ISO 26824:2022

(Main)Particle characterization of particulate systems — Vocabulary

Particle characterization of particulate systems — Vocabulary

This document defines terms that are relevant to the characterization of particles and particulate systems. This document includes such fields as the representation of results of particle size analysis, the descriptive and quantitative representation of particle shape and morphology, sample preparation, specific surface area and porosity characterization and such measurement methods as sedimentation, classification, acoustic methods, laser diffraction, dynamic light scattering, single particle light interaction methods, differential electrical mobility analysis, image analysis and others in a size scale from nanometre to millimetre.

Caractérisation des particules dans les systèmes particulaires — Vocabulaire

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 26824

Second edition

2022-08

Particle characterization of particulate

systems — Vocabulary

Caractérisation des particules dans les systèmes particulaires —

Vocabulaire

Reference number

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

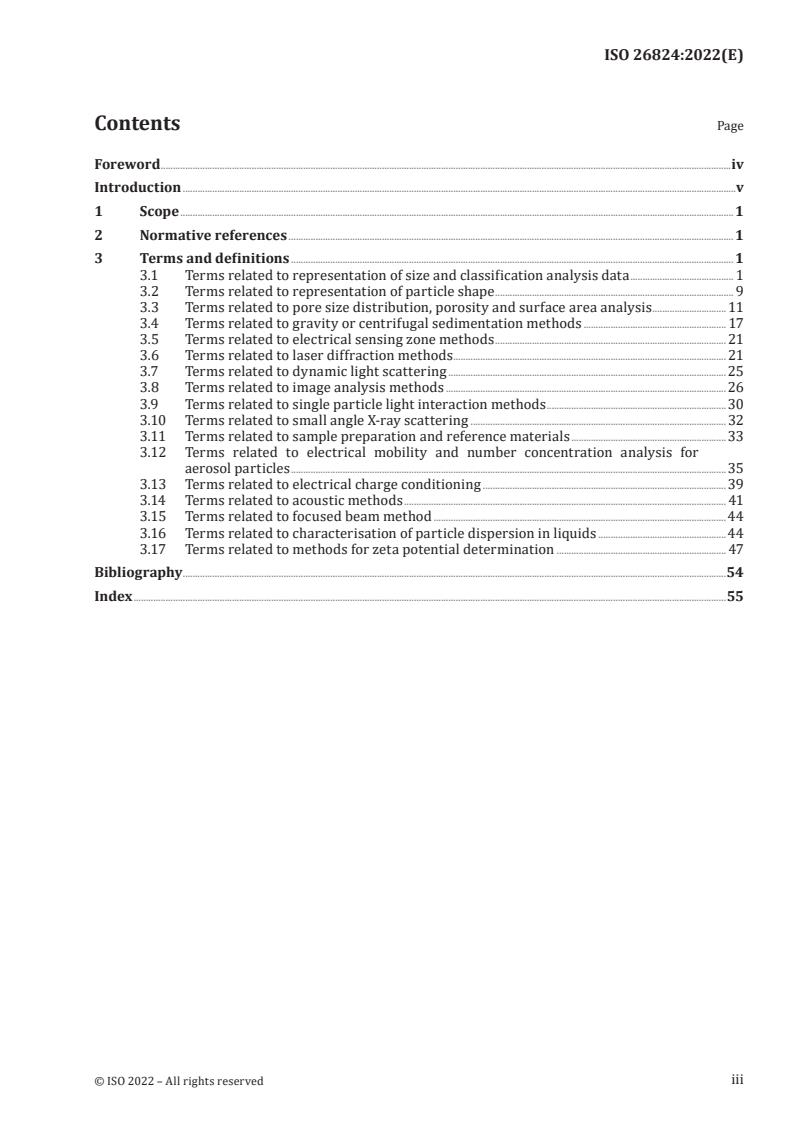

Contents Page

Foreword .iv

Introduction .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

3.1 Terms related to representation of size and classification analysis data . 1

3.2 Terms related to representation of particle shape . 9

3.3 Terms related to pore size distribution, porosity and surface area analysis . 11

3.4 Terms related to gravity or centrifugal sedimentation methods . 17

3.5 Terms related to electrical sensing zone methods . 21

3.6 Terms related to laser diffraction methods . 21

3.7 Terms related to dynamic light scattering . 25

3.8 Terms related to image analysis methods . 26

3.9 Terms related to single particle light interaction methods .30

3.10 Terms related to small angle X-ray scattering . 32

3.11 Terms related to sample preparation and reference materials . 33

3.12 Terms related to electrical mobility and number concentration analysis for

aerosol particles . 35

3.13 Terms related to electrical charge conditioning .39

3.14 Terms related to acoustic methods . 41

3.15 Terms related to focused beam method .44

3.16 Terms related to characterisation of particle dispersion in liquids .44

3.17 Terms related to methods for zeta potential determination . 47

Bibliography .54

Index .55

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 24, Particle characterization including

sieving, Subcommittee SC 4, Particle characterization.

This second edition cancels and replaces the first edition (ISO 26824:2013), which has been technically

revised.

