ISO 9277:2022

(Main)Determination of the specific surface area of solids by gas adsorption — BET method

Determination of the specific surface area of solids by gas adsorption — BET method

This document specifies the determination of the overall specific external and internal surface area of either disperse (e.g. nano-powders) or porous, solids by measuring the amount of physically adsorbed gas according to the method of Brunauer, Emmett and Teller method,[1] based on the 2015 International Union for Pure and Applied Chemistry (IUPAC) recommendations[3]. NOTE For solids exhibiting a chemically heterogeneous surface, for example, metal-carrying catalyst, the BET method gives the overall surface area, whereas the metallic portion of the surface area can be measured by chemisorption methods.

Détermination de l'aire massique (surface spécifique) des solides par adsorption de gaz — Méthode BET

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 9277

Third edition

2022-11

Determination of the specific surface

area of solids by gas adsorption —

BET method

Détermination de l'aire massique (surface spécifique) des solides par

adsorption de gaz — Méthode BET

Reference number

ISO 9277:2022(E)

© ISO 2022

---------------------- Page: 1 ----------------------

ISO 9277:2022(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

© ISO 2022 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 9277:2022(E)

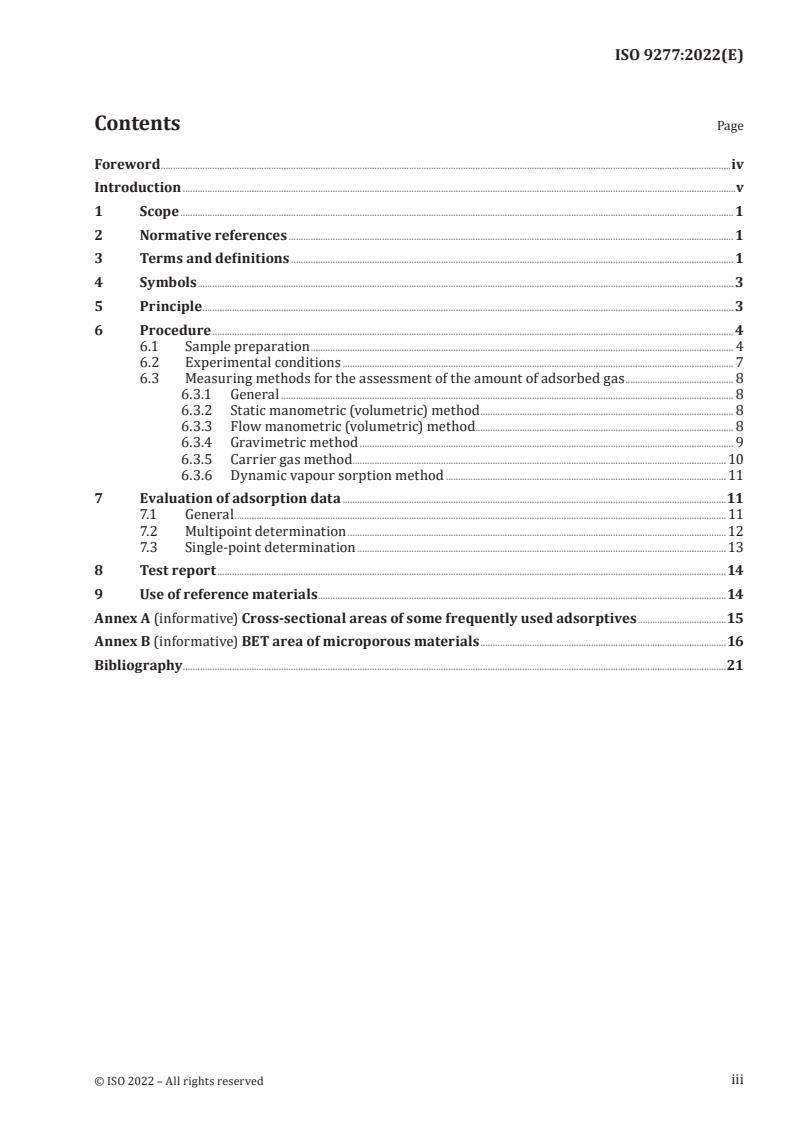

Contents Page

Foreword .iv

Introduction .v

1 S c op e . 1

2 Nor m at i ve r ef er enc e s . 1

3 T erms and definitions . 1

4 S y mb ol s . 3

5 P r i nc iple . 3

6 P rocedure .4

6.1 S ample preparation . 4

6.2 E xperimental conditions . 7

6.3 M easuring methods for the assessment of the amount of adsorbed gas . 8

6.3.1 G eneral . 8

6.3.2 Static manometric (volumetric) method . 8

6.3.3 Flow manometric (volumetric) method . . 8

6.3.4 Gravimetric method . 9

6.3.5 Carrier gas method . . 10

6.3.6 Dynamic vapour sorption method . 11

7 E valuation of adsorption data .11

7.1 G eneral . 11

7.2 M ultipoint determination .12

7.3 Si ngle-point determination . 13

8 Te s t r ep or t .14

9 U se of reference materials .14

Annex A (informative) Cross-sectional areas of some frequently used adsorptives .15

Annex B (informative) BET area of microporous materials .16

Bibliography .21

iii

© ISO 2022 – All rights reserved

---------------------- Page: 3 ----------------------

