ISO 10327:2014

(Main)Air cargo — Main deck containers — Design and testing

Air cargo — Main deck containers — Design and testing

ISO 10327:2014 covers the minimum design and operational testing requirements for general purpose, base-restrained containers exclusively intended for the main or upper deck cargo compartments of main line civil transport aircraft, capable of being used by either airlines or shippers and requiring an airworthiness authority approval (certification). ISO 10327:2014 does not cover the performance requirements and ultimate load testing parameters for airworthiness authorities approval (certification), which are covered in ISO 21100 or, for units approved prior to 2012, ISO 8097:2001. The design and operational testing requirements of ISO 10327:2014 are additional to the performance and certification testing requirements of these International Standards. ISO 10327:2014 does not cover containers with an overall height of 1 625 mm (64 in) or less, that can be loaded on the lower deck compartments of main line civil transport aircraft, which are specified in ISO 6517, nor air-surface main deck containers, which are specified in ISO 4128 and ISO 8323.

Fret aérien — Conteneurs de pont principal — Conception et essais

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10327

Second edition

2014-05-01

Air cargo — Main deck containers —

Design and testing

Fret aérien — Conteneurs de pont principal — Conception et essais

Reference number

©

ISO 2014

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

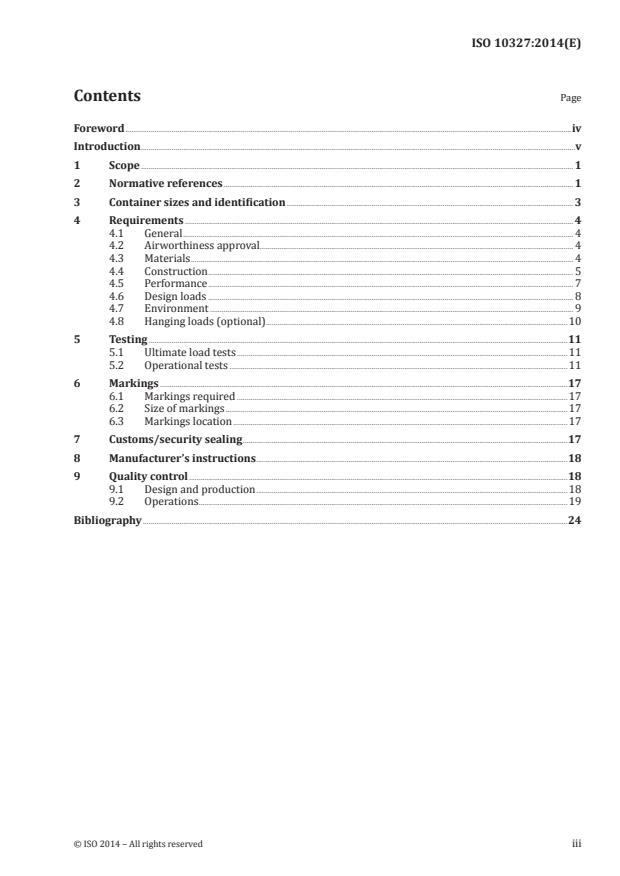

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Container sizes and identification . 3

4 Requirements . 4

4.1 General . 4

4.2 Airworthiness approval . 4

4.3 Materials . 4

4.4 Construction . 5

4.5 Performance . 7

4.6 Design loads . 8

4.7 Environment . 9

4.8 Hanging loads (optional) .10

5 Testing .11

5.1 Ultimate load tests .11

5.2 Operational tests .11

6 Markings .17

6.1 Markings required .17

6.2 Size of markings .17

6.3 Markings location .17

7 Customs/security sealing .17

8 Manufacturer’s instructions .18

9 Quality control .18

9.1 Design and production .18

9.2 Operations .19

Bibliography .24

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 20, Aircraft and space vehicles, Subcommittee

SC 9, Air cargo and ground equipment.

This second edition cancels and replaces the first edition (ISO 10327:1995), which has been technically

revised.

iv © ISO 2014 – All rights reserved

Introduction

The basic functions of main deck air cargo containers are

a) the unitization of cargo during ground handling and transportation, and

b) the restraint of their contents against accelerations encountered in flight.

Throughout this International Standard, the minimum essential criteria are identified by use of the

key word “shall”. Recommended criteria are identified by use of the key word “should” and, while not

mandatory, are considered to be of primary importance in providing safe, economical, and usable air

transport containers. Deviation from recommended criteria should only occur after careful consideration

and thorough service evaluation have shown alternate methods to provide an equivalent level of safety.

