ISO 2177:1972

(Main)Metallic coatings — Measurement of coating thickness — Coulometric method by anodic dissolution

Metallic coatings — Measurement of coating thickness — Coulometric method by anodic dissolution

Revêtements métalliques — Mesurage de l'épaisseur — Méthode coulométrique par dissolution anodique

General Information

Relations

Buy Standard

Standards Content (Sample)

INTERNATIONAL STANDARD @ 2177

~

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION *MFXLlYHAI’OLIHAII 01’1 AHM3ALIMII no CTAHilAPl M3AUMM .ORGANISATION INTERNATIONALE DE NORMALISATION

I

Metallic coatings - Measurement of coating thickness -

Coulometric method by anodic dissolution

First edition - 1972-06-15

~ ~~

Ly

-

Ref. No. IS0 2177-1972 (E)

UDC 669.058 : 531.717 : 621.317.39

(v F.

z

F.

F.

Descriptors : metal coatings, thickness, dimensional measurement, anodic dissolution.

c

N

s

Price based on 4 pages

---------------------- Page: 1 ----------------------

FOREWORD

IS0 (the International Organization for Standardization) is a worldwide federation

of national standards institutes (IS0 Member Bodies). The work of developing

International Standards is carried out through IS0 Technical Committees. Every

Member Body interested in a subject for which a Technical Committee has been set

up has the right to be represented on that Committee. International organizations,

governmental and non-governmental, in liaison with ISO, also take part in the work.

Draft International Standards adopted by the Technical Committees are circulated

to the Member Bodies for approval before their acceptance as International

Standards by the IS0 Council.

International Standard IS0 2177 was drawn up by Technical Committee

ISOKC 107, Metallic and other non-organic coatings.

It was approved in July 1971 by the Member Bodies of the following countries :

Australia Israel Switzerland

Czechoslovakia Italy Thailand

Egypt, Arab Rep. of New Zealand Turkey

Portugal United Kingdom

France

Romania U.S.A.

Germany

South Africa, Rep. of U.S.S.R.

Hungary

India Spain

Ireland Sweden

No Member Body expressed disapproval of the document.

0 International Organization for Standardization. 1972

Printed in Switzerland

---------------------- Page: 2 ----------------------

INTERNATIONAL STANDARD IS0 2177-1972 (E)

Metallic coatings - Measurement of coating thickness -

Coulometric method by anodic dissolution

- the coating dissolves anodically at 100 % efficiency

1 SCOPE AND FIELD OF APPLICATION

(or at a nearly constant value close to this);

This International Standard specifies a procedure for

- a marked change in electrode potential occurs as the

measuring the thickness of metallic coatings by the anodic

coating is penetrated and an increasing area of substrate

dissolution method. The electrodeposited coatings and

is exposed.

substrates to which it applies are given in Table 1. It may

also be used to measure the thickness of coatings applied by

The electrolyte must be chosen in relation to the coating

L

other means, if due account is taken of special features such

and substrate metals, the current density and electrolyte

as the presence of an alloy layer.

circulation within the test cell. Typical electrolytes, which

have been found satisfactory for use with two types of test

apparatus for testing various electrodeposited coatings on

2 PRINCIPLE

specific substrates, are given in Table 2, their applications

being listed in Table 1. The electrolytes satisfactory with

Anodic dissolution of the coating from a well-defined area

one type of apparatus are indicated by symbols Al, A2,

of the coated surface using a suitable electrolyte.

etc., and those satisfactory with a second type of apparatus

by symbols B 1, 62, etc.