ISO 9277:2022(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 24, Particle characterization including

sieving, Subcommittee SC 4, Particle characterization.

This third edition cancels and replaces the second edition (ISO 9277:2010), which has been technically

revised.

The main changes compared to the previous edition are as follows:

— the IUPAC classification of adsorption isotherms has been updated according to Reference [3];

— the description of dynamic vapour sorption (DVS) method in 6.3.6 has been added;

— Annex A has been revised;

— Annex B has been removed;

— the former Annex C (now Annex B) has been revised.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

© ISO 2022 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 9277:2022(E)

Introduction

Gas adsorption allows for assessing surface area of nonporous materials and porous materials with

accessible porosity (which depends on the chosen adsorptive) via the Brunauer, Emmett and Teller

[1],[2]

(BET) theory . The BET theory is applicable only to adsorption isotherms of type II (disperse,

nonporous or macroporous solids) and type IV (mesoporous solids) (see Figure 1, Type II and Type IVa

isotherms). However, in the case of Type IVb isotherms, caution is required since pore condensation can

[3]

occur at quite low p/p (see IUPAC recommendations ). The BET method cannot reliably be applied to

0

solids which absorb the measuring gas. A strategy for BET area determination of microporous materials

(type I isotherms) is described in Annex B.

Key

X relative pressure

Y amount adsorbed

[2]

SOURCE IUPAC Recommendations, 1994. Reproduced with the permission of the authors.

Figure 1 — IUPAC (2015) classification of adsorption isotherms

v

© ISO 2022 – All rights reserved

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 9277:2022(E)

Determination of the specific surface area of solids by gas

adsorption — BET method

1 S cope

This document specifies the determination of the overall specific external and internal surface area of

either disperse (e.g. nano-powders) or porous, solids by measuring the amount of physically adsorbed

[1]

gas according to the method of Brunauer, Emmett and Teller method, based on the 2015 International

[3]

Union for Pure and Applied Chemistry (IUPAC) recommendations .

NOTE For solids exhibiting a chemically heterogeneous surface, for example, metal-carrying catalyst, the

BET method gives the overall surface area, whereas the metallic portion of the surface area can be measured by

chemisorption methods.

