ISO/TR 18146:2015

(Main)Space systems - Space debris mitigation design and operation guidelines for spacecraft

Space systems - Space debris mitigation design and operation guidelines for spacecraft

ISO/TR 18146:2015 contains non-normative information on spacecraft design and operational practices for mitigating space debris. ISO/TR 18146:2015 is a supporting document to the family of international standards addressing space debris mitigation (see 2.2). The purpose of these standards is to minimize the creation of additional space debris by ensuring that spacecraft and launch vehicle orbital stages are designed, operated and disposed of in a manner that prevents them from generating debris throughout their orbital lifetime. ISO/TR 18146:2015 can be used to guide spacecraft engineers in the application of these space debris mitigation standards. Table 1 lists the main debris mitigation requirements defined in the standards and compares them to equivalent recommendations published by the United Nations and the Inter-Agency Space Debris Coordination Committee.

Systèmes spatiaux — Conception de mitigation des débris spatiaux et lignes directrices de manoeuvre de la navette

General Information

Relations

Frequently Asked Questions

ISO/TR 18146:2015 is a technical report published by the International Organization for Standardization (ISO). Its full title is "Space systems - Space debris mitigation design and operation guidelines for spacecraft". This standard covers: ISO/TR 18146:2015 contains non-normative information on spacecraft design and operational practices for mitigating space debris. ISO/TR 18146:2015 is a supporting document to the family of international standards addressing space debris mitigation (see 2.2). The purpose of these standards is to minimize the creation of additional space debris by ensuring that spacecraft and launch vehicle orbital stages are designed, operated and disposed of in a manner that prevents them from generating debris throughout their orbital lifetime. ISO/TR 18146:2015 can be used to guide spacecraft engineers in the application of these space debris mitigation standards. Table 1 lists the main debris mitigation requirements defined in the standards and compares them to equivalent recommendations published by the United Nations and the Inter-Agency Space Debris Coordination Committee.

ISO/TR 18146:2015 contains non-normative information on spacecraft design and operational practices for mitigating space debris. ISO/TR 18146:2015 is a supporting document to the family of international standards addressing space debris mitigation (see 2.2). The purpose of these standards is to minimize the creation of additional space debris by ensuring that spacecraft and launch vehicle orbital stages are designed, operated and disposed of in a manner that prevents them from generating debris throughout their orbital lifetime. ISO/TR 18146:2015 can be used to guide spacecraft engineers in the application of these space debris mitigation standards. Table 1 lists the main debris mitigation requirements defined in the standards and compares them to equivalent recommendations published by the United Nations and the Inter-Agency Space Debris Coordination Committee.

ISO/TR 18146:2015 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/TR 18146:2015 has the following relationships with other standards: It is inter standard links to ISO/TR 18146:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO/TR 18146:2015 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 18146

