ISO/DIS 16152

(Main)Plastics -- Determination of xylene-soluble matter in polypropylene

Plastics -- Determination of xylene-soluble matter in polypropylene

Plastiques -- Détermination des matières présentes dans le polypropylène solubles dans le xylène

General Information

RELATIONS

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 16152

ISO/TC 61/SC 9 Secretariat: KATS

Voting begins on: Voting terminates on:

2020-06-23 2020-09-15

Plastics — Determination of xylene-soluble matter in

polypropylene

Plastiques — Détermination des matières présentes dans le polypropylène solubles dans le xylène

ICS: 83.080.01THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 16152:2020(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2020

---------------------- Page: 1 ----------------------

ISO/DIS 16152:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 16152:2020(E)

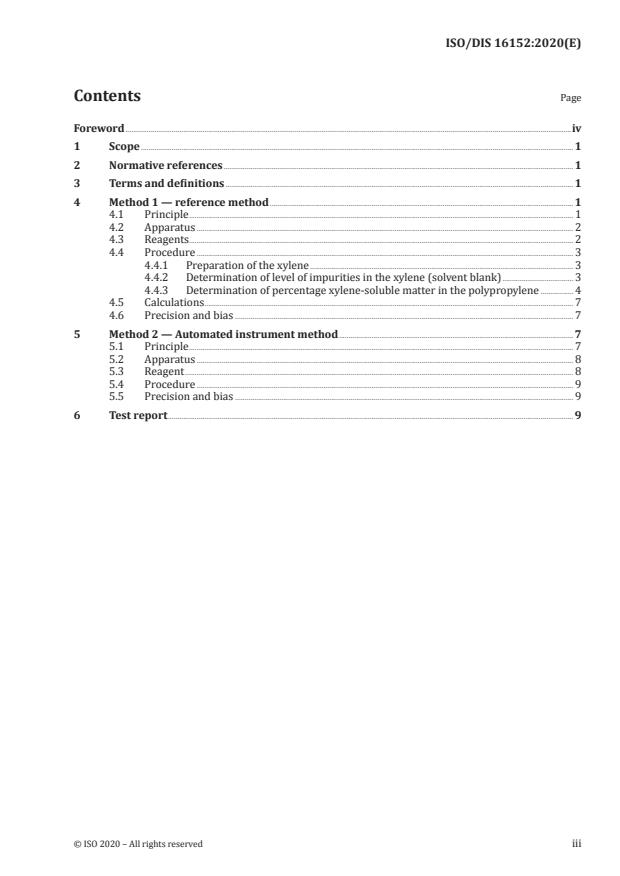

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 1

4 Method 1 — reference method .............................................................................................................................................................. 1

4.1 Principle ........................................................................................................................................................................................................ 1

4.2 Apparatus .................................................................................................................................................................................................... 2

4.3 Reagents........................................................................................................................................................................................................ 2

4.4 Procedure .................................................................................................................................................................................................... 3

4.4.1 Preparation of the xylene ......................................................................................................................................... 3

4.4.2 Determination of level of impurities in the xylene (solvent blank) ..................................... 3

4.4.3 Determination of percentage xylene-soluble matter in the polypropylene ................. 4

4.5 Calculations ................................................................................................................................................................................................ 7

4.6 Precision and bias ................................................................................................................................................................................ 7

5 Method 2 — Automated instrument method .......................................................................................................................... 7

5.1 Principle ........................................................................................................................................................................................................ 7

5.2 Apparatus .................................................................................................................................................................................................... 8

5.3 Reagent .......................................................................................................................................................................................................... 8

5.4 Procedure .................................................................................................................................................................................................... 9

5.5 Precision and bias ................................................................................................................................................................................ 9

6 Test report ................................................................................................................................................................................................................... 9

© ISO 2020 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 16152:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO's adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www .iso .org/ iso/ foreword .htmL.

The committee responsible for this document is Technical Committee ISO/TC 61, Plastics, Subcommittee

SC 9, Thermoplastic materials.This second edition cancels and it replaces ISO16152: 2005. which has been technically revised by

adding an automated instrument method (Method 2)Any feedback or questions on this document should the directed to the user’s national standards body.

