ISO 5772:2015

(Main)Rubber and plastic hoses and hose assemblies for measured fuel dispensing systems - Specification

Rubber and plastic hoses and hose assemblies for measured fuel dispensing systems - Specification

ISO 5772:2015 specifies minimum requirements for three types of hoses in two categories and two classes of hose assemblies used for measured fuel dispensing, including oxygenated fuels (up to a maximum of 15 % oxygenated compounds). The assemblies are intended for use at ambient temperatures between −30 °C and +55 °C for normal temperature class and −40 °C and +55 °C for low temperature class at a working pressure up to and including 16 bar (1,6 MPa). NOTE 1 bar = 0,1 MPa.

Tuyaux et flexibles en caoutchouc et en plastique pour distribution mesurée de carburants — Spécification

General Information

Relations

Overview

ISO 5772:2015 - "Rubber and plastic hoses and hose assemblies for measured fuel dispensing systems - Specification" - defines minimum technical and performance requirements for hoses and hose assemblies used in measured fuel dispensing (including oxygenated fuels up to 15% oxygenates). The standard covers three hose types, two electrical categories and two low‑temperature classes for ambient service from −40 °C (low‑temperature class) or −30 °C (normal class) up to +55 °C, and a maximum working pressure of 16 bar (1,6 MPa).

Key topics and technical requirements

- Hose types and classification

- Type 1: textile reinforced

- Type 2: textile plus helical wire reinforced

- Type 3: fine wire reinforced

- Two temperature classes: normal (−30 °C to +55 °C) and low temperature (−40 °C to +55 °C)

- Two electrical categories: M (metallic bonding wires) and Ω (conductive compounds)

- Materials and construction

- Smooth, fuel‑resistant rubber or thermoplastic elastomer (TPE) linings; weather- and fuel‑resistant covers

- Hoses with metallic bonding must embed at least two metallic wires for electrical continuity

- Pressure performance

- Maximum working pressure: 16 bar (1,6 MPa)

- Proof pressure: 24 bar (2,4 MPa)

- Minimum burst pressure: 48 bar (4,8 MPa)

- Dimensional and mechanical limits

- Minimum lining thickness: 1.6 mm; cover thickness: 1.0 mm

- Concentricity tolerance ≤ 1.0 mm

- Specified internal diameters, bend radii, and length tolerances (measured per ISO 4671 / ISO 1307)

- Physical properties and tests

- Compound requirements (tensile strength: rubber ≥ 9 MPa, TPE ≥ 12 MPa; elongation and ageing limits)

- Finished‑hose requirements: proof/burst testing, volumetric expansion, adhesion between components, low‑temperature flexibility, no leakage, permeation and flammability controls

- Extensive normative annexes (A–I) specifying low‑temperature tests, adhesion after fuel ageing, permeation, flammability, end‑fitting pull‑off, flex/fatigue, leak testing, and test frequencies

Practical applications and users

- Typical users: hose manufacturers, dispenser OEMs, fuel retail operators, quality/compliance engineers, and test laboratories

- Applications: fuel dispensing hoses and assemblies on retail forecourts, measured dispensing installations, and systems handling gasoline, diesel and oxygenated fuel blends (up to 15% oxygenates)

- Value: ensures safe pressure performance, electrical continuity (to prevent static build‑up), low‑temperature flexibility, fuel compatibility and reduced permeation and flammability risk

Related standards

- ISO 1402 (hydrostatic testing), ISO 8033 (adhesion), ISO 4671 (dimensional measurement), ISO 10619‑1 (bending tests), ISO 1817 (resistance to liquids), ISO 6801 (volumetric expansion) - referenced within ISO 5772:2015 for test methods and measurement guidance.

Keywords: ISO 5772:2015, fuel dispensing hoses, rubber and plastic hoses, hose assemblies, oxygenated fuels, working pressure 16 bar, low temperature hoses, hose testing, dispenser hose standards.

Frequently Asked Questions

ISO 5772:2015 is a standard published by the International Organization for Standardization (ISO). Its full title is "Rubber and plastic hoses and hose assemblies for measured fuel dispensing systems - Specification". This standard covers: ISO 5772:2015 specifies minimum requirements for three types of hoses in two categories and two classes of hose assemblies used for measured fuel dispensing, including oxygenated fuels (up to a maximum of 15 % oxygenated compounds). The assemblies are intended for use at ambient temperatures between −30 °C and +55 °C for normal temperature class and −40 °C and +55 °C for low temperature class at a working pressure up to and including 16 bar (1,6 MPa). NOTE 1 bar = 0,1 MPa.

