ISO/TR 22157-2:2004

(Main)Bamboo - Determination of physical and mechanical properties - Part 2: Laboratory manual

Bamboo - Determination of physical and mechanical properties - Part 2: Laboratory manual

ISO/TR 22157-2:2004 provides informative guidelines for staff in laboratories on how to perform tests according to ISO 22157-1:2004.

Bambou — Détermination des propriétés physiques et mécaniques — Partie 2: Manuel de laboratoire

General Information

Relations

Frequently Asked Questions

ISO/TR 22157-2:2004 is a technical report published by the International Organization for Standardization (ISO). Its full title is "Bamboo - Determination of physical and mechanical properties - Part 2: Laboratory manual". This standard covers: ISO/TR 22157-2:2004 provides informative guidelines for staff in laboratories on how to perform tests according to ISO 22157-1:2004.

ISO/TR 22157-2:2004 provides informative guidelines for staff in laboratories on how to perform tests according to ISO 22157-1:2004.

ISO/TR 22157-2:2004 is classified under the following ICS (International Classification for Standards) categories: 79.040 - Wood, sawlogs and sawn timber. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TR 22157-2:2004 has the following relationships with other standards: It is inter standard links to ISO 17070:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO/TR 22157-2:2004 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 22157-2

First edition

2004-05-01

Bamboo — Determination of physical and

mechanical properties —

Part 2:

Laboratory manual

Bambou — Détermination des propriétés physiques et mécaniques —

Partie 2: Manuel de laboratoire

Reference number

©

ISO 2004

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2004

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2004 – All rights reserved

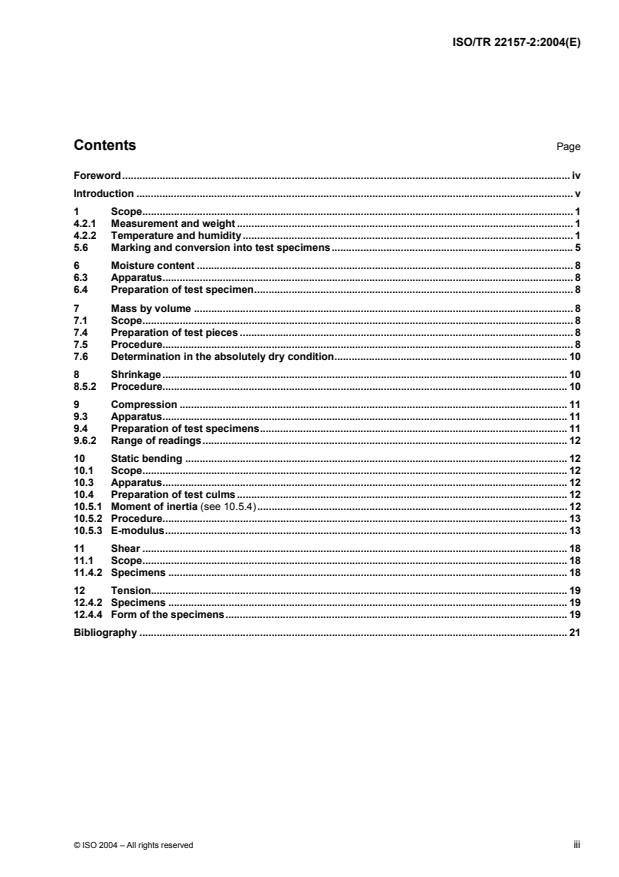

Contents Page

Foreword. iv

Introduction . v

1 Scope. 1

4.2.1 Measurement and weight . 1

4.2.2 Temperature and humidity. 1

5.6 Marking and conversion into test specimens. 5

6 Moisture content. 8

6.3 Apparatus. 8

6.4 Preparation of test specimen. 8

7 Mass by volume . 8

7.1 Scope. 8

7.4 Preparation of test pieces . 8

7.5 Procedure. 8

7.6 Determination in the absolutely dry condition. 10

8 Shrinkage. 10

8.5.2 Procedure. 10

9 Compression. 11

9.3 Apparatus. 11

9.4 Preparation of test specimens. 11

9.6.2 Range of readings. 12

10 Static bending. 12

10.1 Scope. 12

10.3 Apparatus. 12

10.4 Preparation of test culms. 12

10.5.1 Moment of inertia (see 10.5.4). 12

10.5.2 Procedure. 13

10.5.3 E-modulus. 13

11 Shear. 18

11.1 Scope. 18

11.4.2 Specimens. 18

12 Tension. 19

12.4.2 Specimens. 19

12.4.4 Form of the specimens. 19

Bibliography . 21

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In exceptional circumstances, when a technical committee has collected data of a different kind from that

which is normally published as an International Standard (“state of the art”, for example), it may decide by a

simple majority vote of its participating members to publish a Technical Report. A Technical Report is entirely

informative in nature and does not have to be reviewed until the data it provides are considered to be no

longer valid or useful.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TR 22157-2 was prepared by Technical Committee ISO/TC 165, Timber structures, in collaboration with

INBAR, the International Network for Bamboo and Rattan.

iv © ISO 2004 – All rights reserved

Introduction

In many laboratories in bamboo-growing countries all over the world, laboratory staff perform tests on the

properties of bamboo. Visitors to such laboratories have seen how diligent and keen staff are on doing their

work, in many cases under circumstances that are not easy. Many examples can be found of very satisfactory

methods or tools, but such good information stays inside the originating laboratory, due to lack of exchange of

such knowledge. One purpose of this Technical Report is to publish clever methods in order to make these

available for staff all over the world. A second purpose is to give a practical “how to do” explanation on how to

perform tests according to ISO 22157-1.