First edition

2015-10-01

Space systems — Space debris

mitigation design and operation

guidelines for spacecraft

Systèmes spatiaux — Conception de mitigation des débris spatiaux et

lignes directrices de manoeuvre de la navette

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

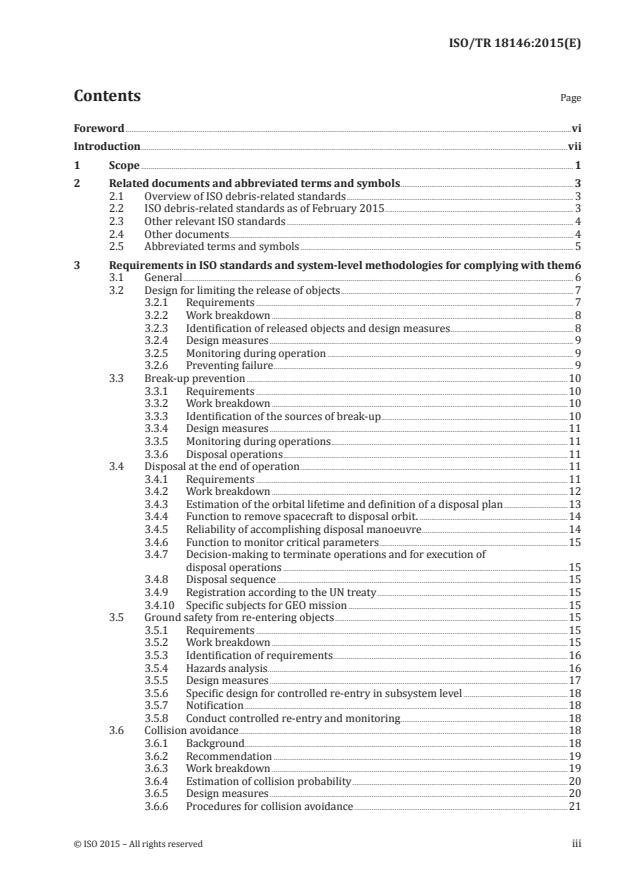

Contents Page

Foreword .vi

Introduction .vii

1 Scope . 1

2 Related documents and abbreviated terms and symbols . 3

2.1 Overview of ISO debris-related standards . 3

2.2 ISO debris-related standards as of February 2015 . 3

2.3 Other relevant ISO standards . 4

2.4 Other documents . 4

2.5 Abbreviated terms and symbols . 5

3 Requirements in ISO standards and system-level methodologies for complying with them 6

3.1 General . 6

3.2 Design for limiting the release of objects . 7

3.2.1 Requirements . 7

3.2.2 Work breakdown . 8

3.2.3 Identification of released objects and design measures . 8

3.2.4 Design measures . 9

3.2.5 Monitoring during operation . 9

3.2.6 Preventing failure . 9

3.3 Break-up prevention .10

3.3.1 Requirements .10

3.3.2 Work breakdown .10

3.3.3 Identification of the sources of break-up .10

3.3.4 Design measures .11

3.3.5 Monitoring during operations .11

3.3.6 Disposal operations .11

3.4 Disposal at the end of operation .11

3.4.1 Requirements .11

3.4.2 Work breakdown .12

3.4.3 Estimation of the orbital lifetime and definition of a disposal plan .13

3.4.4 Function to remove spacecraft to disposal orbit. .14

3.4.5 Reliability of accomplishing disposal manoeuvre .14

3.4.6 Function to monitor critical parameters .15

3.4.7 Decision-making to terminate operations and for execution of

disposal operations .15

3.4.8 Disposal sequence .15

3.4.9 Registration according to the UN treaty .15

3.4.10 Specific subjects for GEO mission .15

3.5 Ground safety from re-entering objects .15

3.5.1 Requirements .15

3.5.2 Work breakdown .15

3.5.3 Identification of requirements .16

3.5.4 Hazards analysis .16

3.5.5 Design measures .17

3.5.6 Specific design for controlled re-entry in subsystem level .18

3.5.7 Notification .18

3.5.8 Conduct controlled re-entry and monitoring .18

3.6 Collision avoidance .18

3.6.1 Background.18

3.6.2 Recommendation .19

3.6.3 Work breakdown .19

3.6.4 Estimation of collision probability .20

3.6.5 Design measures .20

3.6.6 Procedures for collision avoidance .21

3.6.7 Detection of risk .21

3.6.8 Avoidance and return manoeuvres .21

3.7 Protection against the impact of micro-debris .22

3.7.1 Background.22

3.7.2 Recommendation .23

3.7.3 Work breakdown .23

3.7.4 Preventive measures .23

3.8 Quality and reliability assurance .24

4 Debris-related work in the development cycle .25

4.1 Concept of debris-related work in phased planning .25

4.2 Mission analysis phase (phase 0 or pre-phase A) .28

4.2.1 General.28

4.2.2 Debris-related work .28

4.3 Feasibility phase (phase A) .29

4.4 Definition phase (phase B) .29

4.4.1 Work in phase B .29

4.4.2 Work procedure .29

4.5 Development phase (phase C) .30

4.5.1 Work in phase C .30

4.5.2 Conditions .31

4.6 Production phase (phase D) .31

4.6.1 Work in phase D .31

4.6.2 Qualification review .32

4.7 Utilization phase (phase E) .32

4.7.1 Launch preparation .32

4.7.2 Lift-off time .33

4.7.3 Initial operation .33

4.7.4 Normal operation .33

4.7.5 Decision to terminate operations .33

4.7.6 Process for extending mission operations .34

4.8 Disposal phase (phase F) .34

5 System-level considerations .35

5.1 Mission design .35

5.2 Mass allocation .35

5.3 Propellant allocation .36

5.4 Power allocation .36

6 Subsystem/component design and operation .36

6.1 General .36

6.2 Debris-mitigation measures and subsystem-level actions for realizing them .37

6.3 Propulsion subsystem .37

6.3.1 Debris-related design .37

6.3.2 Considerations for propulsion subsystems .37

6.3.3 Consideration in component design .41

6.4 Attitude and orbit control subsystem .43

6.4.1 Debris-related designs .43

6.4.2 Considerations for AOCS .43

6.4.3 Considerations in component design.44

6.5 Power-supply subsystem .44

6.5.1 Debris-related designs .44

6.5.2 Considerations for power-supply subsystems .45

6.5.3 Considerations in component design.46

6.6 TT&C subsystem .47

6.6.1 Debris-related designs .47

