ASTM B381-05

(Specification)Standard Specification for Titanium and Titanium Alloy Forgings

Standard Specification for Titanium and Titanium Alloy Forgings

SCOPE

1.1 This specification covers 34 grades of annealed titanium and titanium alloy forgings as follows:

1.1.1 Grade F-1Unalloyed titanium,

1.1.2 Grade F-2Unalloyed titanium,

1.1.3 Grade F-3Unalloyed titanium,

1.1.4 Grade F-4Unalloyed titanium,

1.1.5 Grade F-5Titanium alloy (6 % aluminum, 4 % vanadium),

1.1.6 Grade F-6Titanium alloy (5 % aluminum, 2.5 % tin),

1.1.7 Grade F-7Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.8 Grade F-9Titanium alloy (3 % aluminum, 2.5 % vanadium),

1.1.9 Grade F-11Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.10 Grade F-12Titanium alloy (0.3 % molybdenum, 0.8 % nickel),

1.1.11 Grade F-13Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.12 Grade F-14Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.13 Grade F-15Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.14 Grade F-16Unalloyed titanium plus 0.04 % to 0.08 % palladium,

1.1.15 Grade F-17Unalloyed titanium plus 0.04 % to 0.08 % palladium,

1.1.16 Grade F-18Titanium alloy (3 % aluminum, 2.5 % vanadium) plus 0.04 % to 0.08 % palladium,

1.1.17 Grade F-19Titanium alloy (3 % aluminum, 8 % vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum),

1.1.18 Grade F-20Titanium alloy (3 % aluminum, 8 % vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum) plus 0.04 % to 0.08 % palladium,

1.1.19 Grade F-21Titanium alloy (3 % aluminum, 2.7 % niobium, 15 % molybdenum, 0.25 % silicon),

1.1.20 Grade F-23Titanium alloy (6 % aluminum, 4 % vanadium, extra low interstitials, ELI),

1.1.21 Grade F-24Titanium alloy (6 % aluminum, 4 % vanadium) plus 0.04 % to 0.08 % palladium,

1.1.22 Grade F-25Titanium alloy (6 % aluminum, 4 % vanadium) plus 0.3 % to 0.8 % nickel and 0.04 % to 0.08 % palladium,

1.1.23 Grade F-26Unalloyed titanium plus 0.08 to 0.14 % ruthenium,

1.1.24 Grade F-27Unalloyed titanium plus 0.08 to 0.14 % ruthenium,

1.1.25 Grade F-28Titanium alloy (3% aluminum, 2.5% vanadium plus 0.08-0.14% ruthenium),

1.1.26 Grade F-29Titanium alloy (6% aluminum, 4% vanadium, extra low interstitial, ELI plus 0.08-0.14% ruthenium),

1.1.27 Grade F-30Titanium alloy (0.3 % cobalt, 0.05 % palladium),

1.1.28 Grade F-31Titanium alloy (0.3 % cobalt, 0.05 % palladium),

1.1.29 Grade F-32Titanium alloy (5 % aluminum, 1 % vanadium, 1 % tin, 1 % zirconium, 0.8 % molybdenum),

1.1.30 Grade F-33Titanium alloy (0.4 % nickel, 0.015 % palladium, 0.025 % ruthenium, 0.15 % chromium),

1.1.31 Grade F-34Titanium alloy (0.4 % nickel, 0.015 % palladium, 0.025 % ruthenium, 0.15 % chromium),

1.1.32 Grade F-35Titanium alloy (4.5 % aluminum, 2 % molybdenum, 1.6 % vanadium, 0.5 % iron, 0.3 % silicon),

1.1.33 Grade F-36Titanium alloy (45 % niobium), and

1.1.34 Grade F-37Titanium alloy (1.5 % aluminum).

1.2 &inch-pound-units;

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 381 – 05

Standard Specification for

1

Titanium and Titanium Alloy Forgings

This standard is issued under the fixed designation B 381; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.1.18 Grade F-20—Titanium alloy (3 % aluminum, 8 %