ISO 5772:2015 specifies minimum requirements for three types of hoses in two categories and two classes of hose assemblies used for measured fuel dispensing, including oxygenated fuels (up to a maximum of 15 % oxygenated compounds). The assemblies are intended for use at ambient temperatures between −30 °C and +55 °C for normal temperature class and −40 °C and +55 °C for low temperature class at a working pressure up to and including 16 bar (1,6 MPa). NOTE 1 bar = 0,1 MPa.

ISO 5772:2015 is classified under the following ICS (International Classification for Standards) categories: 75.200 - Petroleum products and natural gas handling equipment; 83.140.40 - Hoses. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 5772:2015 has the following relationships with other standards: It is inter standard links to ISO 5772:1998. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 5772:2015 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 5772

Second edition

2015-09-15

Rubber and plastic hoses and hose

assemblies for measured fuel

dispensing systems — Specification

Tuyaux et flexibles en caoutchouc et en plastique pour distribution

mesurée de carburants — Spécification

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

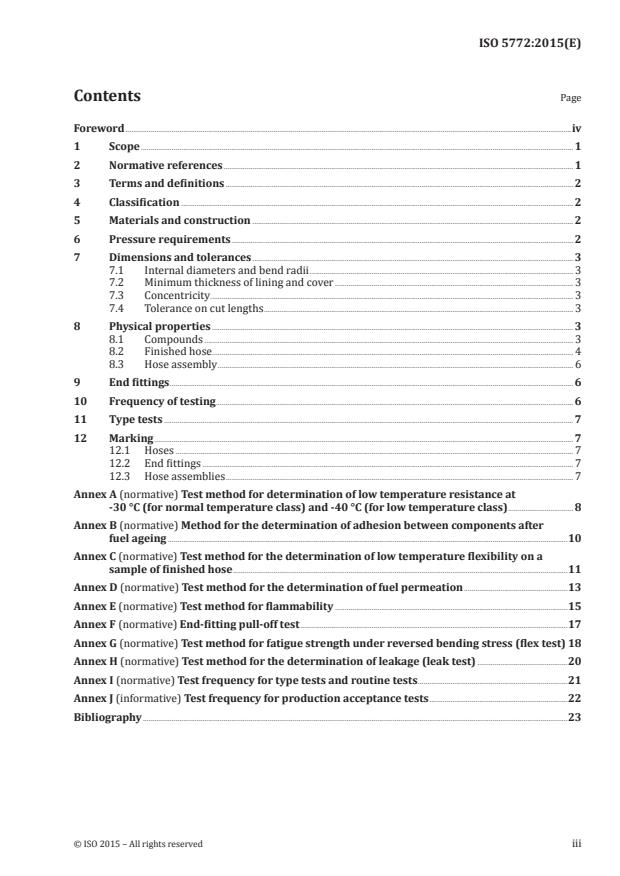

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Classification . 2

5 Materials and construction . 2

6 Pressure requirements . 2

7 Dimensions and tolerances . 3

7.1 Internal diameters and bend radii . 3

7.2 Minimum thickness of lining and cover . 3

7.3 Concentricity. 3

7.4 Tolerance on cut lengths . 3

8 Physical properties . 3

8.1 Compounds . 3

8.2 Finished hose . 4

8.3 Hose assembly . 6

9 End fittings . 6

10 Frequency of testing . 6

11 Type tests . 7

12 Marking . 7

12.1 Hoses . 7

12.2 End fittings . 7

12.3 Hose assemblies . 7

Annex A (normative) Test method for determination of low temperature resistance at

-30 °C (for normal temperature class) and -40 °C (for low temperature class) .8

Annex B (normative) Method for the determination of adhesion between components after

fuel ageing .10

Annex C (normative) Test method for the determination of low temperature flexibility on a

sample of finished hose .11

Annex D (normative) Test method for the determination of fuel permeation .13

Annex E (normative) Test method for flammability .15

Annex F (normative) End-fitting pull-off test .17

Annex G (normative) Test method for fatigue strength under reversed bending stress (flex test) 18

Annex H (normative) Test method for the determination of leakage (leak test) .20

Annex I (normative) Test frequency for type tests and routine tests .21

Annex J (informative) Test frequency for production acceptance tests .22

Bibliography .23

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information.

The committee responsible for this document is ISO/TC 45, Rubber and rubber products, Subcommittee

SC 1, Rubber and plastics hoses and hose assemblies.

