ISO/ASTM 51261:2013

(Main)Practice for calibration of routine dosimetry systems for radiation processing

Practice for calibration of routine dosimetry systems for radiation processing

ISO/ASTM 51261:2013 specifies the requirements for calibrating routine dosimetry systems for use in radiation processing, including establishing measurement traceability and estimating uncertainty in the measured dose using the calibrated dosimetry system. NOTE 1 Regulations or other directives exist in many countries that govern certain radiation processing applications such as sterilization of healthcare products and radiation processing of food requiring that absorbed-dose measurements be traceable to national or international standards (ISO 11137-1, Refs (1-3)2).

Pratique d'étalonnage des appareils de mesure dosimétrique routinier pour le traitement par irradiation

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO/ASTM

STANDARD 51261

Second edition

2013-04-15

Practice for calibration of routine

dosimetry systems for radiation

processing

Practique d’étalonnage des appareils de mesure dosimétrique

routinier pour le traitement par irradiation

Reference number

© ISO/ASTM International 2013

PDF disclaimer

ThisPDFfilemaycontainembeddedtypefaces.InaccordancewithAdobe’slicensingpolicy,thisfilemaybeprintedorviewedbutshall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe’s licensing policy. Neither the ISO Central

Secretariat nor ASTM International accepts any liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies

and ASTM members. In the unlikely event that a problem relating to it is found, please inform the ISO Central Secretariat or ASTM

International at the addresses given below.

© ISO/ASTM International 2013

Allrightsreserved.Unlessotherwisespecified,nopartofthispublicationmaybereproducedorutilizedinanyformorbyanymeans,electronicormechanical,

including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO’s member body in the country of the

requester. In the United States, such requests should be sent to ASTM International.

ISO copyright office ASTMInternational,100BarrHarborDrive,POBoxC700,

Case postale 56 • CH-1211 Geneva 20 West Conshohocken, PA 19428-2959, USA

Tel. +41 22 749 01 11 Tel. +610 832 9634

Fax +41 22 749 09 47 Fax +610 832 9635

E-mail copyright@iso.org E-mail khooper@astm.org

Web www.iso.org Web www.astm.org

Published in the United States

ii © ISO/ASTM International 2013 – All rights reserved

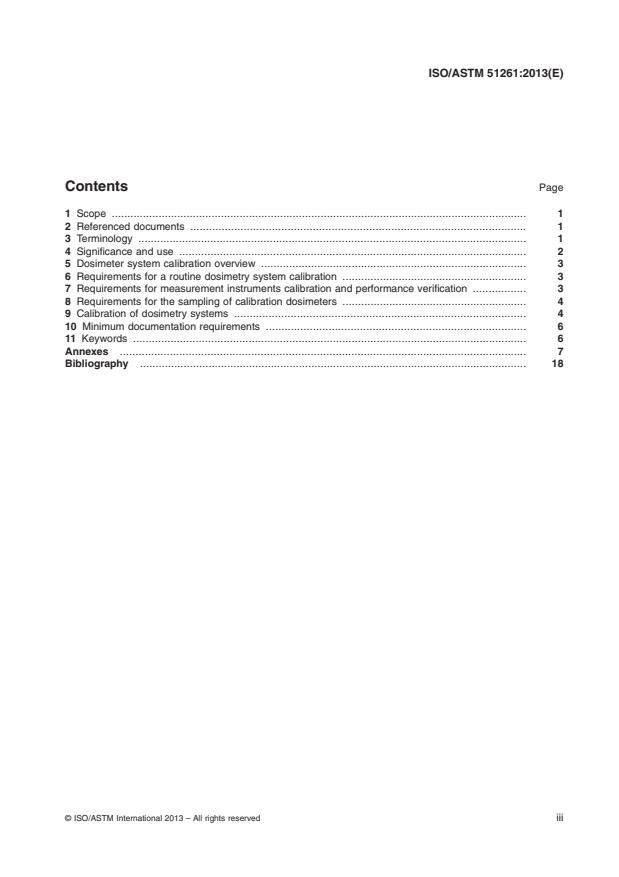

Contents Page

1 Scope . 1

2 Referenced documents . 1

3 Terminology . 1

4 Significance and use . 2

5 Dosimeter system calibration overview . 3

6 Requirements for a routine dosimetry system calibration . 3

7 Requirements for measurement instruments calibration and performance verification . 3

8 Requirements for the sampling of calibration dosimeters . 4

9 Calibration of dosimetry systems . 4

10 Minimum documentation requirements . 6

11 Keywords . 6

Annexes . 7

Bibliography . 18

© ISO/ASTM International 2013 – All rights reserved iii

Foreword

ISO(theInternationalOrganizationforStandardization)isaworldwidefederationofnationalstandardsbodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

Draft International Standards adopted by the technical committees are circulated to the member bodies for

voting. Publication as an International Standard requires approval by at least 75% of the member bodies

casting a vote.

ASTM International is one of the world’s largest voluntary standards development organizations with global

participation from affected stakeholders. ASTM technical committees follow rigorous due process balloting

procedures.