2 vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum)

1.1 This specification covers 34 grades of annealed tita-

plus 0.04 % to 0.08 % palladium,

nium and titanium alloy forgings as follows:

1.1.19 Grade F-21—Titanium alloy (3 % aluminum, 2.7 %

1.1.1 Grade F-1—Unalloyed titanium,

niobium, 15 % molybdenum, 0.25 % silicon),

1.1.2 Grade F-2—Unalloyed titanium,

1.1.20 Grade F-23—Titanium alloy (6 % aluminum, 4 %

1.1.3 Grade F-3—Unalloyed titanium,

vanadium, extra low interstitials, ELI),

1.1.4 Grade F-4—Unalloyed titanium,

1.1.21 Grade F-24—Titanium alloy (6 % aluminum, 4 %

1.1.5 Grade F-5—Titanium alloy (6 % aluminum, 4 %

vanadium) plus 0.04 % to 0.08 % palladium,

vanadium),

1.1.22 Grade F-25—Titanium alloy (6 % aluminum, 4 %

1.1.6 Grade F-6—Titanium alloy (5 % aluminum, 2.5 %

vanadium) plus 0.3 % to 0.8 % nickel and 0.04 % to 0.08 %

tin),

palladium,

1.1.7 Grade F-7—Unalloyed titanium plus 0.12 to 0.25 %

1.1.23 Grade F-26—Unalloyed titanium plus 0.08 to

palladium,

0.14 % ruthenium,

1.1.8 Grade F-9—Titanium alloy (3 % aluminum, 2.5 %

1.1.24 Grade F-27—Unalloyed titanium plus 0.08 to

vanadium),

0.14 % ruthenium,

1.1.9 Grade F-11—Unalloyed titanium plus 0.12 to 0.25 %

1.1.25 Grade F-28—Titanium alloy (3% aluminum, 2.5%

palladium,

vanadium plus 0.08–0.14% ruthenium),

1.1.10 Grade F-12—Titanium alloy (0.3 % molybdenum,

1.1.26 Grade F-29—Titanium alloy (6% aluminum, 4%

0.8 % nickel),

vanadium, extra low interstitial, ELI plus 0.08–0.14% ruthe-

1.1.11 Grade F-13—Titanium alloy (0.5 % nickel, 0.05 %

nium),

ruthenium),

1.1.27 Grade F-30—Titanium alloy (0.3 % cobalt, 0.05 %

1.1.12 Grade F-14—Titanium alloy (0.5 % nickel, 0.05 %

palladium),

ruthenium),

1.1.28 Grade F-31—Titanium alloy (0.3 % cobalt, 0.05 %

1.1.13 Grade F-15—Titanium alloy (0.5 % nickel, 0.05 %

palladium),

ruthenium),

1.1.29 Grade F-32—Titanium alloy (5 % aluminum, 1 %

1.1.14 Grade F-16—Unalloyed titanium plus 0.04 % to

vanadium, 1 % tin, 1 % zirconium, 0.8 % molybdenum),

0.08 % palladium,

1.1.30 Grade F-33—Titanium alloy (0.4 % nickel, 0.015 %

1.1.15 Grade F-17—Unalloyed titanium plus 0.04 % to

palladium, 0.025 % ruthenium, 0.15 % chromium),

0.08 % palladium,

1.1.31 Grade F-34—Titanium alloy (0.4 % nickel, 0.015 %

1.1.16 Grade F-18—Titanium alloy (3 % aluminum, 2.5 %

palladium, 0.025 % ruthenium, 0.15 % chromium),

vanadium) plus 0.04 % to 0.08 % palladium,

1.1.32 Grade F-35—Titanium alloy (4.5 % aluminum, 2 %

1.1.17 Grade F-19—Titanium alloy (3 % aluminum, 8 %

molybdenum, 1.6 % vanadium, 0.5 % iron, 0.3 % silicon),

vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum),

1.1.33 Grade F-36—Titanium alloy (45 % niobium), and

1.1.34 Grade F-37—Titanium alloy (1.5 % aluminum).

1

This specification is under the jurisdiction of ASTM Committee B10 on

1.2 The values stated in inch-pound units are to be regarded

Reactive and Refractory Metals and Alloys and is the direct responsibility of

as standard. The values given in parentheses are mathematical

Subcommittee B10.01 on Titanium.