The main changes are as follows:

— All definition clauses have been rearranged as subclauses in Clause 3 and all terms and clauses have

been renumbered.

— Latest revisions and documents from ISO/TC 24/SC 4 have been incorporated, as well as

harmonization with ISO/TC 229 general definitions.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

Introduction

Since the last revision of this document in 2013, about 24 ISO standards have been published by

ISO/TC 24/SC 4 and about 15 projects are currently under construction together with the 5-year

revision of the existing standards. Therefore, terms and definitions of each standard, which are relevant

for other standards should be collected and adjusted to a uniform nomenclature.

Especially the interdisciplinary application fields of particle and particulate systems characterization

- from mining and construction industry, pharmaceutical and food industry, medicine and life sciences,

chemical industry, microelectronics and nanotechnology - need transparency and unambiguous

terminology. The development of international trade not only of measurement devices for particle

characterization, but also of process equipment for the production and treatment of particulate systems

need the comparability of quality and performance parameters as well as international health, safety

and environmental protection regulations.

The structuring and presentation rules applied to the terminological entries are based on a clause

structure, which represents the methods of sample preparation, measurement results presentation and

the analysis methods, starting with more general terms in each clause.

The clause headlines address "Terms related to" technical fields, which are understood as a kind of

domain with validity of the definitions limited to the indicated field.

The following particle properties are covered in the clauses given in brackets:

— particle size (3.1, 3.4 to 3.10, 3.12 to 3.15)

— particle shape (3.2, 3.8)

— particle number concentration (3.5, 3.9 and 3.12)

— pore size, pore volume (3.3)

— surface area (3.3, 3.10)

— electrical charge in aerosols (3.13)

— zeta potential in liquid dispersion (3.17)

— particle dispersion in liquids (3.16).

Data uncertainty related definitions are given in 3.1 and 3.11

v

INTERNATIONAL STANDARD ISO 26824:2022(E)

Particle characterization of particulate systems —

Vocabulary

1 Scope

This document defines terms that are relevant to the characterization of particles and particulate

systems. This document includes such fields as the representation of results of particle size analysis,

the descriptive and quantitative representation of particle shape and morphology, sample preparation,

specific surface area and porosity characterization and such measurement methods as sedimentation,

classification, acoustic methods, laser diffraction, dynamic light scattering, single particle light

interaction methods, differential electrical mobility analysis, image analysis and others in a size scale

from nanometre to millimetre.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1 Terms related to representation of size and classification analysis data

3.1.1

particle

minute piece of matter with defined physical boundaries

Note 1 to entry: A physical boundary can also be described as an interface.

Note 2 to entry: A particle can move as a unit.

Note 3 to entry: This general particle definition applies to nano-objects (3.1.7).

[SOURCE: ISO 26824:2013, 1.1]

3.1.2

agglomerate

collection of weakly or medium strongly bound particles (3.1.1) where the resulting external surface

area is similar to the sum of the surface areas of the individual components

Note 1 to entry: The forces holding an agglomerate together are weak forces, for example van der Waals forces or

simple physical entanglement.

Note 2 to entry: Agglomerates are also termed secondary particles and the original source particles are termed

primary particles (3.1.4).

[SOURCE: ISO 26824:2013, 1.2]

3.1.3

aggregate

particle (3.1.1) comprising strongly bonded or fused particles where the resulting external surface area

is significantly smaller than the sum of surface areas of the individual components

Note 1 to entry: The forces holding an aggregate together are strong forces, for example covalent bonds, or those

resulting from sintering or complex physical entanglement or otherwise combined former primary particles

(3.1.4).

Note 2 to entry: Aggregates are also termed secondary particles and the original source particles are termed

primary particles (3.1.4).

[SOURCE: ISO 26824:2013, 1.3]

3.1.4

primary particle

original source particle (3.1.1) of agglomerates (3.1.2) or aggregates (3.1.3) or mixtures of the two

Note 1 to entry: Constituent particles (3.1.5) of agglomerates (3.1.2) or aggregates (3.1.3) at a certain actual state

can be primary particles, but often the constituents are aggregates.

Note 2 to entry: Agglomerates (3.1.2) and aggregates (3.1.3) are also termed secondary particles.

[SOURCE: ISO 26824:2013, 1.4]

3.1.5

constituent particle

identifiable, integral component of a larger particle (3.1.1)

Note 1 to entry: The constituent particle structures may be primary particles (3.1.4) or aggregates (3.1.3).

Note 2 to entry: See Figure 1.

Note 3 to entry: Constituent particles are considered as the smallest dispersible units of a large particle.

Key

1 agglomerate - constituent particles are identical to primary particles

2 aggregate with covalent bond - constituent particles are identical to primary particles

3 aggregate, produced from initially formed, primary particles (of approximetly 10 or more times smaller size

than the widths of the aggregate) which coalesce during the pyrogenic process and sinter into long chains (the

visible large circle-like parts never existed as isolated particles before)

4 example of an agglomerate, formed from aggregates (key 3), which are the constituent particles-

Figure 1 — Examples for agglomerates and aggregates of constituent particles and primary

particles (not identifiable as such in all cases)

[SOURCE: ISO/TS 80004-2:2015, 3.3, modified — Figure 1 has been added, Note 1 has been modified,

Note 2 and 3 have been added]

3.1.6

nanoscale

length range approximately from 1 nm to 100 nm

Note 1 to entry: Properties that are not extrapolations from larger sizes are predominantly exhibited in this

length range.

