ASTM D3500-90(2003)

(Test Method)Standard Test Methods for Structural Panels in Tension

Standard Test Methods for Structural Panels in Tension

SIGNIFICANCE AND USE

These test methods determine the tensile properties of structural panels in response to stresses acting in the plane of the panel.

Test Method A—This test method is suited to material that is uniform with respect to tensile properties. It is normally applied to structural panels and plywood of clear, straight-grained veneers. It may also be used to evaluate the strength of scarf and finger joints and other manufacturing process variables that can be expected to influence the tensile properties of structural panels in a uniform manner across the width of the sheet.

Test Method B—This test method employs large test specimens and responds well to all manufacturing variables and growth characteristics that affect the tensile properties of structural panels.

It is recommended that where comparisons are to be made that the same test method and specimen size be used throughout. This is because the volume of material included in a test specimen can influence the tensile strength regardless of whether the material properties are uniform throughout the sheet or vary widely due to the presence of growth or manufacturing features.

SCOPE

1.1 These test methods cover the determination of the tensile properties of structural panels.

1.2 Structural panels in use include plywood, waferboard, oriented strand board and composites of veneer, and other wood-based layers.

1.3 Test Method A, Tensile Test for Small Specimens:

1.3.1 This test method employs small specimens that should have a reduced cross section at the center of their length to avoid failure in the grip area. The transition from full width of specimen to reduced section at the center should be gradual to minimize stress concentration.

1.3.2 When the measurements of elastic properties are to be made, the length of the reduced cross section at the center should be of sufficient length to accommodate an extensometer.

1.4 Test Method B, Tensile Test for Large Specimens:

1.4.1 This test method employs large specimens and responds well to manufacturing variables, plywood growth characteristics, and other defects influencing the tensile properties of structural panels.

1.4.2 The test specimens are large enough to contain the maximum sized defects found in plywood panels. The test specimens have a constant cross section since the size and location of defects control the location of failures and the effect of stress concentration at the grips is overshadowed.

1.4.3 This test method is recommended for the following:

1.4.3.1 Comparative tests of structural panels,

1.4.3.2 Determining the influence of any specific strength reducing defects on the tensile properties of structural panels,

1.4.3.3 Determination of tensile properties of plywood and composites containing veneer with growth and manufacturing characteristics.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3500–90(Reapproved 2003)

Standard Test Methods for

Structural Panels in Tension

This standard is issued under the fixed designation D 3500; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 These test methods cover the determination of the 2.1 ASTM Standards:

tensile properties of structural panels. D 2395 Test Methods for Specific Gravity of Wood and

1.2 Structural panels in use include plywood, waferboard, Wood-Base Materials

oriented strand board and composites of veneer, and other D 4442 Test Method for Direct Moisture Content Measure-

wood-based layers ment of Wood and Wood-Base Materials

1.3 Test Method A, Tensile Test for Small Specimens:

3. Significance and Use

1.3.1 This test method employs small specimens that should

3.1 These test methods determine the tensile properties of

have a reduced cross section at the center of their length to

avoid failure in the grip area. The transition from full width of structural panels in response to stresses acting in the plane of

the panel.

specimen to reduced section at the center should be gradual to

minimize stress concentration. 3.2 Test Method A—This test method is suited to material

that is uniform with respect to tensile properties. It is normally

1.3.2 When the measurements of elastic properties are to be

made, the length of the reduced cross section at the center applied to structural panels and plywood of clear, straight-

grained veneers. It may also be used to evaluate the strength of

shouldbeofsufficientlengthtoaccommodateanextensometer.

1.4 Test Method B, Tensile Test for Large Specimens: scarf and finger joints and other manufacturing process vari-

ables that can be expected to influence the tensile properties of

1.4.1 This test method employs large specimens and re-

sponds well to manufacturing variables, plywood growth structural panels in a uniform manner across the width of the

sheet.

characteristics, and other defects influencing the tensile prop-

3.3 Test Method B—This test method employs large test

erties of structural panels.

1.4.2 The test specimens are large enough to contain the specimens and responds well to all manufacturing variables

and growth characteristics that affect the tensile properties of

maximum sized defects found in plywood panels. The test

specimens have a constant cross section since the size and structural panels.

3.4 It is recommended that where comparisons are to be

location of defects control the location of failures and the effect

of stress concentration at the grips is overshadowed. made that the same test method and specimen size be used

throughout. This is because the volume of material included in

1.4.3 This test method is recommended for the following:

1.4.3.1 Comparative tests of structural panels, a test specimen can influence the tensile strength regardless of

whether the material properties are uniform throughout the

1.4.3.2 Determining the influence of any specific strength

reducing defects on the tensile properties of structural panels, sheet or vary widely due to the presence of growth or

manufacturing features.

