ISO/DIS 20291-1

(Main)Air cargo -- Restraint slings

Air cargo -- Restraint slings

Fret aérien -- Câbles d'arrimage

General Information

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 20291-1

ISO/TC 20/SC 9 Secretariat: AFNOR

Voting begins on: Voting terminates on:

2020-01-23 2020-04-16

Air cargo — Restraint slings —

Part 1:

Design and testing

Fret aérien — Câbles d'arrimage —

Partie 1: Conception et essais

ICS: 55.180.30

THIS DOCUMENT IS A DRAFT CIRCULATED

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

BEING ACCEPTABLE FOR INDUSTRIAL,

This document is circulated as received from the committee secretariat.

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 20291-1:2020(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2020

---------------------- Page: 1 ----------------------

ISO/DIS 20291-1:2020(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 20291-1:2020(E)

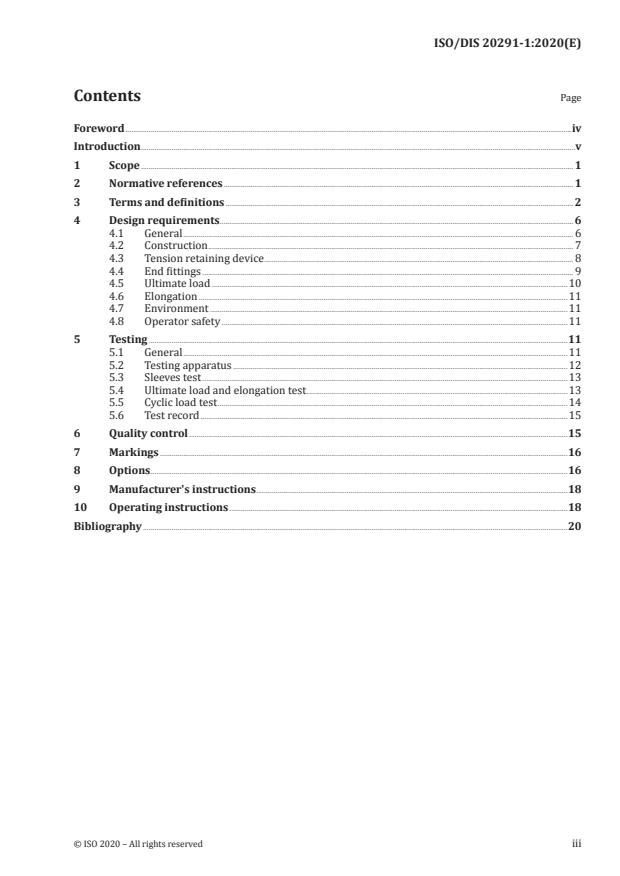

Contents Page

Foreword ........................................................................................................................................................................................................................................iv

Introduction ..................................................................................................................................................................................................................................v

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 2

4 Design requirements ........................................................................................................................................................................................ 6

4.1 General ........................................................................................................................................................................................................... 6

4.2 Construction .............................................................................................................................................................................................. 7

4.3 Tension retaining device ................................................................................................................................................................. 8

4.4 End fittings ................................................................................................................................................................................................. 9

4.5 Ultimate load .........................................................................................................................................................................................10

4.6 Elongation ................................................................................................................................................................................................11

4.7 Environment ..........................................................................................................................................................................................11

4.8 Operator safety ....................................................................................................................................................................................11

5 Testing ..........................................................................................................................................................................................................................11

5.1 General ........................................................................................................................................................................................................11

5.2 Testing apparatus ..............................................................................................................................................................................12

5.3 Sleeves test ..............................................................................................................................................................................................13

5.4 Ultimate load and elongation test ........................................................................................................................................13

5.5 Cyclic load test ......................................................................................................................................................................................14

5.6 Test record ...............................................................................................................................................................................................15

6 Quality control .....................................................................................................................................................................................................15

7 Markings ....................................................................................................................................................................................................................16

8 Options .........................................................................................................................................................................................................................16

9 Manufacturer's instructions ..................................................................................................................................................................18

10 Operating instructions ................................................................................................................................................................................18

Bibliography .............................................................................................................................................................................................................................20

© ISO 2020 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 20291-1:2020(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/ iso/ foreword .html.International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International

Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies

casting a vote.ISO 20291-1 was prepared by Technical Committee ISO/TC 20, Aircraft and space vehicles, Subcommittee

SC 9, Air cargo and ground equipment.This is the first edition of this document.

