ISO 15759:2002

(Main)Medical infusion equipment — Plastics caps with inserted elastomeric liner for containers manufactured by the Blow-Fill-Seal (BFS) process

Medical infusion equipment — Plastics caps with inserted elastomeric liner for containers manufactured by the Blow-Fill-Seal (BFS) process

Matériel de perfusion à usage médical — Capsules plastiques avec un joint à base d'élastomère pour récipients (flacons plastiques) produits par le procédé simultané d'extrusion/soufflage/remplissage (ESR)

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 15759

First edition

2002-04-01

Medical infusion equipment — Plastics

caps with inserted elastomeric liner for

containers manufactured by the Blow-Fill-

Seal (BFS) process

Matériel de perfusion à usage médical — Capsules plastiques avec un joint

à base d'élastomère pour récipients (flacons plastiques) produits par le

procédé simultané d'extrusion/soufflage/remplissage (ESR)

Reference number

©

ISO 2002

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not be

edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In downloading this file,

parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation parameters

were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the unlikely event

that a problem relating to it is found, please inform the Central Secretariat at the address given below.

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or ISO's

member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.ch

Web www.iso.ch

Printed in Switzerland

©

ii ISO 2002 – All rights reserved

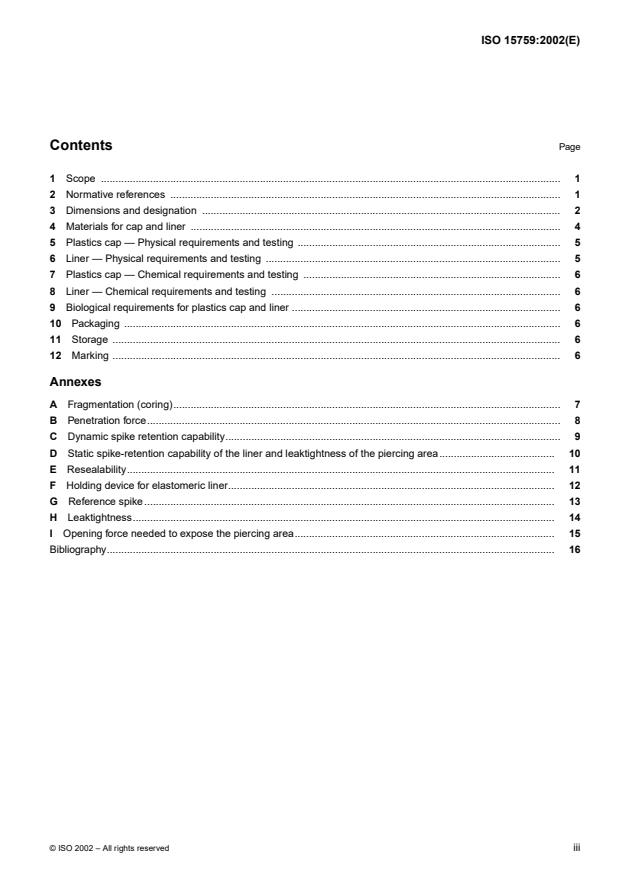

Contents Page

1 Scope . 1

2 Normative references . 1

3 Dimensions and designation . 2

4 Materials for cap and liner . 4

5 Plastics cap — Physical requirements and testing . 5

6 Liner — Physical requirements and testing . 5

7 Plastics cap — Chemical requirements and testing . 6

8 Liner — Chemical requirements and testing . 6

9 Biological requirements for plastics cap and liner . 6

10 Packaging . 6

11 Storage . 6

12 Marking . 6

Annexes

A Fragmentation (coring). 7

B Penetration force. 8

C Dynamic spike retention capability. 9

D Static spike-retention capability of the liner and leaktightness of the piercing area. 10

E Resealability. 11

F Holding device for elastomeric liner. 12

G Reference spike. 13

H Leaktightness. 14

I Opening force needed to expose the piercing area. 15

Bibliography. 16

©

ISO 2002 – All rights reserved iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies (ISO

member bodies). The work of preparing International Standards is normally carried out through ISO technical

committees. Each member body interested in a subject for which a technical committee has been established has

the right to be represented on that committee. International organizations, governmental and non-governmental, in

liaison with ISO, also take part in the work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 3.

