ASTM F67-13(2017)

(Specification)Standard Specification for Unalloyed Titanium, for Surgical Implant Applications (UNS R50250, UNS R50400, UNS R50550, UNS R50700)

Standard Specification for Unalloyed Titanium, for Surgical Implant Applications (UNS R50250, UNS R50400, UNS R50550, UNS R50700)

ABSTRACT

This specification covers the chemical, mechanical, and metallurgical requirements for four grades of unalloyed titanium strips, sheets, plates, bars, billets, forgings, and wires used for the manufacture of surgical implants. The four grades identified here are defined as follows: Grade 1—UNS R50250; Grade 2—UNS R50400; Grade 3—UNS R50550; and Grade 4—UNS R50700. Mill products may be supplied with a descaled or pickled, abrasive blasted, chemically milled, ground, machined, peeled, or polished finish, or as specified by the purchaser. Materials shall be furnished in the hotworked, cold-worked, forged, annealed, or stress-relieved condition. Mechanical properties to which the titanium materials shall conform are ultimate tensile strength, yield strength, elongation, and reduction of area.

SCOPE

1.1 This specification covers the chemical, mechanical, and metallurgical requirements for four grades of unalloyed titanium strip, sheet, plate, bar, billet, forging, and wire used for the manufacture of surgical implants.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F67 −13 (Reapproved 2017)

Standard Specification for

Unalloyed Titanium, for Surgical Implant Applications (UNS

R50250, UNS R50400, UNS R50550, UNS R50700)

ThisstandardisissuedunderthefixeddesignationF67;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E1409TestMethodforDeterminationofOxygenandNitro-

gen in Titanium and TitaniumAlloys by Inert Gas Fusion

1.1 This specification covers the chemical, mechanical, and

E1447Test Method for Determination of Hydrogen in Tita-

metallurgical requirements for four grades of unalloyed tita-

nium and Titanium Alloys by Inert Gas Fusion Thermal

nium strip, sheet, plate, bar, billet, forging, and wire used for

Conductivity/Infrared Detection Method

the manufacture of surgical implants.

E1941Test Method for Determination of Carbon in Refrac-

1.2 The values stated in either SI units or inch-pound units

toryandReactiveMetalsandTheirAlloysbyCombustion

are to be regarded separately as standard. The values stated in

Analysis

each system may not be exact equivalents; therefore, each

E2371Test Method for Analysis of Titanium and Titanium

system shall be used independently of the other. Combining

AlloysbyDirectCurrentPlasmaandInductivelyCoupled

values from the two systems may result in non-conformance

Plasma Atomic Emission Spectrometry (Performance-

with the standard.

Based Test Methodology)

1.3 This international standard was developed in accor-

E2626Guide for Spectrometric Analysis of Reactive and

dance with internationally recognized principles on standard- Refractory Metals

ization established in the Decision on Principles for the

F981Practice for Assessment of Compatibility of Biomate-

Development of International Standards, Guides and Recom- rials for Surgical Implants with Respect to Effect of

mendations issued by the World Trade Organization Technical

Materials on Muscle and Insertion into Bone

Barriers to Trade (TBT) Committee. IEEE/ASTM SI 10American National Standard for Metric

Practice

2. Referenced Documents

2.2 Aerospace Material Specification:

AMS 2249Chemical Check Analysis Limits, Titanium and

2.1 ASTM Standards:

Titanium Alloys

B265Specification for Titanium and Titanium Alloy Strip,

AMS 2380Approval and Control of Premium Quality Tita-

Sheet, and Plate

nium Alloys

B348Specification for Titanium and Titanium Alloy Bars

AMS 2631Ultrasonic Inspection TitaniumAlloy Bar, Billet

and Billets

and Plate

B381Specification for Titanium and Titanium Alloy Forg-

2.3 ISO Standards:

ings

ISO 5832-2Implants for Surgery—Metallic Materials—

E8/E8MTest Methods for Tension Testing of Metallic Ma-

Unalloyed Titanium

terials

ISO 6892Metallic Materials—Tensile Testing at Ambient

E29Practice for Using Significant Digits in Test Data to

Temperature

Determine Conformance with Specifications

ISO 9001Quality Management Systems

E290Test Methods for Bend Testing of Material for Ductil-

ity

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

This specification is under the jurisdiction of ASTM Committee F04 on

3.1.1 lot, n—the total number of mill products produced

Medical and Surgical Materials and Devices and is the direct responsibility of

from the same melt heat under the same conditions at essen-

Subcommittee F04.12 on Metallurgical Materials.

tially the same time.

