ASTM B857-02

(Specification)Standard Specification for Shaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors, Coated-Steel Supported (ACSS/TW)

Standard Specification for Shaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors, Coated-Steel Supported (ACSS/TW)

ABSTRACT

This specification covers shaped wire compact concentric-lay-stranded aluminum conductors, steel supported (ACSS/TW) for use as overhead electrical conductors. Electric-butt welds, cold-pressure welds, and electric-butt, cold upsed welds in the finished individual aluminum wires composing the conductor may be made during the stranding process. The electrical resistivity of the material shall meet the minimum resistivity specified. The rated strength of the completed conductor may be determined by mechanical tests. Mass and density of the conductors shall be determined.

SCOPE

1.1 This specification covers shaped wire compact concentric-lay-stranded aluminum conductors, steel supported (ACSS/TW) for use as overhead electrical conductors (see Explanatory Note 1).

1.2 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the specification. For conductor sizes designated by AWG or kcmil sizes, the requirements in SI units are numerically converted from the corresponding requirements in inch-pound units. For conductor sizes designation by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding values stated or derived in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.2.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

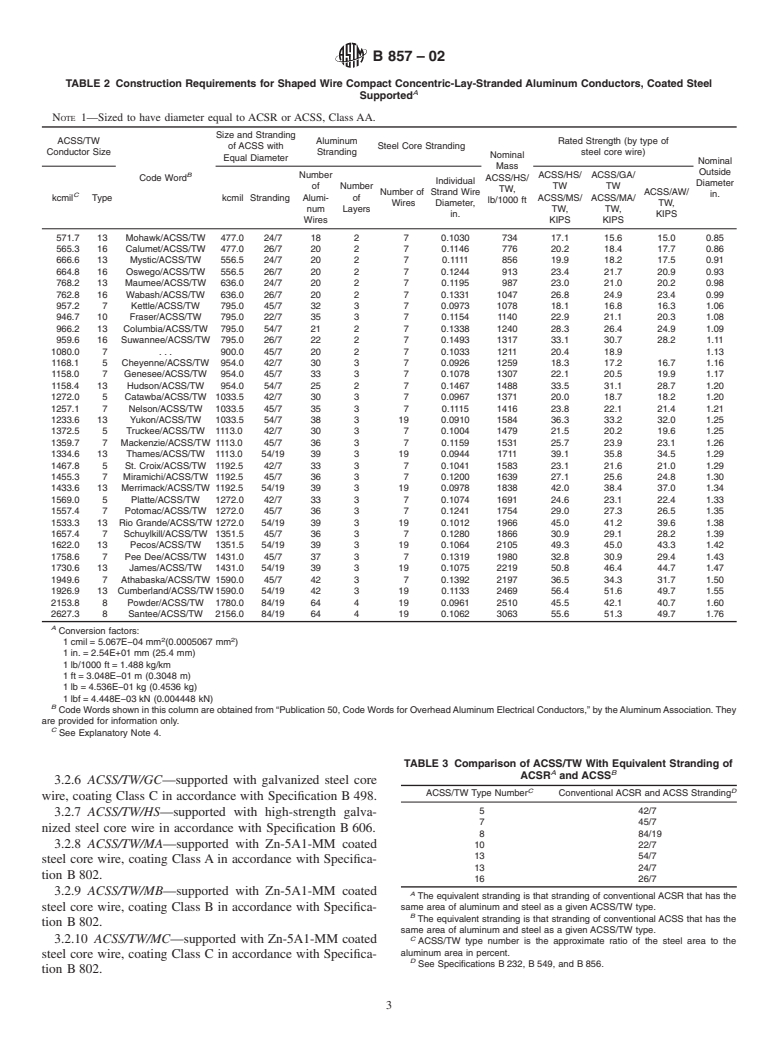

1.3 ACSS/TW is designed to increase the aluminum area for a given diameter of conductor by the use of trapezoidal shaped wires (TW). The conductors consist of a central core of round steel wire(s) surrounded by two or more layers of trapezoidal aluminum 1350-0 wires. Different strandings of the same size of conductor are identified by type, which is the approximate ratio of steel area to aluminum area expressed in percent (see Table 1, Table 2, and Table 3 ). For the purpose of this specification, the sizes listed in Table 1 and Table 2 are tabulated on the basis of the finished conductor having an area or outside diameter equal to that of specified sizes of standard ACSR, ACSS, and ACSR/TW so as to facilitate conductor selection.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 857 – 02

Standard Specification for

Shaped Wire Compact Concentric-Lay-Stranded Aluminum

1

Conductors, Coated-Steel Supported (ACSS/TW)

This standard is issued under the fixed designation B 857; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASTM Standards:

B 232 Specification for Concentric-Lay-Stranded Alumi-

1.1 This specification covers shaped wire compact

2

num Conductors, Coated Steel Reinforced (ACSR)

concentric-lay-stranded aluminum conductors, steel supported

B 263 Test Method for Determination of Cross-Sectional

(ACSS/TW) for use as overhead electrical conductors (see

2

Area of Stranded Conductors

Explanatory Note 1).