Draft International Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this International Standard may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

International Standard ISO 15759 was prepared by Technical Committee ISO/TC 76, Transfusion, infusion and

injection equipment for medical and pharmaceutical use.

Annexes A, B, C, D, E, F, G, H and I form a normative part of this International Standard.

©

iv ISO 2002 – All rights reserved

Introduction

The materials used to manufacture Blow-Fill-Seal containers are primary packaging materials suitable for storing

infusion solutions until they are administered. This International Standard deals with plastic caps with inserted

elastomeric liners for use with Blow-Fill-Seal containers and describes their dimensional and functional

requirements. This International Standard takes into account that the cap is not a primary packaging component.

©

ISO 2002 – All rights reserved v

INTERNATIONAL STANDARD ISO 15759:2002(E)

Medical infusion equipment — Plastics caps with inserted

elastomeric liner for containers manufactured by the Blow-Fill-Seal

(BFS) process

1 Scope

This International Standard specifies the dimensional and functional requirements for plastics caps with inserted

elastomeric liners, attached to the infusion container (BFS container) by welding or by collar technique. These caps

are intended for use in the packaging and handling of liquid drugs for parenteral delivery.

2 Normative references

The following normative documents contain provisions which, through reference in this text, constitute provisions of

this International Standard. For dated references, subsequent amendments to, or revisions of, any of these

publications do not apply. However, parties to agreements based on this International Standard are encouraged to

investigate the possibility of applying the most recent editions of the normative documents indicated below. For

undated references, the latest edition of the normative document referred to applies. Members of ISO and IEC

maintain registers of currently valid International Standards.

ISO 48:1994, Rubber, vulcanized or thermoplastic — Determination of hardness (hardness between 10 IRHD and

100 IRHD)

ISO 2768-1:1989, General tolerances — Part 1: Tolerances for linear and angular dimensions without individual

tolerance indications

ISO 3302-1:1996, Rubber — Tolerances for products — Part 1: Dimensional tolerances

ISO 7500-1:1999, Metallic materials — Verification of static uniaxial testing machines — Part1:

Tension/compression testing machines — Verification and calibration of the force-measuring system

ISO 7864:1993, Sterile hypodermic needles for single use

ISO 8536-4:1998, Infusion equipment for medical use — Part 4: Infusion sets for single use, gravity feed

ISO 8871:1990, Elastomeric parts for aqueous parenteral preparations

©

ISO 2002 – All rights reserved 1

3 Dimensions and designation

3.1 Plastics cap for attachment by welding technique (Form A)

General tolerances for Form A plastics caps shall be in accordance with ISO 2768-1; dimensions shall be in

accordance with Figure 1. Elastomeric liners for such caps shall be in accordance with ISO 3302-1.

Dimensions in millimetres

Key

1 Measuring point at the centre

a

Diameter of score line.

Figure 1

Plastics cap(s) of Form A in accordance with this International Standard shall be designated as follows:

Cap ISO 15759-BFS-A

©

2 ISO 2002 – All rights reserved

3.2 Plastics cap for attachment by collar technique (Form B)

Dimensions for Form B plastics caps shall be in accordance with Figure 2.

Dimensions in millimetres

Key

1 Measuring point at the centre

a

Diameter of score line.

Figure 2

Plastics cap(s) of Form B in accordance with this International Standard shall be designated as follows:

Cap ISO 15759-BFS-B

©

ISO 2002 – All rights reserved 3

3.3 Elastomeric liner

Dimensions for elastomeric liners for plastics caps of Form A or Form B shall be in accordance with Figure 3.

