ISO/TS 210:2014

(Main)Essential oils — General rules for packaging, conditioning and storage

Essential oils — General rules for packaging, conditioning and storage

ISO/TS 210:2014 describes the specifications to be met by the containers intended for containing essential oils, as well as recommendations relating to their conditioning and storage. Essential oils are used for different purposes: food use, pharmaceutical use, perfumery and cosmetic use, reference samples or test samples, and industrial raw materials.

Huiles essentielles — Règles générales d'emballage, de conditionnement et de stockage

General Information

Relations

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 210

First edition

2014-06-01

Essential oils — General rules for

packaging, conditioning and storage

Huiles essentielles — Règles générales d’emballage, de

conditionnement et de stockage

Reference number

ISO/TS 210:2014(E)

©

ISO 2014

---------------------- Page: 1 ----------------------

ISO/TS 210:2014(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2014

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2014 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/TS 210:2014(E)

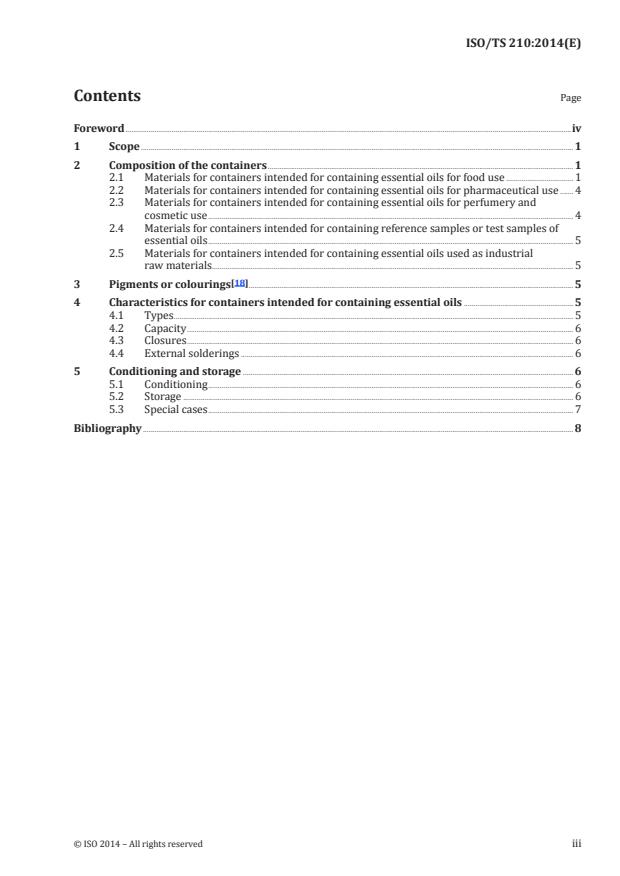

Contents Page

Foreword .iv

1 Scope . 1

2 Composition of the containers . 1

2.1 Materials for containers intended for containing essential oils for food use . 1

2.2 Materials for containers intended for containing essential oils for pharmaceutical use . 4

2.3 Materials for containers intended for containing essential oils for perfumery and

cosmetic use . 4

2.4 Materials for containers intended for containing reference samples or test samples of

essential oils . 5

2.5 Materials for containers intended for containing essential oils used as industrial

raw materials . 5

[18]

3 Pigments or colourings . 5

4 Characteristics for containers intended for containing essential oils .5

4.1 Types. 5

4.2 Capacity . 6

4.3 Closures . 6

4.4 External solderings . 6

5 Conditioning and storage . 6

5.1 Conditioning . 6

5.2 Storage . 6

5.3 Special cases . 7

Bibliography . 8

© ISO 2014 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/TS 210:2014(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 54, Essential oils.

This first edition of ISO/TS 210 cancels and replaces ISO/TR 210:1999 which has been technically

revised.

iv © ISO 2014 – All rights reserved

---------------------- Page: 4 ----------------------

TECHNICAL SPECIFICATION ISO/TS 210:2014(E)

Essential oils — General rules for packaging, conditioning

and storage

1 Scope

This Technical Specification describes the specifications to be met by the containers intended for

containing essential oils, as well as recommendations relating to their conditioning and storage.

Essential oils are used for different purposes:

— food use;

— pharmaceutical use;

— perfumery and cosmetic use;

— reference samples or test samples;

— industrial raw materials.