[SOURCE: ISO/TS 80004-1:2015, 2.1]

3.1.7

nano-object

discrete piece of material with one, two or three external dimensions in the nanoscale (3.1.6)

Note 1 to entry: The second and third external dimensions are orthogonal to the first dimension and to each

other.

[SOURCE: ISO/TS 80004-1:2015, 2.5]

3.1.8

nanomaterial

material with any external dimension in the nanoscale (3.1.6) or having internal structure or surface

structure in the nanoscale

[SOURCE: ISO/TS 80004-1:2015, 2.4]

3.1.9

particle size

x

d

linear dimension of a particle (3.1.1) determined by a specified measurement method and under

specified measurement conditions

Note 1 to entry: Different methods of analysis are based on the measurement of different physical properties.

Independent of the particle property actually measured, the particle size is reported as a linear dimension, e.g. as

the equivalent spherical diameter (3.1.10).

Note 2 to entry: Examples of size descriptors are those based at the opening of a sieve or a statistical diameter,

e.g. the Feret diameter, measured by image analysis.

Note 3 to entry: In ISO 9276 the symbol ‘x’ is used to denote the particle size. However, it is recognised that

the symbol ‘d’ is also widely used to designate these values. Therefore the symbol ‘x’ may be replaced by ‘d’.

[ISO 9276-1:1998, 3.1]

[SOURCE: ISO 9276-1:1998, 4.2, modified – text reformated]

3.1.10

equivalent diameter

equivalent spherical diameter

diameter of a sphere that produces a response by a given particle-sizing method, that is equivalent to

the response produced by the particle (3.1.1) being measured

Note 1 to entry: The physical property to which the equivalent diameter refers is indicated using a suitable

subscript [ISO 9276-1:1998].

Note 2 to entry: For discrete-particle-counting, light-scattering instruments, an equivalent optical diameter is

used.

Note 3 to entry: Other material constants like density of the particle are used for the calculation of the equivalent

diameter like Stokes diameter or sedimentation equivalent diameter. The material constants, used for the

calculation, should be reported additionally.

Note 4 to entry: For inertial instruments, the aerodynamic diameter is used. Aerodynamic diameter is the

−3

diameter of a sphere of density 1 000 kg m that has the same settling velocity as the irregular particle.

[SOURCE: ISO/TS 80004-6:2021, 4.1.5]

3.1.11

type of quantity

r

specification of the quantity of a distribution, a cumulative (3.1.13) or a density measure (3.1.14).

Note 1 to entry: The type is indicated by the general subscript, r, or by the appropriate value of r as follows:

number: r = 0

length: r = 1

area: r = 2

volume or mass: r = 3

[SOURCE: ISO 9276-1:1998, 4.3]

3.1.12

particle size distribution

distribution of particles (3.1.1) as a function of particle size (3.1.9)

Note 1 to entry: Particle size distribution may be expressed as cumulative distribution (3.1.13) or a distribution

density (3.1.14) (distribution of the fraction of material in a size class, divided by the width of that class).

[SOURCE: ISO/TS 80004-6:2013, 3.1.2]

3.1.13

cumulative distribution

Q (x)

r

distribution of the fraction of material smaller (undersize) than given particle sizes (3.1.9)

Note 1 to entry: If the cumulative distribution, Q (x), is calculated from histogram data, only individual points

r

Q = Q (x ) are obtained. Each individual point of the distribution, Q (x ), defines the relative amount of particles

r,i r i r i

smaller than or equal to x . The continuous curve is calculated by suitable interpolation algorithms. The

i

normalized cumulative distribution extends between 0 and 1, i.e. 0 and 100 %.

i i

QQ==ΔΔq x with 1 ≤ v ≤ i ≤ n.

r,iv∑ r, ∑ r,v v

v=1 v=1

where

i (subscript) number of the size class with upper limit x

i

ν (integer, see subscript i)

n total number of size classes

Q relative amount of particles in size class with upper limit x

r,ν ν

Note 2 to entry: When plotted on a graph paper with a logarithmic abscissa the cumulative values, Q , i.e. the

r,i

ordinates of a cumulative distribution, do not change. However, the course of the cumulative distribution curve

changes but the relative amounts smaller than a certain particle size remain the same. Therefore, the following

equation holds:

Q (x) = Q (In x)

r r

Note 3 to entry: The cumulative oversize distribution is given by 1−Q (x).

r

[SOURCE: ISO 9276-1:1998, 5.2]

3.1.14

distribution density

q (x)

r

distribution of the fraction of material in a size class, divided by the width of that class

Note 1 to entry: Under the presupposition that the cumulative distribution (3.1.13), Q (x), is differentiable, the

r

continuous distribution density, q (x), is obtained from

r

dQx

()

r

qx()=

r

dx

Conversely, the cumulative distribution (3.1.13), Q (x), is obtained from the distribution density, q (x), by

r r

integration:

x

i

Qx = qx dx

() ()

ri r

∫

x

min

Note 2 to entry: The more common term “density distribution” can be misunderstood in the context of

sedimentation methods, so an alternative has been adopted.