Dimensions in millimetres

Key

1 Trimming edge max. ∅ 30,2

Figure 3

Elastomeric liners in accordance with this International Standard shall be designated as follows:

Elastomeric liner ISO 15759

Figure 3 illustrates a typical liner design. Other liner designs are permitted.

4 Materials for cap and liner

4.1 Materials shall be in accordance with the requirements in clauses 6, 7, 8 and 9. The choice of plastic and

elastomeric materials shall be subject to agreement between manufacturer and customer.

4.2 Resistance to ageing depends largely on presterilization techniques, storage and handling conditions. The

period during which cap and liner shall comply with the requirements of this International Standard is subject to

agreement between manufacturer and customer.

4.3 The shelf life of the liner while in contact with the drug is determined by compatibility tests to be carried out by

the user.

4.4 ISO 2230 describes storage guidelines for vulcanized elastomeric parts.

©

4 ISO 2002 – All rights reserved

5 Plastics cap — Physical requirements and testing

5.1 Leaktightness

When testing the leaktightness of the covered piercing area in accordance with annex H, no leakage shall be

observed.

5.2 Opening force

When testing the opening force needed to expose the piercing area in accordance with annex I, the required force

shall not exceed 80 N, and shall not tear the cap outside the piercing area.

6Liner — Physical requirements and testing

6.1 General requirements

6.1.1 Injection gates and sprues are not allowed in the sealing area, i.e. between cap and liner.

6.1.2 Marks, indentations and spacers are allowed. The height of spacers shall not exceed 0,3 mm.

6.2 Hardness

Hardness requirements shall be agreed between manufacturer and customer. The hardness shall not differ from the

nominal value by more than ± 5 IRHD when tested in accordance with ISO 48.

6.3 Fragmentation (coring)

When testing for fragmentation in accordance with annex A, no more than two fragments of diameter equal to or

greater than 50µm shall be observed per 10 piercings.

6.4 Penetration force

When testing for penetration in accordance with annex B, the force required to penetrate the liner shall not exceed

80 N. The average value shall not exceed 75 N.

6.5 Dynamic spike-retention capability

When tested in accordance with annex C, the measured retention force shall not fall below 20 N.

6.6 Static spike-retention capability

When tested in accordance with annex D, no leakage shall be observed between the spike and liner during a period

of .4h

6.7 Resealability

When piercing the liner with a hypodermic needle in accordance with annex E, the requirements concerning

resealability shall be fulfilled, and no air shall escape.

©

ISO 2002 – All rights reserved 5

7 Plastics cap — Chemical requirements and testing

The plastics material used to manufacture the cap shall be physiologically harmless.

8Liner — Chemical requirements and testing

The characteristics of the liner material shall not exceed the limits specified in Table 1, when tested in accordance

with ISO 8871.

Table 1 — Chemical limits for elastomeric liner

Test method as described in

Characteristics Limits

ISO 8871:1990

Reducing matter (oxidizables) � 7,0 mlc(KMnO)= 2 mmol/l per

Annex C

20 ml

2+ +2

Heavy metals (calculated as Pb)A� 10µgPb /10 mlnnexD

+

+

Ammonium (calculated as NH )A� 20µgNH /10 ml nnex E

4 4

Acidity/alkalinity � 1,0 mlc(HCl) or

Annex G

c(NaOH)= 5 mmol/l per 20 ml

Residue on evaporation (total solids) � 4mg/100 ml Annex H

Volatile sulfides (at pH≈ 2) Coloration of lead acetate paper

Annex J

� 50µgMa S/20 cm of closure

2+ 2+

Zinc (calculated as Zn ) Zn � 50µg/10 ml Annex K

Conductivity � 40µS/cm Annex L

Turbidity Not exceeding the opalescence of

Annex M

suspension No. 3

9 Biological requirements for plastics cap and liner

Biological r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.