Current edition approved March 1, 2017. Published April 2017. Originally

approved in 1966. Last previous edition approved in 2013 as F67–13. DOI:

10.1520/F0067-13R17.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Society of Automotive Engineers (SAE), 400 Commonwealth

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Dr., Warrendale, PA 15096-0001.

Standards volume information, refer to the standard’s Document Summary page on Available from American Society for Quality (ASQ), 600 N. Plankinton Ave.,

the ASTM website. Milwaukee, WI 53203.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F67−13 (2017)

A

TABLE 2 Product Analysis Tolerances

3.1.2 cold work, n—any mechanical deformation process

Limit or Maximum of Tolerance Under the

performed below the recrystallization temperature which re-

Element Specified Range %, Minimum or Over the

sults in strain hardening of the material.

B

(mass/mass) Maximum Limit

3.1.3 hot work, n—any mechanical deformation process

Nitrogen up to 0.05 0.02

Carbon 0.10 0.02

performed above the recrystallization temperature.

Hydrogen up to 0.015 0.0020

3.1.4 alpha case, n—oxygen, nitrogen or carbon-enriched,

Iron up to 0.25 0.10

Iron over 0.25 0.15

alpha-stabilized surface which results from elevated tempera-

Oxygen up to 0.20 0.02

ture exposure.

Oxygen over 0.20 0.03

A

Refer to AMS 2249.

4. Product Classification

B

Under minimum limit not applicable for elements where only a maximum

percentage is indicated.

4.1 ProductclassificationsareconsistentwithSpecifications

B265, B348, and B381.

4.1.1 Strip—Any product 0.188 in. (4.76 mm) and under in

thickness and less than 24 in. (610 mm) wide.

4.1.2 Sheet—Any product 0.188 in. (4.76 mm) and under in

5.1.4 Form (sheet, strip, plate, bar, billet, forging, wire, or

thickness and 24 in. (610 mm) or more in width.

other forms),

4.1.3 Plate—Any product 0.188 in. (4.76 mm) thick and

5.1.5 Condition (see 6.1),

over and 10 in. (254 mm) wide and over, with widths greater

5.1.6 Mechanical properties (if applicable, for special

than five times thickness. Plate up to 4 in. (102 mm), thick

conditions),

inclusive is covered by this specification.

5.1.7 Finish (see 6.2),

4.1.4 Bar—Rounds, flats, or other shapes from 0.188 in.

5.1.8 Applicable dimensions and tolerances including size,

(4.76 mm) to 4 in. (102 mm) in diameter or thickness. (Other

thickness, width, and length (exact, random, multiples) or

sizes and shapes by special order.)

drawing number,

4.1.5 Forging bar—Bar as described in 4.1.4 used in the

5.1.9 Special tests (if any), and

production of forgings. This product may be furnished in the

5.1.10 Other requirements.

hot worked condition.

4.1.6 Billet—A solid semi-finished section hot rolled or

6. Manufacture

forgedfromaningot,withacrosssectionalareagreaterthan16

6.1 Condition—Material shall be furnished in the hot-

2 2

in. (10322 mm ) whose width is less than 5 times its

worked, cold-worked, forged, annealed, or stress-relieved con-

thickness.

dition.

4.1.7 Forging—Any product of work on metal formed to a

6.2 Finish—The mill product may be furnished as descaled

desired shape by impact or pressure in hammers, forging

or pickled, abrasive blasted, chemically milled, ground,

machines, upset presses, or related forming equipment.

machined, peeled, polished, or as specified by the purchaser.

4.1.8 Wire—Rounds,flatsorothershapeslessthan0.188in.

On billets, bars, plates, and forgings, it is permissible to

(4.76 mm) in diameter or thickness.

remove minor surface imperfections by spot grinding if such

4.1.9 Other—Other forms and shapes, including tubing,

grinding does not reduce the dimension below the minimum

may be provided by agreement between purchaser and sup-

permitted by the dimensional tolerance ordered.

plier.

