oSIST prEN 16976:2023

(Main)Ambient air - Determination of the particle number concentration of atmospheric aerosol

Ambient air - Determination of the particle number concentration of atmospheric aerosol

This European Standard specifies a standard method for determining the particle number concentration in ambient air in a range up to about 107 cm–3 for averaging times equal to or larger than 1 min. The standard method is based on a Condensation Particle Counter (CPC) operated in the counting mode and an appropriate dilution system for concentrations exceeding the counting mode range. It also defines the performance characteristics and the minimum requirements of the instruments to be used. The lower and upper sizes considered within this document are 10 nm and a few micrometres, respectively. This document describes sampling, operation, data processing and QA/QC procedures including calibration parameters.

Außenluft - Bestimmung der Partikelanzahlkonzentration des atmosphärischen Aerosols

Dieses Dokument beschreibt ein Standardverfahren zur Bestimmung der Partikelanzahlkonzentration in Außenluft im Bereich bis etwa 107 cm−3 für Mittelungszeiten von mindestens 1 min. Das Standardverfahren basiert auf einem im Zählmodus betriebenen Kondensationspartikelzähler (en: Condensation Particle Counter, CPC) mit geeignetem Verdünnungssystem für Konzentrationen, die den Bereich des Zählmodus überschreiten. Weiterhin werden Leistungskenngrößen und Mindestanforderungen für geeignete Geräte definiert. Die in diesem Dokument betrachteten unteren und oberen Partikelgrößen sind 10 nm bzw. einige Mikrometer. Dieses Dokument beschreibt Probenahme, Betrieb des Geräts, Datenverarbeitung und QA/QC-Maßnahmen, einschließlich der Kalibrierparameter.

Air ambiant Détermination de la concentration en nombre de particules de l'aérosol atmosphérique

Le présent document décrit une méthode normalisée de détermination de la concentration en nombre de particules dans l'air ambiant sur une plage allant jusqu'à 107 cm–3 environ, pour des durées de calcul des moyennes supérieures ou égales à 1 min. La méthode normalisée repose sur l’utilisation d’un compteur de particules à noyaux de condensation (CNC) fonctionnant en mode comptage et d’un système de dilution approprié pour les concentrations en dehors de la plage du mode comptage. Il définit également les caractéristiques de performance et les exigences minimales relatives aux instruments à utiliser. Les tailles de particules minimale et maximale considérées dans le présent document sont, respectivement, de 10 nm et quelques micromètres. Le présent document décrit le prélèvement, le fonctionnement, le traitement des données et les procédures d'assurance qualité et de contrôle qualité, y compris les paramètres d'étalonnage.

Zunanji zrak - Določevanje številčne koncentracije delcev atmosferskih aerosolov

General Information

Relations

Standards Content (Sample)

SLOVENSKI STANDARD

oSIST prEN 16976:2023

01-junij-2023

Zunanji zrak - Določevanje številčne koncentracije delcev atmosferskih aerosolov

Ambient air - Determination of the particle number concentration of atmospheric aerosol

Außenluft - Bestimmung der Partikelanzahlkonzentration des atmosphärischen Aerosols

Air ambiant Détermination de la concentration en nombre de particules de l'aérosol

atmosphérique

Ta slovenski standard je istoveten z: prEN 16976

ICS:

13.040.20 Kakovost okoljskega zraka Ambient atmospheres

oSIST prEN 16976:2023 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

---------------------- Page: 1 ----------------------

oSIST prEN 16976:2023

prEN 16976:2023 (E)