2 Normat ive references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 8213, Chemical products for industrial use — Sampling techniques — Solid chemical products in the

form of particles varying from powders to coarse lumps

ISO 14488, Particulate materials — Sampling and sample splitting for the determination of particulate

properties

3 T erms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

adsorption

enrichment of the adsorptive gas at the external and accessible internal surfaces of a solid material

3.2

physisorption

weak bonding of the adsorbate (3.2), reversible by small changes in pressure or temperature

3.3

adsorbate

adsorbed gas

3.4

adsorptive

gas or vapour to be adsorbed

3.5

adsorbent

solid material on which adsorption (3.1) occurs

1

© ISO 2022 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 9277:2022(E)

3.6

isotherm

relationship between the amount of gas adsorbed and the equilibrium pressure of the gas, at constant

temperature

3.7

volume adsorbed

volumetric equivalent of adsorbed amount (3.8) expressed as gas at standard conditions of temperature

and pressure (STP)

3.8

adsorbed amount

number of moles of gas adsorbed at a given pressure and temperature

3.9

monolayer capacity

volumetric equivalent of monolayer amount expressed as gas at standard conditions of temperature

and pressure

3.10

surface area

area of the external surface of a solid plus the internal surface of its accessible macro-, meso- and

micropores (3.16)

3.11

specific surface area

absolute surface area (3.10) of the sample divided by sample mass

3.12

molecular cross-sectional area

molecular area of the adsorbate (3.2), i.e. the area occupied by an adsorbate molecule in the complete

monolayer

3.13

nanopore

pore with width of about 100 nm or less

3.14

macropore

pore with width greater than approximately 50 nm

3.15

mesopore

pore with width between approximately 2 nm and 50 nm

3.16

micropore

pore with width of approximately 2 nm or less

3.17

relative pressure

ratio of the equilibrium adsorption (3.1) pressure, p, to the saturation vapour pressure (3.18), p , at

0

analysis temperature

3.18

saturation vapour pressure

vapour pressure of the bulk liquefied adsorptive gas at the temperature of adsorption (3.1)

2

© ISO 2022 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 9277:2022(E)

3.19

free space

head space

dead space

dead volume

volume of the sample holder not occupied by the sample

4 Symbols

Table 1 presents the symbols used in this document, together with their common units derived from

the SI. For comparison purposes, the lUPAC symbols are also given. All specific dimensions are related

to sample mass in grams.

Table 1 — Symbols

Symbol Quantity Unit

2

a molecular cross-sectional area nm

m

2 −1

specific surface area m g

a

s

a

C BET parameter 1

23 −1

L Avogadro constant (L = 6,022 × 10 ) mol

m mass of the solid sample g

a

specific mass adsorbed 1

m

a

−1

n specific amount adsorbed mol·g

a

−1

specific monolayer capacity of adsorbate mol g

n

m

−1

n specific monolayer capacity derived from multipoint measurement mol g

m,mp

−1

specific monolayer capacity derived from single-point measurement mol g

n

m,sp

p pressure of the adsorptive in equilibrium with the adsorbate Pa

p saturation vapour pressure of the adsorptive Pa

0

a

p/p relative pressure of the adsorptive 1

0

−1 −1

R molar gas constant (= 8,314) J mol K

r radius of uniform nonporous spheres nm

s

t time min

T temperature K

3 −1

V specific volume adsorbed cm g

a

3 −1

V specific micropore volume cm g

p,micro

−3

ρ (mass) density g cm

2 −1

u combined standard uncertainty for the certified specific surface area of a BET refer- m g

c

ence material

a

k coverage factor for the combined standard uncertainty 1

2 −1

U expanded uncertainty (U = k u ) for the certified specific surface area of a BET refer- m g

c

ence material

a

According to ISO 80000-1, the unit for any quantity of dimension one (at present commonly termed “dimensionless”) is

the unit one, symbol 1.

5 Principle

The method specified involves the determination of the amount of adsorbate or adsorptive gas required

to cover the external and the accessible internal pore surfaces of a solid (see Figure 2) with a complete

monolayer of adsorbate. This monolayer capacity can be calculated from the adsorption isotherm using

Formula (1) (see 7.1). Any gas may be used, provided it is physically adsorbed by weak bonds at the

3

© ISO 2022 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 9277:2022(E)

surface of the solid (van der Waals forces) and can be desorbed by a decrease in pressure at the same

temperature.

