ISO 10961:2010

(Main)Gas cylinders — Cylinder bundles — Design, manufacture, testing and inspection

Gas cylinders — Cylinder bundles — Design, manufacture, testing and inspection

ISO 10961:2010 specifies the requirements for the design, construction, testing and initial inspection of a transportable cylinder bundle. It is applicable to cylinder bundles containing compressed gas, liquefied gas and mixtures thereof. It is also applicable to cylinder bundles for acetylene. It does not apply to packages in which cylinders are manifolded together in a support frame which is designed to be fixed permanently to a road vehicle, to a railway wagon or to the ground as a customer storage vessel. It does not apply to cylinder bundles which are designed for use in extreme environmental or operational conditions when additional and extraordinary requirements are imposed to maintain safety standards, reliability and performance, e.g. offshore cylinder bundles. Specific requirements for acetylene cylinder bundles containing acetylene in a solvent are included in an annex. ISO 10961 does not, however, cover acetylene cylinder bundles with solvent-free acetylene cylinders. ISO 10961 is intended primarily for industrial gases other than liquefied petroleum gases (LPGs), but it may also be used for LPGs.

Bouteilles à gaz — Cadres de bouteilles — Conception, fabrication, essais et inspection

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10961

First edition

2010-01-15

Gas cylinders — Cylinder bundles —

Design, manufacture, testing and

inspection

Bouteilles à gaz — Cadres de bouteilles — Conception, fabrication,

essais et inspection

Reference number

ISO 10961:2010(E)

©

ISO 2010

---------------------- Page: 1 ----------------------

ISO 10961:2010(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2010

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2010 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 10961:2010(E)

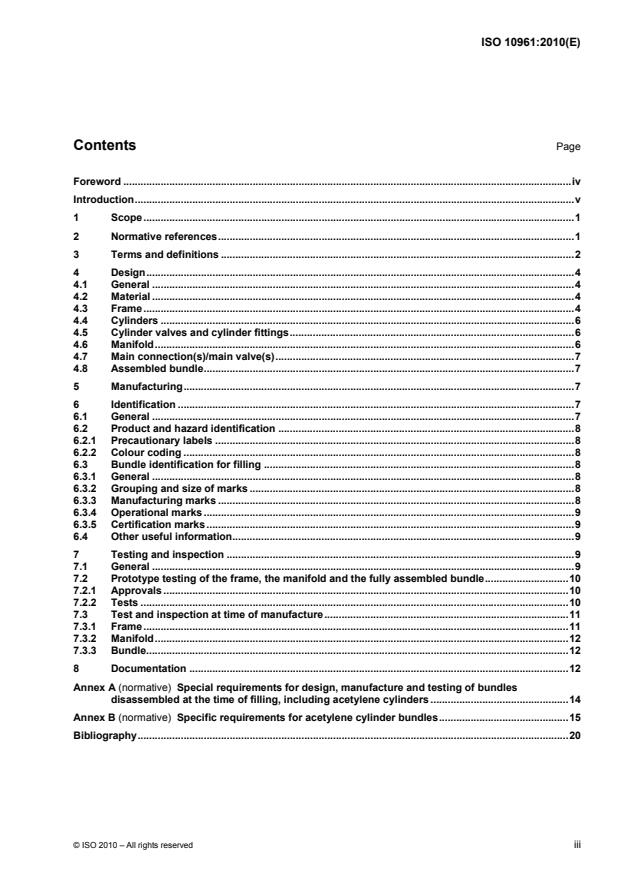

Contents Page

Foreword .iv

Introduction.v

1 Scope.1

2 Normative references.1

3 Terms and definitions .2

4 Design.4

4.1 General .4

4.2 Material .4

4.3 Frame.4

4.4 Cylinders .6

4.5 Cylinder valves and cylinder fittings.6

4.6 Manifold.6

4.7 Main connection(s)/main valve(s).7

4.8 Assembled bundle.7

5 Manufacturing.7

6 Identification .7

6.1 General .7

6.2 Product and hazard identification .8

6.2.1 Precautionary labels .8

6.2.2 Colour coding .8

6.3 Bundle identification for filling .8

6.3.1 General .8

6.3.2 Grouping and size of marks .8

6.3.3 Manufacturing marks .8

6.3.4 Operational marks .9

6.3.5 Certification marks .9

6.4 Other useful information.9

7 Testing and inspection .9

7.1 General .9

7.2 Prototype testing of the frame, the manifold and the fully assembled bundle.10

7.2.1 Approvals .10

7.2.2 Tests .10

7.3 Test and inspection at time of manufacture.11

7.3.1 Frame.11

7.3.2 Manifold.12

7.3.3 Bundle.12

8 Documentation .12

Annex A (normative) Special requirements for design, manufacture and testing of bundles