conversions to SI units that are provided for information only

Current edition approved Jan. 1, 2005. Published January 2005. Originally

and are not considered standard.

approved in 1961. Last previous edition approved in 2003 as B 381 – 03.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

cation SB-381 in Section II of that Code.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B381–05

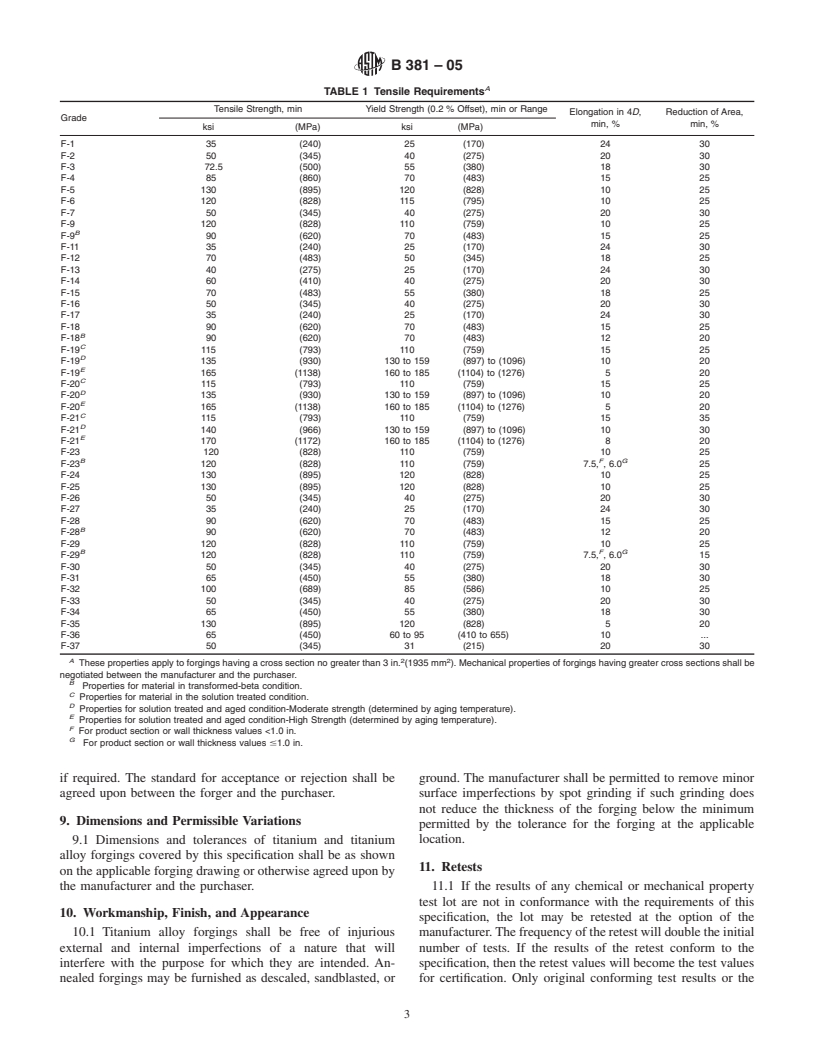

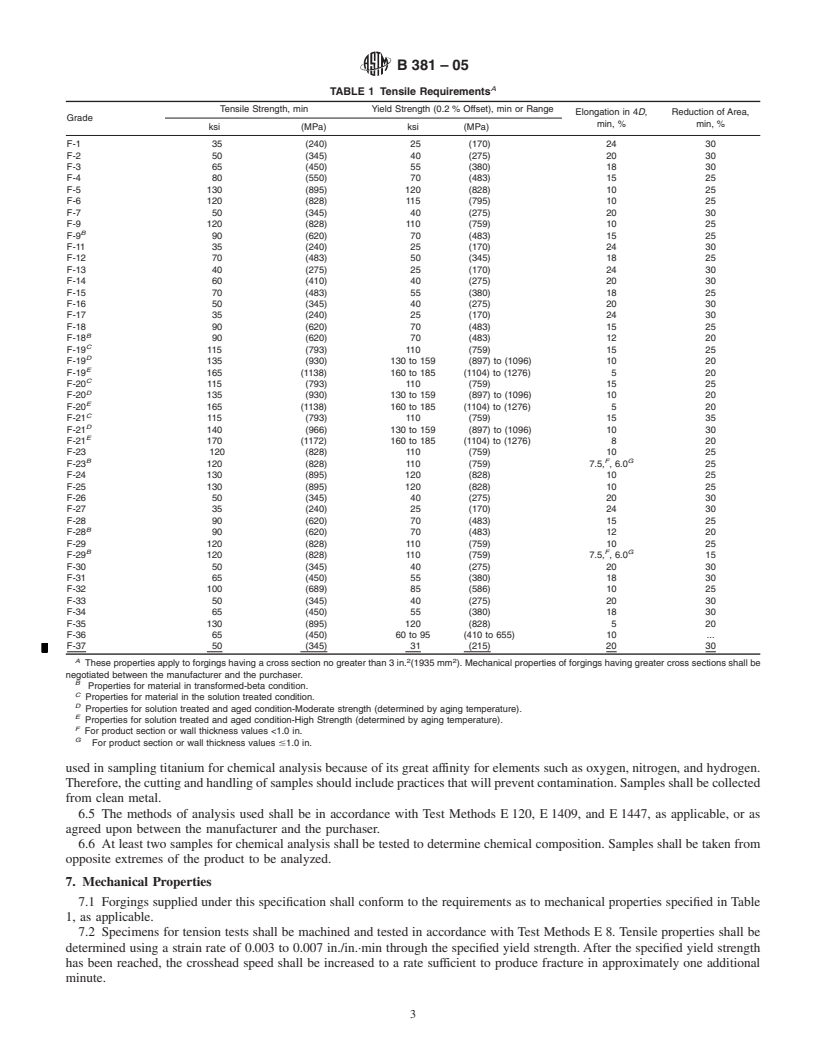

2. Referenced Documents 6.1.1 The elements listed in Table 2 are intentional alloy

3

additionsorelementswhichareinherenttothemanufacturerof

2.1 ASTM Standards:

titanium sponge, ingot or mill product.

B 348 Specification for Titanium and Titanium Alloy Bars

6.1.1.1 Elements other than those listed in Table 2 are

and Billets

deemed to be capable of occurring in the grades listed in Table

E8 Test Methods for Tension Testing of Metallic Materials

2 by and only by way of unregulated or unanalyzed scrap

E29 Practice for Using Significant Digits in Test Data to

additions to the ingot melt. Therefore, product analysis for

Determine Conformance with Specifications

elements not listed in Table 2 shall not be required unless

E 120 Test Methods for ChemicalAnalysis of Titanium and

4

specified and shall be

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B381–03 Designation: B 381 – 05

Standard Specification for

1

Titanium and Titanium Alloy Forgings

This standard is issued under the fixed designation B 381; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

2

1.1 This specification covers 3334 grades of annealed titanium and titanium alloy forgings as follows:

1.1.1 Grade F-1—Unalloyed titanium,

1.1.2 Grade F-2—Unalloyed titanium,

1.1.3 Grade F-3—Unalloyed titanium,

1.1.4 Grade F-4—Unalloyed titanium,

1.1.5 Grade F-5—Titanium alloy (6 % aluminum, 4 % vanadium),

1.1.6 Grade F-6—Titanium alloy (5 % aluminum, 2.5 % tin),

1.1.7 Grade F-7—Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.8 Grade F-9—Titanium alloy (3 % aluminum, 2.5 % vanadium),

