ISO 15389:2023

(Main)Space systems — Flight-to-ground umbilicals

Space systems — Flight-to-ground umbilicals

This document defines the general criteria for the development of flight-to-ground umbilical systems used by a space system. These criteria apply to the service arms or equivalent mechanisms, umbilical carriers and plates, couplings, connectors, withdrawal and retract devices, handling mechanisms and control systems for mechanisms, as well as the prevention of accidental cross-connection.

Systèmes spatiaux — Ombilicaux bord-sol

La présente Norme internationale définit les critères généraux concernant le développement des systèmes ombilicaux bord-sol utilisés par un système spatial. Les critères spécifiés ici se limitent aux bras ou mécanismes équivalents, aux supports et plaques ombilicaux, aux raccords, aux connecteurs, aux dispositifs de retrait et de rétraction, aux mécanismes de manutention et aux systèmes de contrôle des mécanismes.

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 15389

Second edition

2023-09

Space systems — Flight-to-ground

umbilicals

Systèmes spatiaux — Ombilicaux bord-sol

Reference number

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

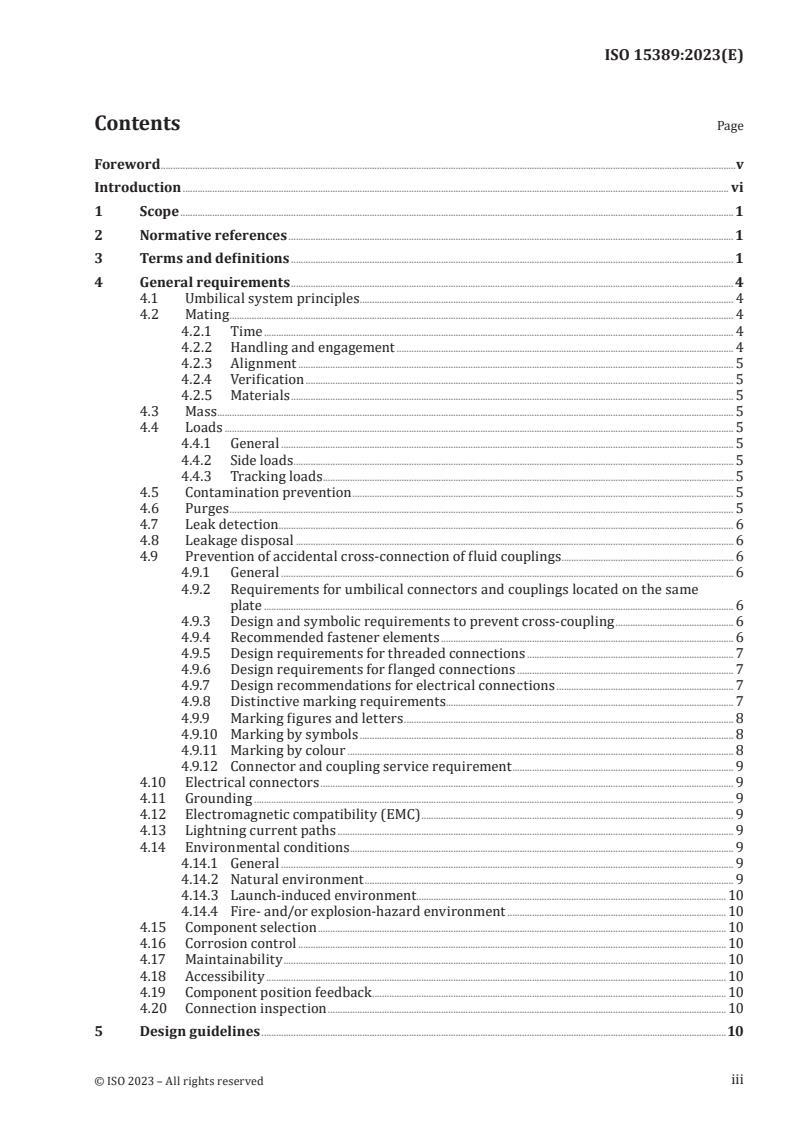

Contents Page

Foreword .v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 General requirements . 4