A pilot project between ISO and ASTM International has been formed to develop and maintain a group of

ISO/ASTM radiation processing dosimetry standards. Under this pilot project, ASTM Committee E61,

RadiationProcessing,isresponsibleforthedevelopmentandmaintenanceofthesedosimetrystandardswith

unrestricted participation and input from appropriate ISO member bodies.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. Neither ISO nor ASTM International shall be held responsible for identifying any or all such patent

rights.

International Standard ISO/ASTM 51261 was developed by ASTM Committee E61, Radiation Processing,

through Subcommittee E61.01, Dosimetry, and by Technical Committee ISO/TC 85, Nuclear energy, nuclear

technologies and radiological protection.

iv © ISO/ASTM International 2013 – All rights reserved

An American National Standard

Standard Practice for

Calibration of Routine Dosimetry Systems for Radiation

Processing

This standard is issued under the fixed designation ISO/ASTM 51261; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision.

1. Scope E178 Practice for Dealing With Outlying Observations

E2628 Practice for Dosimetry in Radiation Processing

1.1 This practice specifies the requirements for calibrating

E2701 Guide for Performance Characterization of Dosim-

routine dosimetry systems for use in radiation processing,

etersandDosimetrySystemsforUseinRadiationProcess-

includingestablishingmeasurementtraceabilityandestimating

ing

uncertainty in the measured dose using the calibrated dosim-

2.2 ISO/ASTM Standards:

etry system.

51607 Practice for Use of an Alanine-EPR Dosimetry Sys-

NOTE 1—Regulations or other directives exist in many countries that

tem

govern certain radiation processing applications such as sterilization of

51707 Guide for Estimating Uncertainties in Dosimetry for

healthcare products and radiation processing of food requiring that

Radiation Processing

absorbed-dose measurements be traceable to national or international

2.3 International Commission on Radiation Units and

standards (ISO11137-1, Refs (1-3) ).

Measurements Reports:

1.2 The absorbed-dose range covered is up to 1 MGy.

ICRU Report 85a Fundamental Quantities and Units for

1.3 The radiation types covered are photons and electrons

Ionizing Radiation

with energies from 80 keV to 25 MeV.

2.4 ISO Standards:

1.4 This document is one of a set of standards that provides

ISO 11137-1 Sterilization of health care products—

recommendations for properly implementing dosimetry in

Radiation—Requirements for the development, validation

radiation processing, and describes a means of achieving

and routine control of a sterilization process for medical

compliance with the requirements of ASTM E2628 “Practice

devices

for Dosimetry in Radiation Processing” for the calibration of

2.5 ISO/IEC Standards:

routinedosimetrysystems.Itisintendedtobereadinconjunc-

17025 GeneralRequirementsfortheCompetenceofTesting

tion withASTM E2628 and the relevantASTM or ISO/ASTM

and Calibration Laboratories

standard practice for the dosimetry system being calibrated

2.6 Joint Committee for Guides in Metrology (JCGM)

referenced in Section 2.

Reports:

1.5 This standard does not purport to address all of the

JCGM 100:2008, GUM 1995, with minor corrections,

safety concerns, if any, associated with its use. It is the

Evaluation of measurement data – Guide to the Expres-

responsibility of the user of this standard to establish appro-

sion of Uncertainty in Measurement

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3. Terminology

3.1 Definitions:

2. Referenced documents

3.1.1 approved laboratory—laboratory that is a recognized

2.1 ASTM Standards:

nationalmetrologyinstitute;orhasbeenformallyaccreditedto

E170 TerminologyRelatingtoRadiationMeasurementsand

ISO/IEC 17025; or has a quality system consistent with the

Dosimetry

requirements of ISO/IEC 17025.

3.1.1.1 Discussion—Arecognized national metrology insti-

tute or other calibration laboratory accredited to ISO/IEC

This guide is under the jurisdiction of ASTM Committee E61 on Radiation

Processing and is the direct responsibility of Subcommittee E61.01 on Dosimetry,

17025 should be used in order to ensure traceability to a

and is also under the jurisdiction of ISO/TC 85/WG 3.

national or international standard. A calibration certificate

Current edition approved Aug. 16, 2012. Published April 2013. Originally

published asASTM E1261–88. Last previousASTM edition E1261–00.ASTM

ϵ1

E 1261–94 was adopted by ISO in 1998 with the intermediate designation ISO

15556:1998(E). The present International Standard ISO/ASTM 51261:2013(E) is a Available from International Commission on Radiation Units and Measure-

major revision of ISO/ASTM 51261:2002(E), which replaced ISO 15556. ments, 7910 Woodmont Avenue, Suite 800, Bethesda, MD 20814, USA.

2 5

The boldface numbers given in parentheses refer to the bibliography at the end Available from International Organization for Standardization (ISO), 1, ch. de

of this guide. la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

For referenced ASTM and ISO/ASTM standards, visit the ASTM website, www.iso.ch.

www.astm.org, or contact ASTM Customer Service at service@astm.org. For DocumentproducedbyWorkingGroup1oftheJointCommitteeforGuidesin

Annual Book of ASTM Standards volume information, refer to the standard’s Metrology (JCGM/WG 1). Available free of charge at the BIPM website (http://

Document Summary page on the ASTM website. www.bipm.org).