ISO 20291 consists of the following parts, under the general title Air cargo — Restraint slings:

— Part 1:Design and testing— Part 2: Utilization guidelines and tie down calculations [in preparation]

iv © ISO 2020 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/DIS 20291-1:2020(E)

Introduction

The aim of this Part of ISO 20291 is to standardize the design and testing requirements for air cargo

restraint sling assemblies used as an alternate to restraint straps for tie-down of cargo on board civil

transport aircraft.The civil aviation requirements referred to in the present document are those relating to the design of

transport aircraft. They constitute the set of design requirements internationally agreed in application

of International Civil Aviation Organization (ICAO) Annex 6, Airworthiness of aircraft, to the Convention

on International Civil Aviation.Throughout this document, the minimum essential criteria are identified by use of the key word "shall".

Recommended criteria are identified by use of the key word “should” and, while not mandatory, are

considered of primary importance in providing safe air cargo restraint sling assemblies. Deviation from

recommended criteria should only occur after careful consideration and thorough service evaluation

have shown alternate methods to provide an equivalent level of safety.The requirements of this part of ISO 20291 are expressed in the applicable SI units, with approximate

inch-pound units conversion between brackets for convenience in those countries using that system.

© ISO 2020 – All rights reserved v---------------------- Page: 5 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 20291-1:2020(E)

Air cargo — Restraint slings —

Part 1:

Design and testing

1 Scope

This document specifies the design criteria and testing methods adequate to guarantee the ultimate

strength and operational dependability of cargo restraint sling assemblies made of steel wire rope,

with a 22,25 kN (5 000 lbf) rated ultimate load capability, as can be used by the airline industry in

order to restrain on board civil transport aircraft during flight:a) cargo loaded and tied down onto airworthiness approved air cargo pallets, themselves restrained

into aircraft lower deck, main deck or upper deck cargo systems and meeting the requirements of

ISO 8097 (NAS 3610) or ISO 21100, orb) non unitized individual pieces of cargo, or pieces of cargo placed onto an unrestrained ("floating")

pallet into either lower deck, main deck or upper deck containerized cargo compartments of an

aircraft, to be restrained onto aircraft structure attachment (tie-down) points.2 (two) types of wire rope restraint slings are defined:

a) type A: adjustable length restraint sling assemblies, including a tension retaining device and

termination fittings attached to the wire rope end eyes.b) type B: fixed length restraint sling extensions, to be used in conjunction with a type A cable.

Extensions are usually terminated at both ends by eyes, without additional fittings, and can be

attached through hooks or shackles.Cable assemblies made of steel wire rope are intended to be used in lieu of cargo restraint straps

meeting the requirements of ISO 16049-1, where straps inherent elongation under tension appears

unadvisable for a given tie-down arrangement. Typical examples of loads where substitution of cables

for straps throughout a given tie-down arrangement can be advisable are those for which even limited

movement during flight could be hazardous, such as: heavy vehicles, aircraft engine stands, helicopters,

machinery, etc...The cables specified in this document are intended exclusively for restraint purposes on board aircraft,

and not for use as lifting slings.On the date of publication of this document, no airworthiness approval procedure by Civil Aviation

Authorities is applicable to restraint slings. Their use for cargo restraint, however, remains subject to the

requirements of the approved aircraft type or sub-type Weight and Balance Manual: see ISO 20291-2.

2 Normative referencesThe following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

NOTE Also see informative references in Bibliography.ISO 2408, Steel wire ropes — Requirements

ISO 3108, Steel wire ropes — Test method — Determination of measured breaking force

© ISO 2020 – All rights reserved 1---------------------- Page: 6 ----------------------

ISO/DIS 20291-1:2020(E)

ISO 4117, Air and air/land cargo pallets — Specification and testing

ISO 4171, Air cargo equipment — Interline pallets

ISO 4346, Steel wire ropes for general purposes — Lubricants — Basic requirements

ISO 7166, Aircraft — Rail and stud configuration for passenger equipment and cargo restraint

ISO 7531, Wire rope slings for general purposes — Characteristics and specifications

ISO 7597, Forged steel lifting hooks with latch, grade 8ISO 8097:2001, Aircraft — Minimum airworthiness requirements and test conditions for certified air cargo

unit load devicesISO 8793, Steel wire ropes — Ferrule-secured eye terminations

ISO 8794, Steel wire ropes — Spliced eye terminations for cables

ISO 9788, Air cargo — Double stud tie-down fittings — Design and testing requirements