Note 3 to entry: Differential distribution is also called in statistics "density of a probability or frequency"

[SOURCE: ISO 9276-1:1998, 5.3, modified – “density distribution” replaced with “distribution density”]

3.1.15

distribution density on a logarithmic abscissa

q* (x)

r

distribution density (3.1.14), transformed for a logarithmic abscissa

Note 1 to entry: The density values of a histogram, q* = ‾ q* (x , x ), can be recalculated using the following

r,i r i-1 i

equation which indicates that the corresponding areas underneath the distribution density curve remain

constant. In particular, the total area is equal to 1 or 100 %, independent of any transformation of the abscissa.

∗

qq()ξξ,,ΔΔξ = ()xx x where ξ is any function of x.

ri−−11ii ri ii

Thus the following transformation can be carried out to obtain the distribution density on a logarithmic abscissa

qxΔ ΔQ

qx(),xxΔ

ri, i ri,

∗ ∗ ri−1 ii

qx()=⋅qx or qx()ln ,lnx = = =

rrii,i ri−1 i

lnxx−ln ln xx/ ln xx/

() ()

ii−−1 ii 111ii−

Note 2 to entry: This equation also holds if the natural logarithm is replaced by the logarithm to base 10.

[SOURCE: ISO 9276-1:1998, 6.2]

3.1.16

histogram

graphical representation of a distribution density q (x) (3.1.14), comprising a successive series of

r

rectangular columns with the height of mean distribution density, qx() , and the width of Δx , the

ri, i

area of each represents the relative quantity ΔQ (x), where

r,i

ΔQ

ΔQx(),x

ri,

ri−−1 i

ΔΔQQ= xx,,=qx xxΔ or qq= xx, = =

() () ()

ri,,ri−−11ir ii ri ri−1 i

Δx Δx

i i

Note 1 to entry: The sum of all the relative quantities, ΔQ forms the area beneath the histogram q (x), normalized

r,i r

to 100 % or 1 (condition of normalization). Therefore, following equation holds:

n n

ΔΔQq==x 1= 100 %

∑∑ri,,ri i

i==11i

[SOURCE: ISO 9276-1:1998, 5.1]

3.1.17

concentration distribution density

distribution of the concentration of material in a size class, divided by the width of that class

Note 1 to entry: In aerosol measurement e. g. the distribution density of the particle number concentration is

represented as a function of the particle size.

Note 2 to entry: The concentration distribution density can be calculated from the distribution density (3.1.14)

function of the particle size (3.1.9) by multiplication with the overall sizes measured concentration.

3.1.18

analytical cut size

x

a

cut size with the coarse and the fine material containing equal quantities of misplaced material

Note 1 to entry: Since the relative mass of the fine material as determined by the classification process, is taken

to be equal to the relative mass of the undersize material in the feed, that is Q (x), an analytical cut size x

3,s

corresponding to this definition has to be found.

[SOURCE: ISO 9276-4:2001, 4.3.2]

3.1.19

equiprobable cut size

x

e

cut size, which represents the median of the grade efficiency (3.1.20) curve T(x ) = 0,5

e

Note 1 to entry: The weighted distribution density curves of the fine and the coarse fraction intersect at the

equiprobable cut size x . Independently from other particle sizes (3.1.9), particles of this size have the equal

e

probability to be classified into the fine and into the coarse fraction.

[SOURCE: ISO 9276-4:2001, 3.3.2]

3.1.20

grade efficiency

T(x)

grade efficiency (Tromp's curve, Partial classification efficiency) represents for a certain particle size

(3.1.9) x the ratio of the amount of material present in the coarse material, to the amount of the same

size initially present in the feed material.

[SOURCE: ISO 9276-4:2001, 4.4]

Note 1 to entry: In the dust collection field this efficiency is called as Partial separation efficiency.

3.1.21

reference material

RM

material, sufficiently homogeneous and stable with respect to one or more specified properties, which

has been established to be fit for its intended use in a measurement process

Note 1 to entry: RM is a generic term.

Note 2 to entry: Properties can be quantitative or qualitative, e.g. identity of substances or species.

Note 3 to entry: Uses may include the calibration of a measurement system, assessment of a measurement

procedure, assigning values to other materials, and quality control.

Note 4 to entry: ISO/IEC Guide 99:2007 has an analogous definition but restricts the term “measurement” to

apply to quantitative values. However, ISO/IEC Guide 99:2007, 5.13, Note 3 (VIM), specifically includes qualitative

properties, called “nominal properties”.

