ISO 22157-1:2004

(Main)Bamboo - Determination of physical and mechanical properties - Part 1: Requirements

Bamboo - Determination of physical and mechanical properties - Part 1: Requirements

ISO 22157-1:2004 specifies test methods for evaluating the following characteristic physical and strength properties for bamboo: moisture content, mass per volume, shrinkage, compression, bending, shear and tension.

Bambou — Détermination des propriétés physiques et mécaniques — Partie 1: Exigences

General Information

Relations

Frequently Asked Questions

ISO 22157-1:2004 is a standard published by the International Organization for Standardization (ISO). Its full title is "Bamboo - Determination of physical and mechanical properties - Part 1: Requirements". This standard covers: ISO 22157-1:2004 specifies test methods for evaluating the following characteristic physical and strength properties for bamboo: moisture content, mass per volume, shrinkage, compression, bending, shear and tension.

ISO 22157-1:2004 specifies test methods for evaluating the following characteristic physical and strength properties for bamboo: moisture content, mass per volume, shrinkage, compression, bending, shear and tension.

ISO 22157-1:2004 is classified under the following ICS (International Classification for Standards) categories: 79.040 - Wood, sawlogs and sawn timber. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 22157-1:2004 has the following relationships with other standards: It is inter standard links to ISO 22157:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 22157-1:2004 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 22157-1

First edition

2004-06-01

Bamboo — Determination of physical and

mechanical properties —

Part 1:

Requirements

Bambou — Détermination des propriétés physiques et mécaniques —

Partie 1: Exigences

Reference number

©

ISO 2004

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2004

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2004 – All rights reserved

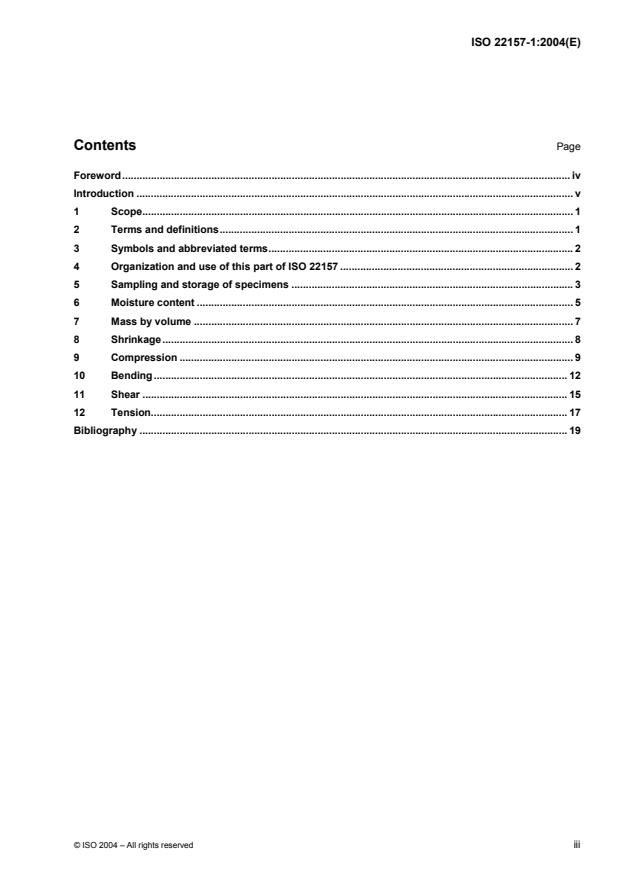

Contents Page

Foreword. iv

Introduction . v

1 Scope. 1

2 Terms and definitions. 1

3 Symbols and abbreviated terms. 2

4 Organization and use of this part of ISO 22157 . 2

5 Sampling and storage of specimens . 3

6 Moisture content . 5

7 Mass by volume . 7

8 Shrinkage. 8

9 Compression . 9

10 Bending. 12

11 Shear . 15

12 Tension. 17

Bibliography . 19

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 22157-1 was prepared by Technical Committee ISO/TC 165, Timber structures, in collaboration with

INBAR, International Network for Bamboo and Rattan.

