ASTM F758-95(2000)

(Specification)Standard Specification for Smooth-Wall Poly(Vinyl Chloride) (PVC) Plastic Underdrain Systems for Highway, Airport, and Similar Drainage

Standard Specification for Smooth-Wall Poly(Vinyl Chloride) (PVC) Plastic Underdrain Systems for Highway, Airport, and Similar Drainage

SCOPE

1.1 This specification covers the requirements for smooth-wall perforated and nonperforated poly(vinyl chloride) (PVC) plastic pipe and couplings for use in subsurface drainage systems of highways, airports, and similar applications in nominal sizes of 4, 6, and 8 in. and in pipe stiffnesses (PS) that are designated as Type PS 28 and Type PS 46 in accordance with its minimum pipe stiffness.

1.2 Molded fittings for use with highway underdrain pipe are in accordance with Specification D3034. For convenience, some of these fittings are reproduced in Annex A1.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

Note 1--Type PS 28 and Type PS 46 indicate "pipe stiffness" of 28 and 46, respectively, as outlined in 11.1.

Note 2--Pipe and fittings should be installed in accordance with Practice D2321, or applicable state or local specifications.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 758 – 95 (Reapproved 2000)

Standard Specification for

Smooth-Wall Poly(Vinyl Chloride) (PVC) Plastic Underdrain

Systems for Highway, Airport, and Similar Drainage

This standard is issued under the fixed designation F 758; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D 1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

Compounds and Chlorinated Poly(Vinyl Chloride)

1.1 This specification covers the requirements for smooth-

(CPVC) Compounds

wall perforated and nonperforated poly(vinyl chloride) (PVC)

D 2122 Test Method for Determining Dimensions of Ther-

plastic pipe and couplings for use in subsurface drainage

moplastic Pipe and Fittings

systems of highways, airports, and similar applications in

D 2152 Test Method for Degree of Fusion of Extruded

nominal sizes of 4, 6, and 8 in. and in pipe stiffnesses (PS) that

Poly(Vinyl Chloride) (PVC) Pipe and Molded Fittings by

are designated as Type PS 28 and Type PS 46 in accordance

Acetone Immersion

with its minimum pipe stiffness.

D 2321 Practice for Underground Installation of Flexible

1.2 Molded fittings for use with highway underdrain pipe

Thermoplastic Sewer Pipe

are in accordance with Specification D 3034. For convenience,

D 2412 Test Method for Determination of External Loading

some of these fittings are reproduced in Annex A1.

Characteristics of Plastic Pipe by Parallel-Plate Loading

1.3 The values stated in inch-pound units are to be regarded

D 2444 Test Method for Impact Resistance of Thermoplas-

as the standard. The values given in parentheses are for

tic Pipe and Fittings by Means of a Tup (Falling Weight)

information only.

D 2564 Specification for Solvent Cements for Poly(Vinyl

NOTE 1—TypePS28andTypePS46indicate“pipestiffness”of28and

Chloride) (PVC) Plastic Piping Systems

46, respectively, as outlined in 11.1.

D 2855 Practice for Making Solvent-Cemented Joints with

NOTE 2—Pipe and fittings should be installed in accordance with

Poly(Vinyl Chloride) (PVC) Pipe and Fittings

Practice D 2321, or applicable state or local specifications.

D 3034 Specification for Type PSM Poly(Vinyl Chloride)

1.4 The following safety hazards caveat pertains only to the

(PVC) Sewer Pipe and Fittings

test methods portion, Section 11, of this specification: This

D 3212 Specification for Joints for Drain and Sewer Plastic

standarddoesnotpurporttoaddressallofthesafetyconcerns,

Pipes Using Flexible Elastomeric Seals

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

D 4396 Specification for Rigid Poly(Vinyl Chloride) (PVC)

of this standard to establish appropriate safety and health

and Related Plastic Compounds for Non-Pressure Piping

practices and determine the applicability of regulatory limita-

Products

tions prior to use.

F 402 Practice for Safe Handling of Solvent

Cements, Primers, and Cleaners Used for Joining Thermo-

2. Referenced Documents

plastic Pipe and Fittings

2.1 ASTM Standards:

F 412 Terminology Relating to Plastic Piping Systems

D 618 Practice for Conditioning Plastics and Electrical

2.2 Federal Standard:

Insulating Materials for Testing

Fed. Std. No. 123 Marking for Shipments (CivilAgencies)

D 1600 Terminology for Abbreviated Terms Relating to

2.3 Military Standard:

Plastics

MIL-STD-129 Marking for Shipment and Storage

This specification is under the jurisdiction ofASTM Committee F-17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land Annual Book of ASTM Standards, Vol 08.02.

