ISO/TR 13571-2:2016

(Main)Life-threatening components of fire — Part 2: Methodology and examples of tenability assessment

Life-threatening components of fire — Part 2: Methodology and examples of tenability assessment

ISO/TR 13571-2:2016 describes the practical application of ISO 13571 as a tool to evaluate effects of fire effluents on people. The method of application, performance criteria and evaluation of the impact are explained and illustrated by two families of examples: application to real-scale tests (Annex A and Annex B) and application to Fire Safety Engineering (Annex C, D and E).

Composants dangereux du feu — Partie 2: Méthodologie et exemples d'analyse de tenabilité

General Information

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 13571-2

First edition

Life-threatening components of fire —

Part 2:

Methodology and examples of

tenability assessment

Composants dangereux du feu —

Partie 2: Méthodologie et exemples d’analyse de tenabilité

PROOF/ÉPREUVE

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

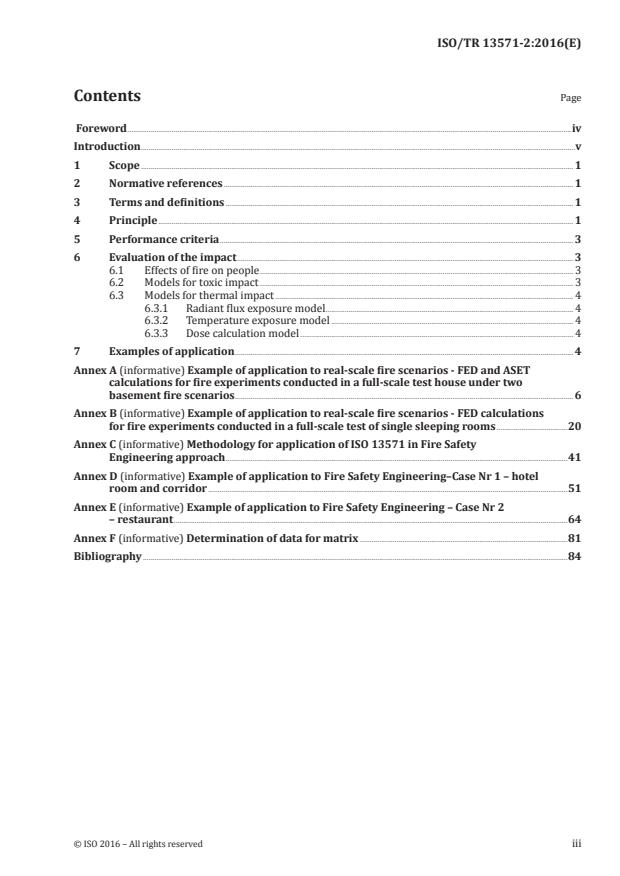

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 1

5 Performance criteria . 3

6 Evaluation of the impact . 3

6.1 Effects of fire on people . 3

6.2 Models for toxic impact . 3

6.3 Models for thermal impact . 4

6.3.1 Radiant flux exposure model . 4

6.3.2 Temperature exposure model . 4

6.3.3 Dose calculation model . 4

7 Examples of application . 4

Annex A (informative) Example of application to real-scale fire scenarios - FED and ASET

calculations for fire experiments conducted in a full-scale test house under two

basement fire scenarios . 6

Annex B (informative) Example of application to real-scale fire scenarios - FED calculations

for fire experiments conducted in a full-scale test of single sleeping rooms .20

Annex C (informative) Methodology for application of ISO 13571 in Fire Safety

Engineering approach .41

Annex D (informative) Example of application to Fire Safety Engineering–Case Nr 1 – hotel

room and corridor .51

Annex E (informative) Example of application to Fire Safety Engineering – Case Nr 2

– restaurant .64

Annex F (informative) Determination of data for matrix .81

Bibliography .84

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www.iso.org/iso/foreword.html.

The committee responsible for this document is ISO/TC 92 Fire Safety, Subcommittee 3, Fire threat to

people and the environment.

iv PROOF/ÉPREUVE © ISO 2016 – All rights reserved

Introduction

Tenability of people in case of fire is an essential safety objective of regulations. Reasons that could lead

to compromised tenability conditions are loss of visibility, thermal and toxic effects. ISO 13571 is a tool

that has been developed to quantify the performance level related to these criteria in case of a fire.

This document presents application cases of ISO 13571. It is structured as follows:

— Clause 4 explains the principle of the application;

— Clause 5 presents the selection of performance criteria;

— Clause 6 presents the evaluation of the impact of fire to people according to ISO 13571;

— Clause 7 introduces the examples detailed in Annexes A, B, D and E.

Examples of application are presented in annexes. The first case of application concerns comparison

of tenability in real-scale fire tests (Annex A and Annex B). The second case presents the methodology

(Annex C) and two example cases (Annex D and Annex E) for application of ISO 13571 as performance

criteria in Fire Safety Engineering studies according to ISO 23932. Annex F presents information on

experimental production of input data.

TECHNICAL REPORT ISO/TR 13571-2:2016(E)

Life-threatening components of fire —

Part 2:

Methodology and examples of tenability assessment

1 Scope

This document describes the practical application of ISO 13571 as a tool to evaluate effects of fire

effluents on people. The method of application, performance criteria and evaluation of the impact are

explained and illustrated by two families of examples: application to real-scale tests (Annex A and

Annex B) and application to Fire Safety Engineering (Annex C, D and E).

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13943 and ISO 13571

apply. ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

4 Principle

Smoke toxicity, to a certain degree, is not a material property. Depending on the environment,

availability of oxygen, thermal attack, flow conditions and surface areas available for combustion, the

chemistry of the combustion of a given material can proceed along various routes and produce species

[1][2][3]

in very different quantities. It is then a systemic parameter, which need a systemic approach, as

stated in ISO 19706.

It is also appropriate to keep the following points in mind:

— The production rates of various gaseous species change according to the combustion regime. In

particular the influential parameters (not exhaustive) are:

— Fuel nature

— Oxygen availability

— Temperature

— Flows received and lost

— The species produced by the combustion are carried away from the initial fire source, and their

effect is related to:

— Sensitivity and activity of people

— Concentrations (instantaneous)

— Exposure times (accumulation)

Furthermore, the thermal effects related to the heat of the gases and smoke produced, along with the

radiant fluxes, which they emit, play a role in the safety of people who are evacuating.

For a given design fire, it is therefore necessary to determine one or more exposure scenarios, which

will make it possible to answer questions about the effects on people according to:

— The fire source and its development;

— The species produced by this fire source and their movement away from the original fire source;

— The evacuation of the people, their path and the toxic and thermal elements to which they are subject

as a function of time.

Finally, it is useful to recall that toxic hazard in enclosures is mainly caused by the combustion of the

contents and furnishings in the enclosure rather than the enclosure itself in the early phases of a fire.

Furthermore, changes in regulations can lead to better insulation of the rooms, modification of the

ventilation, and resistance of windows to bursting, all of which notably change the conditions for the

accumulation of thermal energy and the generation of toxic species.

The following are the objectives of the application of ISO 13571:

— Assess effects of fire on people as a principal criterion for performance evaluation in Fire Safety

Engineering studies, or in comparison of real-scale fire tests,

— Involve realistic fire sources in terms of:

— Kinetics

— Species produced, in particular by including data concerning the toxic species related to the

burning of the contents and furnishings in building fires

— Be able to process all the materials present and not just certain ones

— Consider all potential toxic species, not only CO, as is often seen in practice

— Consider the aspects of production kinetics, movement of gases, and availability of oxygen

— Be able to process several scenarios and their possible variations:

— “Typical” materials/”risky” materials

— Risk in the room of fire origin room and outside the room of origin

— Different fire regimes (smouldering, well ventilated, post-flashover)

— Evacuation plans

— Consider the various risks for people and the associated sanction criteria as a function of thermal

and toxic effects, both instantaneous and by accumulation.