Figure 2 — Schematic cross-section of a particle with surface detected

by the adsorption method shown by dotted line

Nitrogen at its boiling point (about 77 K) was for many decades the adsorptive generally used for

the determination of the specific surface area, mainly because liquid nitrogen was readily available

and relatively strong attractive adsorptive-adsorbent interactions for many systems. However, due

to nitrogen’s quadrupole moment the orientation of a nitrogen molecule is affected by the surface

chemistry of the adsorbent. This leads to uncertainties in the surface area determination by nitrogen

in the order of approximately 20 % for some surfaces. However, argon at 87 K is a great alternative

because argon does, contrary to the diatomic nitrogen molecule, not exhibit a quadrupole moment.

Hence, argon adsorption is less sensitive to the surface chemistry leading to a much more reliable

surface area determination for many adsorbent surfaces. If the sensitivity of the instrument when

2 −1

using argon or nitrogen is insufficient for low specific surface areas of about 1 m g or lower, the

application of krypton adsorption at liquid nitrogen temperature for the specific surface area analysis

is recommended. As a consequence of the low p of about 0,35 kPa for krypton at 77 K, the 'free

0

space' correction (see 3.19) for unadsorbed gas is significantly reduced (to 1/300th) compared to the

conditions of nitrogen adsorption at the same temperature and it becomes possible to manometrically

measure low uptakes of adsorptive with acceptable accuracy. Although at 77 K krypton is about

38,5 K below its triple point temperature, there is some evidence from microcalorimetry and neutron

diffraction studies that in the BET region, the adsorbate may well be in a liquid-like state and therefore

the value of the supercooled liquid is recommended as the effective p for the construction of the BET

0

plot.

The results of measurements with different adsorptives may deviate from each other because of

different molecular areas, different accessibilities to pores (classified into micro-, meso-, macro- and

nanopores) and different measuring temperatures. Moreover, it is well known from the concepts of

fractal analysis that experimental results for the quantities of length and area in the case of irregular

complex structures – such as those which are found in most porous and/or highly dispersed objects –

are not absolute but depend on the measurement scale i.e. the “yardstick” used. This means that less

area is available for larger adsorbate molecules.

The adsorptive gas is admitted to the sample container, which is held at a constant temperature.

The amounts adsorbed are measured in equilibrium with the adsorptive gas pressure p and plotted

against relative pressure, p/p , to give an adsorption isotherm. Adsorption isotherms may be obtained

0

by manometric (volumetric), by gravimetric or by the carrier gas method using continuous or

discontinuous operation (see 6.3).

6 Pr ocedure

6.1 S ample preparatio n

Sampling shall be carried out in accordance with ISO 8213 and ISO 14488. Prior to the determination

of an adsorption isotherm, remove physically adsorbed material from the sample surface by degassing,

while avoiding irreversible changes to the surface. Ascertain the maximum temperature at which

4

© ISO 2022 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 9277:2022(E)

the sample is not affected by thermogravimetric analysis (see Figure 3), by spectroscopic methods,

or by trial experiments using different degassing conditions of time and temperature. When vacuum

conditions are used, degassing to a residual pressure of approximately 1 Pa or better is usually

sufficient. Degassing of the sample can also be performed at elevated temperature by flushing with an

inert gas (e.g. helium, nitrogen, argon). Degassing is complete when a steady value of the residual gas

pressure, p, of its composition or of the sample mass is reached.

Key

X degassing time 1 sample

Y sample mass 2 vacuum generating system

T temperature too low: long degassing time 3 balance

1

T optimum temperature 4 oven

2

T temperature too high: gas evolution due to

3

decomposition of the sample

Figure 3 — Thermogravimetric control of degassing

Using the vacuum technique, isolate the heated sample container from the pump and trap (at time t in

i

Figure 4). If the pressure is nearly constant over a period of 15 min to 30 min, degassing is complete.

