ASTM D5345-98

(Specification)Standard Specification for Prediluted Aqueous Ethylene Glycol Base Low-Silicate Engine Coolant (50 Volume % Minimum) for Heavy-Duty Engines Requiring an Initial Charge of Supplemental Coolant Additive (SCA) (Withdrawn 2000)

Standard Specification for Prediluted Aqueous Ethylene Glycol Base Low-Silicate Engine Coolant (50 Volume % Minimum) for Heavy-Duty Engines Requiring an Initial Charge of Supplemental Coolant Additive (SCA) (Withdrawn 2000)

SCOPE

1.1 This specification covers the requirements for a prediluted aqueous ethylene glycol base low-silicate engine coolant (50 volume percent minimum) for cooling systems of heavy-duty engines. When used without further dilution, this product will function effectively during both summer and winter to provide protection from corrosion, freezing at least to -36.7°C (-34.0°F), and boiling at least to 108°C (226°F).

1.2 Prediluted coolant meeting this specification requires both an initial charge of a supplemental coolant additive (SCA) and regular maintenance doses of an SCA to continue the protection in certain operating heavy-duty engine cooling systems, particularly those of the wet cylinder liner-in-block design. The SCA additions are defined by and are the primary responsibility of the engine or vehicle manufacturer. If they provide no instructions, follow the SCA supplier's recommended instructions.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5345 – 98

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Prediluted Aqueous Ethylene Glycol Base Low-Silicate

Engine Coolant (50 Volume Percent Minimum) for Heavy-

Duty Engines Requiring an Initial Charge of Supplemental

Coolant Additive (SCA)

This standard is issued under the fixed designation D 5345; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1122 Test Method for Density or Relative Density of

Engine Coolants Concentrates and Engine Coolants by the

1.1 This specification covers the requirements for a predi-

Hydrometer

luted aqueous ethylene glycol base low-silicate engine coolant

D 1126 Test Method for Hardness in Water

(50 volume percent minimum) for cooling systems of heavy-

D 1177 Test Method for Freezing Point of Aqueous Engine

duty engines. When used without further dilution, this product

Coolants

will function effectively during both summer and winter to

D 1193 Specification for Reagent Water

provide protection from corrosion, freezing at least to − 36.7°C

D 1287 Test Method for pH of Engine Coolants and Anti-

(−34.0°F), and boiling at least to 108°C (226°F).

rusts

1.2 Prediluted coolant meeting this specification requires

D 1293 Test Methods for pH of Water

both an initial charge of a supplemental coolant additive (SCA)

D 1384 Test Method for Corrosion Test for Engine Coolants

and regular maintenance doses of an SCA to continue the

in Glassware

protection in certain operating heavy-duty engine cooling

D 1881 Test Method for Foaming Tendencies of Engine

systems, particularly those of the wet cylinder liner-in-block

Coolants in Glassware

design. The SCA additions are defined by and are the primary

D 1882 Test Method for Effect of Cooling System Chemical

responsibility of the engine or vehicle manufacturer. If they

Solutions on Organic Finishes for Automotive Vehicles

provide no instructions, follow the SCA supplier’s recom-

D 1888 Test Methods for Particulate and Dissolved Matter

mended instructions.

in Water

1.3 The values stated in SI units are to be regarded as the

D 2570 Test Method for Simulated Service Corrosion Test-

standard. The values given in parentheses are for information

ing of Engine Coolants

only.

D 2809 Test Method for Cavitation Corrosion and Erosion-

1.4 This standard does not purport to address all of the

Corrosion Characteristics of Aluminum Pumps with En-

safety concerns, if any, associated with its use. It is the

gine Coolants

responsibility of the user of this standard to establish appro-

D 3306 Specification for Ethylene Glycol Base Engine

priate safety and health practices and determine the applica-

Coolant for Automobile and Light Duty Service

bility of regulatory limitations prior to use.