6.6.2 Considerations for TT&C subsystems .47

6.6.3 Considerations in component design.48

6.7 Structural subsystem .48

6.7.1 Debris-related design .48

iv © ISO 2015 – All rights reserved

6.7.2 Considerations for structural subsystems .49

6.8 Thermal-control subsystem .49

6.8.1 Debris-related design .49

6.8.2 Considerations for thermal-control subsystem .50

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2. www.iso.org/directives

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received. www.iso.org/patents

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 20, Aircraft and space vehicles, Subcommittee

SC 14, Space systems and operations.

vi © ISO 2015 – All rights reserved

Introduction

Coping with debris is essential to preventing the deterioration of the orbital environment and ensuring

the sustainability of space activities. Effective actions must also be taken to ensure the safety of those

on the ground from re-entering objects that were disposed of from low-Earth orbit.

Recently, the orbital environment has become so deteriorated by debris that action must be taken to

prevent damage due to the impact. Collision avoidance manoeuvres should be taken to avoid large

debris (larger than 10 cm, for example), which can be observed from the ground. Spacecraft design

should protect against micro-debris (even smaller than 1 mm) that can cause critical damage to

vulnerable components.

The following ISO standards and technical reports cover these issues: ISO 24113, Space systems — Space

debris mitigation requirements; ISO/TR 16158, Space systems — Avoiding collisions with orbiting objects;

ISO 16126, Space systems — Assessment of the survivability of unmanned spacecraft against space debris

and meteoroid impacts to ensure successful post-mission disposal. Other ISO documents, introduced in

Clause 2, are currently being developed to encourage debris mitigation and protection from debris

impact. Table 1 shows those requirements together with the recommendations in the United Nations

Space Debris Mitigation Guidelines and the Inter-Agency Space Debris Coordination Committee (IADC)

space debris guidelines referred to in the UN guidelines.

Reliability and quality shortfalls have resulted in fragmentation events that generated thousands

of fragments. ISO 24113 and other debris-mitigation guidelines make the assumption that space

hardware quality and reliability issues have been addressed by other management programs. But for

low-cost or low-criticality missions, spacecraft of reduced quality have been developed. The failure

of such spacecraft may not pose critical damage to their owners but they may adversely affect the

environment and impair the sustainability of space activities. This Technical Report suggests activities

that can improve reliability and quality sufficiently to avoid this problem. This aspect of space-debris

mitigation is particularly important for micro-satellites developed by universities and newcomers to

space activities.

TECHNICAL REPORT ISO/TR 18146:2015(E)

Space systems — Space debris mitigation design and

operation guidelines for spacecraft

1 Scope

This Technical Report contains non-normative information on spacecraft design and operational

practices for mitigating space debris.

This Technical Report is a supporting document to the family of international standards addressing

space debris mitigation (see 2.2). The purpose of these standards is to minimize the creation of

additional space debris by ensuring that spacecraft and launch vehicle orbital stages are designed,

operated and disposed of in a manner that prevents them from generating debris throughout their

orbital lifetime.

This Technical Report can be used to guide spacecraft engineers in the application of these space debris

mitigation standards. Table 1 lists the main debris mitigation requirements defined in the standards

and compares them to equivalent recommendations published by the United Nations and the Inter-

Agency Space Debris Coordination Committee.

In Clause 3, the main space debris mitigation requirements are reported and discussed. Clause 4

provides guidance for life-cycle implementation of space debris mitigation related activities.