2 PROOF/ÉPREUVE © ISO 2016 – All rights reserved

5 Performance criteria

The selection of criteria to consider is conducted in early phases of a project, before any detailed study.

These criteria will make it possible to determine whether a given exposure scenario (i.e. a fire scenario

combined with an evacuation scenario) is a success or failure. This concept depends above all on the

susceptibility of the people to the fire effluent. In the application of ISO 13571, the objective that a

person could realize his/her own evacuation without any assistance.

In fact, each person is different and according to their constitution, age, gender, possible underlying

conditions, etc. the FEC and FED which they can endure before being incapacitated varies. There is,

however, no feedback from experience which can be used in statistical terms. Due to the lack of precise

knowledge in this field, approximating the distribution of individual susceptibilities by a log-normal

distribution with a median value of one as thresholds for the FED and FEC is proposed. Half the

population is therefore considered as being able to tolerate FED and FEC each having a value of one, and

the other half is more sensitive and cannot tolerate values of FED and FEC equal to or above one.

As an example of a safety criterion that provides protection for a larger fraction of the population,

ISO 13571:2012, A.5.2 shows that a value 0,3 protects a significant portion of the more sensitive people.

At this value, 11,4 % of the population remains vulnerable to incapacitation by exposure to the fire

effluent. It should be kept in mind that one of the consequences of the distribution described by the

ISO 13571:2012 standard for the sensitivity of individuals (log-normal law) is that there is no value for

the criterion which is low enough to guarantee protection of all occupants in an evacuation situation.

Designing a facility such that the FED and FEC values are kept to extremely low values is likely to require

immediate detection and suppression or to preclude otherwise desirable construction and furnishing

products. It is the regulator’s role to weigh these considerations.

6 Evaluation of the impact

6.1 Effects of fire on people

The impact of fire effluent on a person depends on two interacting components. The first is the location

of a person and how that location might change during the course of the fire. The second is the evolving

concentrations of the effluent constituents where the person is located.

A fire safety assessment could be made considering the evolution of tenability for a person who is

stationary at one position in a room. This would apply to people who are asleep or medically confined.

Such an application in real-scale fire tests is presented in Annex A. Assessment could also consider the

exposure of a person moving along an egress path with its travel path in real-scale fire tests (Annex B)

or included in a Fire Safety Engineering approach (Annexes C to E).

The exposure models used are those described in ISO 13571:2012. In particular, they cover the toxic and

thermal models, but do so independently. For the toxic models, the effects of the asphyxiating and irritating

gases are considered separately. See ISO 19706 for more details on the relevance of these models.

6.2 Models for toxic impact

Toxic effluents can have two principal mechanisms of action on people when considering acute

exposure. Depending on their nature, they are classified into two categories:

— asphyxiating gases (CO, HCN, etc.)

— irritating gases (HCl, HBr, etc.)

There are also indirect effects like those of the low oxygen concentration (hypoxia) or high CO

concentration (hyperventilation). Other effects exist, like clogging of the respiratory tracts because of

the presence of soot.

The evaluation of the effects related to exposure to smoke requires knowledge of the central concepts.

[4] [5]

The References and present a review of the art of these concepts.

Because of the complexity of the problem, there are various models incorporating toxic effects.

Although all of them can be used, a first consensus was established on the models given in ISO 13571.

In the ISO 13571 models, the asphyxiating gases, incorporated using the calculation of a Fractional

Effective Dose (FED), and the irritating gases, incorporated using the calculation of Fractional Effective

Concentration (FEC), are considered separately.

Thus, the asphyxiating gases (mainly CO, and HCN) are considered from the perspective of an

accumulation mechanism, and the irritants (mainly HCl, HBr, HF, SO , NO, NO , acrolein, and

2 2

formaldehyde) from that of their instantaneous effect. These assumptions are only valid when

considering short-term acute effects at an incapacitating level of exposure. For irritants, other, dose-

related aspects need to be included when considering long exposures or lethality levels.

One of the limits of the ISO 13571 asphyxiant gas model is that it does not incorporate the rarefaction

of oxygen, O , which also has an asphyxiating effect. However, in many situations this effect can be

considered to be minor compared with the effects of CO and HCN. CO is considered as producing a

hyperventilation factor in ISO 13571.

6.3 Models for thermal impact

Three mechanisms are considered: hyperthermia linked to exceeding the body’s thermal regulation

capacity, skin burns, and burns in the bronchial tubes. In most cases, bronchial tube burns take place at

higher exposure levels than skin burns.

There are two models proposed in ISO 13571 one for radiant flux exposure and one for exposure

to convective heat exchange – and they are synthesized in the form of an FED making it possible to

calculate the cumulative dose.

6.3.1 Radiant flux exposure model

Two formulas are proposed in ISO 13571. The first makes it possible to calculate the time to get second-

degree burns on the skin; the second makes it possible to calculate the time to reach the pain threshold.

It should be noted that the skin temperature depends on the applied flux density at the surface and the

ease with which the blood carries away the energy reaching under the skin. Because of this there is a

−2

threshold located around 2,5 kW.m , below which exposure to the flux does not cause a significant

temperature increase of the skin and above which the temperature increase occurs quickly. A greater

exposure can however be acceptable with the exposure time is short, especially when considering

passing before an opening leading to an area on fire. Further details can be found in ISO 13571.

6.3.2 Temperature exposure model

Two formulas are included in ISO 13571, according to whether the subject is dressed normally or

lightly dressed (even naked) for calculating the time necessary to become incapacitated (for an air

environment at less than 10 % relative humidity).

6.3.3 Dose calculation model

The dose effect linked to the accumulation of the temperature is calculated using the thermal model

FED equation of ISO 13571.

7 Examples of application

Annex A presents an example of application of ISO 13571 to a series of real-scale fire tests performed on

houses with different designs of floors between the basement and the rest of the house, in two different

basement fire scenarios. The objective of the study was to better understand the impact of basement

4 PROOF/ÉPREUVE © ISO 2016 – All rights reserved

fires on the ability of occupants on the upper storeys to escape. ISO 13571 models are used to monitor

tenability conditions at various locations in the upper storeys. The example gives a relative comparison

between different designs, using FED as the comparison criterion, without considering any specific

evacuation scenario.

Annex B presents the application of ISO 13571 to different real-scale fire scenarios on a single sleeping

room. Analysis is based on the time to reach compromised tenability conditions using thermal and

toxic models of ISO 13571 and different evacuation strategies. The results identify the main factor

comprising tenability for each scenario, according to occupant’s behaviour.

Annex C presents a methodology to apply ISO 13571 to Fire Safety Engineering studies. It refers to

ISO 23932 and proposes a mathematical approach that allows obtaining tenability data as performance

criteria. This methodology is based on a construction of a source term of toxic gases in addition to a

source term of heat release in the Design Fire Scenario studied. It proposes ways to obtain data for each

fire stage and presents the input data in a matricial shape.