This procedure also establishes the absence of leaks. The specific surface area should be related to the

mass of the degassed sample.

5

© ISO 2022 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 9277:2022(E)

Key

X time p (t) leak

3

Y pressure 1 sample

t time of sample isolation 2 vacuum generating system

1

p (t) degassing complete, apparatus tight 3 manometer

1

p (t) incomplete degassing 4 oven

2

Figure 4 — Pressure control of degassing

After degassing, the sample container is cooled to the measuring temperature. It should be noted that,

at low gas pressures, the temperature of the sample needs some time to equilibrate due to the reduced

thermal conductivity within the sample cell.

6

© ISO 2022 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 9277:2022(E)

Key

X time p fixed pressure limit

L

Y1 temperature 1 pressure curve

Y2 pressure 2 temperature curve

Figure 5 — Pressure controlled heating

For sensitive samples, a pressure-controlled heating (see Figure 5) is recommended. This procedure

consists in varying the heating rate in relationship to the gas pressure evolved from a porous material

during the degassing under vacuum conditions. When a fixed pressure limit p (usually around 7 Pa

L

to 10 Pa) is overtaken due to the desorbed material from the sample surface, the temperature increase

is stopped and the temperature is kept constant until the pressure falls below the limit, at that point

the system continues the temperature ramp. This procedure is particularly suitable to avoid structural

changes in microporous materials when fast heating rates can damage fragile structures due to a

vigorous vapour release. In addition, the method is very safe in preventing sample elutriation when

water or other vapour are released from the pores in very fine powder materials.

6.2 Experimental conditions

The precision of the measurement depends on the control of the following conditions.

a) The temperature or the p value of the adsorptive should be monitored during the analysis.

0

b) The purity of the adsorptive and any helium used to calibrate volumes or as a carrier gas should be

at least 99,999 %. If necessary, the gases should be dried and cleaned, for example, oxygen removed

from nitrogen.

c) The saturation vapour pressure p of the adsorptive at the measuring temperature can either be

0

determined directly using a nitrogen vapour pressure thermometer, or it can be monitored and

determined by measurement of the thermostat bath temperature.

d) The validity of the result depends on careful sampling and sample preparation.

In the discontinuous static procedure, at least three points within the relative pressure range for which

the BET equation is valid (typically 0,05 to 0,3) should be measured in equilibrium. For continuous

measurements, the deviation from equilibrium must be controlled either by occasional interruption of

the gas flow or by control measurements using the discontinuous method.

7

© ISO 2022 – All rights reserved

---------------------- Page: 12 ----------------------

ISO 9277:2022(E)

6.3 Measuring method s for the assessment of the amount of adsorbed gas

6.3.1 General

The various types of apparatus used for the determination of physisorption isotherms may be divided

into manometric and gravimetric methods, whereby static or dynamic techniques may be used in either

case. The manometric method is generally considered the most suitable technique for undertaking

physisorption measurements with nitrogen, argon and argon at cryogenic temperatures (i.e. 77 K and

87 K, the boiling point of nitrogen and argon respectively).

Gravimetric adsorption techniques are especially convenient for measurements with vapours (e.g.

water vapour or some organic adsorptives) at temperatures not too far removed from ambient. At low

temperatures (in particular at cryogenic temperatures), however, it can become difficult to control

convection effects and to measure the exact temperature of the adsorbent.