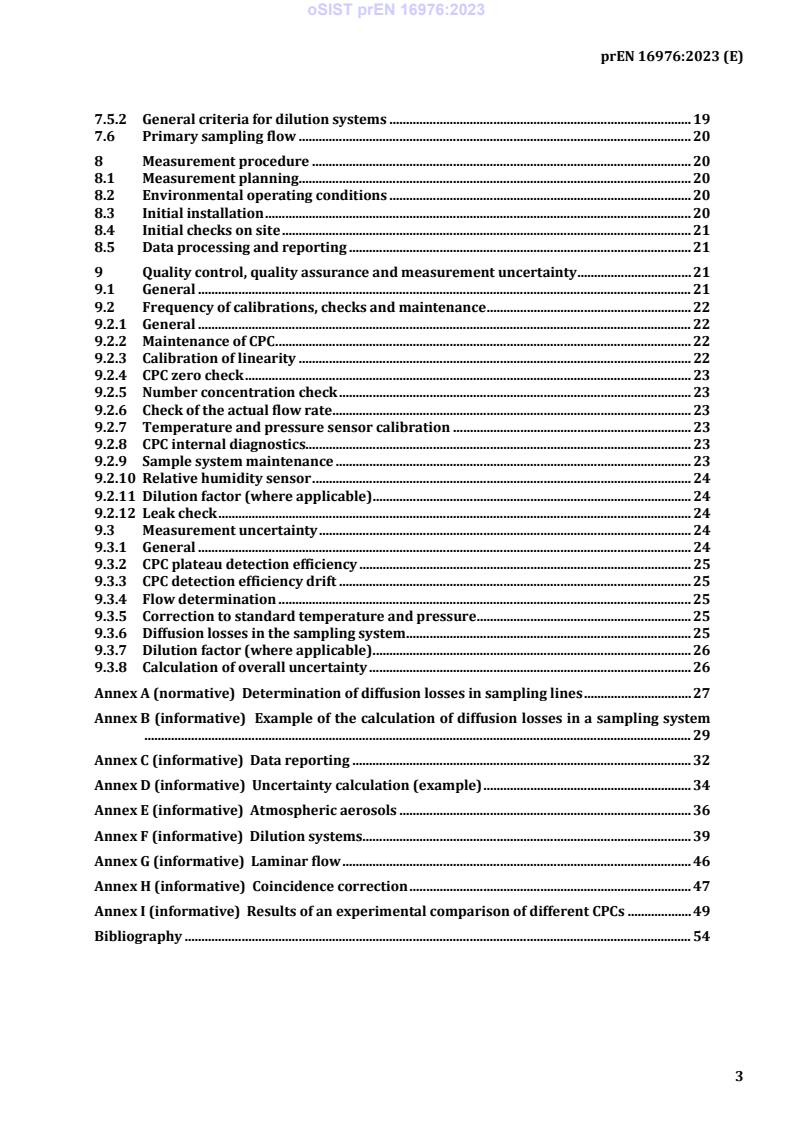

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

3.1 Aerosol properties. 6

3.2 Instrument performance . 7

3.3 Flow rates . 7

4 Atmospheric aerosol . 8

5 Description of the method . 8

5.1 Sampling and conditioning . 8

5.1.1 Sampling . 8

5.1.2 Drying . 10

5.1.3 Dilution . 10

5.2 Determination of the number concentration with a CPC . 10

5.2.1 Condensation growth . 10

5.2.2 Optical detection . 12

6 CPC performance criteria and test procedures . 13

6.1 General. 13

6.2 General requirements for the CPC . 13

6.3 Test conditions . 14

6.4 Performance characteristics and criteria . 14

6.5 Test procedures . 15

6.5.1 Calibrated flow rate . 15

6.5.2 Number concentration measurement range . 15

6.5.3 Number concentration detection limit . 15

6.5.4 Calibration factor . 15

6.5.5 Instrument-specific assessment of linearity and slope of response . 16

6.5.6 Detection efficiency curve at low particle size . 16

6.5.7 Upper particle size detection limit . 17

6.5.8 Zero count rate . 17

6.5.9 Response time . 17

6.5.10 Dependence of flow rate on supply voltage. 17

6.5.11 Accuracy of temperature and pressure sensor calibration . 17

6.5.12 Effect of failure of mains voltage . 17

7 Performance criteria and test procedures for the sampling and conditioning system

. 18

7.1 General requirements . 18

7.2 Performance characteristics and criteria . 18

7.3 Diffusion losses . 18

7.4 Relative humidity. 19

7.5 Dilution . 19

7.5.1 Dilution factor . 19

2

---------------------- Page: 2 ----------------------

oSIST prEN 16976:2023

prEN 16976:2023 (E)