1.4.3.3 Determination of tensile properties of plywood and

composites containing veneer with growth and manufacturing

4. Control of Moisture Content

characteristics.

4.1 Structural panel specimens to be tested at specific

1.5 This standard does not purport to address all of the

moisture contents or after reaching equilibrium moisture con-

safety concerns, if any, associated with its use. It is the

tent at specific temperature and relative humidity conditions

responsibility of the user of this standard to establish appro-

shall be conditioned to approximate constant weight in con-

priate safety and health practices and determine the applica-

trolled atmospheric conditions. For approximating moisture

bility of regulatory limitations prior to use.

conditions of structural panels used under dry conditions, a

relative humidity of 65 6 2 % at a temperature of (68 6 6°F)

These test methods are under the jurisdiction of ASTM Committee D07 on

(20 6 3°C) is recommended.

Wood and are the direct responsibility of Subcommittee D07.03 on Panel Products.

Current edition approved Oct. 26, 1990. Published December 1990. Originally

published as D 3500 – 76. Last previous edition D 3500 – 76 (1986). Annual Book of ASTM Standards, Vol 04.10.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

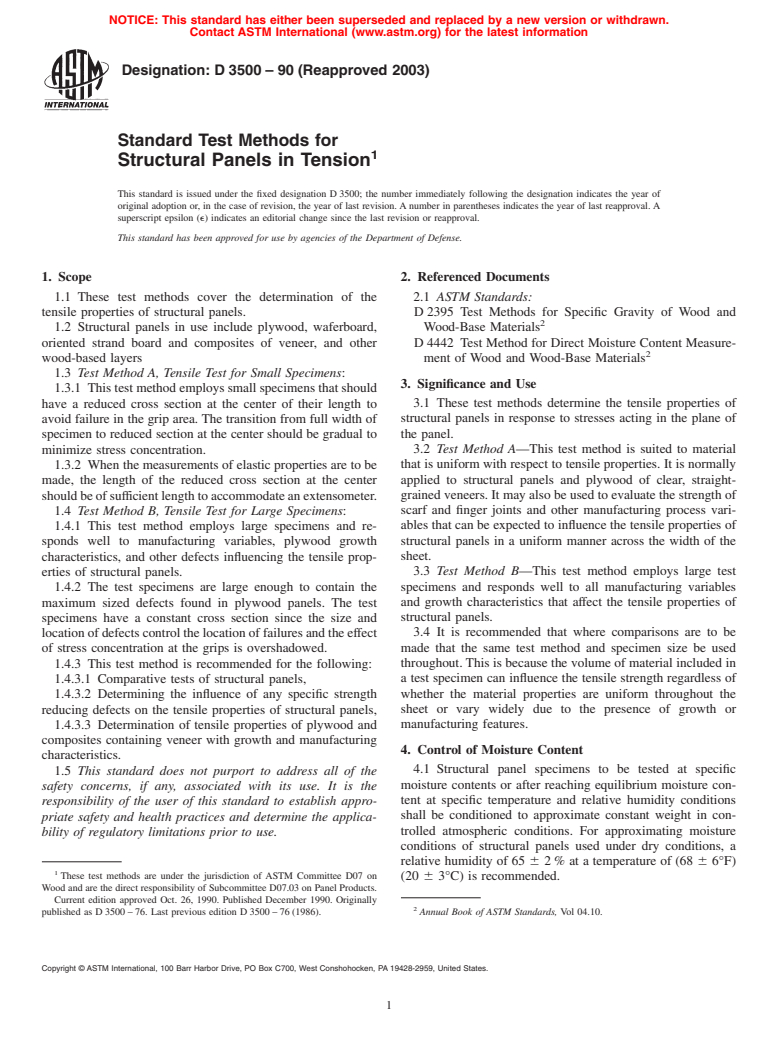

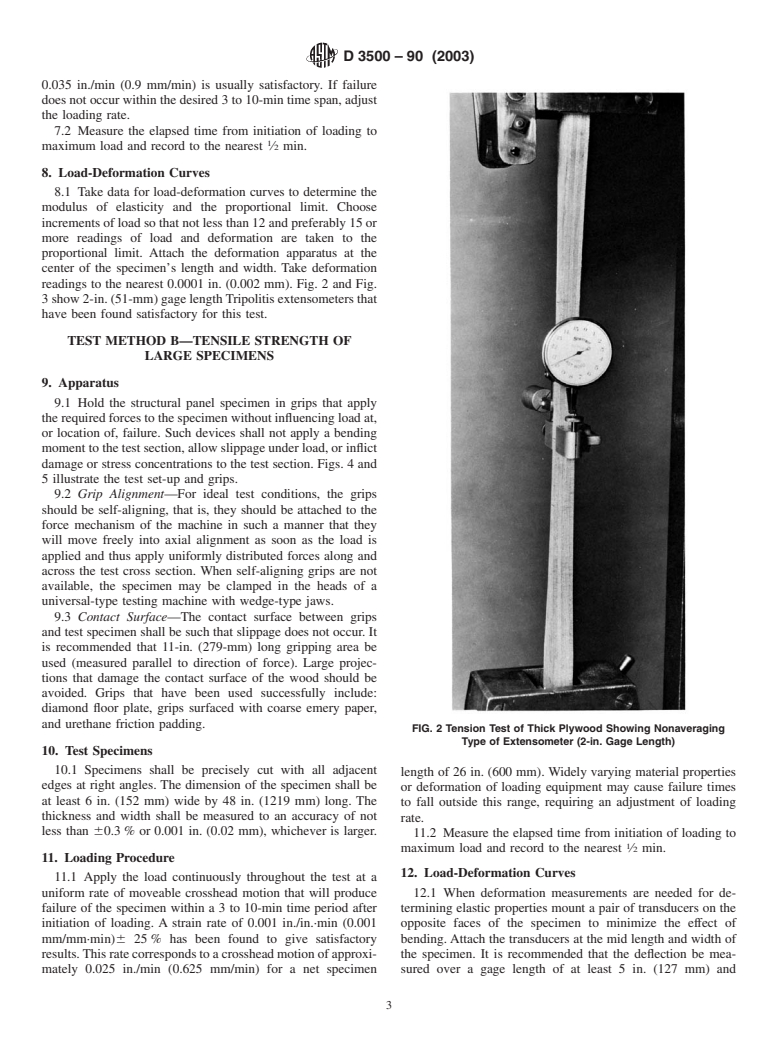

D3500–90 (2003)

5. Variables Influencing Tensile Properties of Structural plywood or composites with the grain of the individual veneer

Panels plies or laminations making grain angles of individual veneer

lamina of 0 or 90°,TypeAshall be used for material over ⁄4 in.

5.1 Moisture Content—Moisture content shall be deter-

(6 mm) in thickness and Type B for material ⁄4 in. (6 mm) or

mined in accordance with Test Method D 4442.

lessinthickness.Forplywoodwithanangleotherthan0or90°

5.2 Specific Gravity—Determine specific gravity in accor-