Indication of the end point of the test by the change in

electrode potential (and hence cell voltage) occurring when

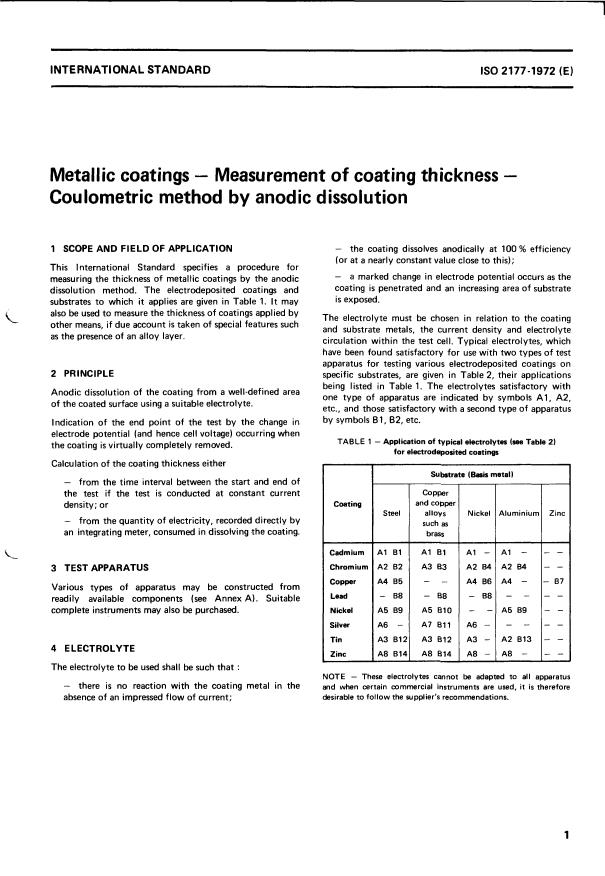

TABLE 1 - Application of typical electrolytes (see Table 2)

the coating is virtually completely removed.

for electrodeposited coatings

Calculation of the coating thickness either

Substrate (Basis metali

- from the time interval between the start and end of

the test if the test is conducted at constant current Copper

and copper

Coating

density; or

alloys Plluminium

Steel Nickel

- from the quantity of electricity, recorded directly by

such as

an integrating meter, consumed in dissolving the coating.

brass

Cadmium Al 81 Al 81 Al - Al -

Chromium A2 82 A3 83 A2 B4 A2 84

3 TEST APPARATUS

--

A4 85 A4 86 A4 -

Coppar

Various types of apparatus may be constructed from

--

Lead - 88 - 88 - 88

readily available components (see Annex A). Suitable

--

complete instruments may also be purchased. Nickel A5 89 A5 810 A5 89

--

Silver A6 - A7 Ell A6 -

Tin A3 812 A3 812 A3 - A2 813

4 ELECTROLYTE

Zinc A8 814 A8 814 A8 - A8 -

The electrolyte to be used shall be such that :

NOTE - These electrolytes cannot te adapted to all apparatus

- there is no reaction with the coating metal in the

and when certain commercial instruments are used, it is therefore

desirable to follow the supplier's recommendations.

absence of an impressed flow of current;

1

---------------------- Page: 3 ----------------------

IS0 2177-1972 (E)

TABLE 2 - Typical electrolytes

Electrolyte

Notes

Potassium iodide (Ki) : 100 gli, with traces of iodine

Sodium sulphate (Na, SO, : 1 O0 911

Hydrochloric acid (HCI) : 73 g/I

Dilute 175 ml of hydrochloric acid

(d = 1.18) to 1 litre

or

Sodium hydroxide (NaOH) : 150 g/I

Sodium potassium tartrate (NaKC, H, O, 1 : 80 g

i in 1 iitrp

J . .

Ammonium nitrate (NH, NO, ) : 100 g

Ammonium nitrate (NH, NO, ) : 30 g

.. 1

i in litre

Sodium thiocyanate (NaCNS) : 30 g

Sodium nitrate (NaNO, ) : 1 O0 g

1 in 1 litre

Nitric acid ("0,) : 5 g

J

Potassium thiocyanate (KCNS) : 180 g/i

-

Sodium chloride (NaCl) : 100 g/l

Potassium chloride (KCI) : 30 g

in 1 litre

Ammonium chloride (NH, Ci) : 30 g

Orthophosphoric acid (H, PO, ) : 186 g

Dilute 118 ml of orthophosphoric acid

in 1 litre

(d = 1.751 and 10 g of chromic oxide

Chromic oxide (CrO, ) : 10 g

i

to 1 litre

Sodium carbonate (Na, CO, I : 100 g/1

For coatings up to 5 pm

~~

Orthophosphoric acid (H, PO, : 98 g/i

Dilute 64 ml of orthophosphoric acid

(d = 1.751 to 1 litre

A

...

E

/--y

,e!**

NORME INTERNATIONALE 2177

‘*!e 4

Revêtements métalliques - Mesurage de l’épaisseur -

Méthode coulométrique par dissolution anodique

Première édition - 1972-06 15

:I

CDU 669.058 : 531.717 : 621.317.39 Réf. NO IS0 2177-1972 (F)

?J

P-

m

c

r- Descripteurs . ievetement rnelaliiqiie, epdisseur, mesure de diriieiisiori, disçolutioil anodique

r-

c

N

Prix base sur 4 pages

---------------------- Page: 1 ----------------------

E

AVANT-PROPOS

IS0 (Organisation Internationale de Normalisation) est une fédération mondiale

de normalisation (Comités Membres ISO). L’élaboration de

d‘organismes nationaux

Normes Internationales est confiée aux Comités Techniques ISO. Chaque Comité

Membre intéressé par une étude a le droit de faire partie du Comité Technique

correspondant. Les organisations internationales, gouvernementales et non

gouvernementales, en liaison avec I’ISO, participent égaiement aux travaux.