7.5.2 General criteria for dilution systems . 19

7.6 Primary sampling flow . 20

8 Measurement procedure . 20

8.1 Measurement planning . 20

8.2 Environmental operating conditions . 20

8.3 Initial installation . 20

8.4 Initial checks on site . 21

8.5 Data processing and reporting . 21

9 Quality control, quality assurance and measurement uncertainty . 21

9.1 General . 21

9.2 Frequency of calibrations, checks and maintenance . 22

9.2.1 General . 22

9.2.2 Maintenance of CPC . 22

9.2.3 Calibration of linearity . 22

9.2.4 CPC zero check . 23

9.2.5 Number concentration check . 23

9.2.6 Check of the actual flow rate . 23

9.2.7 Temperature and pressure sensor calibration . 23

9.2.8 CPC internal diagnostics. 23

9.2.9 Sample system maintenance . 23

9.2.10 Relative humidity sensor . 24

9.2.11 Dilution factor (where applicable) . 24

9.2.12 Leak check . 24

9.3 Measurement uncertainty . 24

9.3.1 General . 24

9.3.2 CPC plateau detection efficiency . 25

9.3.3 CPC detection efficiency drift . 25

9.3.4 Flow determination . 25

9.3.5 Correction to standard temperature and pressure . 25

9.3.6 Diffusion losses in the sampling system . 25

9.3.7 Dilution factor (where applicable) . 26

9.3.8 Calculation of overall uncertainty . 26

Annex A (normative) Determination of diffusion losses in sampling lines . 27

Annex B (informative) Example of the calculation of diffusion losses in a sampling system

. 29

Annex C (informative) Data reporting . 32

Annex D (informative) Uncertainty calculation (example) . 34

Annex E (informative) Atmospheric aerosols . 36

Annex F (informative) Dilution systems. 39

Annex G (informative) Laminar flow . 46

Annex H (informative) Coincidence correction . 47

Annex I (informative) Results of an experimental comparison of different CPCs . 49

Bibliography . 54

3

---------------------- Page: 3 ----------------------

oSIST prEN 16976:2023

prEN 16976:2023 (E)

European foreword

This document (prEN 16976:2023) has been prepared by Technical Committee CEN/TC 264 “Air

quality”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

This document will supersede CEN/TS 16976:2016.

In comparison with the previous edition, the following technical modifications have been made:

— 1: The lower limit of the measured particle size range is set to be 10 nm and thus identical to MPSS

(Mobility Particle Size Spectrometers) measurements (see CEN/TS 17434). In air quality monitoring

networks where MPSS will be used for determining the particle size distribution a CPC may be used

for QA purposes for the MPSS data.

— 3: The parameter “calibration factor” was introduced and defined. The terms and definitions for the

various flow rates were revised and rearranged.

— 5.1.2: Aerosol diffusion dryer based on silica is excluded, because diffusion losses are too high with

this type of dryer.

— 6.2: Coincidence correction shall be applied. No other correction factors shall be applied unless a

correction for the analysed flow rate is necessary.

— 6.3: All tests are carried out only at one temperature (between 20 °C and 30 °C).

— 6.4: Table 1: Criteria for several performance characteristics were changed, the performance

characteristic “calibration factor” was included.

— 6.5: Some of the test procedures have been revised, a test procedure for the calibration factor was

added.

— 7.2: Two dilution factors are necessary: one for reducing the concentration, an additional one for

drying.

— 7.5: The method of using tracer gas for the determination of the dilution factor of a dilution system

has been removed. General criteria for dilution systems were added.