4.1 Umbilical system principles . 4

4.2 Mating . 4

4.2.1 Time . 4

4.2.2 Handling and engagement . 4

4.2.3 Alignment . 5

4.2.4 Verification . 5

4.2.5 Materials . 5

4.3 Mass . 5

4.4 Loads . 5

4.4.1 General . 5

4.4.2 Side loads . 5

4.4.3 Tracking loads . 5

4.5 Contamination prevention . 5

4.6 Purges . 5

4.7 Leak detection . . 6

4.8 Leakage disposal . 6

4.9 Prevention of accidental cross-connection of fluid couplings. 6

4.9.1 General . 6

4.9.2 Requirements for umbilical connectors and couplings located on the same

plate . 6

4.9.3 Design and symbolic requirements to prevent cross-coupling . 6

4.9.4 Recommended fastener elements . 6

4.9.5 Design requirements for threaded connections . 7

4.9.6 Design requirements for flanged connections . 7

4.9.7 Design recommendations for electrical connections . 7

4.9.8 Distinctive marking requirements. 7

4.9.9 Marking figures and letters . 8

4.9.10 Marking by symbols . 8

4.9.11 Marking by colour . 8

4.9.12 Connector and coupling service requirement . 9

4.10 Electrical connectors . 9

4.11 Grounding . 9

4.12 Electromagnetic compatibility (EMC) . 9

4.13 Lightning current paths . 9

4.14 Environmental conditions . . 9

4.14.1 General . 9

4.14.2 Natural environment . 9

4.14.3 Launch-induced environment . 10

4.14.4 Fire- and/or explosion-hazard environment . 10

4.15 Component selection . 10

4.16 Corrosion control . 10

4.17 Maintainability . 10

4.18 Accessibility . 10

4.19 Component position feedback . 10

4.20 Connection inspection . 10

5 Design guidelines .10

iii

5.1 Pre-flight disconnect . 10

5.2 Inflight umbilical assembly . 11

5.2.1 Inflight preferences . 11

5.2.2 Rise-off umbilical assembly . . 11

5.2.3 Tail service mast .12

5.3 Pre-flight umbilical assembly . 13

5.3.1 General .13

5.3.2 Umbilical couplings . 13

5.3.3 Electrical connectors . .13

5.3.4 Locking devices . 13

5.3.5 Handling system .13

5.3.6 Control system . 14

6 Test and evaluation .14

6.1 Umbilical test types. 14

6.1.1 General . 14

6.1.2 Static test . 14

6.1.3 Dynamic test . 14

6.1.4 Cryogenic test . 14

6.2 Verification test phases for umbilical connectors and couplings .15

6.2.1 General .15

6.2.2 Electrical connectors . .15

6.2.3 Fluid coupling . 15

6.2.4 Umbilical . 15

6.2.5 Unsatisfactory results .15

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 20, Aircraft and space vehicles,

Subcommittee SC 14, Space systems and operations.

This second edition cancels and replaces the first edition (ISO 15389:2001), which has been technically

revised. It also incorporates the Amendment ISO 15389:2001/Amd 1:2005 and the Technical

Corrigendum ISO 15389:2001/Cor 1:2006.

The main changes are as follows:

— addition of 4.9 on the prevention of accidental cross-connection.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

Introduction

This document establishes the general requirements and criteria for flight-to-ground umbilical systems

used by space systems. The purpose of this document is to establish uniform engineering practices

and methods and to ensure the inclusion of essential requirements in the design of reusable flight-to-

ground umbilical systems that support the launch of space systems. This document is not intended to

define how to design umbilicals but to define the minimum requirements for umbilicals.

Prevention of accidental cross-connection of umbilical system connectors and couplings is extremely

important. Launch vehicle and spacecraft assemblies and features are often unique, requiring many

connectors and couplings to be in close proximity to each other. The accidental cross-connection of

service lines can result in very serious and even tragic consequences. For example:

— supplying other gas or fluids;

— supplying gas or fluid under other pressure;

— supplying the electric power with other parameters;

— supplying an error signal (command).