© ISO/ASTM International 2013 – All rights reserved

provided by a laboratory not having formal recognition or for routine absorbed dose measurements, including dose map-

accreditation will not necessarily be proof of traceability to a ping and process monitoring.

national or international standard. 3.1.16 traceability—propertyoftheresultofameasurement

or the value of a standard whereby it can be related to stated

3.1.2 calibration—set of operations that establish, under

references, usually national or international standards, through

specified conditions, the relationship between values of quan-

an unbroken chain of comparisons all having stated uncertain-

tities indicated by a measuring instrument or measuring sys-

ties.

tem,orvaluesrepresentedbyamaterialmeasureorareference

3.1.16.1 Discussion—Measurementtraceabilityisarequire-

material, and the corresponding values realized by standards.

ment of any measurement management system (see Annex

3.1.3 calibration curve—expression of the relation between

A4).

indication and the corresponding measured quantity value.

3.1.17 transfer standard dosimetry system—dosimetry sys-

3.1.4 charged-particle equilibrium (referred to as electron

tem used as an intermediary to calibrate other dosimetry

equilibrium in the case of electrons set in motion by photon

systems.

beamirradiationofamaterial)—conditioninwhichthekinetic

3.1.18 type I dosimeter—dosimeter of high metrological

energy of charged particles (or electrons), excluding rest mass,

quality, the response of which is affected by individual influ-

entering an infinitesimal volume of the irradiated material

ence quantities in a well-defined way that can be expressed in

equals the kinetic energy of charged particles (or electrons)

terms of independent correction factors.

emerging from it.

3.1.19 type II dosimeter—dosimeter, the response of which

3.1.5 dosimeter batch—quantity of dosimeters made from a

isaffectedbyinfluencequantitiesinacomplexwaythatcannot

specific mass of material with uniform composition, fabricated

practically be expressed in terms of independent correction

in a single production run under controlled, consistent condi-

factors.

tions, and having a unique identification code.

3.1.20 uncertainty (of measurement)—parameter associated

3.1.6 dosimeter stock—partofadosimeterbatchheldbythe

with the result of a measurement that characterizes the disper-

user.

sion of the values that could reasonably be attributed to the

3.1.7 dosimetry system—system used for measuring ab-

measurand or derived quantity.

sorbed dose, consisting of dosimeters, measurement instru-

3.1.21 uncertainty budget—quantitative analysis of the

ments and their associated reference standards, and procedures

component terms contributing to the uncertainty of a measure-

for the system’s use.

ment, including their statistical distribution, mathematical

3.1.8 electron equilibrium—charged particle equilibrium

manipulation and summation.

for electrons. (See charged-particle equilibrium.)

3.2 validation (of a process)—establishmentofdocumented

3.1.9 influence quantity—quantity that is not the measurand

evidence, which provides a high degree of assurance that a

but that affects the result of the measurement. specified process will consistently produce a product meeting

its predetermined specifications and quality attributes.

3.1.10 in-situ/in-plant calibration—calibration where the

3.3 verification—confirmation by examination of objective

dosimeter irradiation is performed in the place of use of the

routine dosimeters. evidence that specified requirements have been met.

3.3.1 Discussion—In the case of measuring equipment, the

3.1.10.1 Discussion—In-situ/in-plant calibration of dosim-

result of verification leads to a decision either to restore to

etry systems refers to irradiation of dosimeters along with

service or to perform adjustments, repair, downgrade, or

reference or transfer standard dosimeters, under operating

declare obsolete. In all cases it is required that a written trace

conditions that are representative of the routine processing

of the verification performed be kept on the instrument’s

environment, for the purpose of developing a calibration curve

individual record.

for the routine dosimetry systems.

3.4 Definitions of other terms used in this standard that

3.1.11 measurand—specific quantity subject to measure-

pertain to radiation measurement and dosimetry may be found

ment.

in ASTM Terminology E170. Definitions in ASTM Terminol-

3.1.12 measurement management system—set of inter-

ogy E170 are compatible with ICRU Report 85a; that docu-

related or interacting elements necessary to achieve metrologi-

ment, therefore, may be used as an alternative reference.

cal confirmation and continual control of measurement pro-

cesses.

4. Significance and use

3.1.13 primary standard dosimetry system—dosimetry sys-

4.1 Ionizing radiation is used to produce various desired

tem that is designated or widely acknowledged as having the

effects in products. Examples of applications include the

highest metrologial qualities and whose value is accepted

sterilization of medical products, microbial reduction, modifi-

without reference to other standards of the same quantity.

cation of polymers and electronic devices, and curing of inks,

3.1.14 reference standard dosimetry system—dosimetry

coatings, and adhesives (4).

system, generally having the highest metrological quality

4.2 Absorbed-dose measurements, with statistical controls

available at a given location or in a given organization, from

and documentation, are necessary to ensure that products

which measurements made there are derived.

receive the desired absorbed dose. These controls include a

3.1.15 routine dosimetry system—dosimetry system cali- program that addresses requirements for calibration of routine

brated against a reference standard dosimetry system and used dosimetry system.