Annex D is a first application of methodology proposed in Annex C. The situation is a fire in a hotel room

connected to a corridor equipped with mechanical smoke control devices. Tenability assessment in the

corridor is studied according to the ISO 13571 models. Various scenarios of occupant behaviour are

tested, such as different departure times, a travel trough the corridor or turn back depending on the

conditions. The different evacuation strategies and occupant behaviour lead to contrasted results: in

some scenarios, tenability is driven by thermal effects, and in some other, toxic effects prevails.

Annex E is a second application of the methodology proposed in Annex C. The situation is a fire in a

restaurant equipped with natural smoke control openings and an operating heating, ventilating, and air

conditioning (HVAC) system. The fire starts in a hidden technical room (dishwashing room). Tenability

assessment is performed along two escape routes, considering various pre-movement delays. The

different evacuation strategies and occupant behaviour lead to contrasted results: depending on route

chosen and pre-movement delay, tenability is driven by either thermal effects or toxic effects. Results

are also expressed as success (FED, FEC < 0,3) versus pre-movement delay.

Annex A

(informative)

Example of application to real-scale fire scenarios - FED and ASET

calculations for fire experiments conducted in a full-scale test

house under two basement fire scenarios

A.1 General

An experimental program was undertaken to study the fire performance of various engineered floor

systems used in single-family houses as construction moves away from the traditional solid sawn

[6]

wood joists . The experimental program was conducted using a test facility representing a two-storey

detached single-family house with a basement (referred to as the test house hereafter). It involved full-

scale fire experiments with unprotected floor assemblies located over the basement (unsheathed on

the basement side) using two specific basement fire scenarios. The objective of the study was to better

understand, from the perspective of tenability and structural integrity of the floor assemblies as egress

routes, the impact of basement fires on the ability of occupants on the upper storeys to escape.

The experimental program used a timeline approach to establish the sequence that affects the life

safety and egress of occupants under two specific basement fire scenarios. This sequence included

fire initiation, smoke alarm activation, onset of untenable conditions on upper storeys, and structural

failure of the test floor assembly as a viable egress route on the first storey. The experimental approach

was designed to determine how long egress routes would remain viable from the perspective of both

tenability and structural integrity of the test floor assembly. With the use of engineered joists and

trusses in floor construction, it is desirable that the time to incapacitation of occupants should not be

adversely affected. Structural failure of the floors constructed with alternative engineered products

should not occur prior to the time taken to reach incapacitating levels of smoke, gases and heat. This

involved FED and ASET calculations using experimental data and comparison between ASET and the

floor failure time.

A.2 Experiments

Brief descriptions of the experiments are provided in the following sections. Further details of the

[6]

experimental setup can be found in reference .

A.2.1 Facility

Each storey of the test house had a floor area of 95 m and a ceiling height of 2,4 m. The basement

was partitioned to create a fire compartment representing a 27,6 m basement living area; the

remaining area was not used during the experiments. The fire compartment had a rectangular exterior

opening (2,0 m wide by 0,5 m high) covered with a removable non-combustible panel. The walls of

the fire compartment were lined with 12,7 mm thick regular gypsum board. The gypsum board met

ASTM C1396 and CAN/CSA-A82.27 material standards and consisted of a solid set gypsum core enclosed

in face paper and liner back paper with a weight of 7,8 kg/m , a Flame Spread rating of 15 and Smoke

Developed rating of 0 in accordance with ASTM E84 (UL 723, UBC 8-1,NFPA 255, CAN/ULC-S102). An

enclosed stairwell connected the fire compartment to the first storey. At the top of this stairwell, a

0,81 m wide by 2,05 m high doorway led to the first storey. This doorway either had a door in the closed

position (closed basement doorway) or had no door at all (open basement doorway), depending on the

scenario being studied.

The first storey had an open-plan layout with no partitions. A test floor assembly was constructed on the

first storey directly above the basement fire compartment for each experiment. A range of engineered

6 PROOF/ÉPREUVE © ISO 2016 – All rights reserved

floor systems, including wood I-joist, steel C-joist, metal plate wood truss and metal web wood truss

assemblies as well as solid wood joist assemblies were used in the full-scale fire experiments. A 0,89 m

wide by 2,07 m high doorway led to the exterior. The staircase to the second storey was not enclosed.

The second storey had a corridor (measuring 4,45 m long by 1,10 m wide) and bedrooms. Two bedrooms

(each having a floor area of 16,8 m ) were used as target bedrooms in the experiments. The door to one

of the bedrooms was kept open whereas the door to the other bedroom remained closed. Each bedroom

doorway was 0,81 m wide by 2,05 m high.

A.2.2 Fire scenarios

Two fire scenarios were used in the full-scale fire experiments:

— the doorway from the first storey to the basement had no door (referred to as the open basement

doorway scenario);

— a hollow-core interior door was used in the doorway in the closed position (referred to as the closed

basement doorway scenario).

A simple and repeatable fuel package was developed for use in full-scale experiments to fuel a fire that

simulated a basement living area fire. This fuel package consisted of a mock-up sofa constructed with

9 kg of flexible polyurethane foam without any upholstery fabric, and 190 kg of wood cribs beside and

underneath the mock-up sofa. The polyurethane blocks used were furniture grade flexible foam with

a chemical formula of CH O N and a density of 32,8 kg/m . The fuel package was located

1,91 0,263 0,055

at the centre of the fire compartment in order to provide a greater challenge to the unprotected floor

[7]

assemblies above. The mock-up sofa was ignited in accordance with the ASTM 1537 test protocol

and the wood cribs provided the remaining fire load to sustain the fire for a desired period of time.

To provide the ventilation necessary for combustion and to simulate the fire-induced breakage and

complete fall-out of the window glass, the non-combustible panel that initially covered the exterior

window opening of the fire compartment was manually removed when the temperature reached

300 °C at the opening. This condition was normally reached within 90 s to 120 s after ignition in the

experiments. The exterior door on the first storey was opened at 180 s after ignition and left open to

simulate some occupants evacuating the test house.

A.2.3 Measurements

Various measurement devices were used and data was collected at 5 s intervals in the experiments.

Extensive thermocouple arrays were installed throughout the test house to measure temperatures.

Flame-sensing devices and floor deflection devices were installed on the test floor assemblies.

Residential ionization and photoelectric smoke alarms were installed on each level and in each

bedroom.

Measurements of smoke density and gas concentrations were focused on upper storeys. On the first

storey, smoke and gas sampling ports were located at a quarter point at 0,9 m and 1,5 m above the

floor. On the second storey, smoke and gas sampling ports were located at the centre of the corridor at

0,9 m and 1,5 m above the floor. Smoke and gas samples from these sampling locations were connected

to nondispersive infrared CO/CO gas analyzers, O gas analyzers and smoke density meters. Detailed

2 2

gas analysis using Fourier Transform Infrared (FTIR) spectrometers was only conducted in a limited

number of experiments.

A.2.4 Fire development in the basement fire compartment

Figure A.1 and Figure A.2 show the temperature profiles measured at the centre of the four quadrants

of the basement fire room at the ceiling height for all of the tests. The polyurethane foam used for

the mock-up sofa dominated the initial fire growth. The fast development of the fire from ignition to

attainment of the first temperature peak was consistent for all of the tests. The temperatures at the

ceiling height exceeded 600 °C at approximately 120 s in all of the tests, indicating that the basement

fire compartment reached flashover conditions. Following this initial stage, the effects of ventilation

became more pronounced and the fire became wood-crib-dominated and also involved the unprotected

floor assemblies. Both fire scenarios provided relatively severe and consistent fire exposure to the

unprotected floor assemblies in all experiments.