In Clause 5, the system level aspects stemming from the space debris mitigation requirements are

highlighted, while in Clause 6, the impacts at subsystem and component levels are detailed.

Where it is not directly required by existing ISO standards but considered relevant to spacecraft

operations, design and debris mitigation, content in this Technical Report is labelled as such with

“[information]”.

2 © ISO 2015 – All rights reserved

Table 1 — Comparison of ISO debris-related documents with UN and IADC space debris mitigation Guidelines

Measures ISO International Standards (or Technical Reports) UN Guidelines IADC Guidelines

General measures for avoiding the

ISO 24113, 6.1.1 Recommendation-1 5.1

release of objects

Operational debris Included in above Included in above 5.1

Released objects

Slag from solid motors ISO 24113, 6.1.2.2, 6.1.2.3 -- --

ISO 24113, 6.1.2.1

Combustion products from pyrotechnics -- --

(Combustion Products < 1 mm)

Intentional destruction ISO 24113, 6.2.1 Recommendation-4 5.2.3

ISO 24113, 6.2.2

5.2.2

On-orbital break- Accident during operation Recommendation-2

(Monitoring)

-3

(Probability < 10 )

ups

Post-mission break-up (Passivation,

ISO 24113, 6.2.2.3 (Detailed in ISO 16127) Recommendation-5 5.2.1

etc.)

Recommendation-7

ISO 24113, 6.3.2 (Detailed in ISO 26872)

5.3.1

Disposal at end of (No quantitative requirements)

6.3.2.1: General Requirement.

operation

Reorbit at EOL 235 km+ (1000·Cr·A/m),

Note: ITU-R S.1003-1 recommends; 235

6.3.2.2: 235 km+ (1000·Cr·A/m), e < 0,003

GEO km + 1000 Cr*A/M

e < 0,003

6.3.1: Success Probability > 0,9

Here, A[m ], M[kg], Cr[-]

ISO 24113, 6.3.3 (Detailed in ISO 16164)

Recommendation-6 5.3.2

Reduction of orbital lifetime 6.3.3.1: EOL Lifetime < 25 years

(No quantitative requirements) (Recommend 25 years)

Disposal at end of

6.3.1: Success Probability > 0,9

operation

ISO 24113, 6.3.3.2 (f)

LEO

Transfer to graveyard Mentioned in recommendation-6 5.3.2

(guarantee 100 years’ non-interference)

Other options ISO 24113, 6.3.3.2 (a) ~ (e) -- 5.3.2

Re-entry Avoidance of ground casualties ISO 24113, 6.3.4 (Detailed in ISO 27875) Included in Recommendation-6 5.3.2

Collision avoidance for large debris ISO/TR 16158 (for assessment) Recommendation-3 5.4

Protection from the impact of micro-debris ISO 16126 (for assessment) -- 5.4

2 Related documents and abbreviated terms and symbols

2.1 Overview of ISO debris-related standards

The requirements, recommendations, and best practices for mitigating debris generation and

preventing other debris related problems are now examined.

Figure 1 shows a general diagram of major ISO documents relevant to debris.

Figure 1 — Structure of major ISO debris-related standards

2.2 ISO debris-related standards as of February 2015

The following ISO standards have been published to address space debris mitigation:

(1) ISO 11227:2012, Space systems — Test procedures to evaluate spacecraft material ejector upon

hypervelocity impact

(2) ISO 14200:2012, Space environment (natural and artificial) — Guide to process-based

implementation of meteoroid and debris environmental models (orbital altitude below GEO + 200 km)

(3) ISO 16126:2014, Space systems — Assessment of survivability of unmanned spacecraft against

space debris and meteoroid impacts to ensure successful post-mission disposal

(4) ISO 16127:2014, Space systems — Prevention of break-up of unmanned spacecraft

(5) ISO 16164:2015, Space systems — Disposal of satellites operating in or crossing Low Earth Orbit

(6) ISO 23339:2010, Space systems — Unmanned spacecraft residual propellant mass estimation for

disposal manoeuvres

(7) ISO 24113:2011, Space systems — Space debris mitigation requirements

(8) ISO 26872:2010, Space systems — Disposal of satellites operating at geosynchronous altitude