© ISO/ASTM International 2013 – All rights reserved

4.3 A routine dosimetry system calibration procedure as tainty together with their methods of estimation, statistical

described in this document provides the user with a dosimetry distributions and magnitudes.

system whose dose measurements are traceable to national or

5.3.3 Examples of components of uncertainty in the dosim-

international standards for the conditions of use (see Annex

etry system calibration include inherent variation in dosimeter

A4). The dosimetry system calibration is part of the user’s

response, uncertainty in the calibration irradiation dose, uncer-

measurement management system.

tainty in the calibration curve fit and uncertainty in dosimeter

response correction parameters such as dosimeter thickness,

5. Dosimeter system calibration overview

dosimetermass,unirradiatedresponseandirradiationtempera-

ture.

5.1 Calibrationofaroutinedosimetrysystemconsistsofthe

5.3.4 Additional components of uncertainty might be pres-

following:

entwhentheconditionsofusearedifferentthantheconditions

5.1.1 Selection of the calibration dosimeters from the user

of calibration. In these instances, a calibration verification is

stock (see Section 8).

conducted to quantify a component of uncertainty to account

5.1.2 Irradiation of the calibration dosimeters (see 9.1 and

for these differences (see 9.1.8 and 9.2.9).

9.2).

5.1.3 Calibration and/or performance verification of mea-

6. Requirements for a routine dosimetry system

surement instruments (see Section 7).

calibration

5.1.4 Measurement of the calibration dosimeters response

(see 9.1.6 and 9.2.5.1).

6.1 Dosimetry system calibration shall be conducted for

5.1.5 Analysis of the calibration dosimeter response data

each new dosimeter batch.

(see 9.1.7 and 9.2.6).

NOTE 4—The response of different dosimeter stocks purchased at

5.1.6 Verification of the calibration curve for conditions of

different times from a given dosimeter batch should be verified to ensure

use, if appropriate (see 9.1.8 and Note 2).

equivalent response.Astatistical test should be used to determine if there

5.1.7 Estimation of the combined uncertainty for the condi-

is any significant difference between the stocks. This should be repeated

tions of use (see 9.1.10 and 9.2.7).

at several doses over the calibration dose range.

5.1.8 Verification of the calibration curve at a time other

6.2 Routinedosimetrysystemsshallbecalibratedusingone

than calibration for assessment of continuing validity of the

of the methods described in 9.1 and 9.2.

calibration curve (see 9.1.11, 9.2.9, and Note 2).

6.3 Therationaleforselectingamethodforcalibrationshall

NOTE 2—Calibration verification is conducted as part of the calibration

be documented (see 9.1.4 and 9.2.3).

when the calibration irradiation conditions are different from the condi-

6.4 Recalibration of an existing batch or stock shall be

tions of use (5.1.6). Calibration verification is also conducted between

conducted at a frequency specified by the user based on the

calibrations to ensure continued suitability of the calibration curve for the

known characteristics of the dosimetry system.

conditions of use (5.1.8).

6.4.1 Additional calibration or calibration verification may

5.2 Calibration Irradiation Methods—There are two meth-

be required to determine if changes have occurred that affect

ods for irradiating dosimeters for calibration:

thecalibration.Examplesarechangesinthevaluesofinfluence

5.2.1 Calibration irradiations performed at an approved

quantities, such as temperature or humidity, changes in the use

laboratory followed by a calibration verification exercise.

of the dosimetry system and change in response due to

5.2.2 In-situ/in-plant calibration irradiations of routine do-

dosimeter aging. Changes in influence quantities can result

simeters along with transfer standard dosimeters issued and

from seasonal changes in ambient conditions or changes in

analyzed by an approved laboratory.

source activity or distribution.

NOTE 3—Valid in-situ/in-plant calibration irradiations result in a cali-

6.5 Calibration curves are specific to the measurement

bration curve generated under conditions that are representative of the

instrument used to generate them. They shall not be used with

routineprocessingenvironment.Anin-situ/in-plantcalibrationmaynotbe

otherinstrumentsunlessithasbeendemonstratedthatthedose

valid or may require calibration verification if the calibration conditions

measurements agree within user defined limits.

can not be maintained during routine use. For example, the calibration

6.6 All software associated with dosimetry system and

irradiations are carried out as a single exposure, but the dosimeter is used

for dose measurement of fractionated irradiations. calibration data analysis shall be validated for its intended use.

5.3 Uncertainties:

7. Requirements for measurement instruments

5.3.1 Allmeasurementsofabsorbeddoseneedtobeaccom-

calibration and performance verification

panied by an estimate of uncertainty (see ISO/ASTM 51707,

7.1 All measurement instrumentation associated with the

Refs (5,6) and GUM).

5.3.2 All components of uncertainty should be included in dosimetry system shall either be calibrated, or have its perfor-

mance verified, before use. Performance checks and/or recali-

the estimate, including those arising from calibration, dosim-

brationshallbecarriedoutatuser-specifiedintervals,basedon

eter reproducibility, instrument stability and the effect of

the known characteristics of the instrument.

influencequantities.Afullquantitativeanalysisofcomponents

of uncertainty is referred to as an uncertainty budget and is 7.1.1 Where recognized standards exist, the calibration of

often presented in the form of a table. Typically, the uncer- the instrument shall be traceable to national or international

tainty budget will identify all significant components of uncer- standards.