between the length of the specimens and the grain orientation,

dance with Test Methods D 2395. The specimen may be the

TypeCshallbeusedregardlessofthethicknessofthematerial.

same as that for moisture content determination but must have

3 3

The specimens shall have a thickness equal to that of the

volume of at least 1 in. (16 cm ) if from small specimens (Test

3 3

material. The thickness and the width of each specimen at the

MethodA), and at least 3 in. (49 cm ) if from large specimens

critical section shall be measured to an accuracy of not less

(Test Method B). Specimens containing veneer shall be free of

than 60.3 % or 0.001 in. (0.02 mm) whichever is larger.

visible knots or voids in any ply.

6.1.2 The test specimens shall be properly shaped, using a

TEST METHOD A—TENSILE PROPERTIES template in conjunction with a vertical-spindle wood-work-ing

OF SMALL SPECIMENS

shaper or any other method that will give equally satisfactory

results.

6. Test Specimens

7. Loading Procedure

6.1 Specimens may be of Types A, B, or C in Fig. 1.

6.1.1 When the evaluation of elastic properties as well as 7.1 Hold the specimen in wedge-type self-tightening and

ultimate tensile strength is required, the size and shape of the self-aligning grips. Rate of crosshead motion shall be constant

test specimen shall be selected on the basis of the construction throughoutthetestsuchthatthespecimenbreakswithin3to10

and thickness of the material. For other structural panels, and min after initiation of loading. A crosshead motion rate of

U.S. Customary Metric Equivalents U.S. Customary Metric Equivalents

Units, in. mm Units, in. mm

1 7

⁄4 63 ⁄8 98

1 1

⁄2 13 4 ⁄8 105

125 4 ⁄4 108

1 ⁄8 48 16 406

2 ⁄2 64 20 503

2 ⁄8 67 25 635

2 ⁄8 73 30 762

NOTE 1—A generous radius of curvature at the minimum section as provided in this s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.