(9) ISO 27852:2011, Space systems — Estimation of orbit lifetime

(10) ISO 27875:2010, Space systems — Re-entry safety control for unmanned spacecraft and launch

vehicle orbital stages

2.3 Other relevant ISO standards

The following ISO standards are not specific to space debris mitigation but are considered relevant:

(1) ISO/TR 11225:2012, Space environment (natural and artificial) — Guide to reference and standard

atmosphere models

(2) ISO/TR 11233:2014, Space systems — Orbit determination and estimation — Process for

describing techniques

(3) ISO 14300-1:2011, Space systems — Programme management — Part 1: Structuring of a project

(4) ISO 14623:2003, Space systems — Pressure vessels and pressurized structures — Design and

operation

(5) ISO/TR 16158:2013, Space systems — Avoiding collisions among orbiting objects: Best practices,

data requirements, and operational concepts

(6) ISO 16404:2013, Space systems — Programme management — Requirements management

(7) ISO 27025:2010, Program management — Quality assurance requirements

2.4 Other documents

The following relevant documents are listed to provide the reader with additional background of the

above ISO standards:

(1) UN, Space Debris Mitigation Guidelines of the Scientific and Technical Subcommittee of the

Committee on the Peaceful Uses of Outer Space, Annex IV of A/AC.105/890, 6 March 2007, endorsed by

the United Nations General Assembly under Resolution A/RES/62/217

(2) IADC Space Debris Mitigation Guidelines, IADC-02-01, Revision 1, September 2007, available at

http://www.iadc-online.org/index.cgi?item=docs_pub

(3) Support Document to the IADC Space Debris Mitigation Guidelines, IADC-04-06, Issue 1, 5 October

2004, available at http://www.iadc-online.org/index.cgi?item=docs_pub

4 © ISO 2015 – All rights reserved

(4) ITU Recommendation on GEO Disposal, ITU-R S.1003, January 2004

(5) IADC-08-03 Sensor system to detect impact on spacecraft (http://www.iadc-online.org/)

2.5 Abbreviated terms and symbols

A/m: Area-to-mass

AOCS: Attitude and Orbit Control System

CDR: Critical Design Review

CFRP: Carbon-Fiber-Reinforced Plastic

CNES: Centre National d’Etudes Spatiales

COPUOS: Committee on the Peaceful Uses of Outer Space

Cr: Solar Radiation Pressure Coefficient

DAS: Debris Assessment Software (NASA)

Draft International Standard (drafting phase in the process in ISO for registration of new

DIS:

standard)

DoF: Degrees-of-Freedom

COTS: Commercial Off-The-Shelf

DRAMA: Debris Risk Assessment and Mitigation Analysis (ESA)

e: eccentricity

EOMDP: End-of-Mission (Operation) Disposal Plan

EOL: End of Life

ESA: European Space Agency

FMEA: Failure Mode and Effect Analysis

GEO: Geosynchronous orbit

GPS: Global Positioning System

GTO: Geosynchronous transfer orbit

IADC: Inter-Agency Space Debris Coordination Committee

IRU: Inertial Reference Unit

ISO: International Organization for Standardization

JAXA: Japan Aerospace Exploration Agency

JSpOC: Joint Space Operations Center (USA)

LEGEND: LEO-to-GEO Environment Debris model

LEO: Low Earth orbit

MASTER: Meteoroid and Space Debris Terrestrial Environment Reference

MEO: Medium Earth orbit

MMOD: Micro-Meteoroid Orbital Debris

NOTAM: Notice To Airmen and Notice to Mariners

NSS: NASA Safety Standard

ORDEM: Orbital Debris Engineering Model

ORSAT: Object Re-entry Survival Analysis Tool

PDR: Preliminary Design Review

PNF: Probability of no Failures

QA: Quality Assurance

QR: Qualification Review

RAAN: Right ascension of the ascending node

RCS: Reaction Control System

S/C: Spacecraft

SCARAB: Space Craft Atmospheric Re-entry and Aerothermal Break-up

SDA: Space Data Association,

SDR: System Definition Review

SDMP: Space-Debris-Mitigation Plan

STELA: Semi-analytic Tool for End of Life Analysis (CNES)

USSTRATCOM: United States Strategic Command

STS: Space Transportation System

TLE: Two-Line Element Set

TR: Technical Report (a type of ISO document)

TT&C: Telemetry Tracking and Command

UN: United Nations

United Nations Committee on the Peaceful Uses of Outer Space Scientific and Technical

UNCOPUOS:

Subcommittee

3 Requirements in ISO standards and system-level methodologies for

complying with them

3.1 General

To accomplish comprehensive activities for debris mitigation and protection work, the following steps

are to be considered:

(1) Identifying debris-related requirements, recommendations and best practices.