D 3321 Test Method for Use of the Refractometer for Field

2. Referenced Documents Test Determination of the Freezing Point of Aqueous

Engine Coolants

2.1 ASTM Standards:

D 4327 Test Method for Anions in Water by Chemically

D 512 Test Methods for Chloride Ion in Water

Suppressed Ion Chromatography

D 516 Test Method for Sulfate Ion in Water

D 4656 Specification for a Prediluted Aqueous Ethylene

D 1119 Test Method for Ash Content of Engine Coolants

Glycol Based Engine Coolant (50 Volume % Minimum)

and Antirusts

for Automobiles and Light-Duty Service

D 1120 Test Method for Boiling Point of Engine Coolants

D 4985 Specification for Low Silicate Ethylene Glycol

D 1121 Test Method for Reserve Alkalinity of Engine

Base Engine Coolant for Heavy Duty Engines Requiring a

Coolants and Antirusts

Pre-Charge of Supplemental Coolant Additive (SCA)

This specification is under the jurisdiction of ASTM Committee D-15 on

3. Terminology

Engine Coolants and is the direct responsibility of Subcommittee D15.13 on

Prediluted Engine Coolant.

3.1 Definitions of Terms Specific to This Standard:

Current edition approved October 10, 1998. Published January 1999. Originally

published as D 5345 – 93. Last previous edition D 5345 – 95.

Annual Book of ASTM Standards, Vol 11.01.

3 4

Annual Book of ASTM Standards, Vol 15.05. Discontinued—See 1990 Annual Book of ASTM Standards, Vol 11.01.

