ASTM D1015-05(2015)

(Test Method)Standard Test Method for Freezing Points of High-Purity Hydrocarbons (Withdrawn 2019)

Standard Test Method for Freezing Points of High-Purity Hydrocarbons (Withdrawn 2019)

SIGNIFICANCE AND USE

4.1 The freezing point measured by this test method, when used in conjunction with the physical constants for the hydrocarbons listed in Test Method D1016, allows the determination of the purity of the material under test. A knowledge of the purity of these hydrocarbons is often needed to help control their manufacture and to determine their suitability for use as reagent chemicals or for conversion to other chemical intermediates or finished products.

SCOPE

1.1 This test method covers a procedure for the precise measurement of the freezing points of high-purity hydrocarbons.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 5.1, 6.1 and 6.2.

Note 1: For the calculation of the molal purity of essentially pure compounds from measured freezing points and for procedures to be used for the sampling and determination of purity of certain specific compounds, see Test Method D1016.

WITHDRAWN RATIONALE

This test method covers a procedure for the precise measurement of the freezing points of high-purity hydrocarbons.

Formerly under the jurisdiction of Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants, this test method was withdrawn in December 2019 for the following reasons: (1) D1015 was developed, along with D1016, in the 1940s for the purpose of determination of purity of hydrocarbons using freezing point measurements. This method of testing hydrocarbon purity has been replaced by more precise instrument techniques such as gas chromatography in the industry. (2) The precision statements (repeatability and reproducibility) do not conform to current ASTM requirements and the precision of the method was not obtained in accordance with RR: D02-1007 or ASTM D6300. This standard, together with its companion method D1015, are being withdrawn with no replacement because it is no longer relevant as it is not used by the industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1015 − 05 (Reapproved 2015)

Standard Test Method for

1

Freezing Points of High-Purity Hydrocarbons

This standard is issued under the fixed designation D1015; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers a procedure for the precise 4.1 The freezing point measured by this test method, when

measurement of the freezing points of high-purity hydrocar- used in conjunction with the physical constants for the hydro-

bons. carbonslistedinTestMethodD1016,allowsthedetermination

of the purity of the material under test. A knowledge of the

1.2 The values stated in SI units are to be regarded as the

purity of these hydrocarbons is often needed to help control

standard. The values in parentheses are for information only.

their manufacture and to determine their suitability for use as

1.3 This standard does not purport to address all of the

reagent chemicals or for conversion to other chemical inter-

safety concerns, if any, associated with its use. It is the

mediates or finished products.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use. For specific hazard 4,5