disassembled at the time of filling, including acetylene cylinders .14

Annex B (normative) Specific requirements for acetylene cylinder bundles.15

Bibliography.20

© ISO 2010 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 10961:2010(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 10961 was prepared by Technical Committee ISO/TC 58, Gas cylinders, Subcommittee SC 4,

Operational requirements for gas cylinders.

iv © ISO 2010 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 10961:2010(E)

Introduction

For some applications, the contents of an individual gas cylinder may not satisfy the gas demand, in which

case assemblies of cylinders can be used to supply larger volumes of gas in a single unit. The single unit,

which contains a number of cylinders, is known as a cylinder bundle.

A cylinder bundle is a portable assembly which is designed to be routinely lifted and which consists of a frame

and two or more cylinders connected to a manifold by cylinder valves or fittings so that the cylinders can be

filled, transported and emptied without disassembly.

A cylinder bundle can be subjected to rough handling in the course of normal operations.

There are types of gas cylinder assembly which use cylinder bundle components, but which are designed to

be disassembled at each filling to enable the cylinders to be filled individually. Although these assemblies do

not conform to the basic definition of a cylinder bundle, they are commonly referred to as bundles. Their

special requirements are included in Annex A.

Acetylene cylinder bundles are often filled without disassembly. However, in order to confirm their solvent

content, they are disassembled after a defined number of fillings.

In International Standards, weight is equivalent to a force, expressed in newtons. However, in common

parlance (as used in terms defined in this International Standard), the word “weight” continues to be used to

mean “mass”, even though this practice is deprecated (see ISO 80000-4).

© ISO 2010 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO 10961:2010(E)

Gas cylinders — Cylinder bundles — Design, manufacture,

testing and inspection

1 Scope

This International Standard specifies the requirements for the design, construction, testing and initial

inspection of a transportable cylinder bundle. It is applicable to cylinder bundles containing compressed gas,

liquefied gas and mixtures thereof. It is also applicable to cylinder bundles for acetylene.

This International Standard does not apply to packages in which cylinders are manifolded together in a

support frame which is designed to be fixed permanently to a road vehicle, to a railway wagon or to the

ground as a customer storage vessel. It does not apply to cylinder bundles which are designed for use in

extreme environmental or operational conditions when additional and extraordinary requirements are imposed

to maintain safety standards, reliability and performance, e.g. offshore cylinder bundles.

Some special applications (e.g. electronics) require an alternative design approach. With the agreement of the

inspection body, the manifold and its piping components may be designed and tested at a pressure which is

appropriate to the service conditions.

Specific requirements for acetylene cylinder bundles containing acetylene in a solvent are included in Annex B.

This International Standard does not, however, cover acetylene cylinder bundles with solvent-free acetylene

cylinders.

This International Standard is intended primarily for industrial gases other than liquefied petroleum gases

(LPGs), but it may also be used for LPGs.

Unless otherwise stated, individual cylinders within cylinder bundles will have to conform to applicable

standards for single cylinders. This International Standard specifies the additional requirements that apply

when individual cylinders are assembled into a bundle.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 7225, Gas cylinders — Precautionary labels

ISO 10297, Transportable gas cylinders — Cylinder valves — Specification and type testing

ISO 13769, Gas cylinders — Stamp marking

ISO 14113, Gas welding equipment — Rubber and plastics hose and hose assemblies for use with industrial

gases up to 450 bar (45 MPa)

© ISO 2010 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO 10961:2010(E)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

cylinder bundle

bundle

portable assembly which consists of a frame and two or more cylinders, each of a capacity up to 150 litres and

with a combined capacity of not more than 3 000 litres, or 1 000 litres in the case of toxic gases, connected to

a manifold by cylinder valves or fittings such that the cylinders are filled, transported and emptied without

disassembly

3.2

frame

structural and non-structural members of a bundle which combine all other components together, whilst

providing protection for the bundle's cylinders, valves and manifold and which enable the bundle to be

transported

3.3

cylinder valve

valve which is fitted into a cylinder and to which a manifold is connected in a bundle

