ISO 6626-2:2003

(Main)Internal combustion engines — Piston rings — Part 2: Coil-spring-loaded oil control rings of narrow width made of cast iron

Internal combustion engines — Piston rings — Part 2: Coil-spring-loaded oil control rings of narrow width made of cast iron

ISO 6626-2:2003 specifies the essential dimensional features of coil-spring-loaded oil control rings made of cast iron, types DSF-C, SSF, GSF, DSF and SSF-L. It is applicable to those piston rings in sizes 60 mm to 110 mm, inclusive, for reciprocating internal combustion engines, as well as to those for compressors working under analogous conditions.

Moteurs à combustion interne — Segments de piston — Partie 2: Segments racleurs régulateurs d'huile étroits, en fonte, mis en charge par ressort hélicoïdal

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 6626-2

First edition

2003-03-15

Corrected version

2004-10-15

Internal combustion engines — Piston

rings —

Part 2:

Coil-spring-loaded oil control rings of

narrow width made of cast iron

Moteurs à combustion interne — Segments de piston —

Partie 2: Segments racleurs régulateurs d'huile étroits, en fonte, mis en

charge par ressort hélicoïdal

Reference number

ISO 6626-2:2003(E)

©

ISO 2003

---------------------- Page: 1 ----------------------

ISO 6626-2:2003(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2003

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2003 — All rights reserved

---------------------- Page: 2 ----------------------

ISO 6626-2:2003(E)

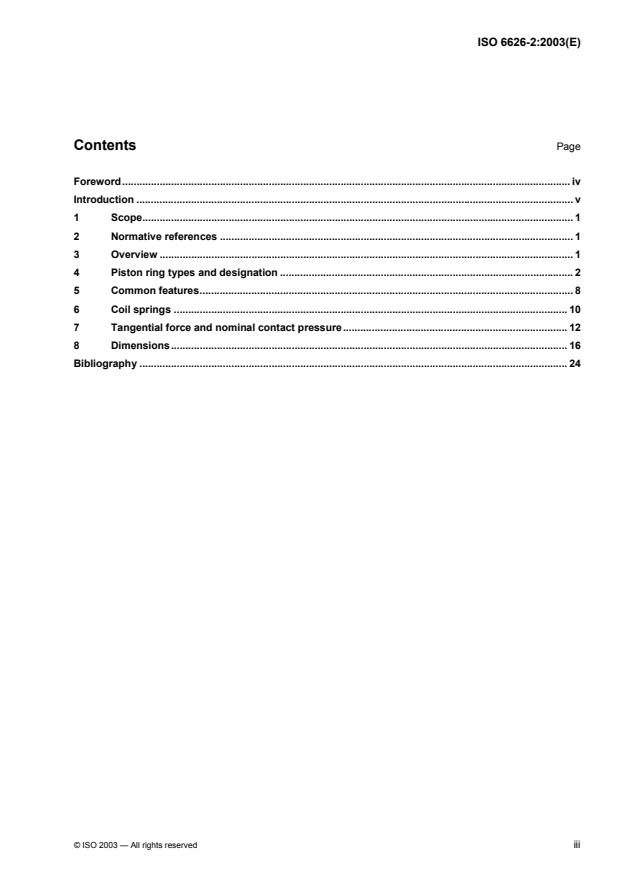

Contents Page

Foreword. iv

Introduction . v

1 Scope. 1

2 Normative references . 1

3 Overview . 1

4 Piston ring types and designation . 2

5 Common features. 8

6 Coil springs . 10

7 Tangential force and nominal contact pressure. 12

8 Dimensions. 16

Bibliography . 24

© ISO 2003 — All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 6626-2:2003(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 6626-2 was prepared by Technical Committee ISO/TC 22, Road vehicles.

ISO 6626 consists of the following parts, under the general title Internal combustion engines — Piston rings:

Part 2: Coil-spring-loaded oil control rings of narrow width made of cast iron

Coil-spring-loaded oil control rings is to form the subject of a future part 1, revising and replacing

ISO 6626:1989.