Therefore, differences in design of connectors and couplings that are located close to each other should

be significant. Such differences can be both in design and in marking for identification.

International cooperation in space engineering assumes international cooperation in design,

manufacture, and operation. The application of uniform methods increases the reliability of space

systems by minimizing the accidental cross-connection of connectors and couplings. The application of

unified symbols promotes mutual understanding and personnel training.

vi

INTERNATIONAL STANDARD ISO 15389:2023(E)

Space systems — Flight-to-ground umbilicals

1 Scope

This document defines the general criteria for the development of flight-to-ground umbilical systems

used by a space system. These criteria apply to the service arms or equivalent mechanisms, umbilical

carriers and plates, couplings, connectors, withdrawal and retract devices, handling mechanisms and

control systems for mechanisms, as well as the prevention of accidental cross-connection.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 14625, Space systems — Ground support equipment for use at launch, landing or retrieval sites —

General requirements

IEC 60364-5-54, Electrical installations of buildings — Part 5: Selection and erection of electrical

equipment — Chapter 54: Earthing arrangements and protective conductors

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

carrier

device that groups coupling (3.3) and connector (3.2) halves together to provide a common means for

their positioning, retention, unlocking, and separation

Note 1 to entry: The term is commonly used in relation to the facility ground-side of umbilical interfaces (3.8).

3.2

connector

device, consisting of two halves, that permits engagement and disengagement of electrical circuits at an

interface (3.8)

3.3

coupling

device, consisting of two halves, that permits transfer of fluid across and disconnection at an interface

(3.8)

3.4

flanged connection

connection at which halves of connectors (3.2) or couplings (3.3) are mated by means of flanges

3.5

ground control

equipment, fluids, or signals, provided for command or control purposes, which are neither on board

nor originate on board the launch vehicle

3.6

handling mechanism

device used to provide positioning, manipulation, and physical dead-weight support of an object

3.7

inflight

term that denotes an occurrence or function after vehicle lift-off (3.10)

3.8

interface

mechanical, thermal, electrical, or operational common boundary between two elements of a system

EXAMPLE Ground-to-vehicle interface, physical interface, or responsibility interface.

3.9

launch processing system

operating consoles, data handling and display equipment, and the associated transmission system

configured to issue commands and analyse and display response data required in checkout and

operation of ground support equipment (GSE) and flight hardware

3.10

lift-off

instant of flight at which the vehicle's contact is terminated with all areas of hold-down and/or support

devices

Note 1 to entry: Lift-off is commonly called "first motion" of the vehicle.

3.11

nipple

half of a hydraulic or gas coupling (3.3) with an external sealing surface

3.12

plate

device that groups coupling and connector (3.2) halves together to provide a common means for

retention

Note 1 to entry: The plate is a passive device, containing cooperating but usually immobile portions of positioning,

locking, and separation machinery.

Note 2 to entry: The term is commonly used in relation to the vehicle side of umbilical interfaces (3.8) or with the

carrier (3.1).

EXAMPLE Carrier plate.

3.13

pre-flight

occurring before vehicle lift-off (3.10)

3.14

rise-off

actuated solely by a vehicle's vertical motion

3.15

service arm

retractable structure, usually attached to a tower used to provide either umbilical requirements,

personnel access, or both to the flight vehicle

Note 1 to entry: A service arm is commonly called access arm, umbilical arm, or swing arm, depending upon

whether it provides services for access only, umbilicals (3.19) only, or both, respectively.

Note 2 to entry: The service-arm retracting motion may be along an arc or in a vertical or horizontal plane.

3.16

T−0

time minus zero

last moment in the launch countdown, measured in seconds, at which time the launch vehicle lifts off

the ground

3.17

tail service mast

retractable structure used to provide umbilical requirements to the aft portion (tail) of a space vehicle

Note 1 to entry: Movement is usually a rotation about a pivot point away from the vehicle.