1.1.9 Grade F-11—Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.10 Grade F-12—Titanium alloy (0.3 % molybdenum, 0.8 % nickel),

1.1.11 Grade F-13—Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.12 Grade F-14—Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.13 Grade F-15—Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.14 Grade F-16—Unalloyed titanium plus 0.04 % to 0.08 % palladium,

1.1.15 Grade F-17—Unalloyed titanium plus 0.04 % to 0.08 % palladium,

1.1.16 Grade F-18—Titanium alloy (3 % aluminum, 2.5 % vanadium) plus 0.04 % to 0.08 % palladium,

1.1.17 Grade F-19—Titanium alloy (3 % aluminum, 8 % vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum),

1.1.18 Grade F-20—Titanium alloy (3 % aluminum, 8 % vanadium, 6 % chromium, 4 % zirconium, 4 % molybdenum) plus

0.04 % to 0.08 % palladium,

1.1.19 Grade F-21—Titanium alloy (3 % aluminum, 2.7 % niobium, 15 % molybdenum, 0.25 % silicon),

1.1.20 Grade F-23—Titanium alloy (6 % aluminum, 4 % vanadium, extra low interstitials, ELI),

1.1.21 Grade F-24—Titanium alloy (6 % aluminum, 4 % vanadium) plus 0.04 % to 0.08 % palladium,

1.1.22 Grade F-25—Titanium alloy (6 % aluminum, 4 % vanadium) plus 0.3 % to 0.8 % nickel and 0.04 % to 0.08 %

palladium,

1.1.23 Grade F-26—Unalloyed titanium plus 0.08 to 0.14 % ruthenium,

1.1.24 Grade F-27—Unalloyed titanium plus 0.08 to 0.14 % ruthenium,

1.1.25 Grade F-28—Titanium alloy (3% aluminum, 2.5% vanadium plus 0.08–0.14% ruthenium),

1.1.26 Grade F-29—Titanium alloy (6% aluminum, 4% vanadium, extra low interstitial, ELI plus 0.08–0.14% ruthenium),

1.1.27 Grade F-30—Titanium alloy (0.3 % cobalt, 0.05 % palladium),

1.1.28 Grade F-31—Titanium alloy (0.3 % cobalt, 0.05 % palladium),

1.1.29 Grade F-32—Titanium alloy (5 % aluminum, 1 % vanadium, 1 % tin, 1 % zirconium, 0.8 % molybdenum),

1.1.30 Grade F-33—Titanium alloy (0.4 % nickel, 0.015 % palladium, 0.025 % ruthenium, 0.15 % chromium),

1.1.31 Grade F-34—Titanium alloy (0.4 % nickel, 0.015 % palladium, 0.025 % ruthenium, 0.15 % chromium),

1.1.32 Grade F-35—Titanium alloy (4.5 % aluminum, 2 % molybdenum, 1.6 % vanadium, 0.5 % iron, 0.3 % silicon), and

1.1.33 Grade F-36—Titanium alloy (45% niobium).

1.2The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only. —Titanium alloy (45 % niobium), and

1.1.34 Grade F-37—Titanium alloy (1.5 % aluminum).

1

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.01 on Titanium.

Current edition approved Nov.Jan. 1, 2003.2005. Published November 2003.February 2005. Originally approved in 1961. Last previous edition approved in 20022003 as

B 381 – 023.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SB-381 in Section II of that Code.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B381–05

1.2

2. Referenced Documents

3

2.1 ASTM Standards:

B 348 Specification for Titanium and Titanium Alloy Bars and Billets

E 8 Test Methods for Tension Testing of Metallic Materials

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

4

E 120 Test Methods for Chemical Analysis of Titanium and Titanium Alloys

E 1409 Test Method for Determination of Oxygen in Titanium and Titanium Alloys by the Inert Gas Fusion Technique

E 1447 Test Method for Determination of Hydrogen in Titanium a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.