The requirements of this International Standard are expressed in the applicable SI units, with

approximate inch-pound units conversion between brackets for convenience in those countries using

that system. Where it is deemed necessary to use exact values, the SI unit ones are to be used. Per

exception, the exact figures are those in inches for container base overall outside dimensions.

INTERNATIONAL STANDARD ISO 10327:2014(E)

Air cargo — Main deck containers — Design and testing

1 Scope

1.1 This International Standard covers the minimum design and operational testing requirements

for general purpose, base-restrained containers exclusively intended for the main or upper deck cargo

compartments of main line civil transport aircraft, capable of being used by either airlines or shippers

and requiring an airworthiness authority approval (certification).

NOTE 1 The metric equivalents for dimensions have been rounded up or down to the nearest millimetre, except

in critical dimensions. Masses have been rounded up to the nearest kilogram and forces have been rounded up to

the nearest 10 N.

NOTE 2 Though nothing technically prevents their being used for baggage, main deck containers are generally

used only for carriage of freight.

1.2 This International Standard does not cover the performance requirements and ultimate load testing

parameters for airworthiness authorities approval (certification), which are covered in ISO 21100 or, for

units approved prior to 2012, ISO 8097:2001. The design and operational testing requirements of this

International Standard are additional to the performance and certification testing requirements of these

International Standards.

1.3 This International Standard does not cover containers with an overall height of 1 625 mm (64 in)

or less, that can be loaded on the lower deck compartments of main line civil transport aircraft, which

are specified in ISO 6517, nor air-surface main deck containers, which are specified in ISO 4128 and

ISO 8323.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 4116:1986, Air cargo equipment — Ground equipment requirements for compatibility with aircraft unit

load devices

ISO 4128:1985, Aircraft — Air mode modular containers

ISO 4171:1993, Air cargo equipment — Interline pallets

ISO 6517:1992, Air cargo equipment — Base-restrained certified containers exclusively for the lower deck

of high-capacity aircraft

ISO 7137:1995, Aircraft — Environmental conditions and test procedures for airborne equipment

ISO 7166:1985, Aircraft — Rail and stud configuration for passenger equipment and cargo restraint

ISO 8097:2001, Aircraft — Minimum airworthiness requirements and test conditions for certified air cargo

unit load devices

ISO 8323:1985, Freight containers — Air/surface (intermodal) general purpose containers — Specification

and tests

ISO/TR 8647:1990, Environmental degradation of textiles used in air cargo restraint equipment

ISO 10046:1996, Aircraft — Methodology of calculating cargo compartment volumes

ISO 11242:1996, Aircraft — Pressure equalization requirements for cargo containers

ISO/PAS 21100:2011, Air cargo unit load devices — Performance requirements and test parameters

1)

CAAC CCAR-21, Certification Procedures for Products and Parts

1)

CAAC CCAR-25, Airworthiness Standards —Transport Category Airplanes

1)

CAAC CCAR-121, Air Carriers Certification and Operations system

1)

CAAC Chinese Technical Standard Order CTSO C90d — Cargo pallets, nets and containers

EASA Part 21, Certification of aircraft and related products, parts and appliances, and of design and

2)

production organisations (Commission Regulation (EU) No. 748/2012)

2)

EASA CS-25, Certification Specifications for Large Aeroplanes

2)

EASA, (European Aviation Safety Agency) EU-OPS 1035 — Quality system

EASA, European Technical Standard Order ETSO C90d — Cargo pallets, nets and containers (Unit Load

2)

Devices)

3)

Japanese Airworthiness Standard Part 3 (Civil Aeronautics Law Article 10 § 4)

4)

U.S. Code of Federal Regulations Title 14 CFR Part 21, Certification Procedures for Products and Parts

4)

U.S. Code of Federal Regulations Title 14 Part 25, Airworthiness Standards: Transport Category Airplanes

4)

U.S. Code of Federal Regulations Title 14 CFR Part 121, Air carriers certification and operation

U.S. Federal Aviation Administration Advisory Circular AC 120-59, Air carriers internal evaluation

4)

programs

4)

U.S. FAA Technical Standard Order TSO C90d, Cargo Pallets, Nets and Containers

5)

EUROCAE ED-14G, Environmental conditions and test procedures for airborne equipment

1) Civil Aviation Administration of China (CAAC) listed documents constitute the Chinese government transport

aircraft airworthiness approval

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.