Figure A.1 — Temperatures in basement fire compartment at 2,4 m height (open basement

doorway)

8 PROOF/ÉPREUVE © ISO 2016 – All rights reserved

Figure A.2 — Temperatures in basement fire compartment at 2,4 m height (closed basement

doorway)

A.3 Upper storey conditions and tenability analysis

Heat, combustion products and smoke produced from fires can, either individually or collectively,

create conditions that are potentially untenable for occupants. Tenability analysis was conducted using

temperatures, concentrations of combustion products and smoke optical densities measured during

the experiments to provide an estimation of the ASET with incapacitation as the end point. The analysis

focused on the conditions on the upper storeys of the test house. The conditions in the basement fire

room would not be survivable once flashover occurred.

Potential exposure to the toxic and asphyxiant gases, heat and smoke obscuration under the test

conditions was analysed independently. Each component was treated as acting independently on the

occupant to create incapacitating conditions and the ASET was the shortest of the times estimated from

consideration of exposure to combustion gas products, heat and smoke obscuration.

A.3.1 Exposure to toxic gases

In regards to the fuel package used in this study, with the combined flaming combustion of polyurethane

foam and wood cribs, the primary gaseous products were expected to be carbon monoxide (CO), carbon

dioxide (CO ) and hydrogen cyanide (HCN) in a vitiated oxygen (O ) environment. Although HCN could

2 2

be produced from the combustion of the polyurethane foam in the fuel package, FTIR spectroscopy

measurements in selected tests indicated that the HCN concentrations on the upper storeys were

well below 30 ppm. These concentrations would not be a concern for occupant life safety on the upper

storeys in the timeframe for incapacitation by CO exposure. As the polyurethane foam has a chemical

formula of CH O N , the fuel package contained no chemical components that would produce

1,91 0,263 0,055

acid halide irritants in the combustion gases. Other potential irritant gases transported to the upper

storeys, such as NO, NO and acrolein, were below the detection limits of the FTIR spectrometers used

in the experiments. Therefore, the analysis for the upper storeys involved CO and CO and oxygen

vitiation only. Figure A.3 shows exemplar concentration-time profiles for CO, CO and O measured

2 2

during experiments.

Figure A.3 — Exemplar CO, CO and O concentrations measured at a quarter point on the first

2 2

storey at 1,5 m height

10 PROOF/ÉPREUVE © ISO 2016 – All rights reserved

The fractional effective dose for incapacitation due to CO was calculated as follows with the CO -

induced hyperventilation factor:

t

CO ×tΔ

%CO

FED = exp

∑

in,CO

35 000 5

t

Since data were collected at 5 s intervals in the experiments, Δt = 0,0833 min. The uncertainty in the

calculation of FED is estimated to be ± 40 %, which takes into consideration of 20 % uncertainty

in,CO

for hyperventilation factor in addition to the normal 35 % uncertainty for FED.

Table A.1 shows the calculated times for the fractional effective dose to reach two typical values

(FED = 1 for healthy adults of average susceptibility, and FED = 0,3 for some susceptible people),

including the uncertainty in the estimated times. The times associated with other FED values can be

calculated, if required.

Table A.1 — Time (in seconds) to the specified FED for exposure to CO with CO

hyperventilation

1st storey SW quadrant 2nd storey corridor

FED = 0,3 1,0 0,3 1,0

in, CO

Tests with open basement doorway

Solid wood joist 205 ± 10 235 ± 15 225 ± 10 255 ± 15

Wood I-joist A 209 ± 5 240 (−15, +5) 225 ± 10 247 ± 15

Steel C-joist 220 (−10, +5) 260 ± 20 245 ± 10 280 ± 20

Metal-plate wood truss 206 ± 7 232 ± 13 235 ± 7 260 ± 10

198 ± 10 233 (−15, +5) 208 ± 12 241 ± 10

Wood I-joist B 198 ± 10 228 ± 5 207 ± 15 241 ± 10

203 ± 10 233 ± 10 218 ± 10 248 ± 15

Metal web wood truss 225 ± 25 265 ± 7 230 ± 25 275 ± 10

Tests with closed basement doorway

Solid wood joist 466 ± 60 676 ± 90 362 ± 30 501 ± 70

a

Metal web wood truss 400 (−55, +40) 510 (−25, + ) 375 ± 35

a

(−50, + )

Wood I-joist A 329 ± 40 484 ± 70 364 ± 35

(−70, +60)

NOTE Calculated based on concentrations at 1,5 m height above the floor

a

Upper range of uncertainty in timing is unavailable due to commencement of fire suppression

For the tests with the open basement doorway, the calculated time difference between FED = 0,3

in,CO

and FED = 1,0 was 40 s or less at any measurement location for any given test. The calculations

in,CO

were associated with the fixed positions where the concentrations were measured and an occupant

would move through different locations in real fire situations. The time difference between the second

storey and first storey reaching either of the two doses was less than 30 s for any given test. Moreover,

the time difference between tests reaching either of the two doses was less than 40 s at any measurement

location. These results indicate a consistent time frame for reaching the incapacitation doses for

exposure to CO in this fire scenario.

For the experiments with the closed basement doorway, the calculated times were at least 60 % longer

to reach FED = 0,3 and at least doubled to reach FED = 1, compared with the open basement

in,CO in,CO

doorway experiments. The closed door impeded the migration of smoke and hot fire gases into the

upper storey(s) and delayed the onset of untenable conditions.

The fractional effective doses for incapacitation due to O vitiation alone, and due to asphyxiant effect

[8]

of CO alone, were also calculated using the methodology given in reference . Under the experimental

conditions of this study, these calculations indicated that the effect of O vitiation and the asphyxiant

effect of CO would cause incapacitation at a later time than the toxic effect of CO.

A.3.2 Exposure to heat

Figure A.4 and Figure A.5 show exemplar temperature profiles measured on the first and second

storeys during the experiments. The temperatures depended on the locations inside the test house. In

the bedroom with the door closed, the temperatures never exceeded 50 °C in any experiment.

The presence of the closed door in the basement doorway made a significant difference in the thermal

conditions on the first and second storeys. The closed door impeded the migration of smoke and hot

fire gases into the upper storeys until it was breached by the fire, and thereby delayed the onset of

untenable thermal conditions on the upper storeys.

Assuming unclothed or lightly clothed subjects, the fractional effective dose for incapacitation due to

the convected heat exposure was calculated using the following equation:

t

34,

T

FED = Δt

∑

in,heat

51× 0

t0

The uncertainty in the calculation of FED is estimated to be ± 25 %. Since there was temperature

in,heat

stratification, the temperatures at the 1,4 m height on each storey were used for the analysis of

convected heat exposure, as this simulated the height of the nose/mouth of an average height individual.

Radiant heat is important when the hot smoke layer is over 200 °C, which corresponds to the threshold

−2 [9]

radiant heat flux of 2,5 kW⋅m to produce second degree burning of skin . The calculation indicated

that the convected heat exposure would result in incapacitation before the radiant heat began to play

a major role on the first and second storeys. Convected heat was the most important source of heat

exposure for occupants on the first and second storeys for the fire scenarios used.

