ASTM A733-99

(Specification)Standard Specification for Welded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe Nipples

Standard Specification for Welded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe Nipples

SCOPE

1.1 This specification covers the requirements for welded and seamless carbon steel pipe nipples, black and zinc-coated (hot-dip galvanized), and welded and seamless austenitic stainless steel pipe nipples in standard steel pipe sizes from 1/8to 12 in. inclusive, in standard or special lengths.

1.1.1 Welded Carbon Steel—Pipe nipples ordered under these requirements are intended for general uses, as described by Specification A 53.

1.1.2 Seamless Carbon Steel—Pipe nipples ordered under these requirements are intended for general and special uses, as described by the applicable Specifications A 53 and A 106 ( see 4.1.1).

1.1.3 Austenitic Stainless Steel—Pipe nipples ordered under these requirements are intended for high-temperature and general corrosion service, as described by Specification A 312 (see 4.1.2).

1.1.4 The text for this specification contains notes and/or footnotes that provide explanatory material. Such notes and footnotes, excluding those in tables, do not contain any mandatory language.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 733 – 99 An American National Standard

Standard Specification for

Welded and Seamless Carbon Steel and Austenitic Stainless

Steel Pipe Nipples

This standard is issued under the fixed designation A 733; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope include the following, as required to describe the desired

material adequately.

1.1 This specification covers the requirements for welded

3.1.1 Quantity (pieces),

and seamless carbon steel pipe nipples, black and zinc-coated

3.1.2 Name of material (carbon steel or austenitic stainless

(hot-dip galvanized), and welded and seamless austenitic

steel pipe nipples) (see 4.1.1 and 4.1.2),

stainless steel pipe nipples in standard steel pipe sizes from

3.1.3 Method of pipe manufacture (butt-welded, electric-

⁄8to 12 in. inclusive, in standard or special lengths.

resistance welded, or seamless). If carbon steel-welded fur-

1.1.1 Welded Carbon Steel—Pipe nipples ordered under

nished, unless otherwise specified (see 4.1.1, Note 1).

these requirements are intended for general uses, as described

3.1.4 Type and grade (if stainless steel),

by Specification A 53.

3.1.5 Finish (carbon steel, black or galvanized),

1.1.2 Seamless Carbon Steel—Pipe nipples ordered under

3.1.6 Size (nominal and weight class or schedule number as

these requirements are intended for general and special uses, as

shown in Table 1, or outside diameter and nominal wall),

described by the applicable Specifications A 53 and A 106 ( see

3.1.7 Length (standard or special, see 4.3),

4.1.1).

3.1.8 Specification number,

1.1.3 Austenitic Stainless Steel—Pipe nipples ordered under

3.1.9 Certification of compliance, if required, and

these requirements are intended for high-temperature and

3.1.10 Special requirements or exceptions to this specifica-

general corrosion service, as described by Specification A 312

tion.

(see 4.1.2).

3.2 In addition, when material is purchased for agencies of

2. Referenced Documents

the U.S. Government, it shall conform to the Supplementary

Requirements as defined herein when specified in the contract

2.1 ASTM Standards:

or purchase order.

A 53 Specification for Pipe, Steel, Black and Hot-Dipped,

Zinc-Coated, Welded and Seamless

4. Requirements

A 106 Specification for Seamless Carbon Steel Pipe for

4.1 Material and Weight—Pipe nipples covered by this

High-Temperature Service

specification shall be made from new, pressure-tested pipe

A 312 Specification for Seamless and Welded Austenitic

2 conforming to the requirements specified in 4.1.1 and 4.1.2.

Stainless Steel Pipes

4.1.1 Carbon Steel—Carbon steel pipe nipples shall be in

2.2 American National Standards Institute Standards:

accordance with the following:

B 1.20.1 Pipe Threads, General Purpose

Method of Pipe Manufacture Specification

B 36.10 Standard for Welded and Seamless Wrought Steel

Welded (Note 1) A 53

Pipe

Seamless (Note 2) A 53

B 36.19 Standard for Stainless Steel Pipe

A 106

3. Ordering Information

NOTE 1—Unless otherwise specified, furnace butt-welded nipples shall

3.1 Orders for material under this specification should be furnished in sizes 4 in. and under for standard and extra strong pipe,

and 2 ⁄2 in. and under for schedule 160 and XXS pipe. Welded nipples in

sizes larger than that indicated for butt welded shall be electric welded.

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

NOTE 2—Material used for a given size may vary with the nipple

Stainless Steel, and Related Alloys, and is the direct responsibility of Subcommittee

manufacturer.

A01.09 on Steel Pipe.

4.1.2 Austenitic Stainless Steel—Austenitic stainless steel

Current edition approved March 10, 1999. Published May 1999. Originally

published as A 733 – 76. Last previous edition A 733 – 93.

pipe nipples shall be in accordance with Specification A 312.

Annual Book of ASTM Standards, Vol 01.01.