[SOURCE: ISO Guide 35:2017, 3.1]

3.1.22

certified reference material

CRM

reference material (3.1.21) characterised by a metrologically valid procedure for one or more specified

properties, accompanied by an RM certificate that provides the value of the specified property, its

associated uncertainty, and a statement of metrological traceability

Note 1 to entry: The concept of value includes a nominal property or a qualitative attribute such as identity or

sequence. Uncertainties for such attributes may be expressed as probabilities or levels of confidence.

Note 2 to entry: Metrologically valid procedures for the production and certification of RMs are given in, among

others, ISO 17034 and ISO Guide 35.

Note 3 to entry: ISO Guide 31 gives guidance on the contents of RM certificates.

Note 4 to entry: ISO/IEC Guide 99:2007, 5.14 has an analogous definition.

[SOURCE: ISO Guide 35:2017, 3.2]

3.1.23

accuracy

closeness of agreement between a test result or measurement result and the true value (3.1.26)

Note 1 to entry: In practice, the accepted reference value is substituted for the true value (3.1.26).

Note 2 to entry: The term “accuracy”, when applied to a set of test or measurement results, involves a combination

of random components and a common systematic error or bias component.

Note 3 to entry: Accuracy refers to a combination of trueness (3.1.25) and precision (3.1.24).

[SOURCE: ISO 3534-2:2006, 3.3.1]

3.1.24

precision

closeness of agreement between independent test/measurement results obtained under stipulated

conditions

Note 1 to entry: Precision depends only on the distribution of random errors and does not relate to the true value

(3.1.26) or the specified value.

Note 2 to entry: The measure of precision is usually expressed in terms of imprecision and computed as a

standard deviation of the test results or measurement results. Less precision is reflected by a larger standard

deviation.

Note 3 to entry: Quantitative measures of precision depend critically on the stipulated conditions. Repeatability

conditions (3.1.28) and reproducibility conditions are particular sets of extreme stipulated conditions.

[SOURCE: ISO 3534-2:2006, 3.3.4]

3.1.25

trueness

closeness of agreement between the expectation of a test result or a measurement result and a true

value (3.1.26)

Note 1 to entry: The measure of trueness is usually expressed in terms of bias.

Note 2 to entry: Trueness is sometimes referred to as “accuracy of the mean”. This usage is not recommended.

Note 3 to entry: In practice, the accepted reference value is substituted for the true value.

[SOURCE: ISO 3534-2:2006, 3.3.3]

3.1.26

true value

value which characterizes a quantity or quantitative characteristic perfectly defined in the conditions

which exist when that quantity or quantitative characteristic is considered

Note 1 to entry: The true value of a quantity or quantitative characteristic is a theoretical concept and, in general,

cannot be known exactly.

Note 2 to entry: For an explanation of the term "quantity", refer to ISO 3534-2:2006, Note 1 of 3.2.1.

[SOURCE: ISO 3534-2:2006, 3.2.5]

3.1.27

repeatability

precision under repeatability conditions (3.1.28)

Note 1 to entry: Repeatability can be expressed quantitatively in terms of the dispersion characteristics of the

results.

[SOURCE: ISO 13320:2020, 3.1.20]

3.1.28

repeatability conditions

observation conditions where independent test/measurement results are obtained with the same

method on identical test/measurement items in the same test or measuring facility by the same

operator using the same equipment within short intervals of time

Note 1 to entry: Repeatability conditions include the following:

— the same measurement procedure or test procedure;

— the same operator;

— the same measuring or test equipment used under the same conditions;

— the same location;

— repetition over a short period of time.

[SOURCE: ISO 3534-2:2006, 3.3.6]

3.1.29

method repeatability

closeness of agreement between multiple measurement results of a given property in different aliquots

of a sample, executed by the same operator using the same instrument under identical conditions

within a short period of time

Note 1 to entry: The variability includes the variabilities of sub sampling technique, of the sampled material

together and of the instrument.

[SOURCE: ISO 13320:2020, 3.1.22]

3.2 Terms related to representation of particle shape

3.2.1

particle shape

external geometric form of a particle (3.1.1)

Note 1 to entry: Macroshape is a description of the overall form of a particle (3.1.1) defined in terms of the

geometrical proportions of the particle. In general, simple geometrical descriptors calculated from size

measurements made on the particle silhouette are used.

Note 2 to entry: Mesoshape description provides information about details of the particle shape and/or surface

structure that are in a size range not much smaller than the particle proportions.

Note 3 to entry: Microshape determines the roughness of shape boundaries using fractal dimension or higher-

order Fourier coefficients for surface-textural analysis.

[SOURCE: ISO/TS 80004-6: 2021, 4.1.3, modified — Notes 1 to 3 have been added from ISO 9276-6:2008,

5.2]

3.2.2

Legendre ellipse of inertia

ellipse with its centre at the particle’s centroid and with the same geometrical moments of inertia, up to

the second order, as the original particle area

Note 1 to entry: The ellipse can be characterized by its major and minor diameters, the position of its centre of

gravity and its orientation.

