ASTM F665-98(2003)

(Classification)Standard Classification for Vinyl Chloride Plastics Used in Biomedical Application

Standard Classification for Vinyl Chloride Plastics Used in Biomedical Application

SIGNIFICANCE AND USE

This classification was developed to permit the addition of descriptive symbols and values for further new formulations with improved properties without complete reorganization of the standard and to facilitate the incorporation of future new test methods to keep pace with changing industry requirements.

SCOPE

1.1 This classification provides guidance to engineers and users in the selection of practical vinyl chloride plastics for medical applications and further provides a method for specifying these materials by use of a simple line call-out designation. This classification excludes vinyl chloride plastics used in long-term implants.

1.2 Use is made of a classification scheme based on the premise that the composition of vinyl chloride plastics, copolymers, fillers, plasticizers, stabilizers, and other additives in these systems can be arranged into characteristic material designations.

1.3 In all cases where the provisions of this classification system would conflict with those of the detailed specification for a particular device, the latter shall take precedence.

Note 1—For cases in which the vinyl chloride plastic may be used for purposes where the requirements are too specific to be completely described by this classification system, it is advisable for the purchaser to consult the supplier to secure adjustment of the properties to suit the actual conditions to which the device is to be subjected.

1.4 The biocompatibility of vinyl chloride plastics as a class of materials has not been established. Since many compositions and formulations fall under this class, it is essential that the fabricators/device manufacturers assure the safety and efficacy of the specific composition or formulation, in its intended application, using state-of-the-art test methods.

1.5 This classification is to assist the interface between the material supplier and the device manufacturer (fabricator) who purchases a formulated vinyl chloride plastic for a component. For those device manufacturers (fabricators) who do their own formulating, compounding, extrusion, molding, and so forth, this classification does not apply.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 665 – 98 (Reapproved 2003)

Standard Classification for

Vinyl Chloride Plastics Used in Biomedical Application

This standard is issued under the fixed designation F 665; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This classification provides guidance to engineers and 2.1 ASTM Standards:

users in the selection of practical vinyl chloride plastics for D 149 Test Method for Dielectric Breakdown Voltage and

medical applications and further provides a method for speci- Dielectric Strength of Solid Electrical Insulating Materials

fying these materials by use of a simple line call-out designa- at Commercial Power Frequencies

tion.This classification excludes vinyl chloride plastics used in D 150 Test Methods for ac Loss Characteristics and Permit-

long-term implants. tivity (Dielectric Constant) of Solid Electrical Insulating

1.2 Use is made of a classification scheme based on the Materials

premisethatthecompositionofvinylchlorideplastics,copoly- D 257 Test Methods for dc Resistance or Conductance of

mers, fillers, plasticizers, stabilizers, and other additives in Insulating Materials

these systems can be arranged into characteristic material D 543 Test Method for Resistance of Plastics to Chemical

designations. Reagents

1.3 In all cases where the provisions of this classification D 570 Test Method for Water Absorption of Plastics

system would conflict with those of the detailed specification D 792 TestMethodsforDensityandSpecificGravity(Rela-

for a particular device, the latter shall take precedence. tive Density) of Plastics by Displacement

D 882 Test Methods for Tensile Properties of Thin Plastic

NOTE 1—For cases in which the vinyl chloride plastic may be used for

Sheeting

purposes where the requirements are too specific to be completely

D 955 Test Method of Measuring Shrinkage from Mold

described by this classification system, it is advisable for the purchaser to

consultthesuppliertosecureadjustmentofthepropertiestosuittheactual Dimensions of Molded Plastics

conditions to which the device is to be subjected.

D 1898 Practice for Sampling of Plastics

D 2124 Method for Analysis of Components in Poly(Vinyl

1.4 The biocompatibility of vinyl chloride plastics as a class

Chloride) Compounds Using an Infrared Spectrophoto-

of materials has not been established. Since many composi-

metric Technique

tions and formulations fall under this class, it is essential that

D 2240 Test Method for Rubber Property—Durometer

the fabricators/device manufacturers assure the safety and

Hardness

efficacy of the specific composition or formulation, in its

F 748 PractoceforSelectingGenericBiologicalTestMeth-

intended application, using state-of-the-art test methods.

ods for Materials and Devices

1.5 This classification is to assist the interface between the

2.2 Other Standards:

material supplier and the device manufacturer (fabricator) who

Title 21 Code of Federal Regulations

purchases a formulated vinyl chloride plastic for a component.

For those device manufacturers (fabricators) who do their own

3. Terminology

formulating, compounding, extrusion, molding, and so forth,

3.1 Definitions:

this classification does not apply.

3.1.1 filler—a relatively inert material added to a plastic to

1.6 This standard does not purport to address all of the

modify its strength, permanence, working properties, or other

safety concerns, if any, associated with its use. It is the

qualities, or to lower costs.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

Annual Book of ASTM Standards, Vol 10.01.

Annual Book of ASTM Standards, Vol 08.01.

1 4

This classification is under the jurisdiction of ASTM Committee F04 on Discontinued; See 1997 Annual Book of ASTM Standards, Vol 08.01.

Medical and Surgical Materials and Devicesand is the direct responsibility of Annual Book of ASTM Standards, Vol 09.01.

Annual Book of ASTM Standards, Vol 13.01.

Subcommittee F04.11on Polymeric Materials.