This corrected version of ISO 6626-2:2003 incorporates the following corrections:

bibliographical information has been added;

in Figures 10 and 11, item 2 of the legend to each figure has been corrected from “8 times” to “0,8 times”

the diameter of the wire;

Tables 5 to 8 have been corrected and clarified.

iv © ISO 2003 — All rights reserved

---------------------- Page: 4 ----------------------

ISO 6626-2:2003(E)

Introduction

ISO 6626 is one of a series of International Standards dealing with piston rings for reciprocating internal

[1], [2] [3] [4] [5] [6]

combustion engines. Others are ISO 6621 , ISO 6622 , ISO 6623 , ISO 6624 , ISO 6625 and

[8]

ISO 6627 .

The common features and dimensional tables presented in this part of ISO 6626 constitute a broad range of

variables and, in selecting a particular ring type, the designer must bear in mind the conditions under which it

will be required to operate.

It is also essential that the designer refer to the specifications and requirements of ISO 6621-3 and

ISO 6621-4 before completing a selection.

© ISO 2003 — All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 6626-2:2003(E)

Internal combustion engines — Piston rings —

Part 2:

Coil-spring-loaded oil control rings of narrow width made of

cast iron

1 Scope

This part of ISO 6626 specifies the essential dimensional features of coil-spring-loaded oil control rings made

of cast iron, types DSF-C, SSF, GSF, DSF and SSF-L. It is applicable to those piston rings in sizes 60 mm to

110 mm, inclusive, for reciprocating internal combustion engines, as well as to those for compressors working

under analogous conditions.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 6621-3, Internal combustion engines — Piston rings — Part 3: Material specifications

ISO 6621-4, Internal combustion engines — Piston rings — Part 4: General specifications

ISO 6621-5, Internal combustion engines — Piston rings — Part 5: Quality requirements

3 Overview

The coil-spring-loaded oil control ring types are specified in Figures 1 to 6. Their common features and the

features' dimensions are specified in Tables 1 and 2 and shown in Figures 7 and 8. Essential features of coil-

springs are shown in Figures 9 to 13. Tables 3 and 4 specify different classes of contact pressure, while

Tables 5 to 8 give the dimensions and forces of coil-spring-loaded oil control rings.

For the cast iron part the recommended material is Class 10 in accordance with ISO 6621-3. For special

applications, material Classes 20 to 50 may be used.

Variation from these in face design and spring groove may be used, as recommended by individual

manufacturers, in plain or chromed versions.

The tangential forces of coil-spring-loaded control rings can be varied over a wide range. For explanations and

recommendations, see Clause 7.

© ISO 2003 — All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 6626-2:2003(E)

4 Piston ring types and designation

4.1 Types DSF-C, SSF, GSF, DSF and SSF-L

4.1.1 General features and dimensions

See Figure 1 and Tables 5, 6, 7 and 8.

Figure 1 — Types DSF-C, SSF, GSF, DSF and SSF-L

2 © ISO 2003 — All rights reserved

---------------------- Page: 7 ----------------------

ISO 6626-2:2003(E)

4.2 Type DSF-C, coil-spring-loaded bevelled edge oil control ring, chromium plated and

profile ground

4.2.1 General features and dimensions

See Figure 2 and Table 5.

4.2.1 Designation of a Type DSF-C piston ring in accordance with ISO 6626-2

EXAMPLE Coil-spring-loaded bevelled edge oil control ring, chromium plated and profile ground (DSF-C), of nominal

diameter d = 80 mm (80), nominal ring width h = 2,5 mm (2,5), made of grey cast iron, non-heat treated, material

1 1

subclass 11 (MC11), having a selected closed gap of 0,20 mm min. (SO2), a chromium layer thickness on the lands of

0,10 mm (CR2), reduced slot length (WK), a coil spring with reduced heat set (WF), and a variable pitch with coil diameter

d ground (CSE), with tangential force F in accordance with the medium nominal contact pressure class (PNM) and the

7 t

ring marked with the manufacturer's mark (MM):

Piston ring ISO 6626-2 DSF-C - 80 ×××× 2,5 - MC11 / S02 CR2 WK WF CSE PNM MM

Dimensions in millimetres

Key

1 reference plane

Figure 2 — Type DSF-C

© ISO 2003 — All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 6626-2:2003(E)

4.3 Type SSF, coil-spring-loaded slotted oil control ring

4.3.1 General features and dimensions

See Figure 3 and Table 6.