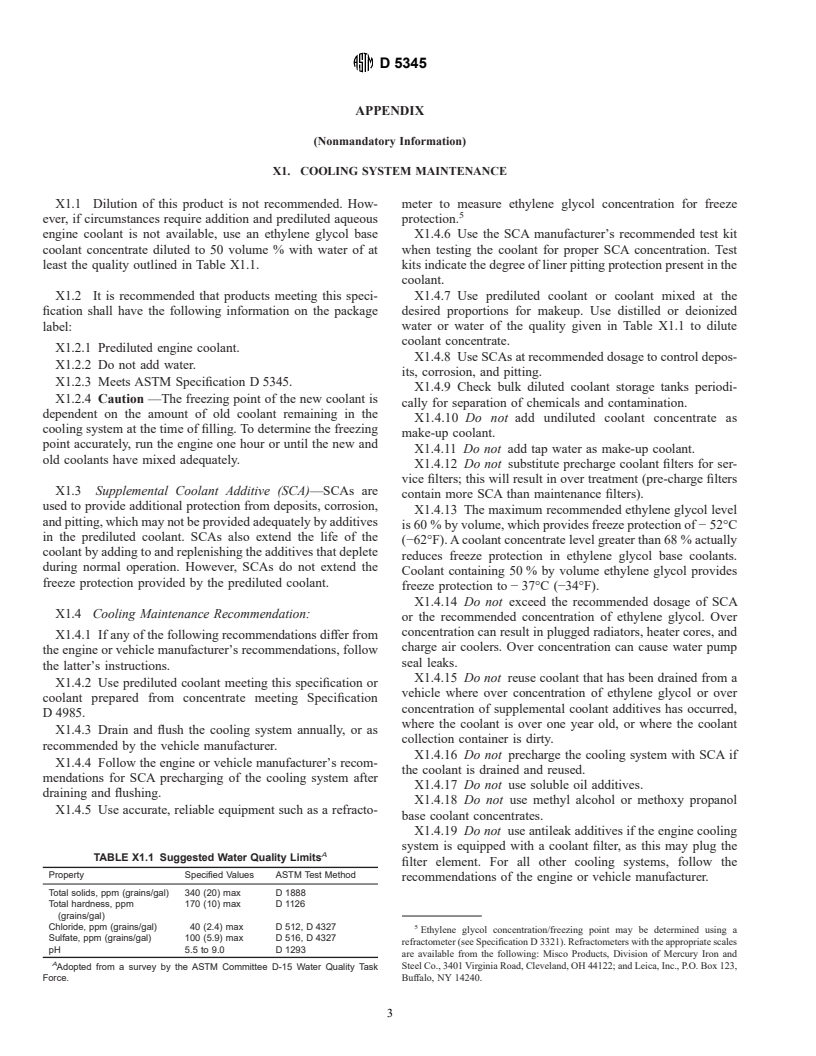

D 5345

TABLE 2 General Requirements of the Unadjusted Prediliuted

3.1.1 heavy duty engine—a diesel, gasoline, or similarly

Product

fueled internal combustion engine, having operating character-

Property Specified Values ASTM Test Method

istics of a long duty cycle at or near maximum rated conditions.

A

Color Distinctive .

3.1.2 Discussion—Such engines are typically used in off-

Effect on non-metals No adverse affect .

highway machinery for agriculture, mining, earth-moving, and

Storage stability . under consideration

construction; Classes 5 through 8 over the road trucks and

Foaming D 1881

buses; high output stationary engine installations; and locomo- Volume, mL 150 max

Break time, s 5 max

tive and marine installations (see Specifications D 3306 and

A

Preferred color, green to blue-green.

D 4656 for coolant requirements for automobiles, vans, and

pickup trucks, Classes 1 through 4).

3.1.3 supplement coolant additive (SCA)—a material added

before SCA addition, shall conform to the chemical and

to the cooling system of a heavy-duty engine to provide physical property requirements prescribed in Table 1 and to the

additional cavitation protection and corrosion inhibition and to

general requirements prescribed in Table 2.

minimize deposits on heat transfer surfaces. 5.2 Prediluted aqueous ethylene glycol base engine coolant,

after adjustment and before SCA addition, shall conform to the

4. General Requirements

laboratory test performance requirements prescribed in Table 3.

4.1 Prediluted aqueous ethylene glycol base engine coolant

5.3 Report the freezing point of the prediluted aqueous

shall consist essentially of ethylene glycol and water and shall

ethylene glycol base coolant as packaged. This freezing point

contain suitable corrosion inhibitors, dye, and a foam suppres-

shall be − 37°C (−34°F) or below.

sor. Other glycols, such as propylene and diethylene, may be

5.4 Adjust the freezing point of the prediluted aqueous

included up to a maximum of 15 % of the glycols contained in

ethylene glycol base coolant to − 37°C (−34°F) with deionized

the product, if the chemical and physical properties in Table 1

water. Use this concentration-adjusted product for all of the

are met. For example, 15 % of a 50 % aqueous glycol solution

performance requirements testing specified under this specifi-

could contain up to 7.5 % of glycols other than ethylene glycol.

cation and listed in Table 3 and for Footnote A of Table 1.

The coolant also shall conform to the general requirements

given in Table 2.

6. Keywords

4.2 This product shall be prepared using deionized water

6.1 engine coolant; ethylene glycol; heavy-duty engine

that meets Type IV reagent water specifications (see Specifi-

service; low-silicate coolant; prediluted

cation D 1193). This practice minimizes the formation of hard

water scale and avoids the introduction of mineral components,

A

TABLE 3 Performance Requirements of the Adjusted Prediluted

such as chlorides and sulfates, which can increase the corrosion

Product

rate of aluminum and iron. The use of Type IV reagent water

ASTM Test

Property Specified Values

also minimizes interferences that may cause coolant instability

Method

or SCA compatibility problems.

B

Corrosion in glassware D 1384

4.3 When installed in accordance with the vehicle manufac-

Weight loss, mg/specimen

Copper 10 max

turers’ recommendations and those on the product label, this

Solder 30 max

product shall be suitable for use in a properly maintained

Brass 10 max

cooling system (see Appendix X1) in normal service for a Steel 10 max

Ca

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.