ISO 22157 consists of the following parts, under the general title Bamboo — Determination of physical and

mechanical properties:

Part 1: Requirements

Part 2: Laboratory manual

iv © ISO 2004 – All rights reserved

Introduction

This part of ISO 22157 was originally prepared and submitted by INBAR, the International Network for Bamboo

and Rattan, which is an international agency with its head office in Beijing. The aim is to bring bamboo towards

the level of an internationally recognized and accepted building and engineering material. INBAR aims to do so in

favour of the well-being of lower income groups in developing countries, and in favour of a better environment in

bamboo-growing countries.

Discussion about the need of an International Standard started already in 1988, during the International Bamboo

Workshop in Cochin, India. Due to lack of funds, the real work started as late as in 1997, when INBAR was

launched as an International Agency, and when the Dutch Government provided the required funding.

In 1998, draft texts were written and distributed to a group of specialists inside INBAR who acted as volunteers

and spent their time and expertise to propose improvements. Members of this group met for the first time in a

meeting on 30-31 October 1998 in San José, Costa Rica. Participants were N.S. Adkoli, K. Ghavami,

R. Gnanaharan, H.N.S. Jagadeesh, J.J.A. Janssen, K.S. Pruthi, I.V. Ramanuja Rao, D. Sands, J.O. Siopongco,

K. Stochlia and D. Tingley.

During 1999, the results from this meeting were incorporated in the draft texts. In September, these were

discussed in a meeting with ISO/TC 165 in Harbin, China. In October 1999, a meeting took place with

representatives of the National Standard Institutes of Bangladesh, China, Colombia, Ecuador, Ethiopia, India,

Indonesia, Nepal, Philippines, Tanzania, Thailand and Vietnam. This meeting was held at FPRDI in Los Baños,

Philippines. The outcome of this meeting was a considerable improvement of the texts, and a general agreement

to submit the draft texts to ISO for the formal procedure.

Besides INBAR, CIB (especially committee W 18 B) has also been involved in the preparation. Discussions during

meetings of W 18 B (e.g. Singapore 1987 and Kuala Lumpur 1992) have greatly contributed.

Because this part of ISO 22157 is the first Iinternational Standard on bamboo, it does not cancel or replace

other documents in whole or in part, besides the draft documents prepared and distributed for internal

discussion by INBAR during 1998 and 1999. For similar reasons, significant technical changes from previous

editions apply only to these previous draft documents.

INTERNATIONAL STANDARD ISO 22157-1:2004(E)

Bamboo — Determination of physical and mechanical

properties —

Part 1:

Requirements

1 Scope

This part of ISO 22157 specifies test methods for evaluating the following characteristic physical and strength

properties for bamboo: moisture content, mass per volume, shrinkage, compression, bending, shear and

tension.

This part of ISO 22157 covers tests on specimens of bamboo that are conducted to obtain data, which can be

used to establish characteristic strength functions and to arrive at the allowable stresses. The data can also

be used to establish the relationship between mechanical properties and factors, such as moisture content,

mass per volume, growth site, position along the culm, presence of node and internode, etc., for quality-

control functions.

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

bamboo culm

single shoot of bamboo that is usually hollow, except at nodes which are often swollen

2.2

bamboo clump

cluster of bamboo culms emanating from two or more rhizomes in the same place

2.3

cross-sectional area

area of the section perpendicular to the direction of the principal fibres and vessels

2 2

NOTE This is calculated as (π/4) × [D − (D − 2t) ], in which D and t are the means of the outer diameter and the wall

thickness, resulting from measurements on the specimen.

2.4

outer diameter

diameter of a cross-section of a piece of bamboo measured from two opposite points on the outer surface

2.5

moisture content

percentage of water related to oven-dry mass

2.6

wall thickness

thickness of the wall of a piece of bamboo

3 Symbols and abbreviated terms

The following symbols and units apply.

2 2 2

A The cross-sectional area in mm , Calculated as (π/4) × [D − (D − 2t) ], in which D and t are the

means of the measurements on the specimen.

D The outer diameter in mm.

δ Deflection or deformation in mm (pronounced “delta”).

E The modulus of elasticity in MPa.

F The load in N.

G The shear modulus in MPa.

I The second moment of area in mm .

B

L Full span in bending; length of test piece in compression, shear and tension, in mm.

m Mass in g (kg is also allowed as a unit).

MC Moisture content in %.

π Usually taken as 3,14.

ρ Mass by volume (density) in kg/m (pronounced “rho”).

σ Stress in MPa (pronounce “sigma”).

t Wall thickness in mm.

