ISO 703:1975

(Main)Conveyor belts — Troughability — Characteristic and method of test

Conveyor belts — Troughability — Characteristic and method of test

Courroies transporteuses — Aptitude à la mise en auge — Caractéristique et méthode d'essai

General Information

Relations

Buy Standard

Standards Content (Sample)

INTERNATIONAL STANDARD 703

INTERNATIONAL ORGANIZATION FOR STANOAROIZATION .METnLHAPOnHM OPrAHM3AUMR no CTAHLIAPTM3AUMM .ORGANISATION INTERNATIONALE DE NORMALISATION

Conveyor belts - Troughability - Characteristic and

method of test

Courroies transporteuses - Aptitude à la mise en auge - Caractéristique et méthode d'essai

First edition - 1975-05-01

I

w UDC 621.867.212.3/.5 : 620.11 Ref. No. IS0 703-1975 (E)

-

m IC

z

Descriptors : belts, conveyor belts, tests, bend tests, flexibility.

m

O

IC

s

Price based on 3 pages

---------------------- Page: 1 ----------------------

FOREWORD

IS0 (the International Organization for Standardization) is a worldwide federation

of national standards institutes (IS0 Member Bodies). The work of developing

International Standards is carried out through IS0 Technical Committees. Every

Member Body interested in a subject for which a Technical Committee has been set

up has the right to be represented on that Committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work.

Draft International Standards adopted by the Technical Committees are circulated

to the Member Bodies for approval before their acceptance as International

Standards by the IS0 Council.

Prior to 1972, the results of the work of the Technical Committees were published

as IS0 Recommendations; these documents are now in the process of being

transformed into International Standards. As part of this process, Technical

Committee ISO/TC 41 has reviewed IS0 Recommendation R 703 and found it

technically suitable for transformation. International Standard IS0 703 therefore

replaces IS0 Recommendation R 703-1968 to which it is technically identical.

IS0 Recommendation R 703 was approved by the Member Bodies of the following

countries :

Australia Egypt, Arab Rep. of South Africa, Rep. of

Austria Finland Spain

Belgium France Sweden

Brazil Germany Switzerland

Chile India Turkey

Czechoslovakia Italy United Kingdom

Denmark Japan Yugoslavia

The Member Body of the following country expressed disapproval of the

Recommendation on technical grounds :

Ireland

No Member Body disapproved the transformation of ISO/R 703 into an

International Standard.

O International Organization for Standardization, 1975

Printed in Switzerland

---------------------- Page: 2 ----------------------

IS0 703-1975 (E)

I NTE RNATl ONA L STAN DARD

Conveyor belts - Troughability - Characteristic and

method of test

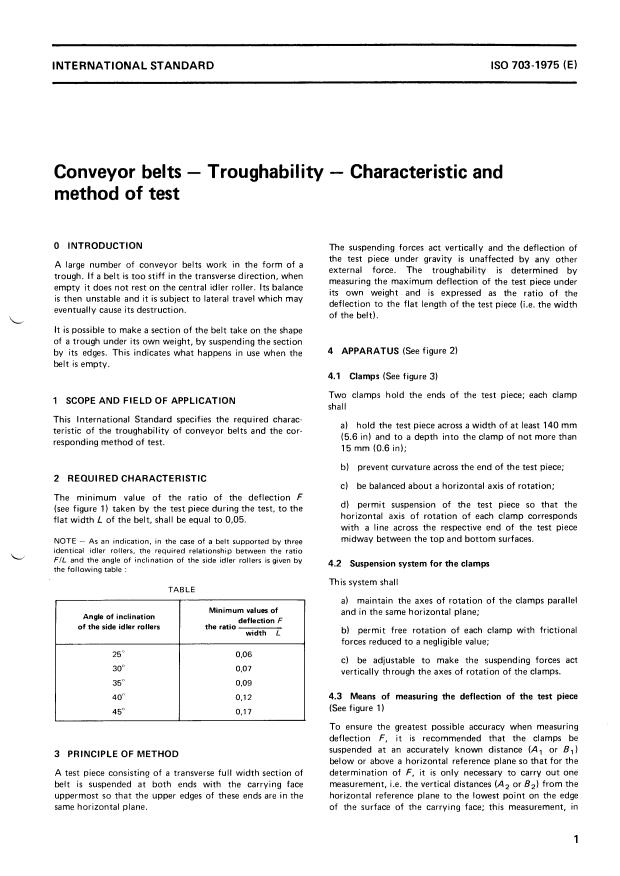

O INTRODUCTION

act vertically and the deflection of

The suspending forces

the test piece under gravity is unaffected by any other

A large number of conveyor belts work in the form of a

external force. The troughability is determined by

trough. If a belt is too stiff in the transverse direction, when

measuring the maximum deflection of the test piece under

empty it does not rest on the central idler roller. Its balance

its own weight and is expressed as the ratio of the

is then unstable and it is subject to lateral travel which may

deflection to the flat length of the test piece (i.e. the width

its destruction.

eventually cause

of the belt).