© ISO/ASTM International 2013 – All rights reserved

7.1.2 Where recognized standards do not exist, the perfor- 9.1.3 Transport of Calibration Samples—The effect of in-

mance of the instrument shall be verified in accordance with tended transportation on dosimeter response shall be evaluated

industry or manufacturer recommended practices and proce- toestablishcriteriaforacceptablepackagingandtransportation

dures. of calibration dosimeters. The evaluation should be based on

characterization data of the routine dosimetry system (see

NOTE 5—For example, the Alanine-EPR dosimetry system employs

ASTM E2701).

electron paramagnetic resonance (EPR) spectroscopy for analysis. The

9.1.4 Irradiation Conditions—Arationale shall be prepared

properoperationoftheEPRspectrometerisverifiedwithappropriateEPR

spin reference such as irradiated alanine dosimeters, pitch sample, or for the calibration target dose levels, their spacing and irradia-

Mn(II) in CaO (see ISO/ASTM Practice 51607).

tionconditions,forexample,doserateandirradiationtempera-

ture specified to the approved laboratory. Document the allow-

7.1.3 When maintenance or modification of the measure-

able variation from these conditions.

ment instrumentation has occurred that may affect its perfor-

9.1.4.1 Forexample,fordoserangesoflessthanonedecade

mance, instrument performance shall be verified and, if neces-

(factor of ten), dose levels should be distributed arithmetically

sary, the instrument shall be re-calibrated.

uniformly (for example, 10, 20, 30, 40, 50 kGy). For dose

8. Requirements for the sampling of calibration

ranges of more than one decade, dose levels should be

dosimeters

distributedgeometricallyuniformly(forexample,1.0,1.5,2.3,

8.1 Dosimeters selected for the calibration shall constitute a

3.4, 5.1, 7.6, 11.4, 17.1, 25.6, 38.4, 57.7, 86.5 kGy).

representativesampleofthedosimeterstockheldbytheuserto

9.1.5 Dosimeter Irradiation—The dosimeters shall be irra-

be used in routine processing.These dosimeters are referred to

diated at an approved laboratory to the specified absorbed

as ‘calibration dosimeters’.

doses. The absorbed dose is usually specified in terms of

8.2 Calibration dosimeters shall be labelled to ensure seg-

absorbed dose to water.

regation and identification throughout the calibration exercise.

9.1.5.1 The approved laboratory shall report deviations

8.3 The number of dose levels required for developing the

from the conditions specified by the user (see 9.1.4).

calibration curve depends on the range of utilization. At least

9.1.6 Dosimeter Response Measurement—The performance

five dose levels shall be used for each factor of ten span of

of measurement instrumentation shall be verified (see 7.1).

absorbed dose (for example, choose five dose levels fora5to

9.1.6.1 Measure the calibration dosimeter response upon

50 kGy range).

return from the approved laboratory in accordance with the

8.3.1 The minimum number of dose levels to be used in the

users calibration and measurement procedures.

calibration can be determined as follows: divide the maximum

9.1.7 Analysis of Dosimetry Data:

dose (D ) of the dose range by the minimum dose (D )of

max min 9.1.7.1 If required, each dosimeter response shall be ad-

the dose range; calculate log (base 10) of this ratio: Q =

justed for dosimeter parameters such as dosimeter thickness,

log(D /D ).If Qisequaltoorgreaterthan1,calculate5 3

max min mass or unirradiated dosimeter response following established

Q, and round this up to the nearest integer value. This value

measurement practice.

representstheminimumnumberofdoselevelstobeused.If Q

9.1.7.2 The individual dosimeter response, the sample stan-

is less than 1 use five dose levels.

dard deviation and the coefficient of variation of the replicate

8.4 Aminimum of four dosimeters for each dose level shall

measurements at each dose level shall be determined and

be used. However, using a larger number of dosimeters per

documented.

dose level may reduce the uncertainty associated with the

NOTE 6—In general, if the coefficient of variation at any dose level is

calibration.

greater than a user-defined limit, a re-determination of the data should be

9. Calibration of dosimetry systems considered (for example, perform a visual inspection to identify potential

dosimeter damage, repeat the calibration irradiation at the dose level or

9.1 Calibration of Dosimetry Systems using irradiations at

perform an outlier test).

an approved laboratory:

9.1.7.3 Derivethecalibrationcurveinmathematicalform, y

9.1.1 Overview—TheroutinedosimetermaybeaTypeIor

= f(x), where dosimeter response is the dependent variable (y)

Type II dosimeter. The calibration irradiation at an approved

and absorbed dose is the independent variable (x). Choose an

laboratory has the advantage that the dosimeters are irradiated

analytical form (for example, linear, polynomial, or exponen-

to known doses under well-controlled and documented condi-

tial) that provides an appropriate fit to the measured data. The

tions. However, when conditions of use (in-situ/in-plant) differ

ease of deriving dose from measured dosimeter response (the

from calibration conditions, significant uncertainties may be

mathematical inverse of the analytical form) may also be a

introducedinthecombineduncertaintyoftheroutineabsorbed

consideration in selecting the analytical form (see Annex A2

dosemeasurement.Transportofthedosimeterstoandfromthe

and Annex A3).

approvedlaboratorymayalsointroduceuncertaintiesfrompre-

9.1.7.3.1 The resulting calibration curve shall be evaluated

and post-irradiation influence quantities that are difficult to

characterize. for goodness of fit within user defined limits.