5. Ordering Information 7. Chemical Composition

5.1 Inquiriesandordersformaterialunderthisspecification 7.1 The heat analysis shall conform to the chemical com-

shall include the following information: positionofTable1.Ingotanalysismaybeusedforreportingall

5.1.1 Quantity (weight or number of pieces), chemical requirements, except hydrogen. Samples for hydro-

5.1.2 Grade (1, 2, 3, or 4), genshallbetakenfromthefinishedmillproduct.Suppliershall

5.1.3 ASTM designation and date of issue, not ship material with chemistry outside the requirements

5.1.3.1 Units to be certified – SI or inch-pound, specified in Table 1 for the applicable grade.

TABLE 1 Chemical Requirements

A

Composition , % (mass/mass)

Element

Grade 1 Grade 2 Grade 3 Grade 4

UNS R50250 UNS R50400 UNS R50550 UNS R50700

Nitrogen, max 0.03 0.03 0.05 0.05

Carbon, max 0.08 0.08 0.08 0.08

B

Hydrogen, max 0.015 0.015 0.015 0.015

Iron, max 0.20 0.30 0.30 0.50

Oxygen, max 0.18 0.25 0.35 0.40

Titanium balance balance balance balance

A

Forgings are designated Grade F-1, F-2, F-3, or F-4 respectively. Forging compositions are as specified in Table 1.

B

Maximum hydrogen content for billet is 0.0100 wt%.

F67−13 (2017)

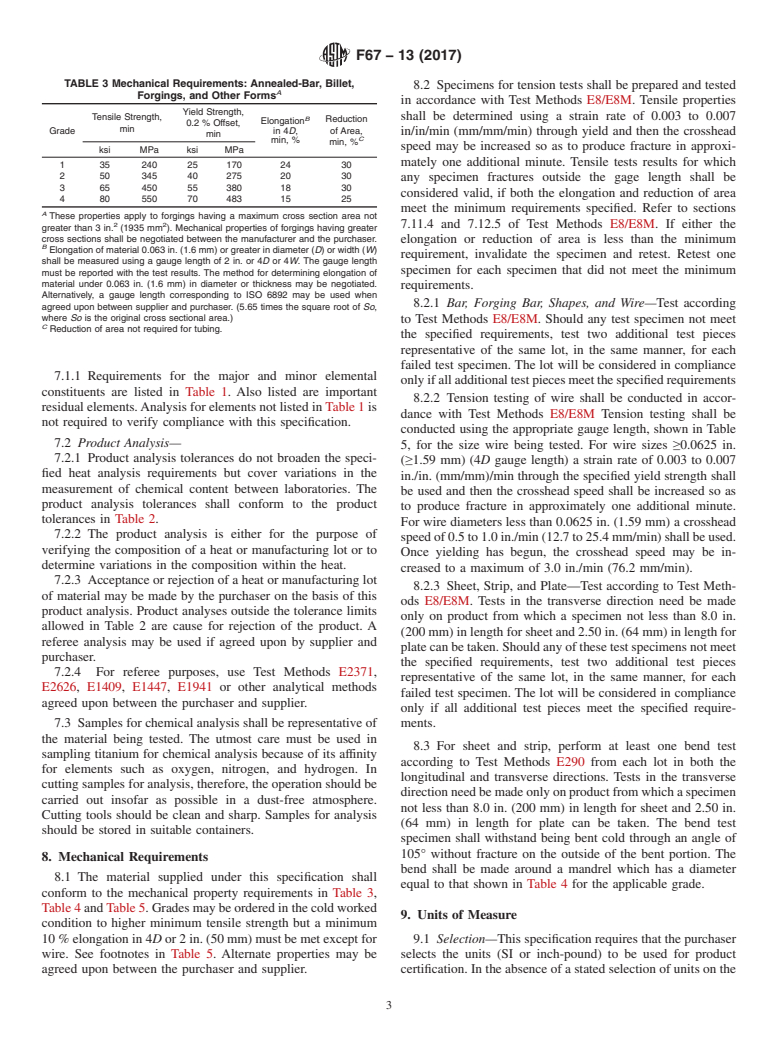

TABLE 3 Mechanical Requirements: Annealed-Bar, Billet,

8.2 Specimens for tension tests shall be prepared and tested

A

Forgings, and Other Forms

in accordance with Test Methods E8/E8M. Tensile properties

Yield Strength,

shall be determined using a strain rate of 0.003 to 0.007

Tensile Strength, B

Reduction

Elongation

0.2 % Offset,

min

Grade in 4D, of Area,

in/in/min (mm/mm/min) through yield and then the crosshead

min

C

min, %

min, %

speed may be increased so as to produce fracture in approxi-

ksi MPa ksi MPa

mately one additional minute. Tensile tests results for which

1 35 240 25 170 24 30

2 50 345 40 275 20 30

any specimen fractures outside the gage length shall be

3 65 450 55 380 18 30

considered valid, if both the elongation and reduction of area

4 80 550 70 483 15 25

meet the minimum requirements specified. Refer to sections

A

These properties apply to forgings having a maximum cross section area not

2 2

7.11.4 and 7.12.5 of Test Methods E8/E8M. If either the

greater than 3 in. (1935 mm ). Mechanical properties of forgings having greater

cross sections shall be negotiated between the manufacturer and the purchaser.

elongation or reduction of area is less than the minimum

B

Elongation of material 0.063 in. (1.6 mm) or greater in diameter (D) or width (W)

requirement, invalidate the specimen and retest. Retest one

shall be measured using a gauge length of 2 in. or 4D or 4W. The gauge length

specimen for each specimen that did not meet the minimum

must be reported with the test results. The method for determining elongation of

material under 0.063 in. (1.6 mm) in diameter or thickness may be negotiated.

requirements.