ISO 10254, Air cargo and ground equipment — VocabularyISO 16049-1, Air cargo — Restraint straps — Part 1: Design criteria and testing methods (TSO/ETSO C172a)

ISO 16049-2, Air cargo — Restraint straps — Part 2: Utilization guidelines and lashing calculations

ISO 17893, Steel wire ropes — Vocabulary, designation and classificationISO 20291-2, Air cargo — Restraint slings — Part 2: Utilization guidelines and lashing calculations

[in preparation]ISO 21100, Air cargo unit load devices — Performance requirements and test parameters (TSO/ETSO C90d)

CAAC CCAR-25, Airworthiness Standards — Transport Category AirplanesCS-25, Certification Specifications for Large Aeroplanes

JAS Part 3 (Civil Aeronautics Law Article 10 § 4)

14 CFR Part 25, Airworthiness Standards: Transport Category Airplanes

3 Terms and definitions

For the purpose of this document, the definitions in ISO 10254, ISO 17893 and the following apply:

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp1) CAAC CCAR-25 constitutes the Chinese government transport aircraft airworthiness approval Standards, and

can be obtained from the Civil Aviation Authority of China (CAAC).2) EASA CS-25 constitutes the European governments transport aircraft airworthiness approval Standards, and

can be obtained from: European Aviation Safety Agency (EASA), Otto Platz 1, Postfach 101253, D-50452 Cologne,

Germany, or at www .easa .europa .eu.3) The Japanese Airworthiness Standard Part 3 (ISBN 4-89279-661-1) constitutes the Japanese government

transport aircraft airworthiness approval Standards, and can be obtained from the Civil Aviation Bureau (CAB) of

the Ministry of Land, Infrastructure, Tourism and Transport, Tokyo, Japan, or at www .mlit .go .jp .en.

4) 14 CFR Part 25 constitutes the U.S.A. government transport aircraft airworthiness approval Standards, and

can be obtained from: U.S. Government Printing Office, Mail Stop SSOP, Washington DC 20402-9328, or at www

.gpoaccess .gov .ec .fr.2 © ISO 2020 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/DIS 20291-1:2020(E)

— IEC Electropedia: available at http:// www .electropedia .org/

3.1

restraint sling assembly (type A)

elementary tie-down unit made of steel wire rope cable with end fittings and tension retaining device,

used for restraint of cargo on board civil transport aircraft. It consists of 1 (one) fixed length end and

one adjustable end, and can be used in conjunction with one or two extensions(s)3.2

restraint sling extension (type B)

fixed length steel wire rope (cable) with end eyes but no tension retaining device, with or without

end fittings, used in conjunction with a restraint sling assembly to extend usable length between

attachment points3.3

tie-down

fact of restraining cargo movements in relation to an aircraft's structure, throughout the range of

relative accelerations resulting from the allowable flight envelope, by means of an appropriate use of a

number of elementary tie-down devices against each direction of restraint3.4

tensioning device

mechanical device inducing and maintaining a tensile force in the load restraint assembly (e.g. lever,

ratchet, winch, cam, over-centre device, or equivalent)3.5

tension retaining device

part connecting to the wire rope and retaining any force induced between the ends of the assembly

3.6end fitting

connecting component

metallic device connecting a wire rope end to the attachment point on the aircraft structure, the pallet

edge track, another restraint element, or the load to be restrained (see examples in Figure 3, D1 to D3)

Note 1 to entry: The end fittings most commonly used on air cargo restraint slings include:

(a) retainer or latch equipped hook (see example in Figure 3, D1),(b) air cargo tie-down double stud (male) fitting (see example in Figure 3, D4) conforming to ISO 9788,

connected to the cable directly or through an intermediate ring,(c) ring (see example in Figure 3, D2) or wire rope end loop (eye) compatible with hooks.

3.7tension force indicator

device that indicates the tensile force applied to the restraint sling assembly (see example in Figure 3, C)

3.8length of restraint sling assembly

3.8.1

fixed length (l )

length of a fixed end, measured from the force bearing point of the end fitting to the outer turning

radius of the connection of the wire rope to the tension retaining device (see Figure 1)

Note 1 to entry: This length can be zero, i.e. the end fitting directly attached to the tensioning device.