This second edition cancels and replaces the first edition (ISO 5772:1998), which has been technically

revised to include the following changes:

— working pressure is 16 bar (1,6 MPa) instead of 12 bar (1,2 MPa) but proof pressure and burst

pressure remain the same;

— minimum tensile strength of lining and cover has been increased from 7 MPa to 9 MPa;

— extraction of the lining for low temp hoses has been added and the Low Temperature Bending test

is to be done at 25 °C with the force to bend specified;

— hose fuel permeation, flammability, assembly flex test, and assembly leak test have been added.

All the annexes form an integral part of this International Standard.

iv © ISO 2015 – All rights reserved

INTERNATIONAL STANDARD ISO 5772:2015(E)

Rubber and plastic hoses and hose assemblies for

measured fuel dispensing systems — Specification

WARNING — Persons using this International Standard should be familiar with normal

laboratory practice. This International Standard does not purport to address all of the

safety problems, if any, associated with its use. It is the responsibility of the user to establish

appropriate safety and health practices and to ensure compliance with any national regulatory

conditions.

1 Scope

This International Standard specifies minimum requirements for three types of hoses in two categories

and two classes of hose assemblies used for measured fuel dispensing, including oxygenated fuels (up

to a maximum of 15 % oxygenated compounds).

The assemblies are intended for use at ambient temperatures between −30 °C and +55 °C for normal

temperature class and −40 °C and +55 °C for low temperature class at a working pressure up to and

including 16 bar (1,6 MPa).

NOTE 1 bar = 0,1 MPa.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 37, Rubber, vulcanised or thermoplastic — Determination of tensile stress-strain properties

ISO 188, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

ISO 1307, Rubber and plastics hoses — Hose sizes, minimum and maximum inside diameters, and tolerances

on cut-to-length hoses

ISO 1402, Rubber and plastics hoses and hose assemblies — Hydrostatic testing

ISO 1817, Rubber, vulcanized or thermoplastic — Determination of the effect of liquids

ISO 4649, Rubber, vulcanized or thermoplastic — Determination of abrasion resistance using a rotating

cylindrical drum device

ISO 4671, Rubber and plastics hoses and hose assemblies — Methods of measurement of the dimensions of

hoses and the lengths of hose assemblies

ISO 6801, Rubber or plastics hoses — Determination of volumetric expansion

ISO 7326, Rubber and plastics hoses — Assessment of ozone resistance under static conditions

ISO 8031:2009, Rubber and plastics hoses and hose assemblies — Determination of electrical resistance

and conductivity

ISO 8033, Rubber and plastics hose — Determination of adhesion between components

ISO 8330, Rubber and plastics hoses and hose assemblies — Vocabulary

ISO 10619–1, Rubber and plastics hoses and tubing — Measurement of flexibility and stiffness — Part 1:

Bending tests at ambient temperature

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 8330 apply.

4 Classification

Hoses for this application shall be divided into the following three types:

a) type 1: textile reinforced;

b) type 2: textile and helical wire reinforced;

c) type 3: fine wire reinforced.

Each type of hose shall be divided into the following two temperature classes:

a) normal temperature class with an ambient working temperature of −30 °C to +55 °C;

b) low temperature class (LT) with an ambient working temperature of −40 °C to +55 °C.

Each type of hose for this application shall be divided into the following two categories:

a) category M: electrically bonded;

b) category Ω: electrically conductive.

Hoses for this application shall be divided into the following two temperature classes:

a) normal temperature class with an ambient working temperature of −30 °C to +55 °C;

b) low temperature class (LT) with an ambient working temperature of −40 °C to +55 °C.

5 Materials and construction

The hose shall consist of the following:

— smooth, fuel resistant lining of rubber or thermoplastic elastomer (TPE);

— suitable reinforcement; related to type;

— non-corrugated, fuel and weather-resistant rubber or TPE cover.

Hose assemblies shall be capable of conducting an electrical charge from coupling to coupling.

When this capability is provided by means of metallic bonding wires, not less than two (metallic)

bonding wires shall be embedded in the hose and the metal used shall have a high resistance to fatigue

and corrosion.

Hoses with metallic wires for electrical conductivity shall be designated “M” and those using conductive

compounds shall be designated “Ω”, the relevant mark being branded on the hose (see Clause 12).

6 Pressure requirements

For all types of hoses, the following shall apply:

a) maximum working pressure: 16 bar (1,6 MPa);

b) proof pressure: 24 bar (2,4 MPa);

c) minimum bursting pressure: 48 bar (4,8 MPa).