6.3.2 Static manometric (volumetric) method

In the static manometric method, a known amount of gas is admitted to a sample bulb thermostated

at the adsorption temperature (see Figure 6). Adsorption of the gas onto the sample occurs, and

the pressure in the confined volume continues to fall until the adsorbate and the adsorptive are in

equilibrium. The amount of adsorbate at the equilibrium pressure is the difference between the amount

of gas admitted and the amount of adsorptive remaining in the gas phase. Measurement of the pressure

is required together with temperatures and volumes of the system. The volumes are most easily

determined by gas expansion of an inert gas such as helium. The free space volume must be determined

before or after the measurement of the adsorption isotherm. The calibration of the volumes of the

system is done manometrically using helium at the measuring temperature. It should be noted that some

materials can adsorb and/or absorb helium. In this case, corrections can be made after measuring the

adsorption isotherm. If the measurement of the free space volume can be separated from the adsorption

measurement, the use of helium can be avoided. The void volume of the empty sample cell is measured

at ambient temperature using nitrogen. Subsequently, a blank experiment (with the empty sample cell)

is performed under the same experimental conditions (temperature and relative pressure range) as

the sorption measurements. The required correction for the sample volume is made by entering the

sample density or by pycnometric measurement with nitrogen at ambient temperature at the start of

the adsorption analysis (in case nitrogen adsorption effects can be neglected). The determination of the

free space volume may be avoided using difference measurements, that is, by means of a reference and

sample tube connected by a differential transducer. During sample measurement and determination

of the dead volume, it is recommended that the liquid level in the cooling bath be maintained, unless

otherwise compensated, at least 15 mm above the sample and constant to within 1 mm.

6.3.3 Flow manometric (volumetric) method

The flow manometric method is similar to the static manometric method, the difference is such that

gas is continuously fed to the sample at a relatively low flow rate rather than the series of batch doses.

By this method, the change in cell pressure is continuously measured at a controlled flow rate. The

adsorbed amount is determined by comparing the rate of pressure rise with the adsorptive gas to

that with a non-adsorbing gas such as helium used for calibration. An alternative approach, which

directly determines the quantity of gas adsorbed, is to measure the pressure difference between the

reference and sample tubes at the same volume of adsorptive gas fed. One volume is connected via a

flow control valve to the sample tube while the other volume is similarly connected to a balance tube

without sample. Because gas is continuously introduced, the analysis can, under some circumstances,

be completed in a shorter period than using a static manometric method. However, special care has to

be taken to ensure that the flow rate is low enough so that the adsorptive and adsorbate are close to

equilibrium at all times. Determination of the dead volume and control of the liquid level in the cooling

bath are recommended using the same requirements as described in 6.3.1.

8

© ISO 2022 – All rights reserved

---------------------- Page: 13 ----------------------

ISO 9277:2022(E)

6.3.4 Gravimetric method

In the continuous gravimetric method, the mass of gas adsorbed is measured as a function of the

gas pressure in the sample container using a microbalance (see Figure 7). Before measurement of

the adsorption isotherm, the buoyancy of the balance in the adsorptive should be measured at room

temperature and at measurement temperature. The buoyancy of the sample should be measured

at room temperature in helium. By using an equal-arm instrument, the buoyancy of the balance is

eliminated and that of the sample compensated for using a compact counterweight of the same density

as the sample. Because the sample is not in contact with the thermostat, it is necessary to ensure that it

is always at the measuring temperature. The sample temperature should be monitored.

−2

The zero point of the isotherm should be measured at a vacuum better than 10 Pa because disturbances

due to thermal gas flow exhibit a maximum at about 1 Pa.

In the discontinuous gravimetric procedure, the adsorptive is admitted stepwise and the pressure is

kept constant until the sample mass reaches a constant value.

Key

1 sample 5 calibrated volume (gas burette)

2 dewar vessel with cooling bath 6 saturation pressure tube

3 vacuum-generating system 7 adsorptive

4 manometer 8 gas for dead space measurement (e.g. He)

Figure 6 — Manometric (volumetric) method

9

© ISO 2022 – All rights reserved

---------------------- Page: 14 ----------------------

ISO 9277:2022(E)

Key

1 sample 4 manometer

2 cooling bath 5 balance

3 vacuum-generating system 6 adsorptive

Figure 7 — Gravimetric method

6.3.5

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.