© ISO 2020 – All rights reserved 3---------------------- Page: 8 ----------------------

ISO/DIS 20291-1:2020(E)

3.8.2

adjustable length (l )

maximum length of an adjustable end, measured from the tension device to the force bearing point of

the end fitting (see Figure 1)3.8.3

total length (l)

(l ) + (l ) + length of the tension retaining device

GF GL

Key

1 fixed end

2 adjustable end

3 end fitting

4 tension retaining device

l length

Figure 1 — Adjustable (type A) restraint sling assembly

3.9

length of restraint sling extension (l)

length measured between the force bearing points of each terminal, whether thimbles, hooks or rings

(see Figure 2)Key

1 ferrule

2 thimble

3 end fitting (ring)

4 end fitting (hook)

l length

Figure 2 — Fixed length (type B) restraint sling extensions

3.10

breaking force (BF)

maximum force that the restraint sling assembly withstands when tested in a complete form, i.e. with

tension retaining device and end fittings4 © ISO 2020 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/DIS 20291-1:2020(E)

3.11

hand force (H )

force applied to adjust, latch, or unlatch the restraint sling assembly

3.12

limit load (LL)

maximum load to be expected in service, see CAAC CCAR-25, CS-25, JAS Part 3 or 14 CFR Part 25,

§ 25.301 (a)Note 1 to entry: It is two thirds of ultimate load (see 3.13), i.e. 14,8 kN (3 333 lbf) for a rated ultimate load of

22,2 kN (5 000 lbf).3.13

ultimate load (UL)

limit load multiplied by a safety factor of 1,5, see CAAC CCAR-25, CS-25, JAS Part 3 or 14 CFR Part 25,

§ 25.303Note 1 to entry: It is used for computation of cargo tie-down arrangements, based on the ultimate load factors

defined in the aircraft Weight and Balance Manual in each direction of restraint, throughout the certified flight

envelope of the aircraft type. The restraint sling assembly's rated ultimate load must not exceed the measured

breaking force (BF).3.14

residual tension

tension force which can be measured in the rope of a cable assembly attached between two fixed points,

after its length was adjusted and it was operated and latched with the reference hand force (H ), prior

to application of any external load3.15

competent person

designated person, suitably trained, qualified by knowledge and practical experience and with the

necessary instructions to enable the required tests and examinations to be carried out

[[2]]Note 1 to entry: A competent person can be suitably trained in accordance with 7.2 of ISO 9001:2015, (see in

Bibliography).© ISO 2020 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/DIS 20291-1:2020(E)

Key

A restraint sling assembly (complete) D connecting elements

A1 marking (label) D1 hook with retainer or latch

B tension holding element D2 end ring

B1 steel wire rope D3 shackle with steel pin

C tensioning device (optional) D4 double stud tie-down fitting

C1 possible tension arrangement E1 tension force indicator

C2 example of rope tensioner D connecting elements

Figure 3 — Examples of restraint sling equipment

4 Design requirements

Unless otherwise specified, the design requirements hereafter equally apply to type A and type B

restraint slings as defined in Article 1, Scope, of this document.4.1 General

4.1.1 This document specifies the design criteria for individual restraint sling assemblies, but does

not intend specifying the way they are to be used aboard aircraft to ensure proper restraint throughout

the certified flight envelope. Tie-down arrangements shall meet all the applicable requirements of the

Weight and Balance Manual for the aircraft type or sub-type concerned, particularly as regards, but not

6 © ISO 2020 – All rights reserved---------------------- Page: 11 ----------------------

ISO/DIS 20291-1:2020(E)

necessarily limited to, ultimate load factors to be taken into account to determine the number of cables

to be used in each direction of restraint, maximum angles to be observed with the direction of restraint,

minimum spacing and ultimate load capacity of attachment points, etc.4.1.2 When restraint sling assemblies are attached to the edge rails of a certified air cargo pallet

meeting the requirements of ISO 8097 (NAS 3610) or ISO 21100 (AS 36100A), operating instructions

should duly take into account the restraint net attachment point locations on the pallet edge rail and other

requirements defined by the appropriate ISO 8097 (NAS 3610) or ISO 21100 (AS 36100A) configuration

drawing(s).4.1.4 Subject to proper operating instructions per 4.1.1 and 4.1.2 being defined and complied with,

using restraint sling assemblies manufactured to an adequate design and a tested ultimate load capability

is nevertheless deemed necessary in order to ensure flight safety. General utilization guidelines and

calculation methods adequate to guarantee the effectiveness and ultimate load strength of the tie-down

arrangements performed with cables to restrain cargo on board civil transport aircraft can be found in