τ Shear stress in MPa (pronounced “tau”).

V Volume of test piece in mm , calculated as A × L, or as measured.

W Section modulus in mm .

× Symbol for multiplication.

Subscript

ult Ultimate (used for strength at failure)

NOTE 1 MPa = 1 N/mm

4 Organization and use of this part of ISO 22157

4.1 Introduction

This part of ISO 22157 is organized to provide clear requirements for standard tests to be carried out to

determine the properties of bamboo as a building or engineering material. The manual for laboratory staff,

ISO/TR 22157-2, is complementary to this part.

NOTE This allows for a more formal content of this part of ISO 22157, and a practical and informal guide (a “how to

do it”) in the manual.

2 © ISO 2004 – All rights reserved

4.2 General procedures

4.2.1 Measurement and weight

Prior to each test, the dimensions of each specimen shall be measured correct to

10 mm for the length of the culm,

1 mm for the length or height of a specimen, parallel to the axis of the culm,

1 mm for the diameter of the culm; in each cross-section, the diameter shall be taken twice, in directions

perpendicular to each other, and

0,1 mm for the wall thickness; in each cross-section, the wall thickness shall be taken four times, in the

same places as the diameter has been taken (twice).

The specimen shall be weighed correct to

10 g for a culm,

1 g for a specimen of more than 100 g, and

0,1 g for a specimen of less than 100 g.

4.2.2 Temperature and humidity

To avoid significant changes in strength properties, all test specimens shall be tested within the temperature

range of 27 °C ± 2 °C, and the relative air humidity range of 70 ± 5 %.

NOTE This allows for a comparison of test results, and reproducible tests.

However, if tests are meant for local use of the results in the region itself, or if the laboratory is unable to

follow the conditions specified above, ambient temperature and relative humidity can be used. The exact

values of the temperature and relative humidity of the air shall be recorded, and mentioned in the test report.

4.2.3 Rate of loading

The rate of loading of the testing machine shall not vary by more than ± 20 % from the specified speed for a

given test. The load shall be applied continuously without interruption at the required speed throughout the

test. The rate of traverse of the movable head of the testing machine shall mean the free running or no-load

speed of the head in the mechanical-drive type of machine, and the loaded head speed for testing machines

of the hydraulic loading type.

4.2.4 Calibration

All apparatus and testing equipment used in obtaining data shall be calibrated at sufficiently frequent intervals

to ensure accuracy.

5 Sampling and storage of specimens

5.1 Sampling

Material for any particular species shall be taken:

in the case of tests on properties for commercial purposes: from a number of different localities,

representative of different growth conditions throughout the geographical range of the species;

in the case of scientific research: from localities determined by the purpose of the research, and

mentioned in the design-report of the tests;

From each locality, the selection, marking, etc., of the different consignments, and all the details of the various

clumps and culms, shall be reported.

5.2 Selection

Bamboo culms shall be selected from various clumps in the standing condition, by a qualified person who can

identify the species and understand the various implications involved in conversion and testing. Whenever

necessary and convenient, the testing authority shall inspect the locality before felling.

For scientific research, the culms selected for testing shall be sound and free from any defects, and shall be

representative of average dominant bamboo culms of the locality. For commercial tests, they must fairly

represent the total population that is to be used for construction purposes, even if the entire population has its

drawbacks. Broken, damaged and discoloured bamboos shall be discarded.

The required number of culms shall be randomly selected from different clumps, blocks and compartments.

For commercial tests, they shall be of the same mature age group.

Immediately after selection, the bamboo may be marked “T” in the standing condition, at breast height, and

the testing authority shall be informed of the locality, so that further special instructions, if any, may be

considered.

5.3 Felling, marking and conversion

Before felling, one ring shall be marked at a height of one metre from the ground with white or black paint, and

the following data shall be recorded:

the name of the species (botanical and local);

the name of the locality;

the number of clumps and culms selected;

the age of the culms;

details about the marks on the culms;

number of nodes between ground level and the ring of paint;

date of felling and of despatch;

signature.

Also before felling, each culm shall be marked at a distance of about 0,25 m above the ring of paint; if digits 6

or 9 are used, these shall be underlined.

