ISO 13703-3

(Main)Oil and gas industries including lower carbon energy — Piping systems on offshore production platforms and onshore plants — Part 3: Fabrication

Oil and gas industries including lower carbon energy — Piping systems on offshore production platforms and onshore plants — Part 3: Fabrication

Industries du pétrole et du gaz, y compris les énergies à faible émission de carbone — Conception et installation des systèmes de tuyauterie sur les plates-formes de production en mer et les installations à terre — Partie 3: Fabrication

General Information

Relations

Buy Standard

Standards Content (Sample)

Date: 2023-04-21 Style Definition: Heading 1: Indent: Left: 0 pt, First

line: 0 pt, Tab stops: Not at 21.6 pt

ISO/FDIS 13703-3:2023(E)

Style Definition: Heading 2: Font: Bold, Tab stops: Not

at 18 pt

Style Definition: Heading 3: Font: Bold

ISO/TC 67/SC 6/WG 5

Style Definition: Heading 4: Font: Bold

Date: 2023-xx

Style Definition: Heading 5: Font: Bold

Secretariat: AFNOR Style Definition: Heading 6: Font: Bold

Style Definition: ANNEX

Style Definition: AMEND Terms Heading: Font: Bold

Style Definition: AMEND Heading 1 Unnumbered:

Font: Bold

Formatted: Font: Bold, French (Switzerland)

Formatted: Font: Bold

Oil and gas industries including lower carbon energy — Piping systems on offshore

platforms and onshore plants — Part 3: Fabrication

Industries pétrolières et gazières, y compris les énergies à faible émission de carbone —

Conception et installation des systèmes de tuyauterie sur les plates-formes de production en mer

et les installations à terre — Partie 3 : Fabrication

---------------------- Page: 1 ----------------------

ISO/FDIS 13703-3:2023(E)

© ISO 2023

Commented [eXtyles1]: The reference is to a withdrawn

standard which has been replaced

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part

ISO 20344, Personal protective equipment — Test methods

of this publication may be reproduced or utilized otherwise in any form or by any means, electronic or

for footwear

mechanical, including photocopying, or posting on the internet or an intranet, without prior written

Formatted: Pattern: Clear

permission. Permission can be requested from either ISO at the address below or ISO’s member body

in the country of the requester.

Formatted: Pattern: Clear

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.orgwww.iso.org

Published in Switzerland

ii © ISO 2023 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/FDIS 13703-3:2023(E)

Contents

Foreword . v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 3

4 Abbreviated terms . 7

4.1 Symbols . 7

4.2 Abbreviated terms . 8

5 Health, safety and quality requirements . 9

5.1 Health and safety requirements . 9

5.2 Quality requirement . 10

6 Welding requirements . 12

6.1 General requirements . 12

6.2 Welding processes . 12

6.3 Preparation for welding . 13

6.4 Welder and welding operator performance qualification . 15

7 Welding consumables . 17

7.1 General requirements . 17

7.2 Additional requirements for carbon steel . 18

7.3 Additional requirements for dissimilar welding . 18

7.4 Additional requirements for SS 300-series . 18

7.5 Additional requirements for SS type 22Cr duplex and SS type 25Cr duplex . 19

7.6 Additional requirements for high alloy stainless steels . 19

7.7 Shielding, backing and secondary trailing gases . 19

8 Welding procedure qualification . 20

8.1 General requirements . 20

8.2 Additional requirements for carbon steels . 20

8.3 Additional requirements for SS type 22Cr duplex and SS type 25Cr duplex . 21

8.4 Additional requirements for high alloyed austenitic stainless steels . 21

8.5 Additional requirements for CP titanium . 22

8.6 Additional requirements for materials in sour service . 22

8.7 Welding procedure qualification essential variable . 22

9 Preheat and post weld heat treatment’ . 26

9.1 Preheating . 26

9.2 Post weld heat treatment . 27

10 Bending of pipe . 29

10.1 General requirements . 29

10.2 Heat treatment of bends . 32

10.3 Examination of bends . 33

11 Installation . 34

11.1 General requirements . 34

11.2 Threaded connections . 34

11.3 Bolted connections . 34

12 Inspection, examination and testing . 35

© ISO 2023 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/FDIS 13703-3:2023(E)

12.1 General requirements . 35

12.2 Visual examination . 39

12.3 Magnetic particle examination . 39

12.4 Liquid penetrant examination. 40

12.5 Radiographic examination . 40

12.6 Ultrasonic examination . 41

12.7 Positive materials identification . 42

12.8 Production testing . 43

12.9 Weld metal ferrite testing . 44

12.10 Repairs and replacement . 45

13 Cleaning, leak testing and preservation . 46

13.1 General requirements . 46

13.2 Flushing and cleaning . 47

13.3 Leak testing . 48

13.4 Tightness testing . 49

13.5 Preservation . 50

Annex A (informative) Reference images for oxidation of weldments . 51

Annex B (normative) Requirements for cold bending of pipes . 54

Annex C (Normative) Requirements for hot induction bending of pipes . 58

Annex D (Informative) Guidance to European Pressure Equipment Directive . 60

Bibliography . 61

Foreword . v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 3

4 Abbreviated terms . 7

4.1 Symbols . 7

4.2 Abbreviated terms . 8

5 Health, safety and quality requirements . 9

5.1 Health and safety requirements . 9

5.2 Quality requirement . 10

6 Welding requirements . 12

6.1 General requirements . 12

6.2 Welding processes . 12

6.3 Preparation for welding . 13

6.4 Welder and welding operator performance qualification . 15

7 Welding consumables . 17

7.1 General requirements . 17

7.2 Additional requirements for carbon steel . 18

7.3 Additional requirements for dissimilar welding . 18

7.4 Additional requirements for SS 300-series . 18

7.5 Additional requirements for SS type 22Cr duplex and SS type 25Cr duplex . 19

7.6 Additional requirements for high alloy stainless steels . 19

7.7 Shielding, backing and secondary trailing gases . 19

iv © ISO 2023 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/FDIS 13703-3:2023(E)

8 Welding procedure qualification . 20

8.1 General requirements . 20

8.2 Additional requirements for carbon steels . 20

8.3 Additional requirements for SS type 22Cr duplex and SS type 25Cr duplex . 21

8.4 Additional requirements for high alloyed austenitic stainless steels . 21

8.5 Additional requirements for CP titanium . 22

8.6 Additional requirements for materials in sour service . 22

8.7 Welding procedure qualification essential variable . 22

9 Preheat and post weld heat treatment’ . 26

9.1 Preheating . 26

9.2 Post weld heat treatment . 27

10 Bending of pipe . 29

10.1 General requirements . 29

10.2 Heat treatment of bends . 32

10.3 Examination of bends . 33

11 Installation . 34

11.1 General requirements . 34

11.2 Threaded connections . 34

11.3 Bolted connections . 34

12 Inspection, examination and testing . 35

12.1 General requirements . 35

12.2 Visual examination . 39

12.3 Magnetic particle examination . 39

12.4 Liquid penetrant examination . 40

12.5 Radiographic examination . 40

12.6 Ultrasonic examination . 41

12.7 Positive materials identification . 42

12.8 Production testing . 43

12.9 Weld metal ferrite testing . 44

12.10 Repairs and replacement . 45

13 Cleaning, leak testing and preservation . 46

13.1 General requirements . 46

13.2 Flushing and cleaning . 47

13.3 Leak testing . 48

13.4 Tightness testing . 49

13.5 Preservation . 50

Annex A (informative) Reference images for oxidation of weldments . 51

Annex B (normative) Requirements for cold bending of pipes . 54

Annex C (normative) Requirements for hot induction bending of pipes . 58

Annex D (informative) Guidance to European Pressure Equipment Directive . 60

Bibliography . 61

© ISO 2023 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/FDIS 13703-3:2023(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