12 PROOF/ÉPREUVE © ISO 2016 – All rights reserved

Figure A.4 — Exemplar temperature profiles on upper storeys (open basement doorway)

Figure A.5 — Exemplar temperature profiles on upper storeys (closed basement doorway)

The convective heat exposure depended on the location in the test house. In the closed bedroom, heat

exposure would not cause incapacitation (FED < 0,07 in all experiments). On the first storey, in

in,heat

the corridor or in the open bedroom on the second storey, the calculated times to incapacitation due to

14 PROOF/ÉPREUVE © ISO 2016 – All rights reserved

exposure to the convected heat are given in Table A.2 for FED = 0,3 and FED = 1, including

in,heat in,heat

the uncertainty in the estimated times. Depending on the test conditions (floor assembly type, condition

of doorway to the basement) and locations in the test house, the heat exposure could cause incapacitation

before CO exposure or vice versa.

For the tests with the open basement doorway, the calculated times to reach the heat incapacitation

doses on the first storey were comparable to those for CO exposure and, in most cases, the time

difference for FED to change from 0,3 to 1,0 was also much shorter than that for FED . In the

in,heat in,CO

corridor on the second storey, except for one test, the calculated times for heat exposure to reach the

incapacitation doses were longer than those for CO exposure.

For the tests with the closed basement doorway, the incapacitation doses for heat exposure on the first

storey were reached much later than for the CO exposure. The calculated times for heat incapacitation

were at least double that for the tests with the open basement doorway. The closed door to the basement

impeded the heat transfer to the upper storey(s) and delayed the onset of untenable heat conditions.

The CO exposure dominated incapacitation on both storeys.

Table A.2 — Time (in seconds) to the specified FED for exposure to convective heat

1st storey SW quadrant 2nd storey corridor 2nd storey open bedroom

FED = 0,3 1,0 0,3 1,0 0,3 1,0

in, heat

Tests with open basement doorway

Solid wood joist 230 ± 7 280 ± 15 320 ± 15 435 ± 30 455 ± 30 690 ± 60

Wood I-joist A 205 ± 3 213 ± 3 252 ± 5 330 ± 25 370 ± 30 (FED < 0,8)

a

Steel C-joist 207 ± 2 215 ± 3 250 ± 5 290 ± 10 325 ± 15 460 (−35, + )

Metal-plate wood truss 220 ± 3 240 ± 5 270 ± 10 320 ± 15 345 ± 15

a

(−60, + )

202 ± 2 211 ± 3 229 ± 3 254 ± 10 315 ± 20 (FED < 0,8)

Wood I-joist B 193 ± 2 199 ± 2 217 ± 3 238 ± 6 293 ± 15 (FED < 0,8)

209 ± 2 216 ± 2 234 ± 3 298 ± 25 393 ± 30 (FED < 0,4)

Metal web wood truss 192 ± 2 207 ± 5 225 ± 5 255 ± 10 305 ± 15 (FED < 0,9)

Tests with closed basement doorway

Solid wood joist 1086 ± 30 1196 (−10, +5) 1171 (−55, +35) 1241 (−10, +5) 1263 ± 10 (FED < 0,5)

Metal web wood truss 482 ± 1 486 ± 1 507 ± 2 (FED < 0,5) (FED < 0,1) (FED < 0,1)

Wood I-joist A 786 ± 1 796 ± 1 (FED < 0,2) (FED < 0,2) (FED < 0,1) (FED < 0,1)

NOTE Calculated based on temperatures at 1,4 m height above the floor

a

Upper range of uncertainty in timing is unavailable due to commencement of fire suppression

A.3.3 Visual obscuration by smoke

Visual obscuration by the optically dense smoke tended to be the first hazard to arise that could impede

evacuation by the occupants.

In ISO 13571, the minimum visible brightness difference between an object and its background is used

to estimate the smoke obscuration limit at which occupants cannot see their hands in front of their

faces (a distance of 0,5 m or less). These calculations indicate that occupants cannot see their hands in

front of their faces and become disoriented at a smoke optical density (OD) of 1,7.

During the experiments, the smoke optical density was measured at 0,9 and 1,5 m heights above the

floor on the first and second s

...

TECHNICAL ISO/TR

REPORT 13571-2

First edition

2016-07-01

Life-threatening components of fire —

Part 2:

Methodology and examples of

tenability assessment

Composants dangereux du feu —

Partie 2: Méthodologie et exemples d’analyse de tenabilité

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 1

5 Performance criteria . 3

6 Evaluation of the impact . 3

6.1 Effects of fire on people . 3

6.2 Models for toxic impact . 3

6.3 Models for thermal impact . 4

6.3.1 Radiant flux exposure model . 4

6.3.2 Temperature exposure model . 4

6.3.3 Dose calculation model . 4

7 Examples of application . 4

Annex A (informative) Example of application to real-scale fire scenarios - FED and ASET

calculations for fire experiments conducted in a full-scale test house under two

basement fire scenarios . 6

Annex B (informative) Example of application to real-scale fire scenarios - FED calculations

for fire experiments conducted in a full-scale test of single sleeping rooms .20

Annex C (informative) Methodology for application of ISO 13571 in Fire Safety

Engineering approach .41

Annex D (informative) Example of application to Fire Safety Engineering–Case Nr 1 – hotel

room and corridor .51

Annex E (informative) Example of application to Fire Safety Engineering – Case Nr 2

– restaurant .64

Annex F (informative) Determination of data for matrix .81

Bibliography .84

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www.iso.org/iso/foreword.html.

The committee responsible for this document is ISO/TC 92 Fire Safety, Subcommittee 3, Fire threat to

people and environment.

iv © ISO 2016 – All rights reserved

Introduction

Tenability of people in case of fire is an essential safety objective of regulations. Reasons that could lead

to compromised tenability conditions are loss of visibility, thermal and toxic effects. ISO 13571 is a tool

that has been developed to quantify the performance level related to these criteria in case of a fire.

This document presents application cases of ISO 13571. It is structured as follows:

— Clause 4 explains the principle of the application;

— Clause 5 presents the selection of performance criteria;

— Clause 6 presents the evaluation of the impact of fire to people according to ISO 13571;

— Clause 7 introduces the examples detailed in Annexes A, B, D and E.

Examples of application are presented in annexes. The first case of application concerns comparison

of tenability in real-scale fire tests (Annex A and Annex B). The second case presents the methodology

(Annex C) and two example cases (Annex D and Annex E) for application of ISO 13571 as performance

criteria in Fire Safety Engineering studies according to ISO 23932. Annex F presents information on

experimental production of input data.

TECHNICAL REPORT ISO/TR 13571-2:2016(E)

Life-threatening components of fire —

Part 2:

Methodology and examples of tenability assessment

1 Scope

This document describes the practical application of ISO 13571 as a tool to evaluate effects of fire

effluents on people. The method of application, performance criteria and evaluation of the impact are

explained and illustrated by two families of examples: application to real-scale tests (Annex A and

Annex B) and application to Fire Safety Engineering (Annex C, D and E).

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 13943 and ISO 13571

apply. ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

4 Principle

Smoke toxicity, to a certain degree, is not a material property. Depending on the environment,

availability of oxygen, thermal attack, flow conditions and surface areas available for combustion, the

chemistry of the combustion of a given material can proceed along various routes and produce species

[1][2][3]

in very different quantities. It is then a systemic parameter, which need a systemic approach, as

stated in ISO 19706.

It is also appropriate to keep the following points in mind:

— The production rates of various gaseous species change according to the combustion regime. In

particular the influential parameters (not exhaustive) are:

— Fuel nature

— Oxygen availability

— Temperature

— Flows received and lost

— The species produced by the combustion are carried away from the initial fire source, and their

effect is related to:

— Sensitivity and activity of people

— Concentrations (instantaneous)

— Exposure times (accumulation)

Furthermore, the thermal effects related to the heat of the gases and smoke produced, along with the

radiant fluxes, which they emit, play a role in the safety of people who are evacuating.