— 9.2: The test “Determination of low size cut-off” was removed, the “Number concentration check”

was substantially revised.

— Annex E: The ambient particle number concentration values were updated.

— Annex F: An example of the design of a dilution system and an example for the calculation of the

uncertainty of the dilution factor have been added.

— Annex H: The new Annex “Coincidence correction” was added.

— Annex I: The new Annex “Results of an experimental comparison of different CPCs” was added.

4

---------------------- Page: 4 ----------------------

oSIST prEN 16976:2023

prEN 16976:2023 (E)

Introduction

There is a growing awareness of the significance of aerosol particles with diameters of D < 1 µm for

human health as well as for their climatic impact. To assess air quality, it appears necessary to

supplement gravimetrically determined mass concentrations such as PM2,5 and PM10 with a

measurement of the particle number concentration. Since ultrafine particles with diameters of D < 0,1 µm

make an almost insignificant contribution to the mass of atmospheric aerosol particles, they can best be

detected with counting measuring methods of sufficient sensitivity.

As particle measurement instrumentation allows determining either the particle number concentration

or the particle number size distribution two documents are established:

— one dealing with the determination of the single parameter number concentration (a measure of

“total” number concentration, this document)

— one dealing with the determination of number concentration within a limited number of size ranges

(CEN/TS 17434).

Clauses 5 and 6 contain general information about the method and the expected properties of the aerosol

to be measured.

Clause 7 sets out the performance criteria for CPCs. Specifically, these are the relevant performance

characteristics of CPC instruments (without any sampling system), the respective criteria that shall be

met, and a description of how the tests shall be carried out. In general, these tests are expected to be

carried out by test houses or CPC manufacturers rather than users and could form the basis for type

testing of CPCs in future.

Clause 8 sets out the performance criteria and test procedures for the sampling and conditioning system

(e.g. dilution). These may be applied by manufacturers of sampling systems, test houses or users

(network operators).

Clause 9 sets out requirements for the installation, initial checks and calibrations, and operation of a CPC

and sampling system at a monitoring site, including routine maintenance, data processing (including use

of QA/QC data) and reporting. In general, these will be the responsibility of users (network operators),

though calibrations requiring test aerosols shall only be carried out by suitably qualified laboratories.

Clause 10 sets out Quality Assurance and Quality Control procedures, i.e. the ongoing checks and

calibrations that are required on the CPC and sampling system during operation at a monitoring site. It is

expected that these will be the responsibility of users (network operators), though calibrations requiring

test aerosols shall only be carried out by suitably qualified laboratories. The main sources of

measurement uncertainty are described.

5

---------------------- Page: 5 ----------------------

oSIST prEN 16976:2023

prEN 16976:2023 (E)

1 Scope

This document describes a standard method for determining the particle number concentration in

7 –3

ambient air in a range up to about 10 cm for averaging times equal to or larger than 1 min. The standard

method is based on a Condensation Particle Counter (CPC) operated in the counting mode and an

appropriate dilution system for concentrations exceeding the counting mode range. It also defines the

performance characteristics and the minimum requirements of the instruments to be used. The lower

and upper sizes considered within this document are 10 nm and a few micrometres, respectively. This

document describes sampling, operation, data processing and QA/QC procedures including calibration

parameters.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 27891:2015, Aerosol particle number concentration — Calibration of condensation particle counters

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1 Aerosol properties

3.1.1

particle

small piece of matter with defined physical boundary

Note 1 to entry: The phase of a particle can be solid, liquid, or between solid and liquid and a mixture of any of the

phases.

[SOURCE: ISO 27891:2015, modified]

3.1.2

aerosol

multi-phase system of solid and/or liquid particles suspended in a gas, ranging in particle size from

0,001 µm to 100 µm

3.1.3

number size distribution

frequency distribution of the particle number concentration represented as a function of particle size

6

---------------------- Page: 6 ----------------------

oSIST prEN 16976:2023

prEN 16976:2023 (E)

3.1.4

particle number concentration

number of particles related to the unit volume of the carrier gas

Note 1 to entry: For the exact particle number concentration indication, information on the gaseous condition

(temperature and pressure) or the reference to a standard volume indication is necessary.

