ISO 11723:2016

(Main)Solid mineral fuels — Determination of arsenic and selenium — Eschka's mixture and hydride generation method

Solid mineral fuels — Determination of arsenic and selenium — Eschka's mixture and hydride generation method

ISO 11723:2016 specifies a method using Eschka's mixture during ashing, extraction of the ash residue with acid, and hydride generation atomic absorption spectrometry or hydride generation atomic fluorescence spectrometry, for the determination of arsenic and selenium in solid mineral fuels.

Combustibles minéraux solides — Dosage de l'arsenic et du sélénium — Mélange d'Eschka et méthode par production d'hydrure

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 11723

Second edition

2016-11-15

Solid mineral fuels — Determination

of arsenic and selenium — Eschka’s

mixture and hydride generation

method

Combustibles minéraux solides — Dosage de l’arsenic et du sélénium

— Mélange d’Eschka et méthode par production d’hydrure

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

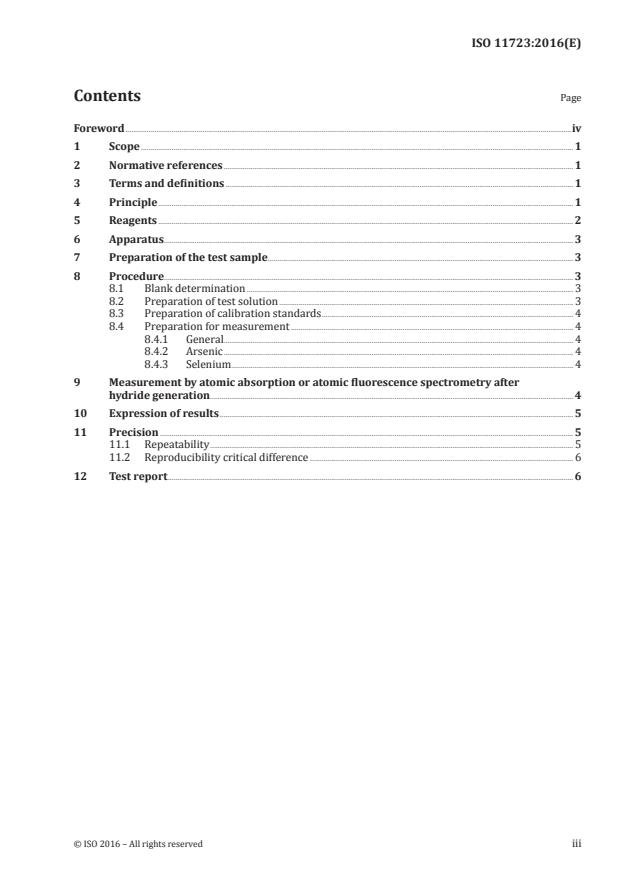

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 1

5 Reagents . 2

6 Apparatus . 3

7 Preparation of the test sample . 3

8 Procedure. 3

8.1 Blank determination . 3

8.2 Preparation of test solution . 3

8.3 Preparation of calibration standards . 4

8.4 Preparation for measurement . 4

8.4.1 General. 4

8.4.2 Arsenic . 4

8.4.3 Selenium . . 4

9 Measurement by atomic absorption or atomic fluorescence spectrometry after

hydride generation . 4

10 Expression of results . 5

11 Precision . 5

11.1 Repeatability . 5

11.2 Reproducibility critical difference . 6

12 Test report . 6

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www.iso.org/iso/foreword.html.

The committee responsible for this document is ISO/TC 27, Solid minerals fuels, Subcommittee SC 5,

Methods of analysis.

This second edition cancels and replaces the first edition (ISO 11723:2004), which has been technically

revised. This document incorporates changes related to dated references and other minor items

following its systematic review.

iv © ISO 2016 – All rights reserved

INTERNATIONAL STANDARD ISO 11723:2016(E)

Solid mineral fuels — Determination of arsenic and

selenium — Eschka’s mixture and hydride generation

method

1 Scope

This document specifies a method using Eschka’s mixture during ashing, extraction of the ash residue

with acid, and hydride generation atomic absorption spectrometry or hydride generation atomic

fluorescence spectrometry, for the determination of arsenic and selenium in solid mineral fuels.

NOTE The method is also applicable to the determination of the analytes by hydride generation inductively

coupled plasma atomic emission spectrometry.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 687, Solid mineral fuels — Coke — Determination of moisture in the general analysis test sample

ISO 1170, Coal and coke — Calculation of analyses to different bases

ISO 3696, Water for analytical laboratory use — Specification and test methods

ISO 5068-2, Brown coals and lignites — Determination of moisture content — Part 2: Indirect gravimetric

method for moisture in the analysis sample

ISO 5069-2, Brown coals and lignites — Principles of sampling — Part 2: Sample preparation for

determination of moisture content and for general analysis

ISO 11722, Solid mineral fuels — Hard coal — Determination of moisture in the general analysis test

sample by drying in nitrogen

ISO 13909-4, Hard coal and coke — Mechanical sampling — Part 4: Coal — Preparation of test samples

ISO 13909-6, Hard coal and coke — Mechanical sampling — Part 6: Coke — Preparation of test samples

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

4 Principle

A known mass of the sample is ignited in intimate contact with Eschka’s mixture in an oxidizing

atmosphere at 800 °C to remove the organic matter. The residue is then extracted with hydrochloric

acid and the analytes determined by hydride generation atomic absorption spectrometry or hydride

generation atomic fluorescence spectrometry.