Formatted: Adjust space between Latin and Asian text,

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

Adjust space between Asian text and numbers

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

Commented [eXtyles2]: The URL

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work. ISO

https://www.iso.org/iso/foreword.html has been redirected to

collaborates closely with the International Electrotechnical Commission (IEC) on all matters of http://www.iso.org/foreword-supplementary-

information.html. Please verify the URL.

electrotechnical standardization.

Commented [eXtyles3]: ISO 13703-3: current stage is

The procedures used to develop this document and those intended for its further maintenance are 50.00

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

Commented [eXtyles4]: Not found, but similar references

different types of ISO documentsdocument should be noted. This document was drafted in accordance

exist

with the editorial rules of the ISO/IEC Directives, Part 2 (see

ISO 13703-1, Petroleum and natural gas industries — Piping

www.iso.org/directiveswww.iso.org/directives).

systems on offshore production platforms and onshore plants

— Part 1: Design

Attention is drawnISO draws attention to the possibility that some of the elementsimplementation of this

Commented [eXtyles5]: ISO 13703-2: current stage is

document may beinvolve the subjectuse of (a) patent(s). ISO takes no position concerning the evidence,

50.00

validity or applicability of any claimed patent rights. in respect thereof. As of the date of publication of

Formatted: Pattern: Clear

this document, ISO had not received notice of (a) patent(s) which may be required to implement this

document. However, implementers are cautioned that this may not represent the latest information,

Formatted: Pattern: Clear

which may be obtained from the patent database available at www.iso.org/patents. ISO shall not be held

Formatted: Pattern: Clear

responsible for identifying any or all such patent rights. Details of any patent rights identified during the

Formatted: Pattern: Clear

development of the document will be in the Introduction and/or on the ISO list of patent declarations

received (see www.iso.org/patents).

Formatted: Pattern: Clear

Formatted: Pattern: Clear

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

Formatted: Pattern: Clear

Formatted: Pattern: Clear

For an explanation onof the voluntary nature of standards, the meaning of ISO specific terms and

Formatted: Pattern: Clear

expressions related to conformity assessment, as well as information about ISO's adherence to the World

Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following URL:

Formatted: Pattern: Clear

www.iso.org/iso/foreword.html.), see www.iso.org/iso/foreword.html.

Formatted: Pattern: Clear

Formatted: Pattern: Clear

This document was prepared by Technical Committee ISO/TC 67, Oil and gas industries including lower

carbon energy, Subcommittee SC 6, Process equipment, piping, systems, and related safety, in collaboration

Formatted: Pattern: Clear

with the European Committee for Standardization (CEN) Technical Committee CEN/TC 12, Materials,

Formatted: Pattern: Clear

equipment and offshore structures for petroleum, petrochemical and natural gas industries, in

accordance with the Agreement on technical cooperation between ISO and CEN (Vienna Agreement). Formatted: Pattern: Clear

Formatted: Pattern: Clear

This first edition of ISO 13703-3, together with ISO 13703-1 and ISO 13703-2, cancels and replaces

Formatted: Pattern: Clear

ISO 13703:2000. It also incorporates the Technical Corrigendum ISO 13703:2000/Cor.1:2002.

Formatted: Default Paragraph Font

The main changes compared to the previous edition are as follows:

Formatted: Pattern: Clear

Formatted: Pattern: Clear

— deletion of the installation and quality control requirements of Clause 10;

Formatted: Pattern: Clear

— deletion of previous Annex C as requirements are addressed in ASME B31.3.

Commented [eXtyles6]: Invalid reference: "ISO 13703

series"

A list of all parts in the ISO 13703 series can be found on the ISO website.

Formatted: Pattern: Clear

Formatted: Pattern: Clear

Formatted: Pattern: Clear

vi © ISO 2023 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/FDIS 13703-3:2023(E)

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at

www.iso.org/members.htmlwww.iso.org/members.html.

© ISO 2023 – All rights reserved vii

---------------------- Page: 7 ----------------------

ISO/FDIS 13703-3:2023(E)

Introduction

The aim of this document is to establish common requirements for the fabrication, welding, inspection,

examination and testing of new, metallic process piping systems designed in accordance with the

requirements of ISO 13703-1, and using bulk piping materials in accordance with ISO 13703-2.

Commented [eXtyles7]: Not found, but similar references

exist

This document makes normative reference to ASME B31.3 as the base code for process piping. Alternative

codes to ASME B31.3 exist for the fabrication, welding, inspection, examination and testing of process

ISO 13703-1, Petroleum and natural gas industries — Piping

systems on offshore production platforms and onshore plants

piping systems along with the potential need to comply with local or national regulatory/jurisdictional

— Part 1: Design

requirements. The user of this document is expected to assess the implications arising from local or

national regulatory/jurisdictional requirements in implementing the requirements herein, including the Commented [eXtyles8]: ISO 13703-2: current stage is

50.00

need to specify additional requirements to those stated. ASME B31.3, Appendix N provides guidance on

its use internationally, and specifically its use within the European Union for which additional

Formatted: Pattern: Clear

requirements to those specified in ASME B31.3 will be necessary to meet the requirements of Directive

Formatted: Pattern: Clear

2014/68/EU on the harmonization of the laws of the Member States relating to the making available on

Formatted: Pattern: Clear

the market of pressure equipment (PED).

Formatted: Pattern: Clear

This document is not intended to inhibit a user from accepting alternative fabrication, welding,

examination or testing solutions for the individual application. This can be particularly appropriate Formatted: Pattern: Clear

where there is innovative or developing technology. Where an alternative to the requirements in this

Formatted: Pattern: Clear

document is offered, the user is expected to review the implications in meeting the performance

Formatted: Pattern: Clear

requirements within this document.

Formatted: Pattern: Clear

Formatted: Pattern: Clear

Formatted: Pattern: Clear

Formatted: Pattern: Clear

Formatted: Pattern: Clear

Commented [eXtyles9]: eXtyles Inline Standards Citation

Match has detected that the standard reference "ASME

B31.3, Appendix N" refers a specific part of an undated

standard. Because part numbers may change between

editions, please check the part number for accuracy or

change to a dated reference.