3.4

cylinder fitting

component, with no gas shut-off capability, which serves as a method for connecting a bundle's manifold to its

individual cylinders when cylinder valves are not fitted to the cylinders

3.5

manifold

piping system for connecting cylinder valves or cylinder fittings to the main valve(s) or main connection(s)

3.6

main valve

valve which is fitted to the manifold and which is used for the isolation of the bundle

3.7

main connection

means of making a gas connection to a bundle

3.8

tare weight

weight of the bundle when empty of gas product

3.9

maximum gross weight

sum of the tare weight of the bundle and the maximum permissible filling weight

3.10

compressed gas

gas which, when packaged under pressure, is entirely gaseous at −50 °C (including all gases with a critical

temperature u −50 °C)

[GHS]

2 © ISO 2010 – All rights reserved

---------------------- Page: 7 ----------------------

ISO 10961:2010(E)

3.11

liquefied gas

gas which, when packaged under pressure, is partially liquid at temperatures above −50 °C

[GHS]

NOTE A distinction is made between:

a) high-pressure liquefied gas: a gas with a critical temperature between −50 °C and +65 °C, and

b) low-pressure liquefied gas: a gas with a critical temperature above +65 °C.

3.12

proof test pressure

hydraulic pressure which demonstrates the structural integrity of the manifold

3.13

burst pressure

〈gas cylinder bundles〉 highest pressure reached in a cylinder or the bundle manifold during a burst test

NOTE Adapted from ISO 10286.

3.14

working pressure

settled pressure for a compressed and dissolved gas at a uniform temperature of 288 K (15 °C) for a full

bundle

3.15

bundle test pressure

test pressure of the cylinder and manifold assembled together

3.16

maximum permissible filling weight

product of the minimum guaranteed water capacity of the cylinders of the bundle and the filling ratio of the gas

contained

3.17

very toxic gas

gas with an LC of less than or equal to 200 ppm (V/V), where the LC value corresponds to one hour of

50 50

exposure to gas and ppm (V/V) indicates parts per million, by volume

NOTE Adapted from ISO 10298.

3.18

toxic gas

gas with an LC of more than 200 ppm but less than or equal to 5 000 ppm, where the LC value

50 50

corresponds to one hour of exposure to gas and ppm (V/V) indicates parts per million, by volume

NOTE Adapted from ISO 10298.

3.19

filling pressure

pressure to which a bundle is filled at the time of filling

3.20

bundle manufacturer

entity that assembles the various components of the bundle into its final configuration

© ISO 2010 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO 10961:2010(E)

3.21

inspection body

independent inspection and testing body approved by the competent authority

[UN Model Regulations]

3.22

competent authority

any national body or authority designated or otherwise recognized as such, having jurisdiction for the transport

of dangerous goods and the approval of gas cylinders

NOTE Adapted from UN Model Regulations.

4 Design

4.1 General

The design of the bundle shall take into consideration its ease of assembly, inspection and operation.

All pressurized components shall, as a minimum requirement, be designed to operate safely in the

temperature range −20 °C to +65 °C.

Where service temperatures outside this range are required, the bundle design shall include additional

requirements (e.g. specific sealing material). Bundles that are filled by weight shall not feature component

parts which are de-mountable without the use of tools, with the exception of the main valve outlet protection

cap.

4.2 Material

Materials for cylinders, valves and all parts which are in contact with the intended gas shall be selected in

accordance with the relevant International Standards on compatibility (e.g. ISO 11114-1 and ISO 11114-2).

4.3 Frame

4.3.1 The frame shall retain securely all the components of the bundle and shall protect them from damage

which might cause leaks. Such damage can be caused by vibration, impact loads or handling loads which can

be expected in normal operation. The method of cylinder restraint shall minimize any vertical or horizontal

movement or rotation of the cylinder. All cylinder displacement which would impose undue strain on the

manifold (see 7.2.2.2) shall be prevented. The total assembly shall be capable of withstanding rough handling,

including being dropped or toppled.

Additionally, no leakage of gas shall be caused during the lifting of the bundle (see 4.3.2).

4.3.2 The frame shall include features designed for the handling and transportation of the bundle. Bundles

can typically be lifted by fork-lift, lift-jack trolley or overhead crane. If the bundle is designed to be lifted by an

overhead crane, lifting eyes shall be provided on the frame. Different designs with one or more lifting eyes are

permitted.