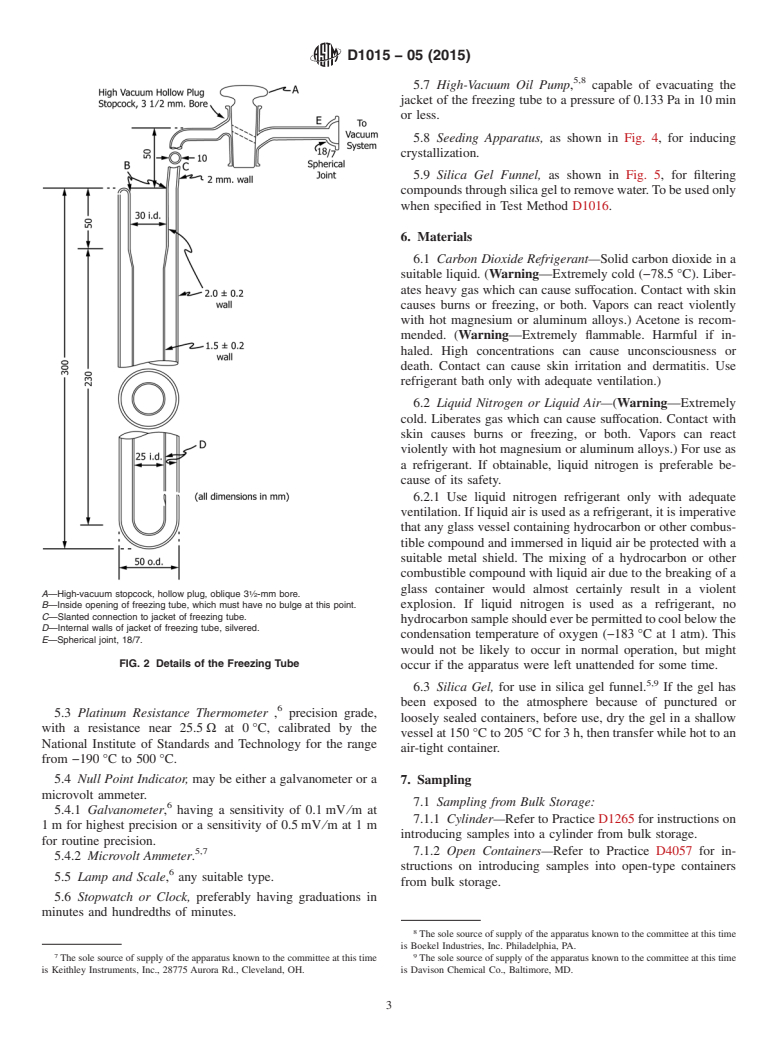

5.1 Freezing-Point Apparatus, as shown in Figs. 1-3

statements, see 5.1, 6.1 and 6.2.

comprising a freezing tube, a metal sheath for the freezing

NOTE 1—For the calculation of the molal purity of essentially pure tube, a Dewar flask for the cooling bath, a Dewar flask for the

compounds from measured freezing points and for procedures to be used

warming bath, a stirring mechanism, suitable clamps and

for the sampling and determination of purity of certain specific

holders for the parts, and the absorption tubes.The outer walls

compounds, see Test Method D1016.

of all Dewar flasks can be covered with adhesive tape to

minimize danger from glass in case of breakage. (Warning—

2. Referenced Documents

Whenusingliquidnitrogenasarefrigerant,provideameansto

2

2.1 ASTM Standards:

prevent condensation of oxygen in the space between the

D1016Test Method for Purity of Hydrocarbons from Freez-

freezing tube and the metal sheath and subsequent sealing of

ing Points

the space by ice forming on the ceramic (or glass) fiber collar.

D1265Practice for Sampling Liquefied Petroleum (LP)

Provide the metal sheath with suitable openings in the sides

Gases, Manual Method

and bottom. Failure to do this may result in breakage of the

D4057Practice for Manual Sampling of Petroleum and

freezing tube when the liquefied oxygen evaporates within the

Petroleum Products

sealed space.)

6

5.2 Resistance Bridge, Mueller type, reading from

3. Summary of Test Method

0.0001Ω to 50Ω, in steps of 0.001Ω.

3.1 The precise experimental measurement of the freezing

point is made from interpretation of time-temperature freezing

4

3

The sole source of supply of the apparatus known to the committee at this time

or melting curves.

is Reliance Glass Works, Inc., Bensenville, IL.

5

If you are aware of alternative suppliers, please provide this information to

ASTM International Headquarters. Your comments will receive careful consider-

1 1

This test method is under the jurisdiction of ASTM Committee D02 on

ation at a meeting of the responsible technical committee, which you may attend.

6

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Apparatus described in 5.2, 5.3, 5.4, and 5.5 was manufactured by the Leeds

Subcommittee D02.04.0D on Physical and Chemical Methods. andNorthrupCo.,Philadelphia,PA,underthefollowingcatalognumbers:resistance

CurrenteditionapprovedJune1,2015.PublishedJuly2015.Originallyapproved bridge, No. 8069 B; platinum resistance thermometer, No. 8163 B; galvanometer,

in 1949. Last previous edition approved in 2010 as D1015–05 (2010). DOI: highest precision, No. 2284 D; galvanometer, routine precision, No. 2430 A; lamp

10.1520/D1015-05R15. andscale,No.2100.Thegalvanometer,routineprecision,No.2430-A,andthelamp

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or and scale, No. 2100, are still available from Leeds and Northrup. The platinum

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM resistance thermometer, No. 8163-B, is no longer available from Leeds and

Standards volume information, refer to the standard’s Document Summary page on Northrup, but is available with the same part number from Yellows Springs

the ASTM website. Instrument Co., Yellow Springs, OH. The resistance bridge No. 8069-B, and the

3

For detail

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.