ISO 17223:2014

(Main)Plastics — Determination of yellowness index and change in yellowness index

Plastics — Determination of yellowness index and change in yellowness index

ISO 17223:2014 specifies an instrumental method for determining the yellowness index and change in yellowness index on clear, translucent, or opaque plastics.

Plastiques — Détermination de l'indice de jaunissement et du changement de l'indice de jaunissement

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 17223

First edition

2014-05-01

Plastics — Determination of

yellowness index and change in

yellowness index

Plastiques — Détermination de l’indice de jaunissement et du

changement de l’indice de jaunissement

Reference number

©

ISO 2014

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

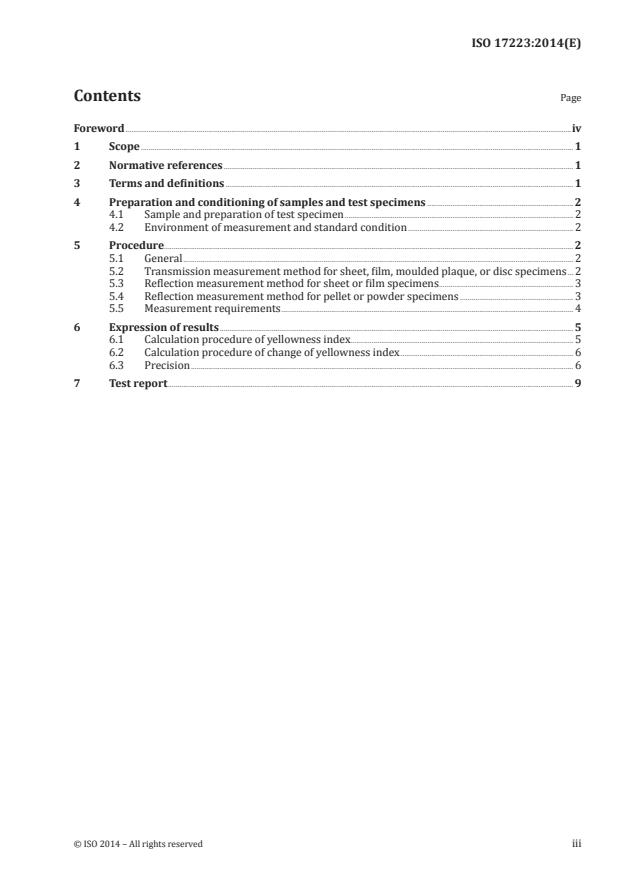

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Preparation and conditioning of samples and test specimens . 2

4.1 Sample and preparation of test specimen . 2

4.2 Environment of measurement and standard condition . 2

5 Procedure. 2

5.1 General . 2

5.2 Transmission measurement method for sheet, film, moulded plaque, or disc specimens . 2

5.3 Reflection measurement method for sheet or film specimens . 3

5.4 Reflection measurement method for pellet or powder specimens . 3

5.5 Measurement requirements . 4

6 Expression of results . 5

6.1 Calculation procedure of yellowness index . 5

6.2 Calculation procedure of change of yellowness index . 6

6.3 Precision . 6

7 Test report . 9

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 61, Plastics, Subcommittee SC 5, Physical-

chemical properties.

iv © ISO 2014 – All rights reserved

INTERNATIONAL STANDARD ISO 17223:2014(E)

Plastics — Determination of yellowness index and change

in yellowness index

1 Scope

This International Standard specifies an instrumental method for determining the yellowness index

and change in yellowness index on clear, translucent, or opaque plastics.

NOTE 1 Specimen shapes can include moulded plaques or discs, films, sheets, powders, and pellets. Plaque, disc,

film, and sheet specimens can have smooth, matt, or patterned surfaces. Fluorescent plastics are not permitted.

NOTE 2 Change in yellowness index is often used to evaluate the effect of environment, e.g. heat, UV exposure,

etc., on colour stability.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 291, Plastics — Standard atmospheres for conditioning and testing

ISO 1043-1, Plastics — Symbols and abbreviated terms — Part 1: Basic polymers and their special

characteristics

ISO 5725-2, Accuracy (trueness and precision) of measurement methods and results — Part 2: Basic method

for the determination of repeatability and reproducibility of a standard measurement method

ASTM E313, Standard Practice for Calculating Yellowness and Whiteness Indices from Instrumentally

Measured Color Coordinates

CIE 15, Colorimetry

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

yellowness index

YI

deviation in chroma from colourless or whiteness toward yellow

3.2

change of yellowness index

ΔYI

difference between yellowness index of specimen before additional test and yellowness index of

specimen after additional test

Note 1 to entry: For example, before and after exposure to specified conditions.

4 Preparation and conditioning of samples and test specimens

4.1 Sample and preparation of test specimen

Samples shall be gathered by a statistical method from the batch to be evaluated. In all cases, the sample

shall be used as received unless the purpose is to evaluate pellets or powders converted into a final

shape, i.e. moulded plaques or discs, films, or sheets.

4.2 Environment of measurement and standard condition

The standard condition of the environment of measurement shall be set as 23 °C/50 % RH condition as

described in ISO 291.

5 Procedure

5.1 General

Colourimetry is derived from calculating tristimulus values by spectral or tristimulus measurements.

In the case of the specimen with the diffusibility of the light, the measuring apparatus shall have an

integrating sphere or other system that can detect diffusion light. Optical geometries, requirements,

and solution for different measurement methods are given in Table 1.

Table 1 — Optical geometries, requirements, and solution for different measurement methods

Optical geometries

Measurement method

in accordance with Requirements Solution

using integrating sphere

CIE 15

Transmission measurements di:0, de:0 A part of the incident light on the Arrange a baffle

integrating sphere shall not irradi- plate that is the

Reflection measurement di:8, de:8

ate a specimen directly. same quality as the

integrating sphere.

Transmission measurements 0:di, 0:de A part of a reflected or transmitted

light from a specimen shall not be

Reflection measurement 8:di, 8:de

introduced into a detector directly.

Optical geometries

Measurement method with-

in accordance with

out integrating sphere

CIE 15

Transmission measurements 0:0 These optical geometries don’t use an integrating

sphere.

Reflection measurement 45a:0, 0:45a, 45x:0,

0:45a

NOTE 1 In the case of measuring a diffusing specimen, satisfying the above-mentioned condition is important.

NOTE 2 In the case of measuring a translucent specimen, the colour or thickness of the specimen might make

an influence.

NOTE 3 Optical geometries are described in CIE 15.

Tristimulus values are represented in the XYZ colour system (2° visual field)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.