9.1.2 Post Irradiation Response—Post-irradiation response 9.1.8 Calibration Verification (as part of calibration)—

characteristics of the routine dosimeter shall be determined Prior to implementation of a calibration curve, a calibration

prior to calibration irradiation and incorporated into the cali- verification shall be performed to assess the suitability of the

bration procedure. calibration curve for the conditions of use. This is usually

© ISO/ASTM International 2013 – All rights reserved

achieved by in-situ/in-plant irradiation of transfer standard 9.1.11 Stability Verification—The suitability of the calibra-

dosimeters supplied by an approved laboratory alongside tioncurveshallbeverifiedoveritsperiodofuseinaccordance

with the requirements of 6.4.1.

representative samples from the routine dosimeter stock under

9.2 In-situ/In-plant Calibration of Routine Dosimetry Sys-

the conditions of use. The dosimetry system being calibrated

tems in a Production Irradiator Using Transfer Standard

andthetransferstandarddosimetrysystemusedforcalibration

Dosimetry System:

verification should, if possible, be based on different types of

9.2.1 Overview—The routine dosimeter may be a Type I or

dosimeters. For example, if the dosimetry system being cali-

Type II dosimeter. The calibration irradiation of the routine

bratedisbasedonalaninedosimeters,andthetransferstandard

dosimeterstogetherwiththetransferstandarddosimetersinthe

dosimetry system is also based on alanine dosimeters, then the

production irradiator has the advantage that the influence

effect of an inappropriate correction for influence quantities,

quantityvaluerangeswillbeverysimilarinroutineapplication

such as temperature, will not be apparent as both systems will

and calibration, provided the calibration irradiation conditions

respond in the same way.

are chosen appropriately. This method takes into account the

9.1.8.1 The calibration verification shall be conducted at a

effect of the influence quantities of the conditions of use to the

minimum of three dose levels targeted near the extremes and

extent that the transfer standard dosimeter response can be

near the center of the calibration dose range.

corrected for the difference between the fixed influence quan-

9.1.8.2 The routine dosimeters for the calibration verifica-

tity values of its calibration and the production irradiation

tion shall be selected from the same dosimeter stock as the

influence quantities profile by the approved laboratory issuing

calibration dosimeters.

and analyzing the transfer standard dosimeters. Care must be

9.1.8.3 Theirradiationoftheroutinedosimetersandtransfer

taken to ensure that the routine dosimeters and transfer

standard dosimeters shall consist of complete pathways

standard dosimeters irradiated together receive the same ab-

through the irradiator.

sorbed dose.

9.1.8.4 The routine and transfer dosimeters shall be irradi- 9.2.2 Post-Irradiation Response—Post-irradiation response

atedsothatitisensuredthattheyreceivethesamedosewithin characteristics of the dosimeter shall be determined prior to

predetermined limits (see Annex A1). calibration irradiation and incorporated into the calibration

procedure.

NOTE 7—The temperatures associated with the calibration verification

9.2.3 Irradiation Conditions—A rationale for target dose

irradiations should be similar to those expected to be encountered during

levelsandirradiationconditionsforcalibrationirradiationshall

routine use of the dosimetry system.

be prepared and documented. The irradiation conditions se-

9.1.8.5 In a few instances it may be impossible to conduct

lected for calibration irradiation should be such that the

the calibration verification as described. In these instances, the

irradiation conditions are similar to those expected during the

user shall develop a verification method and rationale that is

intendeduseoftheirradiator,forexample,duringperformance

capable of demonstrating that the calibration curve of the

qualification and routine process monitoring.

routine dosimetry system is suitable for the conditions of use.

9.2.3.1 Forexample,fordoserangesoflessthanonedecade

The rationale for the need to use this alternative method shall

(factor of ten): dose levels should be distributed arithmetically

be documented.

uniformly (for example, 10, 20, 30, 40, 50 kGy). For dose

ranges of more than one decade, dose levels should be

9.1.8.6 Thecalibrationverificationresultsshallbeevaluated

to identify difference between the measured dose values of the distributedgeometricallyuniformly(forexample,1.0,1.5,2.3,

3.4, 5.1, 7.6, 11.4, 17.1, 25.6, 38.4, 57.7, 86.5 kGy).

routineandtransferstandarddosimetrysystemsandtoprovide

9.2.4 Dosimeter Irradiation—The calibration dosimeters

anestimateofoneofthecomponentsofcalibrationuncertainty

(see Annex A3). shallbeirradiatedwithtransferstandarddosimetersissuedand

analyzed by an approved laboratory. The irradiation phantom

9.1.9 Corrective Action—If the calibration verification re-

used to co-locate the calibration dosimeters and the transfer

sult exceeds a user defined acceptable limit, corrective action

standard dosimeters shall be characterized to ensure both the

inaccordancewiththemeasurementmanagementsystemshall

calibration dosimeters and the transfer standard dosimeters

be implemented.