Note 2 to entry: Macroshape descriptor, geometrical descriptor

[SOURCE: ISO 9276-6:2008, 8.1.2]

3.2.3

geodesic length and thickness

x and x

LG E

approximations for very long and concave particles (3.1.1), such as fibres, calculated from the projection

area A and perimeter P:

Ax==⋅xP 2()xx+

ELGE LG

Note 1 to entry: Macroshape descriptor, geometrical descriptor

[SOURCE: ISO 9276-6:2008, 8.1.2]

3.2.4

ellipse ratio

ratio of the lengths of the axes of the Legendre ellipse of inertia (3.2.3)

Note 1 to entry: Macroshape descriptor, proportion descriptor

[SOURCE: ISO 9276-6:2008, 8.1.3]

3.2.5

Feret diameter

x

F

distance between two parallel tangents on opposite sides of the image of a particle (3.1.1)

[SOURCE: ISO 13322-1:2014, 3.1.5]

3.2.6

aspect ratio

ratio of the minimum Feret diameter to the maximum Feret diameter (3.2.5)

Note 1 to entry: For not very elongated particles (approximately smaller than 1:3)

Note 2 to entry: Macroshape descriptor, proportion descriptor

[SOURCE: ISO 9276-6:2008, 8.1.3, modified — 'Feret diameter' is inserted after 'minimum.']

3.2.7

elongation

ratio of the geodesic thickness to the geodesic length (3.2.3)

Note 1 to entry: For very elongated particles (approximately greater than 1:3), such as fibres

Note 2 to entry: Macroshape descriptor, proportion descriptor

[SOURCE: ISO 9276-6:2008, 8.1.3]

3.2.8

straightness

ratio of the maximum Feret diameter (3.2.5) to the geodesic length (3.2.3)

Note 1 to entry: For very elongated particles (reciprocal of curl)

Note 2 to entry: Macroshape descriptor, proportion descriptor

[SOURCE: ISO 9276-6:2008, 8.1.3]

3.2.9

irregularity

ratio of the diameter of the maximum inscribed circle d and that of the minimum circumscribed

imax

circle d

cmin

Note 1 to entry: Macroshape descriptor, proportion descriptor, (modification ratio)

[SOURCE: ISO 9276-6:2008, 8.1.3]

3.2.10

compactness

s

degree to which the projection area A of the particle (3.1.1) is similar to a circle, considering the overall

form of the particle (3.1.1) with the maximum Feret diameter (3.2.5) x :

Fmax

()4/A π

s=

x

Fmax

Note 1 to entry: Macroshape descriptor, proportion descriptor

[SOURCE: ISO 9276-6:2008, 8.1.3]

3.2.11

box ratio

ratio of the Feret box area to the projected area A

Note 1 to entry: Macroshape descriptor, proportion descriptor

[SOURCE: ISO 9276-6:2008, 8.1.3]

3.2.12

sphericity

Ψ

square of the ratio of the volume equivalent diameter x to the surface equivalent diameter x

v s

2 2

Ψ = xx//=π ⋅xS

()

vs v

Note 1 to entry: Wadell’s sphericity Ψ , also derived from surface area S

Note 2 to entry: Mesoshape descriptor

[SOURCE: ISO 9276-6:2008, 8.2]

3.2.13

circularity

C

degree to which the projection area of the particle (3.1.1) A is similar to a circle, considering the

smoothness of the perimeter P:

x

4πA

A

C==

x

P P

Note 1 to entry: Mesoshape descriptor, also derived from the area equivalent diameter x to the perimeter

A

equivalent diameter x

P

[SOURCE: ISO 9276-6:2008, 8.2]

3.2.14

solidity

S

l

ratio of the projected area A to the the area of the convex hull A (envelope)

C

SA= / A

lC

Note 1 to entry: Measure of the overall concavity of a particle

Note 2 to entry: Mesoshape descriptor

[SOURCE: ISO 9276-6:2008, 8.2]

3.3 Terms related to pore size distribution, porosity and surface area analysis

3.3.1

molecular cross-sectional area

molecular area of the adsorbate, i.e. the area occupied by an adsorbate molecule in the complete

monolayer

[SOURCE: ISO 9277:2010, 3.10]

3.3.2

free space

volume of the sample holder not occupied by the sample

Note 1 to entry: also called head space, dead space, or dead volume

[SOURCE: ISO 9277:2010, 3.14]

3.3.3

specific surface area

absolute surface area of the sample divided by sample mass

[SOURCE: ISO 9277:2010, 3.15]

3.3.4

blind pore

dead end pore

open pore having a single connection with an external surface

Note 1 to entry: also called dead-end-pore

[SOURCE: ISO 15901-2:2006, 3.6]

3.3.5

closed pore

pore totally enclosed by its walls and hence not interconnecting with other pores and not accessible to

fluids

[SOURCE: ISO 15901-1:2016, 3.10]

3.3.6

open pore

pore not totally enclosed by its walls and open to the surface either directly or by interconnecting with

other pores and therefore accessible to fluid

[SOURCE: ISO 15901-1:2016, 3.11]

3.3.7

open porosity

ratio of the volume of open pores and voids to the total volume occupied by the solid