(2) Determining how to comply with these requirements, recommendations, and best practices.

6 © ISO 2015 – All rights reserved

(3) Apply those methods early and throughout development and manufacturing to ensure sound debris

mitigation capability in the final product.

(4) Apply appropriate quality assurance and qualification program to ensure compliance with debris

mitigation requirements

This sub-clause provides methodologies for taking comprehensive action at the system level. More

detailed information for action of subsystem and component levels is provided in Clause 6. The

following specific subjects are emphasized:

(1) Limiting the release of objects in protected orbital regions.

(2) Preventing fragmentation in orbit.

(3) Proper disposal during the end of operation to preserve the environment in protected orbital regions.

(4) Minimization of hazard on the ground from re-entering debris.

(5) Collision avoidance for trackable known objects.

(6) Protection against the impact of micro-debris and meteoroid.

(7) Quality, safety and reliability assurance.

3.2 Design for limiting the release of objects

3.2.1 Requirements

ISO 24113, 6.1 requires avoiding the intentional release of space debris into Earth orbit during

normal operations:

(1) For general objects:

a) Spacecraft and launch vehicle orbital stages shall be designed so as not to release space debris

into Earth orbit during normal operations.

b) Space debris released into Earth orbit as part of normal operations, other than as covered by

next (2), shall remain outside the GEO protected region, and its presence in the LEO protected

region shall be limited to a maximum of 25 years after release.

(2) For the combustion-related products:

a) Pyrotechnic devices shall be designed so as to avoid the release into Earth orbit of products

larger than 1 mm in their largest dimension.

b) Solid rocket motors shall be designed and operated so as to avoid releasing solid combustion

products into the GEO protected region.

c) In the design and operation of solid rocket motors, methods to avoid the release of solid combustion

products that might contaminate the LEO protected region shall be considered.

The following classes of released objects are of concern from an orbital debris mitigation standpoint:

(1) Objects released as directed by mission requirements (ISO 24113, 6.1.1).

(2) Mission-related objects, such as fasteners, under the responsibility of designers (ISO 24113, 6.1.1).

(3) Combustion products from pyrotechnic devices (ISO 24113, 6.1.2.1).

(4) Combustion products from solid motors (ISO 24113, 6.1.2.2).

ISO 24113, 6.1.1.2 states that if objects must unavoidably be released despite requirements in ISO 24113,

6.1.1.1, orbital lifetime of such objects in Low Earth Orbit (LEO) and interference with Geostationary

Earth Orbit (GEO) is to be limited as described in ISO 24113, 6.1.1.2. A typical example is the support

structure utilized in multiple payloads mission.

3.2.2 Work breakdown

Table 2 shows the work breakdown for the actions required to prevent the releasing of debris.

Table 2 — Work breakdown for preventing the release of objects

Process Subjects Major work

Preventive measures I de n t i f ic a t io n of (1) Take preventive design to avoid releasing objects turning into

released objects and space debris. (ISO 24113, 6.1)

design measures

(2) If objects might be released unintentionally, designers will

investigate design problems and take appropriate action during

design phase. (Examples: paint flakes, insulators)

(3) If release is unavoidable, designers will estimate the orbital

lifetime of released objects and check compliance with 6.1.1.2.

Risk detection Monitoring during oper- (1) Confirm that the orbiting characteristics of released parts are

ation as estimated, if needed.

(2) If an unexpected object is detected, the origin of the objects

will be confirmed.

Countermeasures Preventive measures If an object is released unexpectedly, it will be investigated and

appropriate action will be taken to avoid repeating the release in

the following missions.

3.2.3 Identification of released objects and design measures

Identify the parts planned to be released, estimate their orbital lifetimes, and determine the propriety

of their release.