Formatted: Pattern: Clear

Formatted: Pattern: Clear

Formatted: Pattern: Clear

Formatted: Pattern: Clear

Formatted: Pattern: Clear

Formatted: Pattern: Clear

Formatted: Pattern: Clear

viii © ISO 2023 – All rights reserved

---------------------- Page: 8 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 13703-3:2023(E)

Oil and gas industries including lower carbon energy — Piping

systems on offshore platforms and onshore plants — Part 3 :

Fabrication

1 Scope

This document specifies requirements for the fabrication, installation, welding, inspection, examination

and testing of new, metallic piping systems , within temperature range limits for the materials meeting

the requirements of ASME B31.3, on fixed and floating offshore production facilities and onshore

Formatted: Pattern: Clear

production, processing and gas liquefaction plants. For piping systems above pressure class 2500, the

Formatted: Pattern: Clear

requirements of chapter IX of ASME B31.3 shall be complied with, in addition to the requirements stated

Formatted: Pattern: Clear

in this standard.

Formatted: Pattern: Clear

This document is applicable to all pressure retaining components and any non-pressure retaining

component, such as a member of a pipe support, welded directly to a pressure retaining component.

Formatted: Pattern: Clear

Formatted: Pattern: Clear

This document is not applicable to the following:

— marine-related piping systems, e.g. ballasting piping systems, systems covered by classification

societies;

— metallic tubing used for subsea umbilical systems;

NOTE 1 Reference can be made to ISO 13628-5 or API Spec 17E for welding and e

...

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 13703-3

ISO/TC 67/SC 6

Oil and gas industries including lower

Secretariat: AFNOR

carbon energy — Piping systems on

Voting begins on:

2023-07-04 offshore production platforms and

onshore plants —

Voting terminates on:

2023-08-29

Part 3:

Fabrication

Industries du pétrole et du gaz, y compris les énergies à faible teneur

en carbone — Conception et installation des systèmes de tuyauterie

sur les plates-formes de production en mer et les installations à

terre —

Partie 3: Fabrication

ISO/CEN PARALLEL PROCESSING

RECIPIENTS OF THIS DRAFT ARE INVITED TO

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

DOCUMENTATION.

IN ADDITION TO THEIR EVALUATION AS

Reference number

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

ISO/FDIS 13703-3:2023(E)

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

NATIONAL REGULATIONS. © ISO 2023

---------------------- Page: 1 ----------------------

ISO/FDIS 13703-3:2023(E)

FINAL

INTERNATIONAL ISO/FDIS

DRAFT

STANDARD 13703-3

ISO/TC 67/SC 6

Oil and gas industries including lower

Secretariat: AFNOR

carbon energy — Piping systems on

Voting begins on:

offshore production platforms and

onshore plants —

Voting terminates on:

Part 3:

Fabrication

Industries du pétrole et du gaz, y compris les énergies à faible teneur

en carbone — Conception et installation des systèmes de tuyauterie

sur les plates-formes de production en mer et les installations à

terre —

Partie 3: Fabrication

COPYRIGHT PROTECTED DOCUMENT

© ISO 2023

ISO/CEN PARALLEL PROCESSING

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

RECIPIENTS OF THIS DRAFT ARE INVITED TO

ISO copyright office

SUBMIT, WITH THEIR COMMENTS, NOTIFICATION

OF ANY RELEVANT PATENT RIGHTS OF WHICH

CP 401 • Ch. de Blandonnet 8

THEY ARE AWARE AND TO PROVIDE SUPPOR TING

CH-1214 Vernier, Geneva

DOCUMENTATION.

Phone: +41 22 749 01 11

IN ADDITION TO THEIR EVALUATION AS

Reference number

Email: copyright@iso.org

BEING ACCEPTABLE FOR INDUSTRIAL, TECHNO-

ISO/FDIS 13703-3:2023(E)

Website: www.iso.org

LOGICAL, COMMERCIAL AND USER PURPOSES,

DRAFT INTERNATIONAL STANDARDS MAY ON

Published in Switzerland

OCCASION HAVE TO BE CONSIDERED IN THE

LIGHT OF THEIR POTENTIAL TO BECOME STAN-

DARDS TO WHICH REFERENCE MAY BE MADE IN

ii

© ISO 2023 – All rights reserved

NATIONAL REGULATIONS. © ISO 2023

---------------------- Page: 2 ----------------------

ISO/FDIS 13703-3:2023(E)

Contents Page

Foreword .v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 3

4 Abbreviated terms . 7

4.1 Symbols . 7

4.2 Abbreviated terms . 7

5 Health, safety and quality requirements . 9

5.1 Health and safety requirements . 9

5.2 Quality requirement . 10

6 Welding requirements .11

6.1 General requirements . 11

6.2 Welding processes . 12

6.3 Preparation for welding .12

6.4 Welder and welding operator performance qualification . 15

7 Welding consumables .15

7.1 General requirements .15

7.2 Additional requirements for carbon steel . 17

7.3 Additional requirements for dissimilar welding . 17

7.4 Additional requirements for SS 300-series . 17

7.5 Additional requirements for SS type 22Cr duplex and SS type 25Cr duplex . 17

7.6 Additional requirements for high alloy stainless steels . 17

7.7 Shielding, backing and secondary trailing gases . 18

8 Welding procedure qualification .18

8.1 General requirements . 18

8.2 Additional requirements for carbon steels . 19

8.3 Additional requirements for SS type 22Cr duplex and SS type 25Cr duplex . 19

8.4 Additional requirements for high alloyed austenitic stainless steels .20

8.5 Additional requirements for CP titanium . 20

8.6 Additional requirements for materials in sour service . 20

8.7 Welding procedure qualification essential variable . 21

9 Preheat and post weld heat treatment’ .23

9.1 Preheating . 23

9.2 Post weld heat treatment . 24

10 Bending of pipe .26

10.1 General requirements . 26

10.2 Heat treatment of bends . . 29

10.3 Examination of bends .30

11 Installation .31

11.1 General requirements . 31

11.2 Threaded connections . 31

11.3 Bolted connections . 31

12 Inspection, examination and testing .32

12.1 General requirements . 32

12.2 Visual examination . 35

12.3 Magnetic particle examination .36

12.4 Liquid penetrant examination . 36

12.5 Radiographic examination .36

iii

© ISO 2023 – All rights reserved

---------------------- Page: 3 ----------------------

ISO/FDIS 13703-3:2023(E)

12.6 Ultrasonic examination . 37

12.7 Positive materials identification .38

12.8 Production testing . 39

12.9 Weld metal ferrite testing .40

12.10 Repairs and replacement . 41

13 Cleaning, leak testing and preservation.42

13.1 General requirements . 42

13.2 Flushing and cleaning. 43

13.3 Leak testing .44

13.4 Tightness testing . 45

13.5 Preservation .46

Annex A (informative) Reference images for oxidation of weldments .47

Annex B (normative) Requirements for cold bending of pipes .50

Annex C (normative) Requirements for hot induction bending of pipes .54

Annex D (Informative) Guidance to European Pressure Equipment Directive .56

Bibliography .57

iv

© ISO 2023 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/FDIS 13703-3:2023(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 67, Oil and gas industries including lower

carbon energy, Subcommittee SC 6, Process equipment, piping, systems, and related safety, in collaboration

with the European Committee for Standardization (CEN) Technical Committee CEN/TC 12, Materials,

equipment and offshore structures for petroleum, petrochemical and natural gas industries, in

accordance with the Agreement on technical cooperation between ISO and CEN (Vienna Agreement).