B 341/B 341M Specification for Aluminum-Coated (Alu-

1.2 The values stated in inch-pound or SI units are to be

minized) Steel Core Wire forAluminum Conductors, Steel

regarded separately as standard. Each system shall be used

2

Reinforced (ACSR/AZ)

independently of the other. Combining values from the two

B 354 Terminology Relating to Uninsulated Metallic Elec-

systems may result in non-conformance with the specification.

2

trical Conductors

For conductor sizes designated by AWG or kcmil sizes, the

B 498/B 498M Specification for Zinc-Coated (Galvanized)

requirements in SI units are numerically converted from the

Steel Core Wire for Aluminum Conductors, Steel Rein-

correspondingrequirementsininch-poundunits.Forconductor

2

forced (ACSR)

sizes designation by AWG or kcmil, the requirements in SI

B 500/B 500M Specification for Metallic Coated Stranded

units have been numerically converted from corresponding

Steel Core for Aluminum Conductors, Steel Reinforced

values stated or derived in inch-pound units. For conductor

2

(ACSR)

sizesdesignatedbySIunitsonly,therequirementsarestatedor

B 502 SpecificationforAluminum-CladSteelCoreWirefor

derived in SI units.

2

Aluminum Conductors,Aluminum-Clad Steel Reinforced

1.2.1 For density, resistivity, and temperature, the values

B 549 Specification for Concentric-Lay-Stranded Alumi-

stated in SI units are to be regarded as standard.

num Conductors, Aluminum-Clad Steel Reinforced

1.3 ACSS/TWisdesignedtoincreasethealuminumareafor

2

(ACSR/AW)

a given diameter of conductor by the use of trapezoidal shaped

B 606 Specification for High-Strength Zinc-Coated (Galva-

wires (TW). The conductors consist of a central core of round

nized) Steel Core Wire for Aluminum and Aluminum-

steel wire(s) surrounded by two or more layers of trapezoidal

2

Alloy Conductors, Steel Reinforced

aluminum 1350-0 wires. Different strandings of the same size

B 609/B 609M Specification for Aluminum 1350 Round

of conductor are identified by type, which is the approximate

Wire, Annealed and Intermediate Tempers, for Electrical

ratio of steel area to aluminum area expressed in percent (see

2

Purposes

Table 1, Table 2, and Table 3). For the purpose of this

B 779 Specification for Shaped Wire Compact Concentric-

specification, the sizes listed in Table 1 and Table 2 are

Lay-Stranded Aluminum Conductors, Steel-Reinforced

tabulated on the basis of the finished conductor having an area

2

(ACSR/TW)

or outside diameter equal to that of specified sizes of standard

B 802/B 802M Specification for Zinc-5 % Aluminum-

ACSR, ACSS, and ACSR/TW so as to facilitate conductor

Mischmetal Alloy-Coated Steel Core Wire for Aluminum

selection.

2

Conductors, Steel-Reinforced (ACSR)

2. Referenced Documents

B 803 Specification for High-Strength Zinc-5 %

Aluminum-Mischmetal Alloy-Coated Steel Core Wire for

2.1 The following documents of the issue in effect on date

Aluminum and Aluminum-Alloy Conductors, Steel-

ofmaterialpurchaseformpartofthisspecificationtotheextent

2

Reinforced

referenced herein:

E 29 Practice for Using Significant Digits in Test Data to

3

Determine Conformance with Specifications

1

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.07

Conductors of Light Metals.

2

Current edition approved April 10, 2002. Published May 2002. Originally Annual Book of ASTM Standards, Vol 02.03.

3

published as B 857 – 95. Last previous edition B 857 – 01a. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 857–02

TABLE 1 Construction Requirements for Shaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors, Coated Steel

A

Supported

NOTE 1—Sized to have area equal to ACSR or ACSS, Class AA.

Size and Stranding

ACSS/TW Aluminum Rated Streng

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.