Alternatively, a gauge length corresponding to ISO 6892 may be used when

8.2.1 Bar, Forging Bar, Shapes, and Wire—Test according

agreed upon between supplier and purchaser. (5.65 times the square root of So,

where So is the original cross sectional area.)

to Test Methods E8/E8M. Should any test specimen not meet

C

Reduction of area not required for tubing.

the specified requirements, test two additional test pieces

representative of the same lot, in the same manner, for each

failed test specimen. The lot will be considered in compliance

7.1.1 Requirements for the major and minor elemental

onlyifalladditionaltestpiecesmeetthespecifiedrequirements

constituents are listed in Table 1. Also listed are important

8.2.2 Tension testing of wire shall be conducted in accor-

residualelements.AnalysisforelementsnotlistedinTable1is

dance with Test Methods E8/E8M Tension testing shall be

not required to verify compliance with this specification.

conducted using the appropriate gauge length, shown in Table

7.2 Product Analysis—

5, for the size wire being tested. For wire sizes ≥0.0625 in.

7.2.1 Product analysis tolerances do not broaden the speci-

(≥1.59 mm) (4D gauge length) a strain rate of 0.003 to 0.007

fied heat analysis requirements but cover variations in the

in./in. (mm/mm)/min through the specified yield strength shall

measurement of chemical content between laboratories. The

be used and then the crosshead speed shall be increased so as

product analysis tolerances shall conform to the product

to produce fracture in approximately one additional minute.

tolerances in Table 2.

For wire diameters less than 0.0625 in. (1.59 mm) a crosshead

7.2.2 The product analysis is either for the purpose of

speedof0.5to1.0in./min(12.7to25.4mm/min)shallbeused.

verifying the composition of a heat or manufacturing lot or to

Once yielding has begun, the crosshead speed may be in-

determine variations in the composition within the heat.

creased to a maximum of 3.0 in./min (76.2 mm/min).

7.2.3 Acceptance or rejection of a heat or manufacturing lot

8.2.3 Sheet, Strip, and Plate—Test according to Test Meth-

of material may be made by the purchaser on the basis of this

ods E8/E8M. Tests in the transverse direction need be made

product analysis. Product analyses outside the tolerance limits

only on product from which a specimen not less than 8.0 in.

allowed in Table 2 are cause for rejection of the product. A

(200mm)inlengthforsheetand2.50in.(64mm)inlengthfor

referee analysis may be used if agreed upon by supplier and

platecanbetaken.Shouldanyofthesetestspecimensnotmeet

purchaser.

the specified requirements, test two additional test pieces

7.2.4 For referee purposes, use Test Methods E2371,

representative of the same lot, in the same manner, for each

E2626, E1409, E1447, E1941 or other analytical methods

failed test specimen. The lot will be considered in compliance

agreed upon between the purchaser and supplier.

only if all additional test pieces meet the specified require-

7.3 Samples for chemical analysis shall be representative of ments.

the material being tested. The utmost care must be used in

8.3 For sheet and strip, perform at least one bend test

sampling titanium for chemical analysis because of its affinity

according to Test Methods E290 from each lot in both the

for elements such as oxygen, nitrogen, and hydrogen. In

longitudinal and transverse directions. Tests in the transverse

cutting samples for analysis, therefore, the operation should be

directionneedbemadeonlyonproductfromwhichaspecimen

carried out insofar as possible in a dust-free atmosphere.

not less than 8.0 in. (200 mm) in length for sheet and 2.50 in.

Cutting tools should be clean and sharp. Samples for analysis

(64 mm) in length for plate can be taken. The bend test

should be stored in suitable containers.

specimen shall withstand being bent cold through an angle of

105° without fracture on the outside of the bent portion. The

8. Mechanical Requirements

bend shall be made around a mandrel which has a diameter

8.1 The material supplied under this specification shall

equal to that shown in Table 4 for the applicable grade.

conform to the mechanical property requirements in Table 3,

Table4andTable5.Gradesmaybeorderedinthecoldworked

9. Units of Measure

condition to higher minimum tensile s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.