(1) Mission requirements that require dispersing objects

Assess the effects of proposed mission requirements on the environment. If the proposed mission

may deteriorate the environment more than justified by its benefit, system engineering may suggest

alternative approaches.

Examples are:

a) The experiment called “WESTFORD NEEDLES,” conducted in 1961 and 1963, scattered 480 million

needles in orbit. More than 100 clumps of needles have been registered and many of them are still

in orbit. The legacy of Project West Ford can still be found in international policies, including the first

major United Nations accord on activities in outer space that calls for international consultations

before undertaking an experiment which might cause “potentially harmful interference with activities

1)

of other State Parties in the peaceful exploration and use of outer space.

b) Missions that conduct intentional fragmentation (one of the major causes of deterioration of the

orbital environment).

(2) Mission-related objects

Release of the following objects shall be avoided by appropriate mission and spacecraft design

(ISO 24113, 6.1.1):

a) fasteners for deploying and holding devices for panels or antennas

b) nozzle closures for propulsion devices and certain types of solid motor igniters

1) [Ref. NASA, JSC, Orbital Debris Quarterly News, Volume 17, Issue 4 October 2013 http://orbitaldebris.jsc.nasa.

gov/]

8 © ISO 2015 – All rights reserved

c) clamp bands that tie spacecraft and launch vehicles (usually as vehicle components)

Remark: The structural elements which support upper spacecraft used in the case of multi-payloads

launching are allowed to be released due to their unavoidability. Disposal orbit of these elements

should be comply with 6.1.1.2. (Note that these elements usually belong to the launch vehicle, not

the spacecraft.)

(3) Combustion products from pyrotechnic devices

Devices should be selected and/or designed to avoid the production and release of combustion by-

products. Employing vehicle components that trap all fragments and combustion products inside

for segregation (ISO 24113, 6.1.2.1).

(4) Combustion products from solid motors

Solid motors should not generate slag in geosynchronous orbit. (ISO 24113, 6.1.2.2)

In very low Earth orbit, particles smaller than 1 cm will decay quickly. But large-sized slag ejected

in LEO at the end of propulsion burns is a concern; generation of this kind of slag can be prevented

by either designing the nozzle adequately to avoid a pocket upstream of the nozzle that may trap

melting metals or to develop propellant that does not contain metal (i.e. aluminium).

3.2.4 Design measures

In general, only devices that do not release parts into the space environment are to be selected. If parts

would be released for unavoidable reasons, the orbital lifetime of the parts and the impact on other

spacecraft should be assessed, and a final decision should be made about whether to proceed with the

mission. The orbital lifetime can be assessed according to ISO 27852. This Technical Report does not

designate a specific analysis tool but rather requires that the user employ specific techniques depending

upon orbit regime, so that designers can select any tool(s) which adhere to ISO 27852 approved

techniques. Available simplified tools that can be used to estimate the long term orbital lifetime are,

for instance: NASA DAS (Debris Assessment Software), ESA DRAMA (Debris Risk Assessment and

Mitigation Analysis) [an account at https://sdup.esoc.esa.int must be created to obtain a license before

downloading], or CNES STELA (Semi-analytic Tool for End of Life Analysis; https://logiciels.cnes.

fr/content/stela?language=en).

3.2.5 Monitoring during operation

[Information] The release of objects should be confirmed by ground-based space tracking facilities to

ensure that they released as expected and that their orbital lifetimes are sufficiently short. The Space

Situation Report provided by US Joint Space Operations Center (JSpOC) provides a good reference.

3.2.6 Preventing failure

[Information] If objects are released unexpectedly, the origin of the objects should be identified to help

prevent recurrence in future missions. Because such phenomena may indicate a malfunction, the situation

should be reviewed carefully and appropriate action taken to prevent further abnormal conditions.

3.3 Break-up prevention

3.3.1 Requirements

ISO 24113 requires the prevention of space object break-ups in 6.2 as follows:

(1) Intentional break-ups

a) In Earth orbit, intentional break-up of a spacecraft or launch vehicle orbital stage shall be avoided.

(2) Accidental break-ups

a) The probability of accidental break-up of a spacecraft or launch vehicle orbital stage shall be no

-3

greater than 10 until its end of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...