[SOURCE: ISO 27891:2015]

3.2 Instrument performance

3.2.1

coincidence error

error that occurs with counting measuring methods when two or more particles are counted

simultaneously as a single particle

Note 1 to entry: Coincidence error is related to particle number concentration, flow velocity through the sensing

zone and size of sensing zone.

3.2.2

detection efficiency

ratio of the particle number concentration determined by the measuring instrument to the reference

particle number concentration of the aerosol at the instrument's inlet

Note 1 to entry: The detection efficiency depends on particle size and may depend on particle number

concentration.

3.2.3

calibration factor

model- or instrument-specific ratio between the reference FCAE reading and the CPC count rate, both

converted to particle number concentration

3.3 Flow rates

3.3.1

actual flow rate

volumetric flow rate of an individual instrument, measured at its inlet under the actual air conditions

3.3.2

nominal flow rate

volumetric flow rate which a specific CPC model is designed for and which is indicated on the instrument

specification sheet by the manufacturer

Note 1 to entry: The actual flow rate of individual instruments may differ from the nominal flow due to

manufacturing tolerances.

3.3.3

calibrated flow rate

actual flow rate at the time of calibration documented on a calibration certificate

3.3.4

analysed flow rate

volumetric flow rate which is used for instrument internal calculation of the particle number

concentration

7

---------------------- Page: 7 ----------------------

oSIST prEN 16976:2023

prEN 16976:2023 (E)

4 Atmospheric aerosol

Atmospheric aerosols are strongly dependent on their local and regional sources. Especially, the size

distribution in number and mass, as well as the size-resolved chemical composition are highly variable.

Aerosol particles are either emitted directly (primary aerosols) or formed by nucleation and

condensation from pre-cursor gases (secondary aerosol). Combustion processes lead to both primary

and secondary aerosols.

Mass-wise, the global direct emission of aerosol particles is dominated by sea salt, biological material as

well as by desert and volcanic dust. These particles are generally larger than 1 µm. Anthropogenic

emissions in this size range play a minor role on a global scale. Submicrometer natural aerosols consist

mainly of marine sulfate, biogenic organics, and wildfire carbonaceous particles. Submicrometer

anthropogenic aerosols are complex mixtures of primary and secondary particles, consisting mainly of

sulfate, nitrate, organics, and elemental carbon.

Particle number concentrations of atmospheric aerosols cover several orders of magnitude. While

remote marine or free tropospheric aerosols have number concentrations as low as tens or a few hundred

per cubic centimetre, anthropogenically influenced aerosols can contain a few thousand up to one million

particles per cubic centimetre. The number concentration of the anthropogenic aerosol over land,

especially in urban areas is dominated by particles in the size range smaller than 0,1 µm. Major sources

for high number concentrations in this size range are regional new particle formation and local

combustion processes. Average background concentrations in an urban area are several thousands of

particles per cubic centimetre.

For details see Annex E.

5 Description of the method

5.1 Sampling and conditioning

5.1.1 Sampling

The measurement of atmospheric aerosols will always necessitate sampling and the transport of the

sample to the measuring instrument. Moreover, in certain cases the sample has to be processed in terms

of temperature, relative humidity, and particle concentration in order to adapt the aerosol to the

measuring instrument's permissible operating conditions.

The information given on this issue in this document refers to stationary ambient monitoring sites. For

mobile applications (e.g. measurements from aircraft), additional considerations have to be taken into

account.

The measuring instruments shall be accommodated in a protected environment in controlled conditions

(temperature 20 °C to 30 °C).