[SOURCE: ISO 15901-2:2006, 3.17]

3.3.8

contact angle

angle at which a liquid/vapour interface meets the surface of a solid material

[SOURCE: ISO 15901-1:2016, 3.32]

3.3.9

ink bottle pore

narrow necked open pore

[SOURCE: ISO 15901-1:2016, 3.12]

3.3.10

interconnected pore

pore which communicates with one or more other pores

[SOURCE: ISO 15901-2:2006, 3.9]

3.3.11

intraparticle porosity

ratio of the volume of open pores inside the individual particles of a particulate or divided solid sample

to the bulk volume occupied by the sample

[SOURCE: ISO 15901-1:2016, 3.29]

3.3.12

interparticle porosity

ratio of the volume of void space between the individual particles to the bulk volume of the particles or

powder

[SOURCE: ISO 15901-1:2016, 3.28]

3.3.13

macropore

pore of internal width greater than 50 nm

[SOURCE: ISO 15901-1:2016, 3.7]

3.3.14

mesopore

pore of internal width between 2 nm and 50 nm

[SOURCE: ISO 15901-1:2016, 3.8]

3.3.15

micropore

pore of internal width less than 2 nm

[SOURCE: ISO 15901-1:2016, 3.9]

3.3.16

supermicropore

pore with width of approximately 0,7 nm – 2 nm

[SOURCE: ISO 15901-2:2022, 3.14]

3.3.17

ultramicropore

pore with width of approximately < 0,7 nm

[SOURCE: ISO 15901-2:2022, 3.15]

3.3.18

nanopore

pore with width of 100 nm or less

Note 1 to entry: The concept of nanopore overlaps all three traditionally defined major pore size ranges with

micropore (pore with width of about 2 nm or less), mesopore (pore with width between approximately 2 nm

and 50 nm), and macropore (pore with width greater than about 50 nm) and therefore is not based on sorption

behavior or principles. See also Reference [16].

[SOURCE: ISO 15901-2:2022, 3.10, modified — Note 1 has been added]

3.3.19

pore size

internal pore width (e.g. the diameter of a cylindrical pore or the distance between the opposite walls

of a slit) which is a representative value of various sizes of vacant space inside a porous material

[SOURCE: ISO 15901-1:2016, 3.13]

3.3.20

pore volume

volume of open pores unless otherwise stated

[SOURCE: ISO 15901-1:2016, 3.14]

3.3.21

porosimeter

instrument for measuring pore volume and pore size distribution

[SOURCE: ISO 15901-1:2016, 3.1]

3.3.22

porosimetry

methods for the estimation of pore volume, pore size distribution, and porosity

[SOURCE: ISO 15901-1:2016, 3.2]

3.3.23

porosity

ratio of the volume of the accessible pores and voids to the bulk volume occupied by an amount of the

solid

[SOURCE: ISO 15901-1:2016, 3.27]

3.3.24

porous solid

solid with cavities or channels which are deeper than they are wide

[SOURCE: ISO 15901-1:2016, 3.3]

3.3.25

surface area

extent of accessible surface area as determined by a given method under stated conditions

[SOURCE: ISO 15901-1:2016, 3.30]

3.3.26

surface tension

work required to increase a surface area divided by that area.

[SOURCE: ISO 15901-1:2016, 3.31]

3.3.27

through pore

pore which passes all the way through the sample

[SOURCE: ISO 15901-1:2005, 3.27]

3.3.28

void

interstice

space between particles, i.e. an interparticle pore

[SOURCE: ISO 15901-1:2016, 3.6]

3.3.29

adsorbate

adsorbed gas

[SOURCE: ISO 15901-2:2022, 3.1]

3.3.30

adsorbed amount

amount of gas adsorbed at a given pressure, p, and temperature, T

[SOURCE: ISO 15901-2:2022, 3.6]

3.3.31

adsorbent

solid material on which adsorption occurs

[SOURCE: ISO 15901-2:2022, 3.4]

3.3.32

adsorption

enrichment of the adsorptive gas at the external and accessible internal surfaces of a solid material

[SOURCE: ISO 15901-2:2022, 3.2]

3.3.33

adsorptive

gas or vapour to be adsorbed

[SOURCE: ISO 15901-2:2022, 3.3]

3.3.34

equilibrium adsorption pressure

pressure of the adsorptive gas in equilibrium with the adsorbate

[SOURCE: ISO 15901-2:2022, 3.7]

3.3.35

adsorption isotherm

relationship between the amount of gas adsorbed and the equilibrium pressure of the gas, at constant

temperature

[SOURCE: ISO 15901-2:2022, 3.5]

3.3.36

monolayer amount

amount of the adsorbate that forms a monomolecular layer over the surface of the adsorbent

[SOURCE: ISO 15901-2:2022, 3.8]

3.3.37

monolayer capacity

volumetric equivalent of monolayer amount expressed as gas at standard conditions of temperature

and pressure (STP)

[SOURCE: ISO 15901-2:2022, 3.9]