A complete listing of these bodies can be found at www .iso .org/ members .htmL.iv © ISO 2020 – All rights reserved

---------------------- Page: 4 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 16152:2020(E)

Plastics — Determination of xylene-soluble matter in

polypropylene

1 Scope

This international standard specifies a method of determining the mass fraction of a polypropylene

homopolymer of copolymer which is soluble in xylene at 25°C.Other materials with solubilities similar to that of the xylene-soluble fraction, such as additives, may

interfere with the determination.This international standard included two methods which are “reference method (method 1)”and

“automated instrument method (method 2)”, The “reference method” is used to calibrate the method

used for the determination of the xylene-soluble matter in polypropylene.The “automated instrument method” is a method which can be used for the determination if it is

calibrated using the reference method described in clause 4 provided it shows a certain permissible

repeatability.2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 472, Plastics — Vocabulary3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 472 and the following apply

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

—IEC Electropedial available at http:// www .electropedia .org/—ISO Online browsing platform: available at https:// www .iso .org/ obp

3.1

Xylene-soluble fraction

That percentage, by mass, of the polymer that does not precipitate out when a solution of the polymer

in xylene is cooled from reflux temperature to 25°Cand help at that temperature for a specified period

of time.4 Method 1 — reference method

4.1 Principle

The polypropylene is dissolved in hot xylene, then cooled under controlled condition down to 25°C,which

result in the precipitation of the insoluble fraction. The soluble matter remains in the xylene. The xylene

is then evaporated and the residue weighed.© ISO 2020 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO/DIS 16152:2020(E)

4.2 Apparatus

4.2.1 Reflux condenser, length 400mm.

4.2.2 Flat-bottomed flask, capacity 400ml, with one or two necks, or conical flask or cylindrical bottle

of similar capacity.4.2.3 Insulation disc, made of fiberglass or mineral wool.

4.2.4 Magnetic stirrer, with temperature-controlled hotplate, thermostatted oil bath or heating block

capable of maintaining 140°C to 150°C.4.2.5 Stirrer bar.

4.2.6 Pipette, class A, 200ml or equivalent.

4.2.7 Pipette, class A, 100ml or equivalent.

4.2.8 Glass-stoppered flask, 250ml.

4.2.9 Thermostatically controlled water bath , with sufficient cooling capacity to maintain a

constant bath temperature of 25°C±0.5°C while cooling down the flask containing the xylene/polymer

solution (see 4.4.3.8 and 4.4.3.9)4.2.10 Filter paper, fluted, Whatman No. 4, NO.541 or equivalent, at least 125 mm in diameter.

4.2.11 Funnel, 60 , or equivalent, at least 125 mm in diameter.4.2.12 Vacuum oven

4.2.13 Disposable aluminium pans, 300ml capacity, with smooth sides.

4.2.14 Temperature-controlled hotplate.

4.2.15 Analytical balance, with a minimum weighing sensitivity of 0,1g (a sensitivity of 0,01 mg is

preferred).4.2.16 Desiccator, containing an appropriate desiccant.

4.2.17 Timer, preferably with an alarm, reading in minutes.

4.2.18 Oven, conventional forced-air or gravity-convection type.

4.3 Reagents

4.3.1 Reagent-grade ortho-xylene(o-xylene), assay by gas chromatography(GC) 98%min;

ethylbenzene content as determined by GC less than 2%; evaporation residue at 140°Cless than

0,002g/100ml; boiling point 144°C.2 © ISO 2020 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/DIS 16152:2020(E)

4.3.2 Reagent-grade para-xylene(P-xylene), assay by gas chromatography(GC) 98%min;

ethylbenzene content as determined by GC less than 2%; evaporation residue at 140°Cless than

0,002g/100ml; boiling point 138°C.Reagent-grade ortho-xylene(4.3.1) shall be used as the reference solvent whenever there if s dispute

between laboratories on test results, unless the laboratories agree otherwise.4.4 Procedure

4.4.1 Preparation of the xylene

4.4.1.1 Although stabilization of the xylene is not required, antioxidants shall be added to prevent

degradation when testing unstabilized powders or beads.Butylated hydroxytoluene (BHT), 4,4-thiobis(6-tert-butyl-m-cresol)and tetrakis[methylene(3,5-di-tert-

butyl-4-hydroxyhydrocinnamate)methane at an approximate concentration of 0,02g/l of xylene have

been found to be effective stabilizers. Agitate with a magnetic stirrer bar and heat for a minimum of

one hour a t 80°C to 90°C to ensure thorough mixing of the antioxidants and the xylene. This heating

temperature has been chosen as it is suitable for BHT, which is relatively volatile.

4.4.1.2 Degas the xylene every 24h by purging with nitrogen gas for a minimum of 1h.

4.4.2 Determination of level of impurities in the xylene (solvent blank)4.4.2.1 The purpose of the solvent blank is to determine the evaporation residue, i.e. amount of foreign

matter in the xylene.A blank test should preferably be run on every new batch of xylene. If however the xylene is extra-pure

grade (minimum99,5%) and is used immediately after being opened, a blank test is not necessary. If

all the xylene in not used immediately (within 3days), a blank test shall be run. It is recommended that

xylene be purchased in glass or glass-line containers of a size such that the xylene will be used within

3 days of opining .Containers of larger size may be used if the xylene is used up within a short period

of time. The purpose of this time limit is to ensure...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.