This first edition of ISO 13703-3, together with ISO 13703-1 and ISO 13703-2, cancels and replaces

ISO 13703:2000. It also incorporates the Technical Corrigendum ISO 13703:2000/Cor.1:2002.

The main changes compared to the previous edition are as follows:

— deletion of the installation and quality control requirements of Clause 10;

— deletion of previous Annex C as requirements are addressed in ASME B31.3.

A list of all parts in the ISO 13703 series can be found on the ISO website.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

© ISO 2023 – All rights reserved

---------------------- Page: 5 ----------------------

ISO/FDIS 13703-3:2023(E)

Introduction

The aim of this document is to establish common requirements for the fabrication, welding, inspection,

examination and testing of new, metallic process piping systems designed in accordance with the

requirements of ISO 13703-1, and using bulk piping materials in accordance with ISO 13703-2.

This document makes normative reference to ASME B31.3 as the base code for process piping.

Alternative codes to ASME B31.3 exist for the fabrication, welding, inspection, examination and testing

of process piping systems along with the potential need to comply with local or national regulatory/

jurisdictional requirements. The user of this document is expected to assess the implications arising

from local or national regulatory/jurisdictional requirements in implementing the requirements

herein, including the need to specify additional requirements to those stated. ASME B31.3, Appendix N

provides guidance on its use internationally, and specifically its use within the European Union

for which additional requirements to those specified in ASME B31.3 will be necessary to meet the

requirements of Directive 2014/68/EU on the harmonization of the laws of the Member States relating

to the making available on the market of pressure equipment (PED).

This document is not intended to inhibit a user from accepting alternative fabrication, welding,

examination or testing solutions for the individual application. This can be particularly appropriate

where there is innovative or developing technology. Where an alternative to the requirements in

this document is offered, the user is expected to review the implications in meeting the performance

requirements within this document.

vi

© ISO 2023 – All rights reserved

---------------------- Page: 6 ----------------------

FINAL DRAFT INTERNATIONAL STANDARD ISO/FDIS 13703-3:2023(E)

Oil and gas industries including lower carbon energy —

Piping systems on offshore production platforms and

onshore plants —

Part 3:

Fabrication

1 Scope

This document specifies requirements for the fabrication, installation, welding, inspection, examination

and testing of new, metallic piping systems , within temperature range limits for the materials meeting

the requirements of ASME B31.3, on fixed and floating offshore production facilities and onshore

production, processing and gas liquefaction plants. For piping systems above pressure class 2500,

the requirements of chapter IX of ASME B31.3 shall be complied with, in addition to the requirements

stated in this standard.

This document is applicable to all pressure retaining components and any non-pressure retaining

component, such as a member of a pipe support, welded directly to a pressure retaining component.

This document is not applicable to the following:

— marine-related piping systems, e.g. ballasting piping systems, systems covered by classification

societies;

— metallic tubing used for subsea umbilical systems;

NOTE 1 Reference can be made to ISO 13628-5 or API Spec 17E for welding and examination of these

components.

— piping systems with corrosion resistant cladding (either integrally clad or mechanically lined) or

weld overlay, including buttering and associated dissimilar welds;

NOTE 2 Reference can be made to DNVGL-RP-B204 for welding and examination of these systems.

— refractory alloys [with exception of CP titanium Grade 1 (UNS R50250) or Grade 2 (UNS R50400)];

— non-metallic piping assemblies;

— transportation pipeline systems, including flow-lines, designed in accordance with a recognized

pipeline design code.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 3834-2, Quality requirements for fusion welding of metallic materials — Part 2: Comprehensive quality

requirements

ISO 8249, Welding — Determination of Ferrite Number (FN) in austenitic and duplex ferritic-austenitic Cr-

Ni stainless steel weld metals

1

© ISO 2023 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/FDIS 13703-3:2023(E)

ISO 9015-1, Destructive tests on welds in metallic materials — Hardness testing — Part 1: Hardness test on

arc welded joints

ISO 9606 (all parts), Qualification testing of welders — Fusion welding

ISO 9712, Non-destructive testing — Qualification and certification of NDT personnel

ISO 10474, Steel and steel products — Inspection documents

ISO 11666:2018, Non-destructive testing of welds — Ultrasonic testing — Acceptance levels

ISO 11699-1, Non-destructive testing — Industrial radiographic film — Part 1: Classification of film

systems for industrial radiography

ISO 14175, Welding consumables — Gases and gas mixtures for fusion welding and allied processes

ISO 14344, Welding consumables — Procurement of filler materials and fluxes

ISO 14731, Welding coordination — Tasks and responsibilities

ISO 14732, Welding personnel — Qualification testing of welding operators and weld setters for mechanized

and automatic welding of metallic materials

ISO 15156-2, Petroleum and natural gas industries — Materials for use in H2S containing environments in

oil and gas production — Part 2: Cracking-resistant carbon and low alloy steels, and the use of cast irons

ISO 15156-3, Petroleum and natural gas industries — Materials for use in H2S containing environments in

oil and gas production — Part 3: Cracking-resistant CRAs (corrosion-resistant alloys) and other alloys

ISO 15609-1, Specification and qualification of welding procedures for metallic materials — Welding

procedure specification — Part 1: Arc welding

ISO 15614-1, Specification and qualification of welding procedures for metallic materials — Welding

procedure test — Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

ISO 15614-5, Specification and qualification of welding procedures for metallic materials — Welding

procedure test — Part 5: Arc welding of titanium, zirconium and their alloys

ISO 15614-6, Specification and qualification of welding procedures for metallic materials — Welding

procedure test — Part 6: Arc and gas welding of copper and its alloys

ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories

ISO 17636-2, Non-destructive testing of welds — Radiographic testing — Part 2: X- and gamma-ray

techniques with digital detectors

ISO 17781:2017, Petroleum, petrochemical and natural gas industries — Test methods for quality control

of microstructure of ferritic/austenitic (duplex) stainless steels

ISO 18265, Metallic materials — Conversion of hardness values

ISO 22825, Non-destructive testing of welds — Ultrasonic testing — Testing of welds in austenitic steels

and nickel-based alloys

ANSI Z49.1, Safety in Welding, Cutting and Allied Processes

API RP 686, Machinery Installation and Installation Design

ASME B31.3, Process Piping

Boiler ASME, and Pressure Vessel Code, Section II, Materials, Part C:2019, Specifications for welding

rods, electrodes, and filler metals

Boiler ASME, and Pressure Vessel Code, Section V:2019, Non Destructive Testing

2

© ISO 2023 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/FDIS 13703-3:2023(E)

Boiler ASME, and Pressure Vessel Code, Section IX: 2019, Welding and Brazing Qualifications