2 © ISO 2015 – All rights reserved

7 Dimensions and tolerances

7.1 Internal diameters and bend radii

When measured in accordance with ISO 4671, the internal diameter of the hose shall comply with the

values given in Table 1.

When measured in accordance with ISO 10619–1, the minimum bend radii for each diameter of hose

shall comply with the values given in Table 1.

Table 1 — Nominal bore, internal diameter, tolerance, and bend radii

Internal diameter Tolerance Bend radius

Nominal bore

mm mm mm

12 12 60

16 16 ±0,8 80

19 19 100

21 21,0 130

25 25,0 150

32 32,0 175

35 35,0 ±1,25 200

38 38,0 225

40 40,0 225

50 50,0 275

7.2 Minimum thickness of lining and cover

When measured in accordance with ISO 4671, the thickness of the lining shall not be less than 1,6 mm.

The thickness of the cover shall not be less than 1,0 mm.

7.3 Concentricity

When determined in accordance with ISO 4671, the concentricity, based on a total indicator reading

between the internal diameter and the outside surface of the cover, shall not exceed 1,0 mm.

7.4 Tolerance on cut lengths

For cut lengths, the tolerances on length shall be according to ISO 1307. The length of a hose assembly

shall be measured from sealing face to sealing face of the end fittings with a tolerance from the nominal

length of ±1 %.

8 Physical properties

8.1 Compounds

When tested in accordance with the methods in Table 2, the physical properties of the compounds used

for the lining and cover shall comply with the values given in Table 2. Tests shall be carried out either on

samples taken from the hose or from moulded vulcanised sheets at a thickness of 2 mm or moulded test

pieces, vulcanised to the same cured state as the production hoses.

Table 2 — Physical properties of compounds

Requirement

a

Property Unit Test piece Test method

Rubber TPE

Tensile strength

MPa 9 12

Lining and cover, min.

ISO 37

Elongation at break

% 250 350

Lining and cover, min.

Accelerated ageing

— Tensile strength change,

% 20 10

max.

ISO 188

Lining and cover

(air oven method)

14 days at (70 ± 1) °C

— Elongation at break

change, max.

% −35 −20

Lining and cover

Resistance to liquids ISO 1817

70 h at 40 °C in

Test piece cut from

+70 oxygenated fuel

hose or from test

type 3

sheet

Lining swell max.

ISO 1817

+25

70 h at 100 °C in oil

No 3

Lining extracted matter

%

ISO 1817

+10

Normal temperature class

70 h at 40 °C in

max.

oxygenated fuel

Lining extracted matter

type 3 then dry 24 h

+15

at 100 °C

Low temperature class max.

ISO 1817

Cover swell max. +100

70 h at 23 °C in

Liquid B

Low temperature resistance

No cracks under ×10

to lining and cover at −30 °C — Annex A

magnification

(or −40 °C if required)

Test piece from

Abrasion resistance ISO 4649

mm 500 moulded test sheet

Cover compound max. Method A

of cover compound

a

It is necessary that the test report indicated the source of the test piece.

8.2 Finished hose

When tested in accordance with the methods in Table 3, the physical properties of the finished hose

shall comply with the values given in Table 3.

4 © ISO 2015 – All rights reserved

Table 3 — Physical properties of hoses

Property Unit Requirement Test piece Test method

No leakage or

ISO 1402

other signs of

Proof pressure at 24 bar — Full length of hose

weakness nor

Proof test pressure

abrupt twisting

ISO 1402

Short length cut from

Burst pressure, min. bar 48

hose

Burst pressure

Volumetric expansion, max. 2

ISO 6801

At least 1 m cut from

— Type 1 and Type 2 %

hose

1 Test pressure 3 bar

— Type 3

Adhesion between components 2,4

on

N/mm ISO 8033/Annex B

— Un-aged hose, min.

1,8

— Aged hose, min.

T ≥ 0,8 D

Short length cut from

D hose

ISO 10619–1

No kinking or

Ambient temperature bending — Nominal diameter

deformation

greater than 20 % C = 10 × nominal bore

of the outside

diameter

No cracks or

Annex C, Reference

breaks

Low temperature flexibility hose with nominal Annex C

Maximum bend-

bore 16, 19 or 21

ing force 180 N

Change in length at proof

% 0 to +5 Full length of hose ISO 1402

pressure

ISO 7326 168 h at

No cracks under Short length cut from 40 °C, 50 pphm, relative

Ozone resistance of cover —

×2 magnification hose humidity (55 ± 10) %

and elongation 20 %

2 m test piece cut

Fuel permeation of hose max.

ml/ 12 from hose Reference

Annex D

Normal temperature class

(m⋅day) 18 hose with nominal

Low temperature class

bore 16, 19 or 21

Electrical resistance max.