For a given design fire, it is therefore necessary to determine one or more exposure scenarios, which

will make it possible to answer questions about the effects on people according to:

— The fire source and its development;

— The species produced by this fire source and their movement away from the original fire source;

— The evacuation of the people, their path and the toxic and thermal elements to which they are subject

as a function of time.

Finally, it is useful to recall that toxic hazard in enclosures is mainly caused by the combustion of the

contents and furnishings in the enclosure rather than the enclosure itself in the early phases of a fire.

Furthermore, changes in regulations can lead to better insulation of the rooms, modification of the

ventilation, and resistance of windows to bursting, all of which notably change the conditions for the

accumulation of thermal energy and the generation of toxic species.

The following are the objectives of the application of ISO 13571:

— Assess effects of fire on people as a principal criterion for performance evaluation in Fire Safety

Engineering studies, or in comparison of real-scale fire tests,

— Involve realistic fire sources in terms of:

— Kinetics

— Species produced, in particular by including data concerning the toxic species related to the

burning of the contents and furnishings in building fires

— Be able to process all the materials present and not just certain ones

— Consider all potential toxic species, not only CO, as is often seen in practice

— Consider the aspects of production kinetics, movement of gases, and availability of oxygen

— Be able to process several scenarios and their possible variations:

— “Typical” materials/”risky” materials

— Risk in the room of fire origin room and outside the room of origin

— Different fire regimes (smouldering, well ventilated, post-flashover)

— Evacuation plans

— Consider the various risks for people and the associated sanction criteria as a function of thermal

and toxic effects, both instantaneous and by accumulation.

2 © ISO 2016 – All rights reserved

5 Performance criteria

The selection of criteria to consider is conducted in early phases of a project, before any detailed study.

These criteria will make it possible to determine whether a given exposure scenario (i.e. a fire scenario

combined with an evacuation scenario) is a success or failure. This concept depends above all on the

susceptibility of the people to the fire effluent. In the application of ISO 13571, the objective that a

person could realize his/her own evacuation without any assistance.

In fact, each person is different and according to their constitution, age, gender, possible underlying

conditions, etc. the FEC and FED which they can endure before being incapacitated varies. There is,

however, no feedback from experience which can be used in statistical terms. Due to the lack of precise

knowledge in this field, approximating the distribution of individual susceptibilities by a log-normal

distribution with a median value of one as thresholds for the FED and FEC is proposed. Half the

population is therefore considered as being able to tolerate FED and FEC each having a value of one, and

the other half is more sensitive and cannot tolerate values of FED and FEC equal to or above one.

As an example of a safety criterion that provides protection for a larger fraction of the population,

ISO 13571:2012, A.5.2 shows that a value 0,3 protects a significant portion of the more sensitive people.

At this value, 11,4 % of the population remains vulnerable to incapacitation by exposure to the fire

effluent. It should be kept in mind that one of the consequences of the distribution described by the

ISO 13571:2012 standard for the sensitivity of individuals (log-normal law) is that there is no value for

the criterion which is low enough to guarantee protection of all occupants in an evacuation situation.

Designing a facility such that the FED and FEC values are kept to extremely low values is likely to require

immediate detection and suppression or to preclude otherwise desirable construction and furnishing

products. It is the regulator’s role to weigh these considerations.

6 Evaluation of the impact

6.1 Effects of fire on people

The impact of fire effluent on a person depends on two interacting components. The first is the location

of a person and how that location might change during the course of the fire. The second is the evolving

concentrations of the effluent constituents where the person is located.

A fire safety assessment could be made considering the evolution of tenability for a person who is

stationary at one position in a room. This would apply to people who are asleep or medically confined.

Such an application in real-scale fire tests is presented in Annex A. Assessment could also consider the

exposure of a person moving along an egress path with its travel path in real-scale fire tests (Annex B)

or included in a Fire Safety Engineering approach (Annexes C to E).

The exposure models used are those described in ISO 13571:2012. In particular, they cover the toxic and

thermal models, but do so independently. For the toxic models, the effects of the asphyxiating and irritating

gases are considered separately. See ISO 19706 for more details on the relevance of these models.

6.2 Models for toxic impact

Toxic effluents can have two principal mechanisms of action on people when considering acute

exposure. Depending on their nature, they are classified into two categories:

— asphyxiating gases (CO, HCN, etc.)

— irritating gases (HCl, HBr, etc.)

There are also indirect effects like those of the low oxygen concentration (hypoxia) or high CO

concentration (hyperventilation). Other effects exist, like clogging of the respiratory tracts because of

the presence of soot.

The evaluation of the effects related to exposure to smoke requires knowledge of the central concepts.

[4] [5]

The References and present a review of the art of these concepts.

Because of the complexity of the problem, there are various models incorporating toxic effects.

Although all of them can be used, a first consensus was established on the models given in ISO 13571.

In the ISO 13571 models, the asphyxiating gases, incorporated using the calculation of a Fractional

Effective Dose (FED), and the irritating gases, incorporated using the calculation of Fractional Effective

Concentration (FEC), are considered separately.

Thus, the asphyxiating gases (mainly CO, and HCN) are considered from the perspective of an

accumulation mechanism, and the irritants (mainly HCl, HBr, HF, SO , NO, NO , acrolein, and

2 2

formaldehyde) from that of their instantaneous effect. These assumptions are only valid when

considering short-term acute effects at an incapacitating level of exposure. For irritants, other, dose-

related aspects need to be included when considering long exposures or lethality levels.

One of the limits of the ISO 13571 asphyxiant gas model is that it does not incorporate the rarefaction

of oxygen, O , which also has an asphyxiating effect. However, in many situations this effect can be

considered to be minor compared with the effects of CO and HCN. CO is considered as producing a

hyperventilation factor in ISO 13571.

6.3 Models for thermal impact

Three mechanisms are considered: hyperthermia linked to exceeding the body’s thermal regulation

capacity, skin burns, and burns in the bronchial tubes. In most cases, bronchial tube burns take place at

higher exposure levels than skin burns.

There are two models proposed in ISO 13571 one for radiant flux exposure and one for exposure

to convective heat exchange – and they are synthesized in the form of an FED making it possible to

calculate the cumulative dose.

6.3.1 Radiant flux exposure model

Two formulas are proposed in ISO 13571. The first makes it possible to calculate the time to get second-

degree burns on the skin; the second makes it possible to calculate the time to reach the pain threshold.

It should be noted that the skin temperature depends on the applied flux density at the surface and the

ease with which the blood carries away the energy reaching under the skin. Because of this there is a

−2

threshold located around 2,5 kW.m , below which exposure to the flux does not cause a significant

temperature increase of the skin and above which the temperature increase occurs quickly. A greater

exposure can however be acceptable with the exposure time is short, especially when considering

passing before an opening leading to an area on fire. Further details can be found in ISO 13571.

6.3.2 Temperature exposure model

Two formulas are included in ISO 13571, according to whether the subject is dressed normally or

lightly dressed (even naked) for calculating the time necessary to become incapacitated (for an air

environment at less than 10 % relative humidity).

6.3.3 Dose calculation model

The dose effect linked to the accumulation of the temperature is calculated using the thermal model

FED equation of ISO 13571.