3.18

threaded connection

connection at which halves of connectors (3.2) or couplings (3.3) are mated by means of a thread on each

of the halves

3.19

umbilical

device that provides fluid (supply/return and purge) and electrical requirements at physical interfaces

(3.8) between ground facilities and various areas of a space vehicle

3.20

umbilical assembly

mated carrier (3.1) and plate (3.12) containing all couplings (3.3) and connectors (3.2) for a specified

umbilical region of the vehicle

3.21

umbilical service line

fluid line or electrical cable routed through an umbilical (3.19) such as a service arm (3.15) or equivalent

mechanism that is to be disconnected prior to engine ignition or at T−0 (3.16) or in flight

3.22

umbilical supply device

movable structure used to connect and/or disconnect the umbilical plates (3.12) at various locations on

a space vehicle

3.23

umbilical system

functional assembly of all items required for providing fluid and electrical servicing to a launch vehicle

and/or a payload

Note 1 to entry: This system usually includes the following:

— service arms (3.15) or equivalent umbilical supply device (3.22) mechanisms;

— umbilical carriers (3.1) and plates (3.12);

— couplings (3.3) and connectors (3.2), all separation, withdrawal, and retraction devices;

— control equipment;

— control fluids and electrical signals;

— all interconnecting lines across the service arms or the equivalent mechanism on the ground side.

Note 2 to entry: The mating-half interface (3.8) for the couplings/connectors and umbilical carrier should be

located on the exterior surface of the launch vehicle at an orientation compatible with the launch structure.

3.24

union

half of a hydraulic or gas coupling (3.3) with an internal sealing surface

4 General requirements

4.1 Umbilical system principles

The umbilical design shall not require reconnection of disconnected umbilical service lines to abort

safely on the launch pad. Passive umbilical systems disconnected at lift-off by gravity is the preferred

system as opposed to active systems to minimize failure modes and potential damage to the flight

hardware. Adequate safety margins and/or system redundancy shall be included in the design to

preclude premature umbilical disconnect that can jeopardize the flight hardware environment or

vehicle and/or personnel safety. System design shall be a balance between ensuring umbilicals remain

engaged and sealed under all static and dynamic pre-launch environments and safely disconnecting at

lift-off.

Disconnect after lift-off should have at least secondary and, if possible, tertiary modes to ensure vehicle

safety as the primary feature and protection of the ground systems under the launch environment as

a secondary feature. Umbilical failures shall not propagate into the flight vehicle system. Flight-to-

ground umbilical systems shall conform to the general requirements specified in ISO 14625.

4.2 Mating

4.2.1 Time

The time required to connect and verify an umbilical assembly shall be minimized. Factors that should

be considered include:

a) the number of steps required;

b) the number of component parts to be installed or manipulated in the connection process;

c) availability of, and accessibility with, mechanical handling aids;

d) available working space;

e) requirements for operating personnel;

f) safety requirements;

g) alignment requirements;

h) the adaptability to automated verification.

The goal for the time required to perform the mating operation is one work shift or less.

4.2.2 Handling and engagement

Rapid handling and engagement are necessary in order to minimize impact on the ground turnaround

and crew size for launch support. To provide ease with which an umbilical assembly is mated and

connected to a vehicle, consideration shall be given to mass, torque requirements, manual force required

for connection, and rigidity of electrical cables, flex lines, propellant flex lines, ducts for environmental

control systems, etc.

4.2.3 Alignment

The umbilical assembly shall be self-aligning. The design shall not require critical manual horizontal,

vertical, or parallel alignment for mating.

4.2.4 Verification

Mated umbilical assemblies shall allow quick and reliable verification of integrity.

4.2.5 Materials

Umbilical materials shall be compatible with service line media, shall be corrosion-resistant, and shall

meet flammability, odour, and off-gassing, or vacuum-stability requirements that may be required by

the flight hardware system.

4.3 Mass

Umbilical parts shall be as lightweight as feasible to minimize launch-induced loads and ground-

handling requirements.

4.4 Loads

4.4.1 General

Umbilical design shall accommodate all static and dynamic pre-launch loads, such as dead loads, fluid

pressure loads, and catenary loads imposed on all lines running from the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...