Les Prolets de Normes Internationales adoptés par les Comités Techniques sont

soumis aux Comites Membres pour approbation, avant leur acceptation comme

Normes Internationales par le Conseil de I‘ISO.

La Norme internationale IS0 2177 a été établie par le Comité Technique

ISOiTC 1 07, Revêtements métalliques er autres revêtements non organiques.

Elle fut approuvée en juillet 1971 par les Comités Membres des pays suivants ;

Afrique du Sud, Rép. d‘ Irlande Suisse

Allemagne Israel Tchécoslovaquie

Australie Italie Thaïlande

Egypte, Rép. arabe d‘ Nouvelle-Zélande Turquie

Espagne Portugal U.R.S.S.

France Roumanie U.S.A.

Hongrie Royaume-Uni

Suède

I nde

Aücüiï Comité Membre n’a désapprouvé le document.

O Organisation internationale de Normalisation, 1972

imprimé en Suisse

---------------------- Page: 2 ----------------------

NORME INTERNATIONALE IS0 2177-1972 (F)

Revêtements métalliques - Mesurage de l'épaisseur -

Méthode coulométrique par dissolution anodique

i OBJET ET DOMAINE D'APPLICATION

dissolution anodique du revêtement avec un

reridement de 100 "% (ou Urie valeur constante voisine).

1'3 prewite Norrrir Inter ridtiundlt! specitie Uri procede pour

niewret 1 epdi'seur de5 revetempnts métdlliques Felon une appal iiioil d'une variation sensible du potentiel

rriethodr de dissoluriori dnodique Lrs depots d'electrode lorsque le revêtement eTt perfore et qu'une

rlr<'trol\ tii(ciei rl ItJ\ inetdux de bdw duxquels elle dirt? croissante de métal de base est exposée

Cettr methodr

i d[>pIiClUt! Wtit il<)tiii6'\ Cfdils it! TdbledU 1

1 'electrolytr doit etre choisi tiit torictiori du metai dr

prir* L+.~s\ etir iiti\tsee pour mesurer I'epdisseui de

reveternecit et cici rriétai de bdse, de ici densiié de cour-ail7 et

rrvPternents dippiic~iie\ par d'dcitres moyens \'il Pst teriii

(le Id rticddtik)ii de l'électrolyte a l'~i~terteur de Ili cellule

I ofiii>Ic ilrs ;iri'ti[ tildr tes trllrs que Ir prrsrrict! de CuuCht.s

(j ?\>',di Le=, eiectioiviw !ypt!i, qui orir &te trrjuvc\

1 iiildyt.

(,(JilVt!lidt~~~5 Ne[' diillx IviptiS d'appateiiidyt!. POUI COiltrOlei

(les tlepn!\ el~ttc~lyt~c;iir~ dit sur cies rnrirliix (11: t)dw

2 t>fiiNCIPt dpoi o1)r iph, ni dotiim ciai\ it, ?,ihleaii i' !wrs

qpiicdtiorii etdrit eriiirneree5 dari:, io T hltidci 1 Les

LJI\XJII !toil diiotliqiir LI ,c'vrterrieiil 5111 iiiie diie ttit,ri

élec t I < 1 I v tes dot i rid r i t sat I sf act i or I ~ec LI I i type

tititilir dt! id 2LiitdLt' It'VetLit: ell iitiliSdilt 1Jf1 t it?C.tfi)lkI?

{i'

dp(JriJpl I?