The sampling location depends on the measurement task. If the undisturbed atmospheric aerosol is to be

measured, air intake should take place 5 m to 10 m above the ground level. Buildings, vegetation, or the

topography of the terrain may make an even higher sampling point necessary. By contrast, the

measurement of aerosols close to the source (e.g. traffic) calls for much lower sampling points (1,5 m to

4 m above the ground, see Directive 2008/50/EC [1]).

The design of the intake port should permit representative sampling regardless of the direction of the

wind for a broad range of wind velocities. However, this is not a critical condition for the small particles

measured by the CPC. Steps shall be taken to avoid soiling of the sampling lines by particles larger than

10 µm. For this purpose, a PM10 or PM2,5 inlet can be used (see Figure 1). An inlet that removes particles

in the measurement range of the CPC (e.g. a commercial PM1 inlet) shall be avoided.

8

---------------------- Page: 8 ----------------------

oSIST prEN 16976:2023

prEN 16976:2023 (E)

Key

1 PM sampling inlet

2 Primary sampling tube

3 Secondary sampling tube

Figure 1 — Basic design of the aerosol intake port

The sample should ideally be fed via a vertical primary sampling tube without bends to the measuring

instruments. Since gas measuring methods have fundamentally different requirements regarding

sampling, gas and aerosol sampling should be conducted independently of each other.

To reduce diffusion loss, it is necessary to intake aerosol with the aid of a pump at a primary flow rate

(Q ) much higher than the secondary flow rate (Q ). The CPC should sample isoaxially in the central

tot CPC

area from this volumetric flow via a secondary sampling tube that is as short as possible. Flow in the

primary sampling tube should be laminar in order to prevent additional particle loss due to turbulence.

Ideally, a Reynolds number of Re ≤ 2000 shall be aimed for (see 7.2).

The diffusion losses in the sampling system for smallest relevant particle size of 10 nm shall be less than

25 % (see 7.2).

The intake port and lines shall be made of a conductive, corrosion-resistant material with a low surface

roughness (e.g. stainless steel) and electrically earthed. This prevents chemical changes to the aerosol

and particle losses due to electrostatic effects. Flexible tubing of electrically conductive material may also

be used for small connections or short distances. The length of flexible tubing should be below 50 cm.

The inlet and the flow-splitter of the sampling system shall be checked regularly to detect obstructions,

e.g. by insects, and cleaned, if necessary.

9

---------------------- Page: 9 ----------------------

oSIST prEN 16976:2023

prEN 16976:2023 (E)

5.1.2 Drying

Aerosols with a high relative humidity (mist in extreme cases) should be dried, as the size of particles of

hygroscopic materials is strongly influenced by humidity. The requirement is to keep the relative

humidity of the primary flow at the CPC inlet lower than 40 % (see 7.2). The relative humidity at the inlet

of the CPC shall be monitored.

With respect to the temperature conditions three cases are to be distinguished:

— In case the room temperature is higher than 22 °C no aerosol dryer is needed if the ambient dew

point temperature never exceeds 10 °C.

— If the dew point temperature is between 10 °C and the room temperature, the secondary flow shall

be dried.

— In case that the dew point temperature is above the room temperature, the primary flow shall be

dried before entering the room. Additional drying of the secondary flow may be necessary.

There are two recommended methods to dry the aerosol:

— Membrane dryer; preferably used to dry the secondary sampling flow.

— Dilution with dry particle-free air (see 5.1.3); preferably used to dry the primary sampling flow. In

this case the exact dilution ratio shall be known in order to calculate the correct concentrations.

5.1.3 Dilution

Dilution is applied either to reduce the number concentration of the ambient aerosol to the limits of the

CPC's measuring range or to reduce the humidity of the ambient aerosol. In both cases the dilution step

may introduce a high uncertainty which shall be estimated and specified in the report. Where dilution is

not required this step should be avoided. The minimum requirement with respect to accuracy of the

dilution factor for both cases is given in 7.2.

Preferably the CPC selected to measure at any particular site will have a concentration range in counting

mode that covers the expected concentrations. When this is not possible the sample shall be diluted with

particle-free air.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.