According to the use of the essential oils, it is necessary to use appropriate containers which also meet

the requirements of national, European, or international regulations.

This Technical Specification describes the materials to be used for the containers intended for containing

essential oils, depending on the uses listed above. It also gives some general rules and recommendations

relating to the properties of these containers and their conditioning and storage.

NOTE The information given in this Technical Specification does not substitute for the regulations in force in

the different countries.

2 Composition of the containers

Essential oils shall be packed in containers which, by their nature, do not cause alteration of the product

and which protect it against any external attack.

Generally, the container materials shall be inert towards the packed product so as to prevent any

simultaneous damage of the product and of the material.

2.1 Materials for containers intended for containing essential oils for food use

[1]

2.1.1 Glass

Type III glass (soda-calcic glass, according to Pharmacopoeia standards), is advisable as it permits to

keep the organoleptic properties of the essential oils.

Tinted antiactinic glass is always advisable.

2.1.2 Metals and alloys

[2]

2.1.2.1 Stainless steel

These materials shall contain at least 13 % of chromium.

They also may contain nickel and manganese.

© ISO 2014 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO/TS 210:2014(E)

Furthermore, one or more of the following elements in Table 1 may be included, with the following limit

for each of them.

Table 1

Tantalum 1 % max.

Niobium 1 % max.

Zirconium 1 % max.

Molybdenum 4 % max.

Titanium 4 % max.

Aluminium 4 % max.

Copper 4 % max.

[3][4][5]

2.1.2.2 Aluminium and aluminium alloys

2.1.2.2.1 Aluminium shall be at least 99 % pure

The total content of impurities shall not exceed 1 %, and they are limited as shown in Table 2.

Table 2

Iron + Silicon Lower than 1 %

Titanium 0,15 % max.

Chromium, Zinc, Copper, Manganese, Magnesium, 0,1 % max (for each of these elements)

Nickel, Tin

Lead, Thallium, Beryllium, and each of the other pre- 0,05 % max (for each of these elements

sent impurities

Copper Between 0,10 % (m/m) and 0,20 % (m/m), on condition

that the chromium and manganese contents are less

than 0,05 % (m/m)

2.1.2.2.2 In the aluminium alloys, the percentage (m/m) of the elements which may be added or which

are present as impurities, shall not exceed the following values in Table 3.

Table 3

Silicon 13,5 % max.

Magnesium 11 % max.

Manganese 4 % max.

Nickel 3 % max.

Iron 2 % max.

Copper 0,6 % max.

Antimony 0,4 % max.

Chromium 0,35 % max.

Titanium 0,3 % max.

Zirconium 0,3 % max.

Zinc 0,25 % max

Strontium 0,2 % max.

2 © ISO 2014 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/TS 210:2014(E)

Table 3

Tin 0,1 % max.

Arsenic, Tantalum, Beryllium, Thallium, Lead, and each 0,05 % max, with a total ≤ to 0,15 %

of the other impurities present.

The anodization of aluminium or aluminium alloy materials and objects complying with the provisions

of Article 2 and 3 of Reference [3] shall be only carried out in a diluted bath of the following acids or their

mixtures:

— sulfuric acid;

— sulfomaleic acid;

— sulfosalicilic acid;

— oxalic acid;

— phosphoric acid.

The anodic layer may be coloured by pigments or colourings, provided that they are authorized by the

regulations in force in the countries concerning the materials and products in contact with food. (See

Clause 3).

A compulsory final filling operation is applied with the exception of the aluminium or aluminium

alloy materials and products anodized in a phosphoric medium or covered by coating, in conformity

with the Article 4 of Reference [3]. This operation shall be carried out with distilled or demineralized

water containing either 8 g/l of nickel acetate and 1 g/l of cobalt acetate or one of these two salts at the

maximum concentrations indicated.

All the technical conditions and particularly the temperature and the standing time shall be chosen in

such a way that, at the end of the operation, the oxide layer formed during the anodization process, loses

its absorption power due to its natural porosity, and acquires optimum inertness.

[6][7]

2.1.2.3 Tin

This material shall contain at least 97 % of tin, determined as metastannic acid, and not more than 0,5 %

of lead or 300 mg/kg of arsenic.

[6]

2.1.2.4 Copper, zinc, galva

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.