( ?OX i~Olltldlll SdtlStdCtlOrl dVfX It! 5tX;OlId IVlX. d dppimillage

si)ii! icrmes 11~ir les svmt)oles B? B2 etc

~l~f~inliild~i(,i (Ji, p"!Ill illld/ 1 esSdl pdl Id VdlIdtlUII dU

~X)1C!litl~l 1) ?i?Lrl~JtfP (?I [Jdl ~(xi\eqUelit du VUltdy? de Id

crilule d'electt !il\/x) qiii be produit l~iisqiie IP reveterrwit d

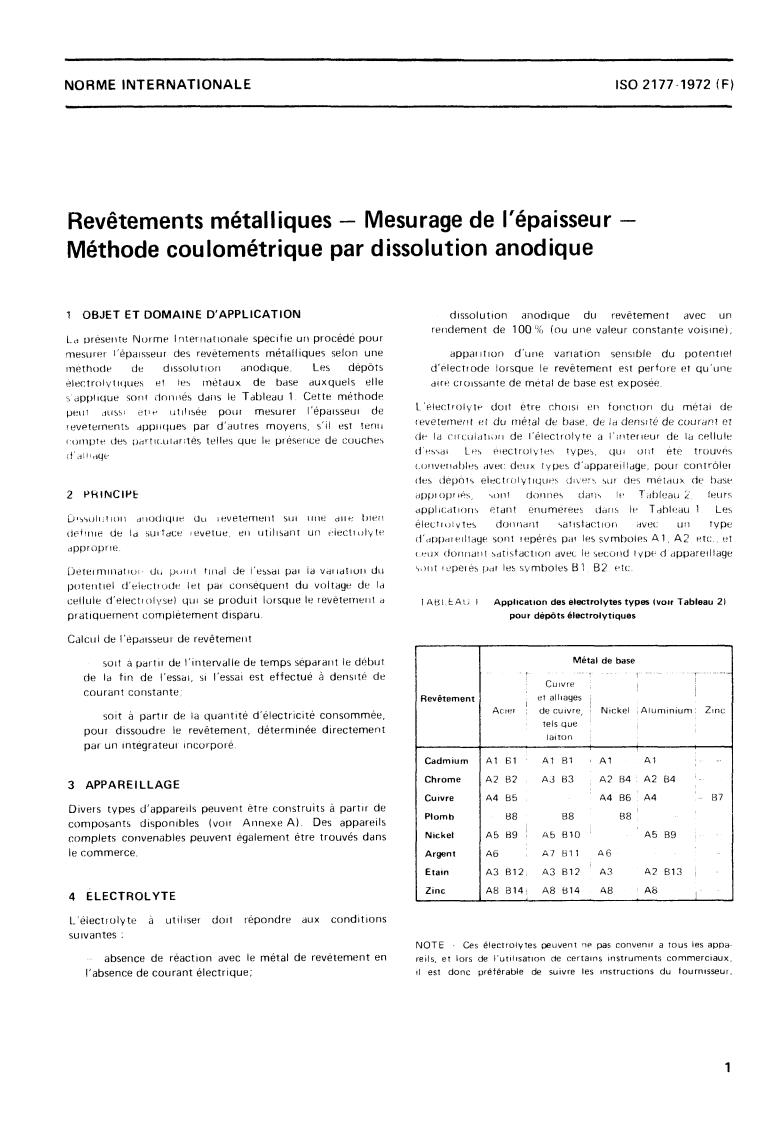

I AH1 t A!) I Application des electrolytes types (voir Tableau 2)

prdtiqiirrnrnt çompletement disparu pour dépôts électrolytiques

Cdlciil de l'epaisseui de revêtemeiit

Metal de base

wit a F)dl tii de i'iiitervdlle de temps sepdrdiit le debiii

r

de Id tin de I'essdi, 51 l'essai est effectue a derisite de

I

Ciiivre I

I

courdnt constante

et alliages

3evêtement

ACWI de cuivre Nlckei Aiuminium Zinc

wit a partir dr là qudritite d'electricite consommee,

tels que

pour dissoudre le revetement, determinée directement

iditon

pat un inteyrateui incuipore

Cadm I u m Al 61 Al B1 Al Al

Chrome A2 82 A3 83 A2 84 A2 84

3 APPAREILLAGE

Cuivre A4 85 A4 B6 A4 B7

Divers types d'dppdreils peuverit etre construits a partir de

Plomb 88 BU 08

composdnts disponibles (voir Anriexr A) Des appareils

Nickel A5 B9 AS E10 A5 B9

complets convenables peuvent egalement etre trouvés ddns

le commerce

Argent Ab A7 H11 A6

Etain A3 812 43 812 A3 A7 613

Zinc A8 814 A8 I314 48 A8

4 ELECTROLYTE

1- eiectiolyte a utili',er doit repondre dux conditions

suivantes .

NOTE 0s électrolytes peuvent tic pas convenir a tous les appd

abserice de reaction dvec le metal de revetement en reils, et lors de l'utilisation de certains instrumt'nts commerciaux

il est donc préférable de suivre les instructions du fournisseur.

l'absence de courant électrique,

1

---------------------- Page: 3 ----------------------

i

i B8 ! Acetate de sodium iCH, i.OON,ir 200 y

AÇetdte d ammonium i( H ~ COONH, )

200 y

Nitrate d'ammonium INH, NO, t 800 y

iBg i

Thiouree IiNn- IL CSI

3 8 y

I 810 i Acide chlorhydrique iHC,I! 12 yil

11

j BI1 I Fluorure de potassium (YFI 100 yiI

I

t

t

' B12 1 Nitrate de potassium iKNO 1 100 y

&ria 1 litre

Chlorure de potdssiurn iKL0 100 y

4

>

1 813 Acide sulfurique (H,S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.