receive the same absorbed dose (seeAnnexA1).The absorbed

9.1.9.1 Correctiveactionmayinclude:repeatingthecalibra-

dose is usually specified in terms of absorbed dose to water.

tion using more appropriate influence quantity conditions

during calibration irradiation, reducing the dose range of the NOTE 8—The temperatures of the routine dosimeters during calibration

irradiation should be similar to those expected to be encountered during

calibration curve, developing calibration curves for specific

routine use of the dosimetry system.

irradiator pathways, applying a correction factor to the routine

dosimeter response in cases where a single factor is applicable

9.2.5 Dosimeter Response Measurement—Verifytheperfor-

over the entire calibration curve, or calibrating using an

mance of the measurement instrumentation (see 7.1-7.1.3).

in-situ/in-plant calibration method (see 9.2).

9.2.5.1 The calibration dosimeter response shall be mea-

9.1.10 Dosimetry System Measurement Uncertainty— sured in accordance with the users’ calibration and measure-

Prepare an estimate of the combined uncertainty in the mea- ment procedures.

sured dose using the calibrated dosimetry system for the 9.2.6 Analysis of Dosimetry Data—Ifrequired,eachdosim-

conditions of use (see Annex A3 and ISO/ASTM 51707). eterresponseshallbeadjustedforresponseparameterssuchas

© ISO/ASTM International 2013 – All rights reserved

dosimeter thickness, mass or unirradiated dosimeter response 9.2.9.1 Changes to the intended conditions of use of the

following established measurement practice. routine dosimetry system may render the calibration curve

9.2.6.1 The individual dosimeter response, the sample stan- unsuitable. An example of such a change is that of dose

dard deviation and the coefficient of variation of the replicate fractioning during the intended use when the calibration

measurements at each dose level shall be determined and irradiation consists of a single exposure. In such instances, the

documented. effect of the change shall be evaluated.

NOTE 9—In general, if any coefficient of variation is greater than a

NOTE 10—Performing a calibration verification is one method of

user-definedlimit,are-determinationofthedatashouldbeconsidered(for

evaluating the effect of changes to the conditions of intended use,

example, perform a visual inspection to identify potential dosimeter

reference 9.1.8 and Note 7.

damage, repeat the calibration irradiation at the dose level or perform an

outlier test).

10. Minimum documentation requirements

9.2.6.2 Derivethecalibrationcurveinmathematicalform, y

10.1 Document the dosimetry system being calibrated in-

= f(x), where dosimeter response is the dependent variable (y)

cluding the dosimeter manufacturer, type and batch number,

and absorbed dose is the independent variable (x). Choose an

and measurement instrumentation.

analytical form (for example, linear, polynomial, or exponen-

10.2 Document the rationale for the calibration method.

tial) that provides an appropriate fit to the measured data. The

10.3 Document the dosimetry system calibration data, irra-

ease of deriving dose from measured dosimeter response (the

diation parameters, irradiation date, transfer standard dosim-

mathematical inverse of the analytical form) may also be a

eters, and description of the irradiation facility used.

consideration in selecting the analytical form (see Annex A2

10.4 Document or reference a description of the radiation

and Annex A3).

source(s) used in calibration and processing, including the

9.2.6.3 Theresultingcalibrationcurveshallbeevaluatedfor

type, nominal activity or beam parameters, and any available

goodness of fit within user defined limits

information on the energy spectrum.

9.2.7 Dosimetry System Measurement Uncertainty—

10.5 Document irradiation temperatures and, if necessary,

Prepare an estimate of the combined uncertainty in the mea-

the relative humidity.

sured dose using the calibrated dosimetry system for the

10.6 Document the combined uncertainty in the measured

conditions of use (see Annex A3 and ISO/ASTM 51707).

dose using the calibrated dosimetry system.

9.2.8 Corrective Action—If the combined uncertainty ex-

10.7 Referencethemeasurementmanagementsystematthe

ceeds a user defined acceptable limit, corrective action in

radiation facility.

accordancewiththemeasurementmanagementsystemshallbe

implemented.

11. Keywords

9.2.8.1 Correctiveactionmayinclude:repeatingthecalibra-

tion using more appropriate calibration irradiation conditions, 11.1 absorbed dose; accredited laboratory; dosimeter; do-

reducing the dose range of the calibration curve, developing simetry system calibration; dosimetry system; electron beam;

calibration curves for specific irradiator pathways. gammaradiation;ionizingradiation;measurementtraceability;

9.2.9 Stability Verification—The suitability of the calibra- radiation processing; reference standard dosimetry system;

tioncurveshallbeverifiedovertheperiodofuseinaccordance routine dosimeter; transfer standard dosimetry system; Type I

with the requirements of 6.4.1. dosimeter; Type II dosimeter; X-ray; X-radiation

© ISO/ASTM International 2013 – All rights reserved

ANNEXES

(informative)

A1. PHANTOM GEOMETRY

A1.1 Aphantomofknownhomogenousmaterialisusedfor differences should be evaluated as part of the calibration

the irradiation of the dosimeters in order to minimize the procedure.