4.2 Threads—Pipe nipples shall be threaded on both ends

Available from American National Standards Institute, 11 West 42nd St., 13th

with NPT taper pipe threads conforming to the requirements of

Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

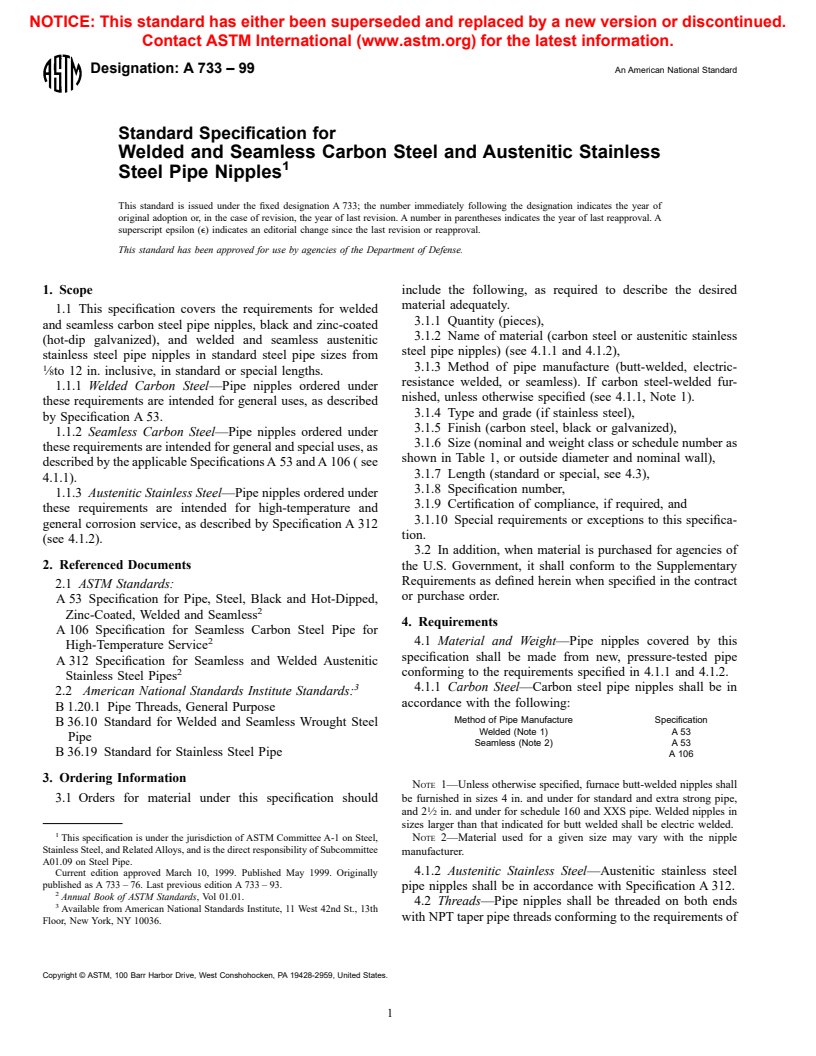

A 733

TABLE 1 Pipe Nipple Sizes According to Weight of Nominal

4.3.1 The standard lengths and sizes of nipples generally

ABCD

Pipe Sizes

available are shown in Table 2. The availability of such nipples

according to pipe size and weight is shown in Table 1.

Weight Pipe Size, in.

4.3.2 Special lengths and sizes of nipples may be specified

1 1 3 1

⁄8 ⁄4 ⁄8 ⁄2 to 6 8 10 12

when required. Standard and special lengths shall conform to

E

Standard (Schedule 40) XXXXXX

the tolerance requirements of 4.3.3.

FE

Extra strong (Schedule XXXXX

4.3.3 Nipples with lengths up through 12 in. (304.8 mm)

80)

Schedule 160 . . . XXXX

long shall have a length tolerance of 6 ⁄16 in. (1.6 mm).

Double extra strong . . . XXXX

Nipples over 12 in. long shall have a tolerance of 6 ⁄8 in. (3.2

A

A comprehensive listing of standardized pipe dimensions is contained in ANSI

mm).

B 36.10 and B 36.19.

B

4.4 End Finish—The ends of the pipe nipples shall be

Butt (furnace)-welded pipe is not made in sizes larger than 4 in. (standard and

extra strong) and larger than 2 ⁄2in. (Schedule 160 and double extra strong).

chamfered on the outside at an angle of 35 6 10 ° to the central

C

Right and left nipples are generally available in standard and extra strong wall

axis. (It is the standard practice that the ⁄8-in. (3.2-mm)

pipe only.

D

Stainless steel may not be available in all sizes and weights. nominal pipe size nipples are not chamfered.) Ends shall be cut

E

12-in. standard and extra strong weight pipe do not have designated schedule

reasonably square to the central axis. All burrs on the inside

numbers.

F shall be removed.

10-in. extra strong pipe is Schedule 60, not Schedule 80.