The culms shall be felled according to good local practice, but the ring of paint shall be kept on the culm. In

the horizontal position the culm shall be divided into parts to be used for tests or to be thrown away. The parts

to be used shall be marked with a ring at the lower end, and the mark of the culm shall be repeated on each

part. Also, a mark regarding the position in the culm shall be added, indicating “bottom”, “middle” or “top”,

each being 1/3 of the usable part of the culm. The height of these parts in the culm shall be recorded, in

metres, from the level where the culm has been felled. Only then shall the culm be divided into parts.

5.4 Despatch

Material should be despatched as early as possible, preferably within two weeks after felling. In case it is not

possible to send the material immediately, the material shall be stored in a shady place, protected from rain,

and free of contact with the soil. If a risk of cracking exists, the ends can be covered with coal tar, paraffin wax

or varnish, or any other appropriate cover.

4 © ISO 2004 – All rights reserved

If the tests are meant for commercial purposes, specimens shall be tested in air-dry conditions. In the case of

scientific research, tests might be done on green specimens, in which case the specimens shall be

despatched immediately. As bamboo is highly susceptible to attack by destroying agents in many countries, it

may need prophylactic treatment to keep it intact during despatch, transit and storage.

All the details of a particular consignment shall be rechecked and signed and dated by the dispatcher. The

details shall be sent along with the documents of the consignments.

5.5 Receipt and storage of the bamboo culms

On receipt of the material by the testing authority, the particulars of identification of the various culms shall be

checked, and a proper record shall be kept.

The bamboo culms shall be stored for as short a duration as possible, in such a way that no deterioration shall

take place.

5.6 Marking and conversion into test specimens

Specimens shall be cut for the various tests, and suitable markings (e.g. project number, consignment number,

culm number, etc.) shall be made for complete identification of each specimen.

The sequence of tests shall be such as to eliminate, as far as possible, changes due to storage and weather

conditions, which might affect the comparison of results.

The number of specimens in each test shall not be less than twelve.

5.7 Test report

The test report shall include the following information:

a) the name and address of the laboratory, the date, and the name of the responsible researcher;

b) a reference to this part of ISO 22157, and to applicable national standards;

c) details of the test specimens, as mentioned in 5.3;

d) temperature and air humidity in the laboratory;

e) equipment used, and any other information which may influence the use of the test results;

f) the test results, including the values of moisture content and the mass per volume, the actual dimensions,

moduli and/or strength values, mode of failure, and any other information which may influence the use of

the test results (e.g. position along the culm);

g) details about the statistical treatment of the test results, including the methods used and the results

obtained; the accuracy of a mean value shall be half the standard deviation, and the accuracy of a

standard deviation shall be half its own standard deviation;

h) data about the adjustment to a 12 % moisture content, if applicable.

6 Moisture content

6.1 Scope

This clause specifies a method for determining the moisture content of bamboo for physical and mechanical

tests.

6.2 Principle

Determination, by weighing, of the loss in mass of the test piece on drying to constant mass. Calculation of the

loss in mass as a percentage of the mass of the test piece after drying.

6.3 Apparatus

6.3.1 Balance, with an accuracy of 0,01 g.

6.3.2 Equipment capable of drying bamboo to an absolutely dry condition, e.g. an electric oven.

6.3.3 Equipment to ensure the retention of moisture in the test pieces, e.g. flasks with ground-glass

necks, and stoppers.

6.4 Preparation of test pieces

Test pieces for determination of moisture content shall be prepared immediately after each mechanical test.

The number of test pieces shall be equal to the number of test pieces for the physical or mechanical test. The

form shall be like a prism, approximately 25 mm wide, 25 mm high and as thick as the wall thickness. The test

pieces shall be taken near to the place of failure, and stored under conditions which ensure that the moisture

content remains unchanged.

6.5 Procedure

The test pieces shall be weighed to an accuracy of 0,01 g, and then dried in an oven at a temperature of

103 ± 2 °C.

After 24 h, the mass shall be recorded at regular intervals of not less than 2 h. Great care shall be taken to

prevent any change in moisture content between removal from the oven and subsequent determinations of

the mass.

The drying shall be considered to be complete when the difference between the successive determinations of

the mass does not exceed 0,01 g.

6.6 Calculation and expression of results

The moisture content MC of each test piece shall be calculated as the loss in mass, expressed as a

percentage of the oven-dry mass, using the following formula:

mm−

o

MC=×100

m

o

where

m is the mass of the test piece before drying;

m is the mass of the test piece after dr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...