference number

©

ISO 2007

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2007 – All rights reserved

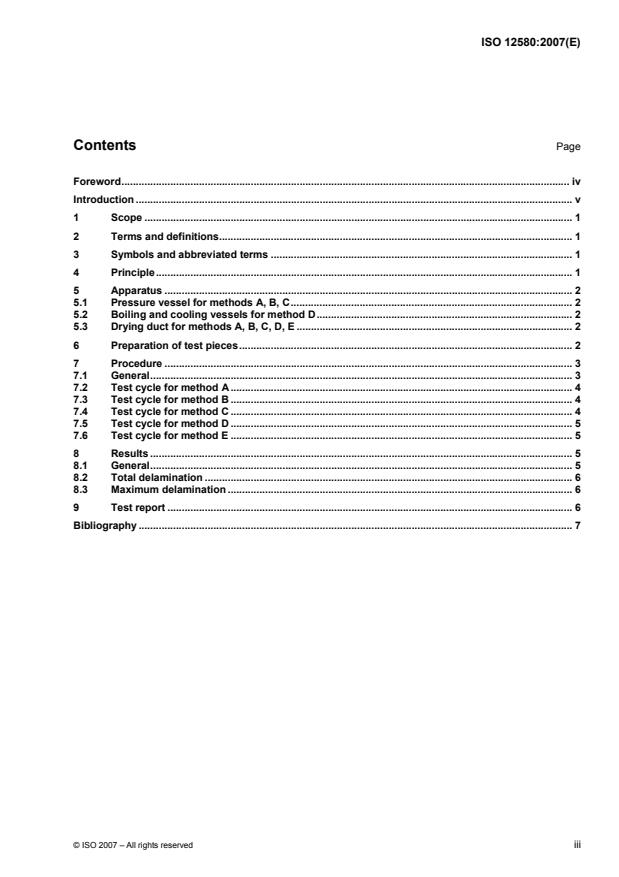

Contents Page

Foreword. iv

Introduction . v

1 Scope . 1

2 Terms and definitions. 1

3 Symbols and abbreviated terms . 1

4 Principle. 1

5 Apparatus . 2

5.1 Pressure vessel for methods A, B, C. 2

5.2 Boiling and cooling vessels for method D. 2

5.3 Drying duct for methods A, B, C, D, E . 2

6 Preparation of test pieces. 2

7 Procedure . 3

7.1 General. 3

7.2 Test cycle for method A. 4

7.3 Test cycle for method B . 4

7.4 Test cycle for method C . 4

7.5 Test cycle for method D . 5

7.6 Test cycle for method E . 5

8 Results . 5

8.1 General. 5

8.2 Total delamination . 6

8.3 Maximum delamination . 6

9 Test report . 6

Bibliography . 7

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 12580 was prepared by Technical Committee ISO/TC 165, Timber structures.

iv © ISO 2007 – All rights reserved

Introduction

This International Standard was developed by TC 165 as a factory quality-assurance test to be used for

structural glulam. It is intended that it be used in conjunction with ISO 12578 and be applied to each

production batch. The frequency of testing and the pass/fail criteria are detailed in ISO 12578. However, there

is nothing in principle that would prevent the test method from being applied to non-structural glulam.

INTERNATIONAL STANDARD ISO 12580:2007(E)

Timber structures — Glued laminated timber — Methods of test

for glue-line delamination

1 Scope

This International Standard specifies five delamination methods for factory quality assurance of the glue line of

glued laminated timber.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

delamination length

sum of the lengths of open glue lines on both end-grain surfaces of each test piece

2.2

glued laminated timber (glulam)

structural member formed by bonding together timber laminations with their grain essentially parallel

2.3

gauge pressure

NOTE Atmospheric pressure at sea level approximates 100 kPa.

3 Symbols and abbreviated terms

b: width of cross-section, in millimetres;

h: depth of cross-section, in millimetres;

l : maximum delamination length of one glue line in the test piece, measured on both end grain

max, delam

surfaces of the test specimen, in millimetres, see Figure 1;

l : length of one glue line, normally the width b, in millimetres, see Figure 1;

glue line

l : delamination length of all glue lines on the two end-grain surfaces in the test piece, in millimetres;

tot, delam

l : entire length of glue lines on the two end-grain surfaces of each test piece, in millimetres.

tot, glue line

4 Principle

A gradient is introduced in the moisture content of the wood to build up internal stresses. This results in tensile

stresses perpendicular to the glue lines, so that an inadequate bonding quality will result in delamination of the

glue lines.

5 Apparatus

5.1 Pressure vessel for methods A, B, C

A pressure vessel designed to safely withstand a gauge pressure of at least 600 kPa and a gauge vacuum of

at least 85 kPa, and equipped with pumps or similar devices capable of giving the required pressure and

vacuum are required.

5.2 Boiling and cooling vessels for method D

Boiling and cooling vessels, of sufficient size to hold the specimens so that they are completely submerged,

are required.

5.3 Drying duct for methods A, B, C, D, E

A drying du

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.