4.5 Galvanized Nipples—Galvanized nipples ordered under

this specification shall be made from pipe coated on the inside

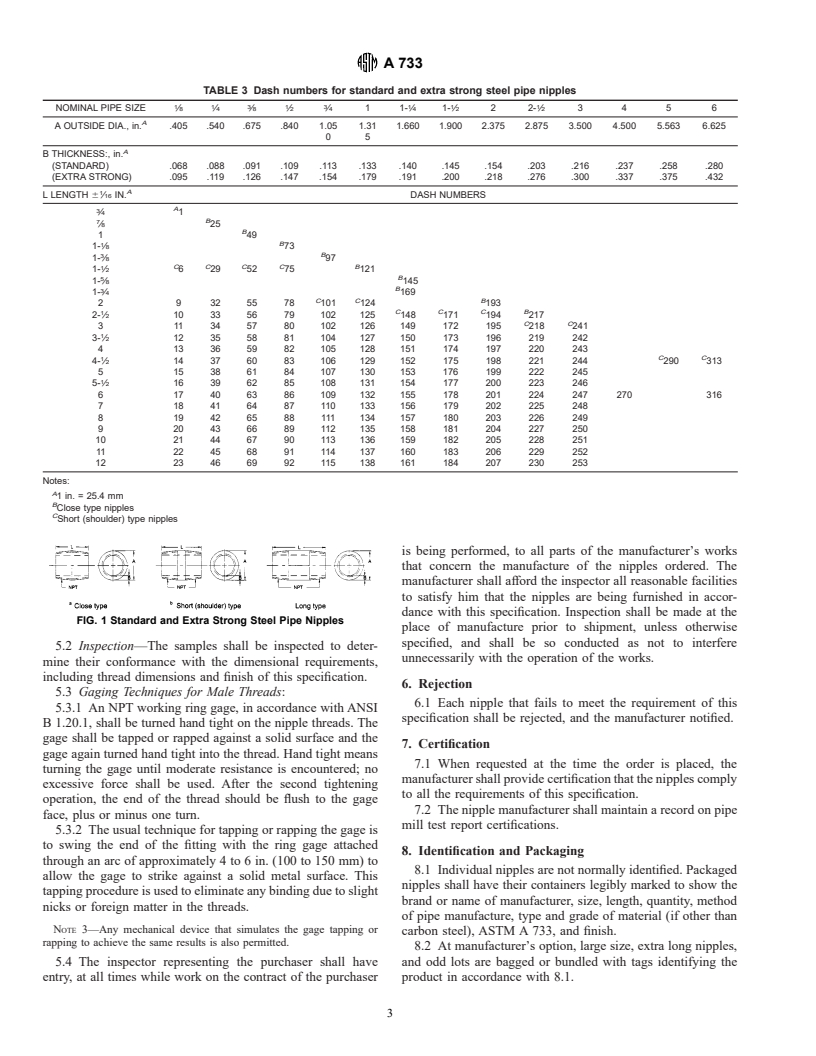

ANSI B 1.20.1, except for “close” nipples where L 4 and V are

and outside by the hot-dip process. Threads and nipple ends are

shorter, due to fewer imperfect threads. It is standard manu-

not galvanized.

facturing practice on all other nipple lengths to vary L 4 plus or

minus two threads. All other dimensions, tolerances, and

5. Sampling and Inspection

gaging practices remain the same as ANSI B 1.20.1, plus 5.3 of

this specification. 5.1 Sampling—Samples of nipples sufficient to determine

4.2.1 Threads shall be right-hand on both ends, except when their conformance with the requirements of this specification

otherwise specified. shall be taken at random for each lot of nipples of the same

4.3 Lengths: pipe size, length, and material.

TABLE 2 Pipe Nipples by Length and Pipe Size

Type of Nipple Nominal Pipe Sizes, in.

1 1 3 1 3 1 1 1 1

⁄8 ⁄4 ⁄8 ⁄2 ⁄4 11 ⁄4 1 ⁄2 22 ⁄2 33 ⁄2 4568 10 12

AB

Pipe Nipple Lengths, in.

3 7 1 3 1 5 3 1 5 3 7 1 1 7 1

Close (cl) ⁄4 ⁄8 11 ⁄8 1 ⁄8 1 ⁄2 1 ⁄8 1 ⁄4 22 ⁄2 2 ⁄8 2 ⁄4 2 ⁄8 33 ⁄8 3 ⁄2 3 ⁄8 4 ⁄2

1 1 1 1 1

1 ⁄2 1 ⁄2 1 ⁄2 1 ⁄2 1 ⁄2

1 1 1 1 1 1 1 1 1

2 ⁄2 2 ⁄2 2 ⁄2 2 ⁄2 2 ⁄2 2 ⁄2 2 ⁄2 2 ⁄2 2 ⁄2

33333333 333

1 1 1 1 1 1 1 1 1 1

3 ⁄2 3 ⁄2 3 ⁄2 3 ⁄2 3 ⁄2 3 ⁄2 3 ⁄2 33 ⁄2 3 ⁄2 3 ⁄2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.