difference between the absorbed doses received by the routine

A1.3 When thick and thin dosimeters are irradiated to-

and transfer standard dosimeters. The phantom design should

gether, the thin dosimeters should be surrounded by sufficient

hold the two types of dosimeters so that they do not signifi-

polymericmaterialtoensurethattheattenuationcharacteristics

cantly influence each other and provide a geometry that is

are similar to the thick dosimeters and that the dosimeters

appropriate for the radiation source employed (see Fig. A1.1

receive the same dose.

and Fig. A1.2 for examples of such phantoms employed for

gamma or X-ray irradiation; see Fig.A1.3 for an example of a A1.4 Dose variation within the phantom can be character-

phantom suitable for high energy electron-beam irradiation).

ized by irradiating the phantom with the same type of dosim-

eter in all the dosimeter positions within the calibration

A1.2 Theuseofaphantomcanresultindifferentirradiation irradiationphantom.However,differenceingeometrybetween

temperature and temperature profile than the conditions of use the routine dosimeters and transfer standard dosimeters must

oftheroutinedosimeterwithoutaphantom.Theeffectofthese be taken into account.

FIG. A1.1 Example of calibration phantom allowing alanine dosimeters to be placed on either side of thin film routine dosimetry system

dosimeter

© ISO/ASTM International 2013 – All rights reserved

FIG. A1.2 Example of calibration phantom allowing reference standard dosimeter ampoules and routine dosimetry system dosimeter to

be placed adjacent to each other

FIG. A1.3 Example of 10 MeV calibration phantom allowing alanine dosimeters and thin-film routine dosimetry system dosimeters to be

irradiated at the same position on the depth-dose curve

A2. CURVE FITTING

© ISO/ASTM International 2013 – All rights reserved

n

A2.1 Curve fitting is the application of regression analysis

SSE 5 w ~y 2 yˆ ! (A2.3)

( i i i

techniques to a set of data where by the selected mathematical

i51

form(model)definesthedependentvariable(Y)intermsofthe

where:

independentvariable(X).Regressionanalysisisusedtofitdata

y = the observed dependent variable at an independent

i

to a model and provide estimates of the fit parameters

variable value,

(coefficients) based on a minimization technique.

yˆ = themodelpredictedvalueofthedependentvariableat

i

the corresponding independent variable, and

A2.2 Regression models are either an empirical or a

w = assigned weight which in most cases is assumed to be

i

mechanistic model. The empirical model describes the general

1 unless a weighting is applied to compensate for a

shapeofthedataset.Theparametersoftheempiricalmodeldo

deviation of homoscedasticity (A2.3.1.3).

not correspond to an underlying biological, chemical or physi-

cal process. The mechanistic model is formulated to provide

NOTE A2.3—When the Gaussian distribution of error assumption is

insight or description of the process under study.

invalid due to appreciable tails in the residuals distribution, the assump-

tionthatleastsquaresprovidesthemaximumlikelihoodfitisalsoinvalid.

A2.3 The two basic types of regression analysis are linear

In these instances a robust method of minimization may be used. The

regression and non-linear regression. Linear regression is

essence of robust fitting is to use a minimization technique that is less

wheretheunknownparameters(coefficients)appearlinearlyin

influenced by potential outliers and the range of the dependent variable.

Several examples of nonlinear robust minimization are Least Absolute

the expression as in Eq A2.1. Non-linear regression is where

Deviation, Lorentzian, and Pearson.

theunknownparameters(coefficients)appearinanon-linearor

nested fashion as in Eq A2.2.

A2.5 Goodnessoffitdescribeshowwellthemodelfitsaset

2 3

y 5 a 1 bx 1 cx 1 dx (A2.1)

of data. Measures of goodness of fit typically summarize the

a

discrepancy between observed values (y) and the values

i

y 5 (A2.2)

c

x

predicted by the model (yˆ).Areview of a plot of the residuals

1 1

S D

b

is critical when assessing goodness of fit.The most commonly

usedstatisticsforassessinggoodnessoffitarethecoefficientof

NOTE A2.1—In the context of regression analysis, the terms linear and

determination, lack of fit sum of squares (F statistic), confi-

non-lineardonotrefertotheshapeoftheplottedcurve,forexample,both

Eq A2.1 and Eq A2.2 represent curved plots.

dence intervals of the fit coefficients, and the F test when

comparing fits between different models. Another powerful

A2.3.1 In both types of regression analysis (linear and

non-statistical evaluation method is a review of the plot of the

nonlinear) several assumptions are made:

residuals.

A2.3.1.1 X is known precisely and all error is in Y. (It is

sufficient that imprecision in measuring X is very small

A2.5.1 A plot of the residuals can reveal behaviour in the

compared to the variability in Y. Error refers to deviation from

data that is otherwise difficult to see in the curve fit.Aplot of

the average.)

the residuals should not demonstrate a form or trend. A

A2.3.1.2 Variability of Y at any X follows a known distri-

residuals plot may also indicate potential or suspect outliers

bution, typically assumed to be Gaussian or near Gaussian.

(see A2.6).

A2.3.1.3 Thestandarddeviationoftheresidualsisthesame 2

A2.5.2 Thecoef

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.