7 Examples of application

Annex A presents an example of application of ISO 13571 to a series of real-scale fire tests performed on

houses with different designs of floors between the basement and the rest of the house, in two different

basement fire scenarios. The objective of the study was to better understand the impact of basement

4 © ISO 2016 – All rights reserved

fires on the ability of occupants on the upper storeys to escape. ISO 13571 models are used to monitor

tenability conditions at various locations in the upper storeys. The example gives a relative comparison

between different designs, using FED as the comparison criterion, without considering any specific

evacuation scenario.

Annex B presents the application of ISO 13571 to different real-scale fire scenarios on a single sleeping

room. Analysis is based on the time to reach compromised tenability conditions using thermal and

toxic models of ISO 13571 and different evacuation strategies. The results identify the main factor

comprising tenability for each scenario, according to occupant’s behaviour.

Annex C presents a methodology to apply ISO 13571 to Fire Safety Engineering studies. It refers to

ISO 23932 and proposes a mathematical approach that allows obtaining tenability data as performance

criteria. This methodology is based on a construction of a source term of toxic gases in addition to a

source term of heat release in the Design Fire Scenario studied. It proposes ways to obtain data for each

fire stage and presents the input data in a matricial shape.

Annex D is a first application of methodology proposed in Annex C. The situation is a fire in a hotel room

connected to a corridor equipped with mechanical smoke control devices. Tenability assessment in the

corridor is studied according to the ISO 13571 models. Various scenarios of occupant behaviour are

tested, such as different departure times, a travel trough the corridor or turn back depending on the

conditions. The different evacuation strategies and occupant behaviour lead to contrasted results: in

some scenarios, tenability is driven by thermal effects, and in some other, toxic effects prevails.

Annex E is a second application of the methodology proposed in Annex C. The situation is a fire in a

restaurant equipped with natural smoke control openings and an operating heating, ventilating, and air

conditioning (HVAC) system. The fire starts in a hidden technical room (dishwashing room). Tenability

assessment is performed along two escape routes, considering various pre-movement delays. The

different evacuation strategies and occupant behaviour lead to contrasted results: depending on route

chosen and pre-movement delay, tenability is driven by either thermal effects or toxic effects. Results

are also expressed as success (FED, FEC < 0,3) versus pre-movement delay.

Annex A

(informative)

Example of application to real-scale fire scenarios - FED and ASET

calculations for fire experiments conducted in a full-scale test

house under two basement fire scenarios

A.1 General

An experimental program was undertaken to study the fire performance of various engineered floor

systems used in single-family houses as construction moves away from the traditional solid sawn

[6]

wood joists . The experimental program was conducted using a test facility representing a two-storey

detached single-family house with a basement (referred to as the test house hereafter). It involved full-

scale fire experiments with unprotected floor assemblies located over the basement (unsheathed on

the basement side) using two specific basement fire scenarios. The objective of the study was to better

understand, from the perspective of tenability and structural integrity of the floor assemblies as egress

routes, the impact of basement fires on the ability of occupants on the upper storeys to escape.

The experimental program used a timeline approach to establish the sequence that affects the life

safety and egress of occupants under two specific basement fire scenarios. This sequence included

fire initiation, smoke alarm activation, onset of untenable conditions on upper storeys, and structural

failure of the test floor assembly as a viable egress route on the first storey. The experimental approach

was designed to determine how long egress routes would remain viable from the perspective of both

tenability and structural integrity of the test floor assembly. With the use of engineered joists and

trusses in floor construction, it is desirable that the time to incapacitation of occupants should not be

adversely affected. Structural failure of the floors constructed with alternative engineered products

should not occur prior to the time taken to reach incapacitating levels of smoke, gases and heat. This

involved FED and ASET calculations using experimental data and comparison between ASET and the

floor failure time.

A.2 Experiments

Brief descriptions of the experiments are provided in the following sections. Further details of the

[6]

experimental setup can be found in reference .

A.2.1 Facility

Each storey of the test house had a floor area of 95 m and a ceiling height of 2,4 m. The basement

was partitioned to create a fire compartment representing a 27,6 m basement living area; the

remaining area was not used during the experiments. The fire compartment had a rectangular exterior

opening (2,0 m wide by 0,5 m high) covered with a removable non-combustible panel. The walls of

the fire compartment were lined with 12,7 mm thick regular gypsum board. The gypsum board met

ASTM C1396 and CAN/CSA-A82.27 material standards and consisted of a solid set gypsum core enclosed

in face paper and liner back paper with a weight of 7,8 kg/m , a Flame Spread rating of 15 and Smoke

Developed rating of 0 in accordance with ASTM E84 (UL 723, UBC 8-1,NFPA 255, CAN/ULC-S102). An

enclosed stairwell connected the fire compartment to the first storey. At the top of this stairwell, a

0,81 m wide by 2,05 m high doorway led to the first storey. This doorway either had a door in the closed

position (closed basement doorway) or had no door at all (open basement doorway), depending on the

scenario being studied.

The first storey had an open-plan layout with no partitions. A test floor assembly was constructed on the

first storey directly above the basement fire compartment for each experiment. A range of engineered

6 © ISO 2016 – All rights reserved

floor systems, including wood I-joist, steel C-joist, metal plate wood truss and metal web wood truss

assemblies as well as solid wood joist assemblies were used in the full-scale fire experiments. A 0,89 m

wide by 2,07 m high doorway led to the exterior. The staircase to the second storey was not enclosed.

The second storey had a corridor (measuring 4,45 m long by 1,10 m wide) and bedrooms. Two bedrooms

(each having a floor area of 16,8 m ) were used as target bedrooms in the experiments. The door to one

of the bedrooms was kept open whereas the door to the other bedroom remained closed. Each bedroom

doorway was 0,81 m wide by 2,05 m high.

A.2.2 Fire scenarios

Two fire scenarios were used in the full-scale fire experiments:

— the doorway from the first storey to the basement had no door (referred to as the open basement

doorway scenario);

— a hollow-core interior door was used in the doorway in the closed position (referred to as the closed

basement doorway scenario).

A simple and repeatable fuel package was developed for use in full-scale experiments to fuel a fire that

simulated a basement living area fire. This fuel package consisted of a mock-up sofa constructed with

9 kg of flexible polyurethane foam without any upholstery fabric, and 190 kg of wood cribs beside and

underneath the mock-up sofa. The polyurethane blocks used were furniture grade flexible foam with

a chemical formula of CH O N and a density of 32,8 kg/m . The fuel package was located

1,91 0,263 0,055

at the centre of the fire compartment in order to provide a greater challenge to the unprotected floor

[7]

assemblies above. The mock-up sofa was ignited in accordance with the ASTM 1537 test protocol

and the wood cribs provided the remaining fire load to sustain the fire for a desired period of time.

To provide the ventilation necessary for combustion and to simulate the fire-induced breakage and

complete fall-out of the window glass, the non-combustible panel that initially covered the exterior

window opening of the fire compartment was manually removed when the temperature reached

300 °C at the opening. This condition was normally reached within 90 s to 120 s after ignition in the

experiments. The exterior door on the first storey was opened at 180 s after ignition and left open to

simulate some occupants evacuating the test house.

A.2.3 Measurements

Various measurement devices were used and data was collected at 5 s intervals in the experiments.

Extensive thermocouple arrays were installed throughout the test house to measure temperatures.

Flame-sensing devices and floor deflection devices were installed on the test floor assemblies.

Residential ionization and photoelectric smoke alarms were installed on each level and in each

bedroom.