ASNT CP-189, Standard for Qualification and Certification of Nondestructive Testing Personnel

ASNT SNT-TC-1A, Personnel Qualification and Certification in Nondestructive Testing

ASTM A380, Standard Practice for Cleaning, Descaling, and Passivation of Stainless Steel Parts, Equipment,

and Systems

ASTM E140, Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers

Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb

Hardness

ASTM E1815, Standard Test Method for Classification of Film Systems for Industrial Radiography

ASTM G48, Standard Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels and

Related Alloys by Use of Ferric Chloride Solution

AWS A4.2M, Standard Procedures for Calibrating Magnetic Instruments to Measure the Delta Ferrite

Content of Austenitic and Duplex Ferritic-Austenitic Stainless Steel

AWS D10.10, Recommended Practices for Local Heating of Welds in Piping and Tubing

EN 10204, Metallic products — Types of inspection documents

PFI ES-3, Fabricating Tolerances

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

alkaline service

service environments containing alkaline compounds such as amines, caustic, carbonates

3.2

bolted connection

connections with bolts, to allow assembly and disassembly, that uses flanges or clamps as connectors.

3.3

carbon equivalent

C

E

numerical value for a steel’s composition that represents the contribution of the relevant elements to

the hydrogen cracking susceptibility of steel

Note 1 to entry: The carbon equivalent is based on:

%%Mn Cr++%%Mo V %%Ni+ Cu

CC=+% + +

E

65 15

where all mass fractions are expressed in percent.

3

© ISO 2023 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/FDIS 13703-3:2023(E)

3.4

closure weld

final weld connecting piping systems, assemblies or sub-assemblies that have been successfully leak

tested, but that itself is not subject to leak testing

Note 1 to entry: Closure welds include any welds made after leak or tightness testing, such as seal welds to

threaded connections, or repair welds made in the event of a leak that are not subject to further leak test, if

approved by owner.

Note 2 to entry: Closure welds are often also referred to as ‘golden welds’.

3.5

computerized imaging technique

CIT

manual or encoded ultrasonic examination technique with capability for computer processed display

or analysis and display of ultrasonic data to provide two or three dimensional surfaces

3.6

confined space

space that is substantially but not necessarily entirely enclosed, and where serious injury can occur

from hazardous substances or conditions within the space or nearby (e.g. lack of oxygen)

Note 1 to entry: Confined space includes access into the internal bore of pipes to install, inspect and remove

internal backing gas dams, and during cleaning, flushing, leak and tightness testing activities.

3.7

cryogenic service

service environments with a minimum design temperature lower than –104 °C

3.8

low-alloy steel

steel with significant alloy additions (e.g. Groups 4 to 6 according to ISO 15608, or P-No. 3 to P-No 5 and

P-No. 15E according to ASME B31.3)

3.9

extrados

outer curved portion of a bend

3.10

fabricator

organization responsible for the fabrication, welding, examination and testing of piping systems

including any externally provided products or services

Note 1 to entry: For the purposes of this document, “fab

...

PROJET

NORME ISO/FDIS

FINAL

INTERNATIONALE 13703-3

ISO/TC 67/SC 6

Industries pétrolières et gazières,

Secrétariat: AFNOR

y compris les énergies à faible

Début de vote:

2023-07-04 émission de carbone — Conception

et installation des systèmes de

Vote clos le:

2023-08-29

tuyauterie sur les plates-formes de

production en mer et les installations

à terre —

Partie 3:

Fabrication

Oil and gas industries including lower carbon energy — Piping

systems on offshore production platforms and onshore plants —

Part 3: Fabrication

TRAITEMENT PARALLÈLE ISO/CEN

LES DESTINATAIRES DU PRÉSENT PROJET SONT

INVITÉS À PRÉSENTER, AVEC LEURS OBSER-

VATIONS, NOTIFICATION DES DROITS DE PRO-

PRIÉTÉ DONT ILS AURAIENT ÉVENTUELLEMENT

CONNAISSANCE ET À FOURNIR UNE DOCUMEN-

TATION EXPLICATIVE.

OUTRE LE FAIT D’ÊTRE EXAMINÉS POUR

ÉTABLIR S’ILS SONT ACCEPTABLES À DES FINS

INDUSTRIELLES, TECHNOLOGIQUES ET COM-

Numéro de référence

MERCIALES, AINSI QUE DU POINT DE VUE

ISO/FDIS 13703-3:2023(F)

DES UTILISATEURS, LES PROJETS DE NORMES

INTERNATIONALES DOIVENT PARFOIS ÊTRE

CONSIDÉRÉS DU POINT DE VUE DE LEUR POSSI-

BILITÉ DE DEVENIR DES NORMES POUVANT

SERVIR DE RÉFÉRENCE DANS LA RÉGLEMENTA-

TION NATIONALE. © ISO 2023

---------------------- Page: 1 ----------------------

ISO/FDIS 13703-3:2023(F)

PROJET

NORME ISO/FDIS

FINAL

INTERNATIONALE 13703-3

ISO/TC 67/SC 6

Industries pétrolières et gazières,

Secrétariat: AFNOR

y compris les énergies à faible

Début de vote:

2023-07-04 émission de carbone — Conception

et installation des systèmes de

Vote clos le:

2023-08-29

tuyauterie sur les plates-formes de

production en mer et les installations

à terre —

Partie 3:

Fabrication

Oil and gas industries including lower carbon energy — Piping

systems on offshore production platforms and onshore plants —

Part 3: Fabrication

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2023

TRAITEMENT PARALLÈLE ISO/CEN

Tous droits réservés. Sauf prescription différente ou nécessité dans le contexte de sa mise en œuvre, aucune partie de cette

publication ne peut être reproduite ni utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique,

LES DESTINATAIRES DU PRÉSENT PROJET SONT

y compris la photocopie, ou la diffusion sur l’internet ou sur un intranet, sans autorisation écrite préalable. Une autorisation peut

INVITÉS À PRÉSENTER, AVEC LEURS OBSER-

VATIONS, NOTIFICATION DES DROITS DE PRO-

être demandée à l’ISO à l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

PRIÉTÉ DONT ILS AURAIENT ÉVENTUELLEMENT

ISO copyright office

CONNAISSANCE ET À FOURNIR UNE DOCUMEN-

TATION EXPLICATIVE.