Available from Superintendent of Documents, U.S. Government Printing

Current edition approved Apr. 10, 2003. Published May 2003. Originally

approved in 1980. Last previous edition approved in 1998 as F 665 – 98. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 665 – 98 (2003)

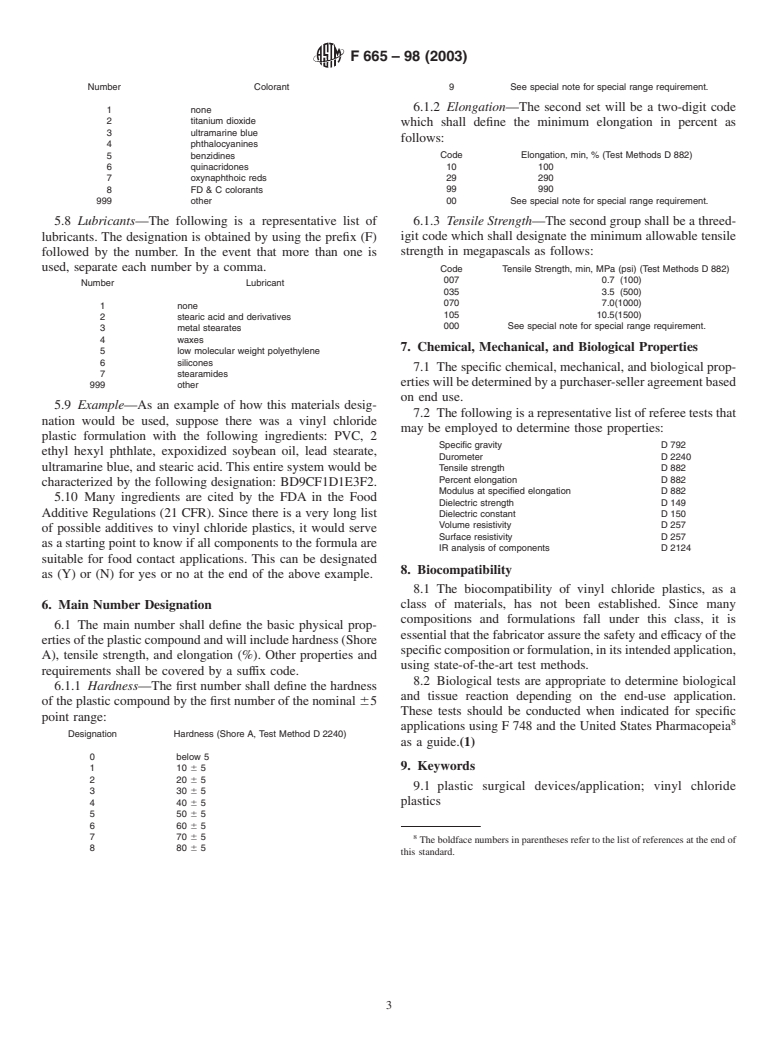

3.1.2 plasticizer—a substance incorporated in a material to

F epoxidized sunflower oil

Z other

increase its workability, flexibility, or distensibility.

3.1.3 stabilizer—a substance added to a plastic that will

Number Primary Plasticizer

retard the deterioration of the plastic due to the effects of heat,

light, or oxidation. 1 none

2 adipic acid derivatives

3.1.4 vinyl chloride plastics—plastics based on polymers of

3 azelaic acid derivatives

vinyl chloride or copolymers of vinyl chloride with other

4 benzoic acid derivatives

monomers, the vinyl chloride being the comonomer of the 5 citric acid derivatives

6 isophthalic acid derivatives

highest concentration by mass.

7 myristic acid derivatives

8 phosphoric acid derivatives

4. Significance and Use 9 phthalic acid derivatives

10 sebacic acid derivatives

4.1 This classification was developed to permit the addition

11 terephthalic acid derivatives

12 polyethers

of descriptive symbols and values for further new formulations

13 polyethylene glycols

with improved properties without complete reorganization of

14 polyesters

the standard and to facilitate the incorporation of future new

999 other

test methods to keep pace with changing industry require-

5.5 Stabilizers—Stabilizationsystemsareusuallycomposed

ments.

of metal soap acceptors and auxiliary organic stabilizers. The

metal soap acceptors are characterized by the metal(s) present.

5. Formulation Designation

The following is a representative list of stabilizers. The

NOTE 2—No judgment is made by ASTM as to the suitability of

designation is obtained by using the prefix (C) followed by the

possible compounds classified by the following system to any specific

letter for the metal, followed by the number for the chelator

biomedical use. Knowledge of formulation composition will only aid in

used. In the event that more than one in each category is

evaluation of a composition for suitability.

present, separate multiple letter or number designations, or

5.1 A letter/number system shall be used that will give

both, by a comma.

guidance to the engineer/user as to the nature of the formula-

Letter Metal in Soap Acceptor

tion. A general knowledge of the types of additives employed

A none

will aid in the evaluation of a particular formulation’s utility in

B barium

a medical application.

C calcium

5.2 Homopolymer—By definition, only one homopolymer

D cadmium

E magnesium

is covered by this classification: poly(vinyl chloride).

F lead

5.3 Copolymer—The following is a representative list of

G strontium

major copolymers of poly(vinyl chloride). To specify the

H tin

I zinc

copolymer, use the prefix (A) followed by the number desig-

Z other

nation for the copolymer. In the event that more than one

copolymer is present, separate the individual number designa-

Number Auxiliary Organic Stabilizer

tions by a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.