ISO 20291-2.4.1.5 The restraint sling assembly shall be designed to be used on and compatible with:

a) the edge rails of air cargo pallets meeting the requirements of ISO 4117 or ISO 4171, airworthiness

approved according to ISO 8097 (NAS 3610, TSO C90c) or ISO 21100 (AS36100A, TSO C90d), or

b) aircraft floor tracks or structural attachment points meeting the requirements of ISO 7166,

either directly, or using ISO 9788 double stud tie-down fittings as intermediate attachment hardware.

4.2 Construction4.2.1 Wire rope shall meet the requirements of ISO 2408, should be of its Annex C class 6x7-FC or

6x7-IWRC, grade 1960 N/mm , 6 mm (¼ inch) diameter, of minimum breaking force 23,4 kN or 25,3 kN,

and should be galvanized (zinc-coated) or stainless steel, of a construction appropriate to guarantee the

required breaking force while keeping maximum flexibility.Note 1 to entry using steel grade 1770 N/mm usually results in a lower breaking force.

4.2.2 In exception from ISO 7531, justified by airworthiness standards (CAAC CCAR-25, CS-25,

JAS Part 3 or 14 CFR Part 25, § 25.303) applicable aboard aircraft, the minimum breaking force of the

new unfinished wire rope shall be the rated ultimate load (UL) of the complete restraint sling assembly

(see 4.5).4.2.3 All wire rope end eyes shall be secured with stainless steel crimped ferrules or swaging sleeves

in accordance with ISO 8793 (see Figure 2). Using cable grips, clips or clamps, or splicing per ISO 8794

are not allowed. The minimum length of plain rope between the inside ends of ferrules terminating a

same wire rope shall be 20 times the nominal rope diameter.4.2.4 All wire rope end eyes shall be protected against direct contact of attached fittings with rope by

a thimble appropriate to the wire rope's diameter, preferably made of galvanized or stainless steel or

aluminium alloy, or otherwise protected against corrosion. Soft or spliced loops are not allowed.

4.2.5 Where a wire rope end has no eye loop, e.g. at a free end of the adjustable end of a type A cable, it

shall be fitted with a stainless steel crimped ferrule stop in order to avoid its disengagement and strands

unwinding.4.2.6 Optionally, all (for type B fixed length extensions) or part (the fixed end of type A adjustable

length cables) of the wire rope may be enclosed in protective semi-soft, e.g. polyamide, PVC or similar,

© ISO 2020 – All rights reserved 7---------------------- Page: 12 ----------------------

ISO/DIS 20291-1:2020(E)

non-load bearing tubing in order to protect it, the hands of the operators, and any piece of cargo an

extension might be passed around (see ISO 20291-2). See 8.3. If provided, such tubing shall be:

a) transparent in order to allow visual cable inspection and verification that it is not broken nor

unduly bent, andb) rigid enough to ensure that the minimum bending radius the wire cable can withstand (see wire

rope manufacturer’s information) is exceeded around a piece of cargo up to at least the cable's

breaking force.4.2.7 In order to allow length adjustment, the wire rope of the adjustable end (l ) of type A cables shall

be fitted with stainless steel ferrules (sleeves) at regular intervals to allow catching by the load retaining

device, capable of withstanding the tension loads sustained during flight. See Figure 4 for dimensions

required.Figure 4 — Type A restraint sling adjustable end sleeves

4.2.8 The load bearing ferrules (sleeves) shall meet the applicable requirements of ISO 8397.

In addition, each sleeve should be attached to the wire rope in such a manner as to be capable of

withstanding in either direction at least 1,25 times the nominal ultimate load of the cable assembly.

See 5.3 for verification testing.4.3 Tension retaining device

4.3.1 Type A adjustable restraint sling assemblies shall include a tension retaining device at the free

end, opposite to the end fitting, of the fixed length (l ) not bearing sleeves.They do not require a tensioning device capable of inducing a wire rope pre-tension. This may

nevertheless be provided as an option (see 8.6), subject to meeting the device elongation requirements

(see 4.6).The type of tension retaining and, if provided, tensioning devices of type A adjustable length restraint

sling assemblies is to be selected on agreement between the manufacturer and the purchaser.

4.3.2 The tension retaining devi...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.