Measurements of smoke density and gas concentrations were focused on upper storeys. On the first

storey, smoke and gas sampling ports were located at a quarter point at 0,9 m and 1,5 m above the

floor. On the second storey, smoke and gas sampling ports were located at the centre of the corridor at

0,9 m and 1,5 m above the floor. Smoke and gas samples from these sampling locations were connected

to nondispersive infrared CO/CO gas analyzers, O gas analyzers and smoke density meters. Detailed

2 2

gas analysis using Fourier Transform Infrared (FTIR) spectrometers was only conducted in a limited

number of experiments.

A.2.4 Fire development in the basement fire compartment

Figure A.1 and Figure A.2 show the temperature profiles measured at the centre of the four quadrants

of the basement fire room at the ceiling height for all of the tests. The polyurethane foam used for

the mock-up sofa dominated the initial fire growth. The fast development of the fire from ignition to

attainment of the first temperature peak was consistent for all of the tests. The temperatures at the

ceiling height exceeded 600 °C at approximately 120 s in all of the tests, indicating that the basement

fire compartment reached flashover conditions. Following this initial stage, the effects of ventilation

became more pronounced and the fire became wood-crib-dominated and also involved the unprotected

floor assemblies. Both fire scenarios provided relatively severe and consistent fire exposure to the

unprotected floor assemblies in all experiments.

Figure A.1 — Temperatures in basement fire compartment at 2,4 m height (open basement

doorway)

8 © ISO 2016 – All rights reserved

Figure A.2 — Temperatures in basement fire compartment at 2,4 m height (closed basement

doorway)

A.3 Upper storey conditions and tenability analysis

Heat, combustion products and smoke produced from fires can, either individually or collectively,

create conditions that are potentially untenable for occupants. Tenability analysis was conducted using

temperatures, concentrations of combustion products and smoke optical densities measured during

the experiments to provide an estimation of the ASET with incapacitation as the end point. The analysis

focused on the conditions on the upper storeys of the test house. The conditions in the basement fire

room would not be survivable once flashover occurred.

Potential exposure to the toxic and asphyxiant gases, heat and smoke obscuration under the test

conditions was analysed independently. Each component was treated as acting independently on the

occupant to create incapacitating conditions and the ASET was the shortest of the times estimated from

consideration of exposure to combustion gas products, heat and smoke obscuration.

A.3.1 Exposure to toxic gases

In regards to the fuel package used in this study, with the combined flaming combustion of polyurethane

foam and wood cribs, the primary gaseous products were expected to be carbon monoxide (CO), carbon

dioxide (CO ) and hydrogen cyanide (HCN) in a vitiated oxygen (O ) environment. Although HCN could

2 2

be produced from the combustion of the polyurethane foam in the fuel package, FTIR spectroscopy

measurements in selected tests indicated that the HCN concentrations on the upper storeys were

well below 30 ppm. These concentrations would not be a concern for occupant life safety on the upper

storeys in the timeframe for incapacitation by CO exposure. As the polyurethane foam has a chemical

formula of CH O N , the fuel package contained no chemical components that would produce

1,91 0,263 0,055

acid halide irritants in the combustion gases. Other potential irritant gases transported to the upper

storeys, such as NO, NO and acrolein, were below the detection limits of the FTIR spectrometers used

in the experiments. Therefore, the analysis for the upper storeys involved CO and CO and oxygen

vitiation only. Figure A.3 shows exemplar concentration-time profiles for CO, CO and O measured

2 2

during experiments.

Figure A.3 — Exemplar CO, CO and O concentrations measured at a quarter point on the first

2 2

storey at 1,5 m height

10 © ISO 2016 – All rights reserved

The fractional effective dose for incapacitation due to CO was calculated as follows with the CO -

induced hyperventilation factor:

t

CO ×tΔ

%CO

FED = exp

∑

in,CO

35 000 5

t

Since data were collected at 5 s intervals in the experiments, Δt = 0,0833 min. The uncertainty in the

calculation of FED is estimated to be ± 40 %, which takes into consideration of 20 % uncertainty

in,CO

for hyperventilation factor in addition to the normal 35 % uncertainty for FED.

Table A.1 shows the calculated times for the fractional effective dose to reach two typical values

(FED = 1 for healthy adults of average susceptibility, and FED = 0,3 for some susceptible people),

including the uncertainty in the estimated times. The times associated with other FED values can be

calculated, if required.

Table A.1 — Time (in seconds) to the specified FED for exposure to CO with CO

hyperventilation

1st storey SW quadrant 2nd storey corridor

FED = 0,3 1,0 0,3 1,0

in, CO

Tests with open basement doorway

Solid wood joist 205 ± 10 235 ± 15 225 ± 10 255 ± 15

Wood I-joist A 209 ± 5 240 (−15, +5) 225 ± 10 247 ± 15

Steel C-joist 220 (−10, +5) 260 ± 20 245 ± 10 280 ± 20

Metal-plate wood truss 206 ± 7 232 ± 13 235 ± 7 260 ± 10

198 ± 10 233 (−15, +5) 208 ± 12 241 ± 10

Wood I-joist B 198 ± 10 228 ± 5 207 ± 15 241 ± 10

203 ± 10 233 ± 10 218 ± 10 248 ± 15

Metal web wood truss 225 ± 25 265 ± 7 230 ± 25 275 ± 10

Tests with closed basement doorway

Solid wood joist 466 ± 60 676 ± 90 362 ± 30 501 ± 70

a

Metal web wood truss 400 (−55, +40) 510 (−25, + ) 375 ± 35

a

(−50, + )

Wood I-joist A 329 ± 40 484 ± 70 364 ± 35

(−70, +60)

NOTE Calculated based on concentrations at 1,5 m height above the floor

a

Upper range of uncertainty in timing is unavailable due to commencement of fire suppression

For the tests with the open basement doorway, the calculated time difference between FED = 0,3

in,CO

and FED = 1,0 was 40 s or less at any measurement location for any given test. The calculations

in,CO

were associated with the fixed positions where the concentrations were measured and an occupant

would move through different locations in real fire situations. The time difference between the second

storey and first storey reaching either of the two doses was less than 30 s for any given test. Moreover,

the time difference between tests reaching either of the two doses was less than 40 s at any measurement

location. These results indicate a consistent time frame for reaching the incapacitation doses for

exposure to CO in this fire scenario.

For the experiments with the closed basement doorway, the calculated times were at least 60 % longer

to reach FED = 0,3 and at least doubled to reach FED = 1, compared with the open basement

in,CO in,CO

doorway experiments. The closed door impeded the migration of smoke and hot fire gases into the

upper storey(s) and delayed the onset of untenable conditions.

The fractional effective doses for incapacitation due to O vitiation alone, and due to asphyxiant effect

[8]

of CO alone, were also calculated using the methodology given in reference . Under the experimental

conditions of this study, these calculations indicated that the effect of O vitiation and the asphyxiant

effect of CO would cause incapacitation at a later time than the toxic effect of CO.

A.3.2 Exposure to heat

Figure A.4 and Figure A.5 show exemplar temperature profiles measured on the first and second

storeys during the experiments. The temperatures depended on the locations inside the test house. In

the bedroom with the door closed, the temperatures never exceeded 50 °C in any experiment.

The presence of the closed door in the basement doorway made a significant difference in the thermal

conditions on the first and second storeys. The closed door impeded the migration of smoke and hot

fire gases into the upper storeys until it was breached by the fire, and thereby delayed the onset of

untenable thermal conditions on the upper storeys.

Assuming unclothed or lightly clothed subjects, the fractional effective dose for incapacitation due to

the convected heat exposure was calculated using the following equation:

t

34,

T

FED = Δt

∑