Case postale 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Genève OUTRE LE FAIT D’ÊTRE EXAMINÉS POUR

ÉTABLIR S’ILS SONT ACCEPTABLES À DES FINS

Tél.: +41 22 749 01 11

INDUSTRIELLES, TECHNOLOGIQUES ET COM-

Numéro de référence

E-mail: copyright@iso.org

MERCIALES, AINSI QUE DU POINT DE VUE

ISO/FDIS 13703-3:2023(F)

Web: www.iso.org

DES UTILISATEURS, LES PROJETS DE NORMES

INTERNATIONALES DOIVENT PARFOIS ÊTRE

Publié en Suisse

CONSIDÉRÉS DU POINT DE VUE DE LEUR POSSI-

BILITÉ DE DEVENIR DES NORMES POUVANT

SERVIR DE RÉFÉRENCE DANS LA RÉGLEMENTA-

ii

© ISO 2023 – Tous droits réservés

TION NATIONALE. © ISO 2023

---------------------- Page: 2 ----------------------

ISO/FDIS 13703-3:2023(F)

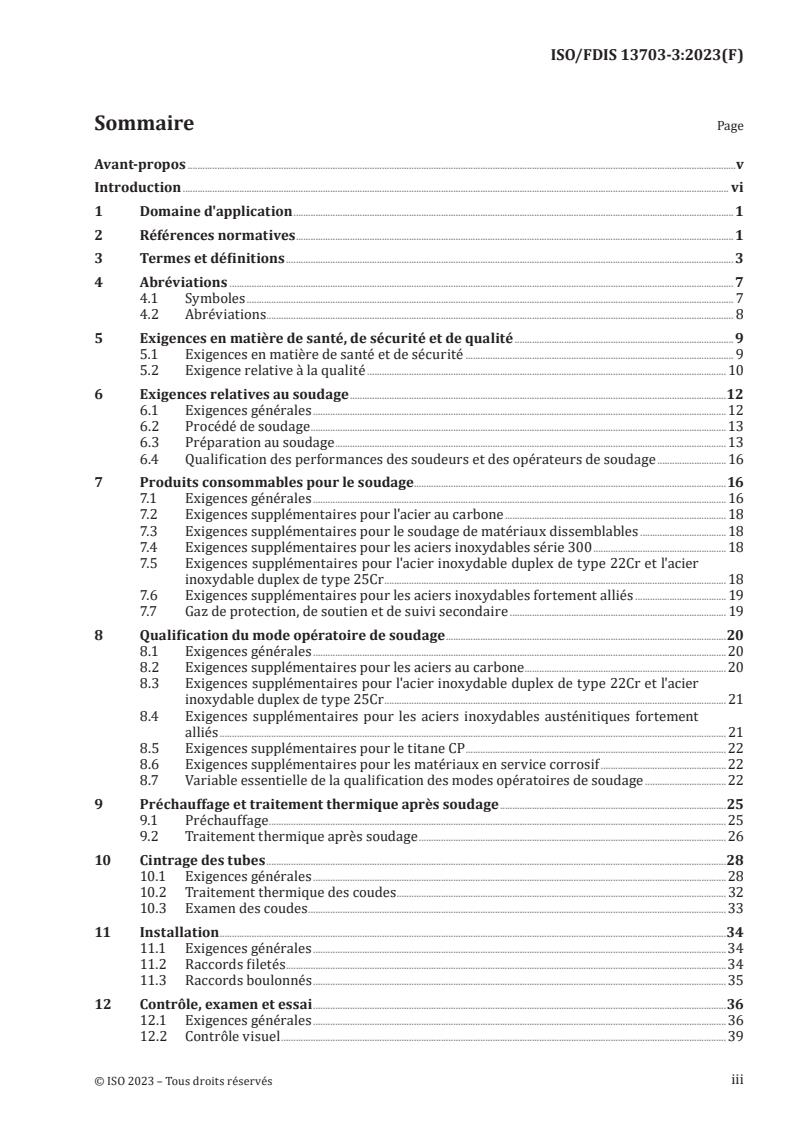

Sommaire Page

Avant-propos .v

Introduction . vi

1 Domaine d'application .1

2 Références normatives .1

3 Termes et définitions . 3

4 Abréviations . 7

4.1 Symboles . 7

4.2 Abréviations. 8

5 Exigences en matière de santé, de sécurité et de qualité . 9

5.1 Exigences en matière de santé et de sécurité . 9

5.2 Exigence relative à la qualité . 10

6 Exigences relatives au soudage .12

6.1 Exigences générales .12

6.2 Procédé de soudage .13

6.3 Préparation au soudage . 13

6.4 Qualification des performances des soudeurs et des opérateurs de soudage . 16

7 Produits consommables pour le soudage .16

7.1 Exigences générales . 16

7.2 Exigences supplémentaires pour l'acier au carbone . 18

7.3 Exigences supplémentaires pour le soudage de matériaux dissemblables . 18

7.4 Exigences supplémentaires pour les aciers inoxydables série 300 . 18

7.5 Exigences supplémentaires pour l'acier inoxydable duplex de type 22Cr et l'acier

inoxydable duplex de type 25Cr . 18

7.6 Exigences supplémentaires pour les aciers inoxydables fortement alliés . 19

7.7 Gaz de protection, de soutien et de suivi secondaire . 19

8 Qualification du mode opératoire de soudage .20

8.1 Exigences générales .20

8.2 Exigences supplémentaires pour les aciers au carbone . 20

8.3 Exigences supplémentaires pour l'acier inoxydable duplex de type 22Cr et l'acier

inoxydable duplex de type 25Cr . 21

8.4 Exigences supplémentaires pour les aciers inoxydables austénitiques fortement

alliés . 21

8.5 Exigences supplémentaires pour le titane CP . 22

8.6 Exigences supplémentaires pour les matériaux en service corrosif .22

8.7 Variable essentielle de la qualification des modes opératoires de soudage .22

9 Préchauffage et traitement thermique après soudage .25

9.1 Préchauffage . 25

9.2 Traitement thermique après soudage . 26

10 Cintrage des tubes .28

10.1 Exigences générales .28

10.2 Traitement thermique des coudes . 32

10.3 Examen des coudes . 33

11 Installation .34

11.1 Exigences générales .34

11.2 Raccords filetés .34

11.3 Raccords boulonnés . 35

12 Contrôle, examen et essai .36

12.1 Exigences générales .36

12.2 Contrôle visuel . 39

iii

© ISO 2023 – Tous droits réservés

---------------------- Page: 3 ----------------------

ISO/FDIS 13703-3:2023(F)

12.3 Magnétoscopie .40

12.4 Contrôle par ressuage .40

12.5 Contrôle radiographique .40

12.6 Examen par ultrasons . 41

12.7 Identification positive des matériaux . 42

12.8 Essais de production . 43

12.9 Contrôle de la ferrite du métal soudé .44

12.10 Réparations et remplacement . 45

13 Nettoyage, essais d'étanchéité et préservation.47

13.1 Exigences générales . 47

13.2 Rinçage et nettoyage .48

13.3 Essai d'étanchéité .49

13.4 Contrôle d'étanchéité . 50

13.5 Préservation . 51

Annexe A (informative) Reference images for oxidation of weldments .52

Annexe B (normative) Exigences pour le cintrage à froid des tubes.56

Annexe C (normative) Exigences pour le cintrage par induction à chaud des tubes .61

Annexe D (Informative) Guidance to European Pressure Equipment Directive .63

Bibliographie .64

iv

© ISO 2023 – Tous droits réservés

---------------------- Page: 4 ----------------------

ISO/FDIS 13703-3:2023(F)

Avant-propos

L'ISO (Organisation internationale de normalisation) est une fédération mondiale d'organismes

nationaux de normalisation (comités membres de l'ISO). L'élaboration des Normes internationales est

en général confiée aux comités techniques de l'ISO. Chaque comité membre intéressé par une étude

a le droit de faire partie du comité technique créé à cet effet. Les organisations internationales,

gouvernementales et non gouvernementales, en liaison avec l'ISO participent également aux travaux.