TECHNICAL REPORT ISO/TR 22157-2:2004(E)

Bamboo — Determination of physical and mechanical

properties —

Part 2:

Laboratory manual

1 Scope

This Technical Report provides informative guidelines for staff in laboratories on how to perform tests

according to ISO 22157-1.

NOTE From here on, this Technical Report will only give information on subclauses of ISO 22157-1 if needed;

consequently the numbering is not successive.

4.2.1 Measurement and weight

NOTE This subclause also refers to: 5.3 Felling, marking and conversion.

The values for length and weight should be taken:

from the culms after their arrival in the lab, which means that culms have been marked already according

to 5.3 of ISO 22157-1;

from the smaller specimens immediately after they have been cut to size in the laboratory. It is wise to

perform this cutting activity in such a way that confusion is avoided.

It is wise laboratory practice to design standard tables in which all data should be recorded. Figure 1 gives an

example of such a table; evidently each laboratory is free to follow this example or not, provided their tables

are as good or even better. In Figure 2 this table is repeated, and filled in by hand as an example of how to

deal with it.

Next, it is wise to make a sketch of each culm, with its nodes, the places of the nodes, and the specimens cut

from this culm and the tests for which these are to be used; see example in Figure 3.

This example shows the bottom and the middle part of a culm; from each part, two samples will be tested in

compression and one in bending, provided the length is sufficient. The reports on those tests will contain more

sketches with dimensions, etc. Evidently, each laboratory is free to design sketches like these, provided they

are clear.

In Figure 3, the white ring as in 5.3 appears at a height of about 0,70 m from which we can guess that a piece

of about 0,30 m has been left in the plantation. The mark “T”, painted at breast height (5.2) appears at a

height of approx. 1,20 m.

Subclause 4.2.1 of ISO 22157-1 also specifies how to determine the diameter and the wall thickness; see

Figure 4 for details. (This Figure refers to 10.5.1 of ISO 22157-1.)

4.2.2 Temperature and humidity

The choice of test condition of 27 ± 2 °C and 70 ± 5 % R.H deviates from that normally adopted for testing

wood products which is 20 °C and 65 % R.H. The first condition is chosen to better reflect the service

environment in countries where bamboo grows. In temperate climates (like W. Europe), the national standard

for timber may be followed. If the link with other conditions is known, it is recommended to add this in the test

report. See also ISO 22157-1, 5.7, last line.

NOTE This subclause is based on contributions from the Canadian and the French Standards Institutes.

Figure 1 — Example of a table as in 5.3 and 4.2.1

2 © ISO 2004 – All rights reserved

Figure 2 — Example of a completed table as in 5.3 and 4.3.1

Name and address of the laboratory:

Mark of the culm:

Sketch of the culm, dimensions and tests to be performed:

Figure 3 — Sketch of a culm (see 4.2.1 and 5.3)

4 © ISO 2004 – All rights reserved

Figure 4 — Diameter and wall thickness of a culm (see 4.2.1 and 10.5.1)

5.6 Marking and conversion into test specimens

The number of specimens should be twelve: the purpose of tests is to predict a property for the whole

population, with tests on one sample only. The more specimens are taken from the sample, the more reliable

is the prediction, but the more expensive as well is the test series. A fair equilibrium exists when the minimum

number of test specimens is twelve.

In a test series, we would like to determine the mean value µ of the population (pronounce “muu”) but we

actually determine the mean value m of the sample. The formula is:

µ = m − t(s/n) (In the origial full formula “+” and “−” are both present, but here we are iinterested in

the “−” only.

where

µ is the mean value of the population;

m is the mean value of the sample;

1)

t is the coefficient from Student's distribution;

s is the standard deviation;

n is the number of specimens in the sample.

The result is:

if n = 4 then

µ = m ± 23,5 %

if n = 8 then

µ = m ± 13,4 %

if n = 12 then

µ = m ± 10,6 %

if n = 16 then µ = m ± 8,8 %

The same variation is presented in Figure 5, top curve.

A similar formula is valid for the standard deviation of the population σ as a function of the standard deviation s

of the sample:

if n = 4 then

0,62s < σ < 2,92s

if n = 8 then 0,71s < σ < 1,80s

if n = 12 then 0,75s < σ < 1,55s

if n = 16 then 0,75s < σ < 1,44s

This can be seen in Figure 5, bottom curve.

NOTE The above is background information to ISO 22156:2004, 7.2.1.

1) Student’s distribution is a statistical distribution, published by the Englishman W.S.Gosset under the pseudonym

“Student”.

6 © ISO 2004 – All rights reserved

µ as function of n

σ as a function of n

Figure 5 — The relationship between µ, σ and n

6 Moisture content

6.3 Apparatus

The glass flasks will be needed only if the test pieces are not put on the balance immediately after preparation,

or if they are left out of the oven for some time during or after drying. If one weighs the pieces immediately, no

problems will be expected.

6.4 Preparation of test specimen

EXAMPLE A test piece is 25 mm high, 25 mm wide, and the wall thickness is 10,0 mm. The mass is 5,00 g. (This

means that the mass per volume is 800 kg/m .) If we suppose the dry weight is 4,46 g, then the calculation of the moisture

content will be:

mm−

o

MC=×100= (5,00− 4,46) / 4,46×100= 12,1

m

o

where

MC is the moisture content;

m is the mass of test piece;

m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...