L

It is possible to make a section of the belt take on the shape

of a trough under its own weight, by suspending the section

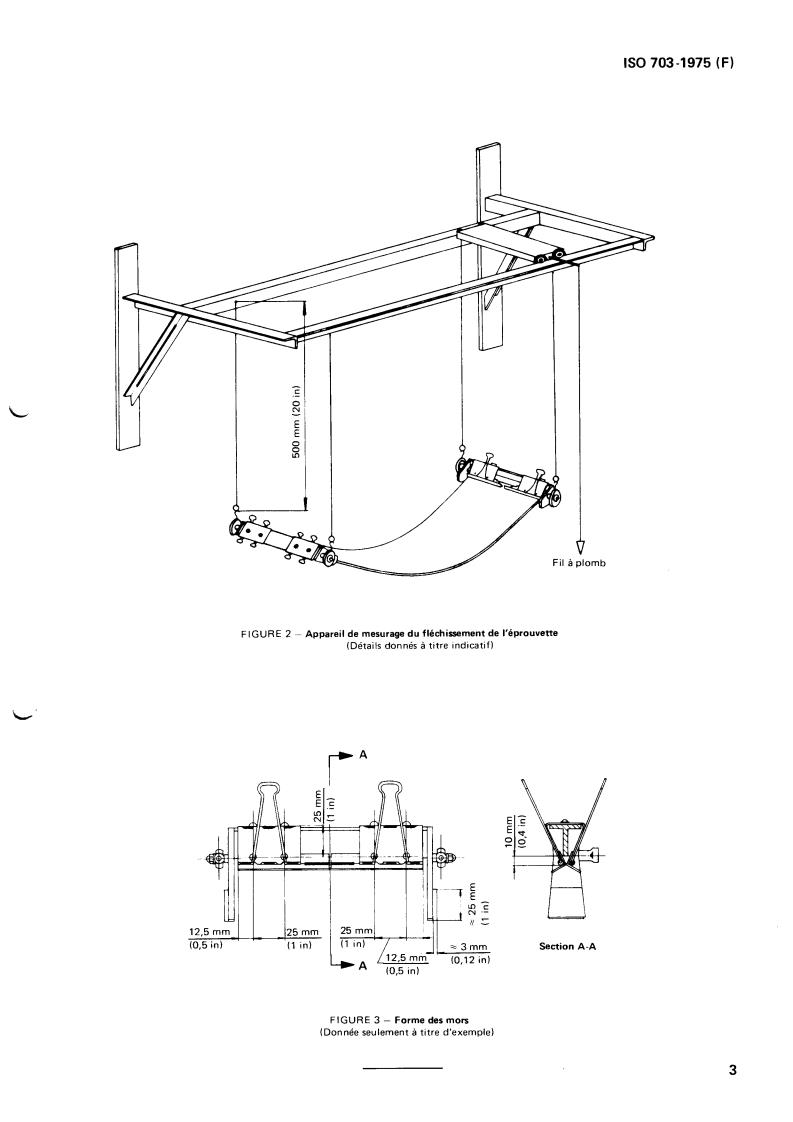

4 APPARATUS (See figure 2)

by its edges. This indicates what happens in use when the

belt is empty.

4.1 Clamps (See figure 3)

Two clamps hold the ends of the test piece; each clamp

1 SCOPE AND FIELD OF APPLICATION

shall

This International Standard specifies the required charac-

a) hold the test piece across a width of at least 140 mm

teristic of the troughability of conveyor belts and the cor-

(5.6 in) and to a depth into the clamp of not more than

responding method of test.

15 mm (0.6 in);

b) prevent curvature across the end of the test piece;

2 REQUIRED CHARACTERISTIC

c) be balanced about a horizontal axis of rotation;

The minimum value of the ratio of the deflection F

d) permit suspension of the test piece so that the

(see figure 1) taken by the test piece during the test, to the

horizontal axis of rotation of each clamp corresponds

flat width L of the belt, shall be equal to 0,05.

with a line across the respective end of t

...

@ 703

NORME INTERNATIONALE

‘*E&

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION -MEXnYHAPOnHAX OPrAH€43AUIII II0 CiAHLIAPTiISAUiIA .ORGANISATION INTERNATIONALE DE NORMALISATION

Courroies transporteuses - Aptitude à la mise en auge -

L

Caractéristique et méthode d’essai

Conveyor belts - Troughability - Characteristic and method of test

Première édition - 1975-05-01

CDU 621.867.212.3/.5 : 620.11 Réf. no : IS0 703-1975 (FI

Descripteurs : courroie. courroie transporteuse, essai, essai de flexion, flexibilité

m

O

O

2

Prix basé sur 3 pages

r.

---------------------- Page: 1 ----------------------

IS0 703-1975 (F)

NORME INTERNATIONALE

Courroies transporteuses - Aptitude à la mise en auge -

Caractéristique et méthode d'essai

Les forces de suspension agissent verticalement et le

O INTRODUCTION

fléchissement de l'éprouvette sous l'effet de la pesanteur

Un grand nombre de courroies transporteuses travaillent en

n'est affecté par aucune autre force extérieure. L'aptitude à

forme d'auge. Si une courroie est trop raide dans le sens

la mise en auge est déterminée en mesurant le fléchissement

transversal, elle ne s'appuie pas, à vide, sur le rouleau

maximal de l'éprouvette sous son propre poids, et elle est

médian. Elle se trouve alors en équilibre instable et se

exprimée par rapport à la longueur à plat de l'éprouvette

déporte latéralement, ce qui peut provoquer sa destruction.

(c'est-à-dire à la largeur de la courroie).

L

On peut, en suspendant par les bords un troncon de

à celui-ci une forme d'auge SOUS son

courroie, faire prendre

propre poids, ce aui donne une indication sur la position

4 APPAREILLAGE (Voir figure 2)

que prendrait en service, à vide, la courroie par rapport aux

augets.

4.1 Mors (Voir figure 3)

Deux mors soutiennent les extrémités de l'éprouvette;

1 OBJET ET DOMAINE D'APPLICATION

chaque mors doit

La présente Norme Internationale spécifie la caractéristique

a) maintenir l'éprouvette sur une largeur d'au moins

requise d'aptitude des courroies transporteuses à la mise en

140 mm (5.6 in) et sur une profondeur dans le mors

auge, et la méthode d'essai correspondante.

n'excédant pas

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.