Dimensions in millimetres

Key

1 reference plane

Figure 3 — Type SSF

4.3.2 Designation of a Type SSF piston ring in accordance with ISO 6626-2

EXAMPLE Coil-spring-loaded slotted oil control ring (SSF) of nominal diameter d = 80 mm (80), nominal ring width

1

h = 2,5 mm (2,5), made of grey cast iron, non-heat treated, material subclass 12 (MC12), constant spring pitch (CSN) and

1

tangential force F in accordance with the low nominal contact pressure class (PNL):

t

Piston ring ISO 6626-2 SSF- 80 ×××× 2,5 - MC12 / CSN PNL

4 © ISO 2003 — All rights reserved

---------------------- Page: 9 ----------------------

ISO 6626-2:2003(E)

4.4 Type GSF coil-spring-loaded double bevelled oil control ring

4.4.1 General features and dimensions

See Figure 4 and Table 7. Top-side marking is mandatory in accordance with ISO 6621-4.

Dimensions in millimetres

Key

1 reference plane

2 mark

Figure 4 — Type GSF

4.4.2 Designation of a Type GSF piston ring in accordance with ISO 6626-2

EXAMPLE Coil-spring-loaded double bevelled oil control ring (GSF) of nominal diameter d = 75 mm (75), nominal

1

ring width h = 2,5 mm (2,5), made of grey cast iron, non-heat treated, material subclass 12 (MC12), with constant spring

1

pitch (CSN) and tangential force F in accordance with the low nominal contact pressure class (PNL):

t

Piston ring ISO 6626-2 GSF- 75 ×××× 2,5 - MC12 / CSN PNL

© ISO 2003 — All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 6626-2:2003(E)

4.5 Type DSF coil-spring-loaded bevelled edge oil control ring

4.5.1 General features and dimensions

See Figure 5 and Table 7.

Dimensions in millimetres

Key

1 reference plane

Figure 5 — Type DSF

4.5.2 Designation of a Type DSF piston ring in accordance with ISO 6626-2

EXAMPLE Coil-spring-loaded double bevelled oil control ring (DSF) of nominal diameter d = 90 mm (90), nominal

1

ring width h = 2,5 mm (2,5), made of grey cast iron, non-heat treated, material subclass 12 (MC12), with constant spring

1

pitch (CSN) and tangential force F in accordance with the reduced nominal contact pressure class (PNR):

t

Piston ring ISO 6626-2 DSF- 90 ×× 2,5 - MC12 / CSN PNR

××

6 © ISO 2003 — All rights reserved

---------------------- Page: 11 ----------------------

ISO 6626-2:2003(E)

4.6 Type SSF-L coil-spring-loaded slotted oil control ring with 0,6 mm nominal land width

4.6.1 General features and dimensions

See Figure 6 and Table 8.

Dimensions in millimetres

Key

1 reference plane

Figure 6 — Type SSF-L

4.6.2 Designation of a Type SSF-L piston ring in accordance with ISO 6626-2

EXAMPLE Coil-spring-loaded slotted oil control ring (SSF-L) of nominal diameter d = 80 m (80), nominal ring width

1

h = 2,5 mm (2,5), made of grey cast iron, non-heat treated, material subclass 12 (MC12), constant spring pitch (CSN) and

1

tangential force F in accordance with the reduced nominal contact pressure class (PNR):

t

Piston ring ISO 6626-2 SSF-L - 80 ×× 2,5 - MC12 / CSN PNR

××

© ISO 2003 — All rights reserved 7

---------------------- Page: 12 ----------------------

ISO 6626-2:2003(E)

5 Common features

5.1 Arrangement of slots

See Figure 7.

5.2 Slot length

5.2.1 Standard slot length

Slot length, w , shall be equal to bridge length, w .

1 2

The tolerance on the difference between w and w shall be 4 mm.

1 2

5.2.2 Reduced slot length (retaining same number and spacing) — Code WK

See Table 1.

Dimensions in millimetres

a) 8 slots for 60 u d < 80 b) 10 slots for 80 u d u 110

1 1

a

cutter diameter

Figure 7 — Arrangement of slots

Table 1 — Reduced slot length

Dimensions in millimetres

d w

1 1

60 u d < 80 6 . 11

1

80 u d u 110 8 . 13

1

8 © ISO 2003 — All rights reserved

---------------------- Page: 13 ----------------------

ISO 6626-2:2003(E)

5.3 Plating thickness — DSF-C (coil-spring-loaded bevelled edge oil control ring, chromium

plated and profile ground)

See Figure 8 and Table 2.