NOTE National regulations might be applicable when lifting eyes are used.

In all cases, lifting eyes shall be designed to withstand a design load of 2 × maximum gross weight. Bundles

with more than one lifting eye shall be designed such that a minimum sling leg angle α of 45° to the horizontal

can be achieved during lifting using the lifting eyes (see Figure 1).

4 © ISO 2010 – All rights reserved

---------------------- Page: 9 ----------------------

ISO 10961:2010(E)

Key

1 lifting eye

2 gas cylinder bundle

α sling leg angle

Figure 1 — Minimum sling leg angle

Where four lifting eyes are used, their design shall be such that they are strong enough to allow the bundle to

be lifted by only two.

Where two or four lifting eyes are used, diametrically opposite lifting eyes shall be aligned with each other to

allow correct lifting using shackle pins.

Lifting equipment shall be designed so that it does not interfere with any pressurized component, e.g. the

manifold.

When a bundle is designed to be moved by fork-lift truck, it shall feature two fork apertures on each side from

which it is to be lifted. The fork apertures shall be positioned symmetrically about the centre of gravity and

their size shall be appropriate to the forks used to move the bundle. The fork apertures shall be designed such

that the bundle cannot accidentally disengage from the forks.

4.3.3 Frame structural members shall be designed for a vertical load of 2 × the maximum gross weight of

the bundle. Design stress levels shall not exceed 0,9 × the yield strength of the material.

4.3.4 The frame design shall ensure that there are no protrusions from the exterior frame structure which

could cause hazards.

4.3.5 There shall be no features in which water and debris can collect to increase the tare weight of bundles

filled by weight, or cause corrosion.

4.3.6 The floor of the bundle frame shall not buckle under normal operational conditions and shall facilitate

the drainage of water and debris from around the base of the cylinders.

4.3.7 The design shall ensure stability under normal operating conditions. The centre of gravity shall stay

within the footprint of the bundle when rotated to an angle of not more than 12° in both directions.

4.3.8 If the frame design includes any movable doors or covers, these shall be capable of being secured in

position with latches, which shall not be capable of being dislodged by operational impact loads.

© ISO 2010 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO 10961:2010(E)

4.3.9 Access shall be maintained to all valves which need to be operated in normal service or in an

emergency.

4.4 Cylinders

Cylinders within a bundle shall be suitable for the intended gas service. They shall all have the same test

pressure, shall be of similar size and shall conform to the appropriate standards covering individual cylinders.

4.5 Cylinder valves and cylinder fittings

4.5.1 Either cylinder valves or a cylinder fitting shall be fitted into the inlet threads of the cylinders within the

bundle. The items selected will depend on the gas service within the bundle and the operational requirements

(e.g. for gases not covered under 4.5.4, cylinder valves are not required).

For acetylene, see Annex B.

4.5.2 Cylinder valves and cylinder fittings shall be compatible with the gas and pressure for which the

bundle is intended.

4.5.3 Cylinder valves and cylinder fittings shall be compatible with the inlet threads of the cylinders.

4.5.4 A cylinder valve shall be used when the bundle contains a very toxic gas or gas mixture, a pyrophoric

gas or a flammable mixture with more than 1 % of pyrophoric components.

4.5.5 A cylinder valve shall not be used for non-toxic liquefied gases.

4.5.6 If the gas is a very toxic liquefied or toxic liquefied gas, the individual cylinders shall be removed from

the frame for filling in accordance with Annex A to ensure that individual cylinders are not overfilled.

4.5.7 When cylinder valves are fitted, their outlet connections shall be of a form appropriate to the product

within the bundle, or of a form which cannot lead to the incorrect connection to equipment designed for other

products.

4.5.8 For non-toxic, non-flammable gases (e.g. CO ) when the use of a safety relief device is required by

2

regulation, the safety relief device shall be designed to avoid cylinder burst.

4.6 Manifold

4.6.1 The manifold and its material shall be compatible with the gas and the pressure for which the bundle

is intended.

For acetylene, see Annex B.

4.6.2 For compressed and liquefied gases, the manifold shall be designed in such a way that the burst

pressure shall be greater than or equal to 1,5 × the test pressure of the cylinders in the bundle.

4.6.3 The proof test pressure of the manifold shall not be less than the test pressure of the cylinders in the

bundle.

With the agreement of the inspection body, the hydraulic pressure test may be replaced by a test using a gas,

provided such an operation does not entail any danger.