5 Reagents

WARNING — Care must be exercised when handling reagents, many of which are toxic and

corrosive.

During the analysis, unless otherwise stated, use only reagents of recognized analytical reagent grade

and water conforming to Grade 1 of ISO 3696.

5.1 Eschka’s mixture, composed of two parts by mass of light magnesium oxide and one part by mass

of anhydrous sodium carbonate.

5.2 Hydrochloric acid (ρ 1,19 g/ml).

5.3 Nitric acid (ρ 1,42 g/ml).

5.4 Potassium iodide solution, 500 g/l. Dissolve 50 g of analytical reagent (AR) grade KI in distilled

water and adjust the volume to 100 ml (for determination of As).

5.5 Sodium borohydride solution. Weigh 1,50 g of sodium borohydride (NaBH ) and 0,4 g of sodium

hydroxide (NaOH) into a plastic bottle of 125 ml capacity and add 100 ml of distilled water. Prepare

freshly on the day of use. Alternatively, commercially available pressed pellets of sodium borohydride

may be used.

5.6 Arsenic stock solution (100 mg/l). Dissolve 0,132 0 g ± 0,000 5 g of arsenic trioxide (As O

2 3

of 99,9 % purity, dried at 110 °C for 1 h) in 25 ml of 20 % KOH solution. Add approximately 50 ml of

water and 20 ml of hydrochloric acid (5.2). Adjust the volume with water to 1 litre in a volumetric flask.

Alternatively, dissolve 0,416 5 g ± 0,000 5 g of sodium arsenate (Na HAsO .7H O) in approximately

2 4 2

100 ml of water. Add 10 ml of hydrochloric acid (5.2) and adjust the volume with water to 1 l in a

volumetric flask.

NOTE A commercially available certified stock solution may be used as an alternative.

5.7 Dilute arsenic stock solution (1 mg/l). Transfer 5 ml of arsenic stock solution to a 500 ml

volumetric flask. Add approximately 100 ml of water and 5 ml of hydrochloric acid (5.2). Adjust to volume

with water.

5.8 Arsenic working standard (50 μg/l). Transfer 5 ml of dilute arsenic stock solution (5.7) to a

100 ml volumetric flask. Add approximately 20 ml of water and of 1 ml hydrochloric acid (5.2). Adjust to

volume with water. Prepare freshly on the day of measurement.

5.9 Selenium stock solution (100 mg/l). Dissolve 0,100 0 ± 0,000 5 g of elemental selenium (of 99,9 %

purity) in a minimum of nitric acid in a beaker. Evaporate to dryness. Add 2 ml of water and evaporate to

dryness; repeat this procedure twice. Add 10 ml of water to the residue and 10 ml of hydrochloric acid

(5.2). Dissolve the residue by heating. Allow the solution to cool and adjust the volume with water to 1 l

in a volumetric flask. Alternatively, dissolve 0,467 4 g ± 0,000 5 g of sodium selenate (Na SeO .10H O) in

2 4 2

approximately 100 ml of water. Add 10 ml of hydrochloric acid (5.2) and adjust the volume with water to

1 l in a volumetric flask.

NOTE A commercially available certified stock solution may be used as an alternative.

5.10 Dilute selenium stock solution (1 mg/l). Transfer 5 ml of selenium stock solution (5.9) to a

500 ml volumetric flask. Add approximately 100 ml of water and 5 ml of hydrochloric acid (5.2). Adjust

to volume with water.

2 © ISO 2016 – All rights reserved

5.11 Selenium working standard (50 μg/l). Transfer 5 ml of dilute selenium stock solution (5.10) to a

100 ml volumetric flask. Add approximately 20 ml of water and 1 ml of hydrochloric acid (5.2). Adjust to

volume with water. Prepare freshly on the day of measurement.

6 Apparatus

6.1 Balance, capable of weighing to the nearest 0,1 mg.

6.2 Crucible, a shallow silica crucible of capacity approximately 25 ml.

6.3 Silica plate, 6 mm thick, having an easy sliding fit in the muffle furnace.

6.4 Muffle furnace, capable of obtaining 800 °C over 2 h from ambient temperature.

6.5 Plastic bottle, wide necked, of capacity 60 ml (autoclavable) with screw-threaded lid.

6.6 Atomic absorption spectrometer or atomic fluorescence spectrometer, equipped with a

hydride generation apparatus.

To minimize potential contamination, clean all laboratory ware with dilute HCl (1 + 10).

7 Preparation of the test sample

The test sample is the general analysis sample, prepared in accordance with ISO

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.