Figure 8 — Plating thickness

Table 2 — Plating thickness

a

Code

Thickness

min.

CR1 0,05

CR2 0,10

a

For plating thickness tolerances, see ISO 6621-4.

5.4 Peripheral edges at gap of chromium plated oil control rings

For features and their dimensions, see ISO 6621-4.

© ISO 2003 — All rights reserved 9

---------------------- Page: 14 ----------------------

ISO 6626-2:2003(E)

6 Coil springs

6.1 Types of coil spring

All values in the dimensional tables of Clause 8 are based on cylindrical coil springs made of round wire. The

three designs shown in Figures 9 to 11 are common. The use of different springs designs may be agreed

between manufacturer and client. Changed spring groove configurations and dimensions could then be

necessary.

Key

1 diameter of wire

Figure 9 — Type CSN coil spring with constant pitch

Key

1 diameter of wire

2 approx. 0,8 × diameter of wire

Figure 10 — Type CSG coil spring with constant pitch (coil diameter, d , ground)

7

10 © ISO 2003 — All rights reserved

---------------------- Page: 15 ----------------------

ISO 6626-2:2003(E)

Key

1 diameter of wire

2 approx. 0,8 × diameter of wire

Figure 11 — Type CSE coil spring with variable pitch (coil diameter, d , ground)

7

Dimensions in millimetres

Key

1 spring gap

2 area with small pitch

a

Latch pin free length

b

Latch pin fixed length

Figure 12 — Position of area with small pitch

© ISO 2003 — All rights reserved 11

---------------------- Page: 16 ----------------------

ISO 6626-2:2003(E)

6.2 Excursion, f

1

Coil spring excursion, f , is the distance between the gap ends of the ring in the free unstressed status,

1

measured at the centre of the coil spring groove (see Figure 13). The maximum value of f shall not exceed

1

0,13 d .

1

6.3 Position of coil spring gap and fixing

The spring gap shall be approx. 180° from the gap and the spring gap ends fixed with a connecting or latch

pin.

Figure 13 — Coil spring excursion

6.4 Material

Coil springs are made of valve spring wire, oil heat-treated. A suitable material for coil spring expanders is

Subclass 62 in accordance with ISO 6621-3.

Springs are available with two different heat set resistance levels (loss of tangential force under load and

temperature):

standard heat resistance;

reduced heat set, code WF.

For test conditions and the permissible loss of tangential forces, see ISO 6621-5.

7 Tangential force and nominal contact pressure

7.1 Tangential force

The tangential force of coil-spring-loaded oil control rings is mainly determined by the force of the spring. The

cast iron part itself has a very small tangential force due to its low radial wall thickness and the decreased

ratio “total free gap/nominal diameter”.

The tangential force measurement only can be used because of the flexible design of the cast iron part of the

coil-spring-loaded oil control rings.

12 © ISO 2003 — All rights reserved

---------------------- Page: 17 ----------------------

ISO 6626-2:2003(E)

7.2 Force factors

Because of the small contribution of the cast iron part in the tangential force, force factors are not necessary

when additional features, materials or both — other than grey cast iron with modulus of elasticity of

2

100 GN/m — are being used.

7.3 Tangential force, F

t

7.3.1 General

The tangential force, F , of a spring-loaded oil control ring is determined by

t

a) nominal diameter, d , in millimetres,

1

b) land width, h , in millimetres, and

5

c) required nominal contact pressure, p , in newtons per square millimetre, calculated from the equation:

o

F = ½ × d × 2h × p

t 1 5 o

The land width, h , depends on the ring type, nominal diameter and ring width. The nominal contact pressure,

5

p , can be selected over a wide range to suit the application and the required oil scraping effect.

o

7.3.2 Specific tangential force, F

tc

The specific tangential force, F , is that required to maintain a spring-loaded oil control ring at a unit contact

tc

2

pressure, p , of 1 N/mm :

ou

F = ½ × d × 2h × p

tc 1 5 ou

In Clause 8, F is tabulated for every ring type.

tc

7.3.3 Actual tangential force, F , and tolerance

t

The actual tangential force of a spring-loaded oil control ring can be calculated with

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.