3.3.38

relative pressure

ratio of the equilibrium adsorption pressure, p, to the saturation vapour pressure, p , at analysis

temperature

[SOURCE: ISO 15901-2:2022, 3.19]

3.3.39

right cylindrical pore

cylindrical pore perpendicular to the surface

[SOURCE: ISO 15901-2:2022, 3.19]

3.3.40

saturation vapour pressure

vapour pressure of the bulk liquefied adsorptive gas at the temperature of adsorption

[SOURCE: ISO 15901-2:2022, 3.20]

3.3.41

volume adsorbed

volumetric equivalent of the amount adsorbed, expressed as gas at standard conditions of temperature

and pressure (STP), or expressed as the adsorbed liquid volume of the adsorbate

[SOURCE: ISO 15901-2:2022, 3.21]

3.3.42

physisorption

weak bonding of the adsorbate, reversible by small changes in pressure or temperature

[SOURCE: ISO 15901-2:2022, 3.16]

3.3.43

powder

porous or nonporous solid composed of discrete particles with maximum dimension less than about 1

mm, powders with a particle size below about 1 μm are often referred to as fine powders

[SOURCE: ISO 15901-1:2016, 3.4]

3.3.44

pore

cavity or channel which is deeper than it is wide, otherwise it is part of the material’s roughness

[SOURCE: ISO 15901-1:2016, 3.5]

3.3.45

pore diameter

diameter of a pore in a model in which the pores typically are assumed to be cylindrical in shape and

which is calculated from data obtained by a specified procedure

[SOURCE: ISO 15901-1:2016, 3.15]

3.3.46

median pore diameter

diameter that corresponds to the 50th percentile of pore volume, i.e. the diameter for which one half of

the pore volume is found to be in larger pores and one half is found to be in smaller pores

[SOURCE: ISO 15901-1:2016, 3.16]

3.3.47

modal pore diameter

mode

pore diameter of the maximum in a differential pore size distribution curve

[SOURCE: ISO 15901-1:2016, 3.17]

3.3.48

hydraulic pore diameter

average pore diameter, calculated as the ratio of pore volume multiplied by four to pore area

[SOURCE: ISO 15901-1:2016, 3.18]

3.3.49

density

ratio of the mass of a certain amount of a sample to the volume occupied by that mass

[SOURCE: ISO 12154:2014, 3.1]

3.3.50

true solid state density

ratio of the sample mass to the volume of the compact solid skeleton of the sample which excludes

the volume of open and closed pores or internal voids and also interparticle voids as in the case of

granulated or highly dispersed samples

[SOURCE: ISO 12154:2014, 3.2]

3.3.51

bulk volume

volume of powder or solids, including all pores (open and closed) and interstitial spaces between

particles

[SOURCE: ISO 15901-1:2016, 3.19]

3.3.52

bulk density

ratio of sample mass to bulk volume

[SOURCE: ISO 15901-1:2016, 3.20]

3.3.53

skeleton volume

volume of the sample including the volume of closed pores (if present) but excluding the volumes of

open pores as well as that of void spaces between particles within the bulk sample

[SOURCE: ISO 15901-1:2016, 3.21]

3.3.54

skeleton density

ratio of sample mass to skeleton volume (3.3.53)

[SOURCE: ISO 15901-1:2016, 3.22; ISO 12154:2014, 3.3]

3.3.55

apparent volume

total volume of the solid constituents of the sample including closed pores and pores inaccessible or not

detectable by the stated method

[SOURCE: ISO 15901-1:2016, 3.23]

3.3.56

apparent density

ratio of sample mass to apparent volume

[SOURCE: ISO 15901-1:2016, 3.24]

3.3.57

envelope volume

total volume of the particle, including closed and open pores, but excluding void space between the

individual particles

[SOURCE: ISO 15901-1:2016, 3.25]

3.3.58

envelope density

ratio of sample mass to envelope volume (3.3.57)

[SOURCE: ISO 15901-1:2016, 3.26]

3.4 Terms related to gravity or centrifugal sedimentation methods

3.4.1

sedimentation

directional motion of particles in a viscous liquid under the action of gravity or centrifugal fields

Note 1 to entry: For a positive density contrast, sedimentation occurs in the direction of gravitational

acceleration; it is counter directed to this acceleration for a negative density contrast.

Note 2 to entry: A downward motion under gravity is also called settling or falling.

Note 3 to entry: An upward motion under gravity is also called creaming (for liquid particles) or more general

rising and floating.

1)

[SOURCE: ISO 13317-1:— , 3.1]

1) Under preparation. Stage at the time of publication: ISO/DIS 13317-1:2022.

3.4.2

migration

directional motion of particles in a viscous liquid under the action of a force field

Note 1 to entry: For a positive density contrast, migration occurs in the direction of gravity or centrifugal

acceleration; it is counter directed to this acceleration for a negative density contrast.

[SOURCE: ISO 13317-1:—, 3.2]

3.4.3

terminal sedimentation velocity

sedimentation velocity in case that gravity or centrifugal force is completely balanced by buoyancy and

drag force

[SOURCE: ISO 13317-1:—, 3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...