L'ISO collabore étroitement avec la Commission électrotechnique internationale (IEC) en ce qui

concerne la normalisation électrotechnique.

Les procédures utilisées pour élaborer le présent document et celles destinées à sa mise à jour sont

décrites dans les Directives ISO/IEC, Partie 1. Il convient, en particulier de prendre note des différents

critères d'approbation requis pour les différents types de documents ISO. Le présent document

a été rédigé conformément aux règles de rédaction données dans les Directives ISO/IEC, Partie 2

(voir www.iso.org/directives).

L'attention est attirée sur le fait que certains des éléments du présent document peuvent faire l'objet de

droits de propriété intellectuelle ou de droits analogues. L'ISO ne saurait être tenue pour responsable

de ne pas avoir identifié tout ou partie de tels droits de brevet. Les détails concernant les références aux

droits de propriété intellectuelle ou autres droits analogues identifiés lors de l'élaboration du document

sont indiqués dans l'Introduction et/ou dans la liste des déclarations de brevets reçues par l'ISO (voir

www.iso.org/brevets).

Les appellations commerciales éventuellement mentionnées dans le présent document sont données

pour information, par souci de commodité, à l'intention des utilisateurs et ne sauraient constituer un

engagement.

Pour une explication de la signification des termes et expressions spécifiques de l'ISO liés à l'évaluation

de la conformité, ou pour toute information au sujet de l'adhésion de l'ISO aux principes de l'Organisation

mondiale du commerce (OMC) concernant les obstacles techniques au commerce (OTC), voir le lien

suivant: www.iso.org/iso/fr/avant-propos.

Le présent document a été élaboré par le comité technique ISO/TC 67, Industries du pétrole et du gaz, y

compris les énergies à faible teneur en carbone, sous-comité SC 6, Équipements des procédés, tuyauterie,

systèmes, et sécurité qui y est rattachée, en collaboration avec le comité technique CEN/TC 12, Matériel,

équipement et structures en mer pour les industries du pétrole, de la pétrochimie et du gaz naturel

du Comité européen de normalisation (CEN), conformément à l'Accord de coopération technique entre

l'ISO et le CEN (Accord de Vienne).

Cette première édition de l'ISO 13703-3, ainsi que l'ISO 13703-1 et l'ISO 13703-2, annule et remplace

l'ISO 13703:2000. Elle incorpore également le Rectificatif technique ISO 13703:2000/Cor.1:2002.

Les principales modifications par rapport à l'édition précédente sont les suivantes:

— suppression des exigences relatives à l'installation et au contrôle de la qualité de l'Article 10;

— suppression de l'Annexe C, ces exigences étant traitées dans la norme ASME B31.3.

Une liste de toutes les parties de la série ISO 13703 se trouve sur le site web de l'ISO.

Il convient que l'utilisateur adresse tout retour d'information ou toute question concernant le présent

document à l'organisme national de normalisation de son pays. Une liste exhaustive desdits organismes

se trouve à l'adresse www.iso.org/fr/members.html.

v

© ISO 2023 – Tous droits réservés

---------------------- Page: 5 ----------------------

ISO/FDIS 13703-3:2023(F)

Introduction

Le présent document a pour objet de définir des exigences communes pour la fabrication, le soudage,

l'inspection, l'examen et l'essai de nouveaux systèmes de tuyauteries industrielles métalliques

conçus dans le respect des exigences de l'ISO 13703-1 et utilisant des matériaux de tuyauterie en vrac

conformément à l'ISO 13703-2.

Le présent document fait référence à la norme ASME B31.3 en tant que code de base pour les

tuyauteries industrielles. Outre l'ASME B31.3, il existe d'autres codes pour la fabrication, le soudage,

l'inspection, l'examen et l'essai des systèmes de tuyauteries industrielles, ainsi que la nécessité

éventuelle de se conformer aux exigences réglementaires/juridictionnelles locales ou nationales.

Dans le cadre de la mise en œuvre des exigences du présent document, l'utilisateur est censé évaluer

les implications découlant des exigences réglementaires ou juridictionnelles locales ou nationales, y

compris la nécessité de spécifier des exigences supplémentaires par rapport à celles qui sont énoncées.

L'Annexe N de la norme ASME B31.3 fournit des indications sur son utilisation à l'échelle internationale,

et plus particulièrement sur son utilisation au sein de l'Union européenne pour laquelle des exigences

supplémentaires à celles spécifiées dans la norme ASME B31.3 seront nécessaires afin de satisfaire aux

exigences de la directive 2014/68/UE relative à l'harmonisation des législations des États membres

concernant la mise à disposition sur le marché des équipements sous pression.

Le présent document n'est pas destiné à empêcher un utilisateur d'accepter d'autres solutions de

fabrication, de soudage, d'examen ou d'essai pour l'application individuelle. De telles solutions

alternatives peuvent notamment être appropriées lorsqu'il s'agit de technologies innovantes ou en

cours de développement. En cas de solution alternative aux exigences du présent document, l'utilisateur

est tenu d'en examiner les implications en termes de respect des exigences de performance énoncées

dans le présent document.

vi

© ISO 2023 – Tous droits réservés

---------------------- Page: 6 ----------------------

PROJET FINAL DE NORME INTERNATIONALE ISO/FDIS 13703-3:2023(F)

Industries pétrolières et gazières, y compris les énergies

à faible émission de carbone — Conception et installation

des systèmes de tuyauterie sur les plates-formes de

production en mer et les installations à terre —

Partie 3:

Fabrication

1 Domaine d'application

Le présent document spécifie les exigences relatives à la fabrication, à l'installation, au soudage, à

l'inspection, à l'examen et aux essais de nouveaux systèmes de tuyauteries métalliques, dans les limites

de la plage de température pour les matériaux répondant aux exigences de la norme ASME B31.3,

sur les installations de production en mer fixes et flottantes et sur les installations de production, de

traitement et de liquéfaction du gaz à terre. Pour les systèmes de tuyauterie dont la classe de pression

est supérieure à 2500, les exigences du chapitre IX de la norme ASME B31.3 doivent être respectées,

ainsi que les exigences énoncées dans la présente norme.

Le présent document s'applique à tous les composants sous pression et à tout composant sans pression,

tel qu'un élément d'un support de tuyauterie, soudé directement à un composant sous pression.

Le présent document ne s'applique pas aux éléments suivants:

— les systèmes de tuyauterie marins, par exemple les systèmes de tuyauterie de ballast, systèmes

couverts par des sociétés de classification;

— les tubes métalliques utilisés pour les faisceaux de câbles immergés;

NOTE 1 Pour le soudage et l'examen de ces composants, il est possible de se référer à l'ISO 13628-5 ou à la

norme API Spec 17E.