ISO 8031:2009, Method

Equivalent to the

1 × 10

4.5, 4.6, or 4.7

Ω length of hose

Category Ω

assembly

Category M 1 × 10 ISO 8031:2009

a) Burning with

a naked flame to

cease within 20 s

of removal of the

burner;

b) no further Length of assembly to

Flammability — Annex E

glowing suit test rig

visible 2 min after

removal of t

...

ISO 5772:2015は、計測された燃料供給システムで使用されるゴムおよびプラスチック製のホースとホースアセンブリに対する最小要件を規定しています。この規格では、2つのカテゴリーと2つのクラスにわたって3つのタイプのホースとホースアセンブリの最小要件が設定されています。これらのアセンブリは、最大15%までの酸素化燃料を含む計測された燃料の供給に使用されることを想定しています。通常温度クラスでは-30℃から+55℃の周囲温度で、低温度クラスでは-40℃から+55℃の温度で使用可能であり、作業圧力は16バール(1.6 MPa)以下に耐えることができます。注意:1バールは0.1 MPaに相当します。

ISO 5772:2015 outlines the specifications for rubber and plastic hoses and hose assemblies used in measured fuel dispensing systems. It sets minimum requirements for three types of hoses in two categories and two classes of hose assemblies. These assemblies are designed for use with measured fuel dispensing, including oxygenated fuels with a maximum of 15% oxygenated compounds. The hoses and assemblies can be used in temperatures ranging from -30 °C to +55 °C for normal temperature class and -40 °C to +55 °C for low temperature class. They can withstand working pressures up to and including 16 bar (1.6 MPa). Note: 1 bar is equal to 0.1 MPa.

ISO 5772:2015는 측정된 연료 분배 시스템에서 사용되는 고무 및 플라스틱 호스 및 호스 어셈블리에 대한 최소 요구 사항을 명시하고 있습니다. 이 표준은 두 가지 범주의 세 가지 유형의 호스 및 호스 어셈블리에 대한 규정을 포함하고 있습니다. 이 어셈블리는 최대 15% 산소화 물질을 포함하는 산소화 연료와 함께 사용될 수 있습니다. 작동 압력은 16 바 (1.6 MPa)를 초과하지 않는 범위에서 정상 온도 클래스에는 -30°C에서 +55°C, 저온 온도 클래스에는 -40°C에서 +55°C의 온도 범위에서 사용할 수 있습니다.

ISO 5772:2015は、計測された燃料の供給システムで使用されるゴム製およびプラスチック製のホースおよびホースアセンブリの最小要件を規定しています。この規格では、2つのカテゴリーと2つのクラスのホースアセンブリに対して3つのタイプのホースの最小要件が定められています。これらのアセンブリは最大15%の酸素化合物を含む酸素化燃料と使用することができます。作業圧力は16バール(1.6 MPa)以下で、通常温度クラスには-30℃から+55℃の温度範囲で、低温クラスには-40℃から+55℃の温度範囲で使用されることが想定されています。

ISO 5772:2015은 측정된 연료 분배 시스템에 사용되는 고무 및 플라스틱 호스 및 호스 어셈블리에 대한 최소 요구 사항을 규정합니다. 이 규격은 두 가지 범주의 세 가지 유형의 호스와 두 가지 클래스의 호스 어셈블리에 대한 최소 요구 사항을 설정합니다. 이러한 어셈블리는 산소화 연료 (최대 15 % 산소화 화합물)를 포함한 측정된 연료 분배에 사용되며, 일반 온도 등급에서는 -30 °C부터 +55 °C까지의 주변 온도에서, 낮은 온도 등급에서는 -40 °C부터 +55 °C까지의 온도에서 작동 압력이 16 바 (1.6 MPa) 이하일 때 사용하기 위해 설계되었습니다. 주의: 1 바는 0.1 MPa와 같습니다.

ISO 5772:2015 is a specification that outlines the minimum requirements for rubber and plastic hoses and hose assemblies used in measured fuel dispensing systems. The standard includes three types of hoses in two categories and two classes of hose assemblies. These assemblies are designed for use with oxygenated fuels up to a maximum of 15% oxygenated compounds. They can be used within a temperature range of -30°C to +55°C for normal temperature class and -40°C to +55°C for low temperature class. The working pressure should not exceed 16 bar (1.6 MPa).

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...