4.6.4 No part of the manifold shall bear against other components in the bundle except at cylinder

valve/fitting interfaces or at defined attachment points to the frame. Contact between dissimilar metals which

could result in damage by galvanic action shall be avoided.

4.6.5 Piping shall be designed, constructed and installed so as to avoid damage due to expansion and

contraction, mechanical shock and vibration. Where the manifold is made of metal, the necessary flexibility

6 © ISO 2010 – All rights reserved

---------------------- Page: 11 ----------------------

ISO 10961:2010(E)

shall be achieved by the use of bends or coils. Flexible hoses or non-metallic pipework should only be used as

part of the fixed pipework on the bundle after trials have proved their acceptability, and the length of such

hoses and pipework shall be kept to a minimum.

4.7 Main connection(s)/main valve(s)

The main connection(s) and main valve(s) shall be compatible with the gas and the pressure for which the

bundle is intended and shall be protected by the frame (e.g. the main connection and main valve shall not

protrude).

4.8 Assembled bundle

The assembled bundle shall be designed so that it withstands the following statically applied loads:

⎯ 2 × the maximum gross weight in all horizontal directions and vertically downwards;

⎯ 1 × the maximum gross weight in the vertical direction upwards.

NOTE This is checked by carrying out the drop tests described in 7.2.2.3.4.

5 Manufacturing

A bundle shall be manufactured in accordance with the design criteria listed in Clause 4.

For this condition to be satisfied, the bundle manufacturer shall:

⎯ use welding procedures in accordance with standards recognized in the country of manufacture,

e.g. ISO 15607;

⎯ use approved welders in accordance with standards recognized in the country of manufacture,

e.g. ISO 9606-1;

⎯ use brazing procedures in accordance with standards recognized in the country of manufacture,

e.g. EN 13134;

⎯ use approved brazers in accordance with standards recognized in the country of manufacture,

e.g. EN 13133.

NOTE The bundle manufacturer is not necessarily identical with the manufacturer(s) of the components.

6 Identification

6.1 General

The requirements for labelling and colour coding as defined in ISO 7225 and ISO 32 do not apply to the

cylinders of a bundle.

However, markings on the individual cylinders can be obscured. Therefore, certain information which must be

checked at the time of filling shall be duplicated on the outside of the bundle (see 6.3). For bundles filled by

weight with products other than acetylene, it is not required that the tare weight be marked on cylinders in

accordance with ISO 13769.

© ISO 2010 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO 10961:2010(E)

6.2 Product and hazard identification

6.2.1 Precautionary labels

Individual cylinders in bundles are not required to have labels attached. The appropriate precautionary labels

and other information in accordance with ISO 7225 shall be attached to the bundle adjacent to the main

connection. The minimum size of the side of the precautionary label shall be 100 mm and shall be in

accordance with the regulations for the transportation of dangerous goods.

6.2.2 Colour coding

The use of the cylinder colours defined in applicable standards, e.g. ISO 32, is not mandatory for cylinders

assembled into a bundle or for the bundle frame itself.

6.3 Bundle identification for filling

6.3.1 General

In addition to the information on individual cylinders in accordance with the relevant marking regulations of the

countries of use, the information specified in 6.3.3 to 6.3.5 shall be clearly identified on a corrosion-resistant

plate permanently fixed on the outside of the bundle. Where there is no conflict with such regulations, all

markings shall be in accordance with ISO 13769.

6.3.2 Grouping and size of marks

The following marks shall be placed in three groups:

⎯ manufacturing marks shall constitute the top group and shall appear consecutively in the sequence given

in 6.3.3;

⎯ the middle group (see 6.3.4) shall include the test pressure, which shall be immediately preceded by the

working pressure when the latter is required;

⎯ certification marks shall constitute the bottom group and shall appear in the sequence given in 6.3.5.

The minimum size of the marks shall be 5 mm.

For additional data for acetylene, see Annex B.

6.3.3 Manufacturing marks

These shall include the following:

⎯ The bundle manufacturer's mark as registered by the competent authority. When the country of

manufacture is not the same as the country of approval, the bundle manufacturer's mark shall be

preceded by the character(s) identifying the country of manufacture as indicated by the distinguishing

signs of motor vehicles in international traffic. The country mark and the bundle manufacturer's mark shall

be separated by a space or slash.

⎯ The serial number assigned by the bundle manufacturer.

⎯ In addition, each frame shall include a un

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.