— les systèmes de tuyauteries avec un revêtement résistant à la corrosion (soit intégralement revêtu,

soit mécaniquement revêtu) ou un recouvrement par soudage, y compris le beurrage et les soudures

dissemblables associées;

NOTE 2 Pour le soudage et l'examen de ces systèmes, il est possible de se référer à la norme DNVGL-

RP-B204.

— les alliages réfractaires [à l'exception du titane CP Grade 1 (UNS R50250) ou Grade 2 (UNS R50400)];

— les assemblages de tuyauteries non métalliques;

— les systèmes de conduite de transport, y compris les conduites d'écoulement, conçus conformément

à un code de conception de conduites reconnu.

2 Références normatives

Les documents suivants sont cités dans le texte de sorte qu'ils constituent, pour tout ou partie de leur

contenu, des exigences du présent document. Pour les références datées, seule l'édition citée s'applique.

Pour les références non datées, la dernière édition du document de référence s'applique (y compris les

éventuels amendements).

1

© ISO 2023 – Tous droits réservés

---------------------- Page: 7 ----------------------

ISO/FDIS 13703-3:2023(F)

ISO 3834-2, Exigences de qualité en soudage par fusion des matériaux métalliques — Partie 2: Exigences de

qualité complète

ISO 8249, Soudage — Détermination de l'indice de ferrite (FN) dans le métal fondu en acier inoxydable

austénitique et duplex ferritique-austénitique au chrome-nickel

ISO 9015-1, Essais destructifs des soudures sur matériaux métalliques — Essais de dureté — Partie 1: Essai

de dureté des assemblages soudés à l'arc

ISO 9606 (toutes les parties), Épreuve de qualification des soudeurs — Soudage par fusion

ISO 9712, Essais non destructifs — Qualification et certification du personnel END

ISO 10474, Aciers et produits sidérurgiques — Documents de contrôle

ISO 11666:2018, Essais non destructifs des assemblages soudés — Contrôle par ultrasons — Niveaux

d'acceptation

ISO 11699-1, Essais non destructifs — Film pour radiographie industrielle — Partie 1: Classification des

systèmes films pour radiographie industrielle

ISO 14175, Produits consommables pour le soudage — Gaz et mélanges gazeux pour le soudage par fusion

et les techniques connexes

ISO 14344, Produits consommables pour le soudage — Approvisionnement en matériaux d'apport et flux

ISO 14731, Coordination en soudage — Tâches et responsabilités

ISO 14732, Personnel en soudage — Épreuve de qualification des opérateurs soudeurs et des régleurs en

soudage pour le soudage mécanisé et le soudage automatique des matériaux métalliques

ISO 15156-2, Industries du pétrole et du gaz naturel — Matériaux pour utilisation dans des environnements

contenant de l'hydrogène sulfuré (H2S) dans la production de pétrole et de gaz — Partie 2: Aciers au

carbone et aciers faiblement alliés résistant à la fissuration, et utilisation de fontes

ISO 15156-3, Industries du pétrole et du gaz naturel — Matériaux pour utilisation dans des environnements

contenant de l'hydrogène sulfuré (H2S) dans la production de pétrole et de gaz — Partie 3: ARC (alliages

résistants à la corrosion) et autres alliages résistant à la fissuration

ISO 15609-1, Descriptif et qualification d'un mode opératoire de soudage pour les matériaux métalliques —

Descriptif d'un mode opératoire de soudage — Partie 1: Soudage à l'arc

ISO 15614-1, Descriptif et qualification d'un mode opératoire de soudage pour les matériaux métalliques —

Épreuve de qualification d'un mode opératoire de soudage — Partie 1: Soudage à l'arc et aux gaz des aciers

et soudage à l'arc du nickel et des alliages de nickel

ISO 15614-5, Descriptif et qualification d’un mode opératoire de soudage pour les matériaux métalliques —

Épreuve de qualification d’un mode opératoire de soudage — Partie 5: Soudage à l’arc sur titane, zirconium

et leurs alliages

ISO 15614-6, Descriptif et qualification d'un mode opératoire de soudage pour les matériaux métalliques —

Épreuve de qualification d'un mode opératoire de soudage — Partie 6: Soudage à l'arc et aux gaz du cuivre

et de ses alliages

ISO/IEC 17025, Exigences générales concernant la compétence des laboratoires d'étalonnages et d'essais

ISO 17636-2, Essais non destructifs des assemblages soudés — Contrôle par radiographie — Partie 2:

Techniques par rayons X ou gamma à l'aide de détecteurs numériques

ISO 17781:2017, Industries du pétrole, de la pétrochimie et du gaz naturel — Méthodes d'essai pour le

contrôle de la qualité de la microstructure des aciers inoxydables austénitiques/ferritiques (duplex)

ISO 18265, Matériaux métalliques — Conversion des valeurs de dureté

2

© ISO 2023 – Tous droits réservés

---------------------- Page: 8 ----------------------

ISO/FDIS 13703-3:2023(F)

ISO 22825, Essais non destructifs des assemblages soudés — Contrôle par ultrasons — Contrôle des

soudures en aciers austénitiques et en alliages à base nickel

ANSI Z49.1, Safety in Welding, Cutting and Allied Processes

API RP 686, Machinery Installation and Installation Design

ASME B31.3, Process Piping

Boiler ASME, and Pressure Vessel Code, Section II, Materials, Part C:2019, Specifications for welding

rods, electrodes, and filler metals

Boiler ASME, and Pressure Vessel Code, Section V:2019, Non Destructive Testing

Boiler ASME, and Pressure Vessel Code, Section IX: 2019, Welding and Brazing Qualifications

ASNT CP-189, Standard for Qualification and Certification of Nondestructive Testing Personnel

ASNT SNT-TC-1A, Personnel Qualification and Certification in Nondestructive Testing

ASTM A380, Standard Practice for Cleaning, Descaling, and Passivation of Stainless Steel Parts, Equipment,

and Systems

ASTM E140, Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness, Vickers

Hardness, Rockwell Hardness, Superficial Hardness, Knoop Hardness, Scleroscope Hardness, and Leeb

Hardness

ASTM E1815, Standard Test Method for Classification of Film Systems for Industrial Radiography

ASTM G48, Standard Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels and

Related Alloys by Use of Ferric Chloride Solution

AWS A4.2M, Standard Procedures for Calibrating Magnetic Instruments to Measure the Delta Ferrite

Content of Austenitic and Duplex Ferritic-Austenitic Stainless Steel

AWS D10.10, Recommended Practices for Local Heating of Welds in Piping and Tubing

EN 10204, Produits métalliques — Types de documents de contrôle

PFI ES-3, Fabricating Tolerances

3 Termes et définitions

Pour les besoins du présent document, les termes et définitions suivants s'appliquent.

L'ISO et l'IEC tiennent à jour des bases de données terminologiques destinées à être utilisées en

normalisation, consultables aux adresses suivantes:

— ISO Online browsing platform: disponible à l'adresse https:// www .iso .org/ obp

— IEC Electropedia: disponible à l'adresse https:// www .electropedia .org/

3.1

service alcalin

environnements de service contenant des composés alcalins t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.