Drainage. Annual Book of ASTM Standards, Vol 08.04.

Current edition approved Sept. 10, 1995. Published November 1995. Originally Annual Book of ASTM Standards, Vol 08.03.

published as F 758 – 82. Last previous edition F 758 – 93. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Annual Book of ASTM Standards, Vol 08.01. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 758 – 95 (2000)

TABLE 2 Dimensions of Bends

3. Terminology

3.1 Definitions—Definitions are in accordance with Termi-

nology F 412, and abbreviations are in accordance with Ter-

minology D 1600, unless otherwise specified.The abbreviation

for poly(vinyl chloride) plastic is PVC.

4. Classification

4.1 Two classes (or pipe stiffness) are included and desig-

nated as PS 28 and PS 46 as determined in accordance with

11.1.

5. Materials

in.

Socket Length of

5.1 The pipe shall be made of PVC plastic having a A

Depth Tangent

Nominal

Angle Radius

minimum cell classification of 12454 or 12364 as defined in

Size, in.

Dimen-sion Dimen-sion

Specification D 1784 or a minimum cell classification of 11432

J, min L, min

or 11332 as defined in specification D 4396. Homopolymer

4 45° 16, 24, 36 1.750 2.00

90° 16, 24, 36

PVC compounds must equal or exceed the requirements of the

listed cell classification numbers.

6 45° 24, 36 3.000 3.50

5.2 Rework Material—Rework material from the manufac- 90° 24, 36

turer’sownpipeorfittingsproductionmaybeusedbythesame

8 45° 24, 36 4.000 5.00

manufacturer, provided that the pipe or fabricated fittings

90° 24, 36

produced meet all the requirements of this specification.

mm

6. Joint Systems Socket Length of

A

Depth Tangent

Nominal

Angle Radius

6.1 Gasket-TypeJoints,meetingtheapplicablerequirements

Size, in.

Dimen-sion Dimen-sion

of Specification D 3212, may be utilized.

J, min L, min

6.2 Solvent-Cement-Type Joints, made with bell ends meet-

4 45° 406.4 609.6 914.4 44.44 50.80

90° 406.4 609.6 914.4

ing the requirements of Table 1; stop-type couplings in

conformance with Table 2; or sleeve-type couplings in con-

6 45° 609.6 914.4 76.20 88.90

formance with Table 3, may be utilized.

90° 609.6 914.4

6.2.1 Belled ends shall be formed so as to provide a uniform

8 45° 609.6 914.4 101.60 127.00

shoulder around the entire circumference of the pipe.

90° 609.6 914.4

A

Socket dimensions shall be as shown in Table 1.

TABLE 1 Socket-Type Bell Dimensions

(Belled Ends for Solvent-Cement-Type Pipe and Bends)

6.2.2 Solvent-cemented joints shall be made using PVC

cement meeting the requirements of Specification D 2564, and

shall be made in accordance with Practice D 2855 and Practice

F 402.

7. Requirements Requirements

in.

7.1 Workmanship—The pipe shall be homogeneous

C

throughout and essentially uniform in color, opacity, density,

B

Nominal A Bell

and other properties. The inside and outside surfaces shall be

Socket

Size, in. Entrance Depth,

Bottom

semimatte or glossy in appearance (depending on the type of

min

plastic) and free of chalking, sticky, or tacky material. The

4 4.235 6 0.009 4.210 6 0.009 1.750

6 6.305 6 0.011 6.270 6 0.011 3.000

surfaces shall be free of excessive bloom, that is, slight bloom

8 8.424 6 0.012 8.388 6 0.012 4.000

is acceptable. The pipe walls shall be free of cracks, holes,

blisters, voids, foreign inclusion, or other defects that are

mm

visible to the naked eye and that may affect the wall integrity.

C

B

Holes deliberately placed in perforated pipe are acceptable.

Nominal A Bell

Socket

Size, in. Entrance Depth,

Bloom or chalking may develop in pipe exposed to direct rays

Bottom

min

of the sun (ultraviolet radiant energy) for extended periods and

4 107.57 6 0.22 106.93 6 0.22 44.44

consequently these requirements do not apply to pipe after

6 160.15 6 0.28 159.26 6 0.28 76.20

extended exposure to direct rays of the sun.

8 213.97 6 0.30 213.06 6 0.30 101.60

7.2 Dimensions and Tolerance:

F 758 – 95 (2000)

A

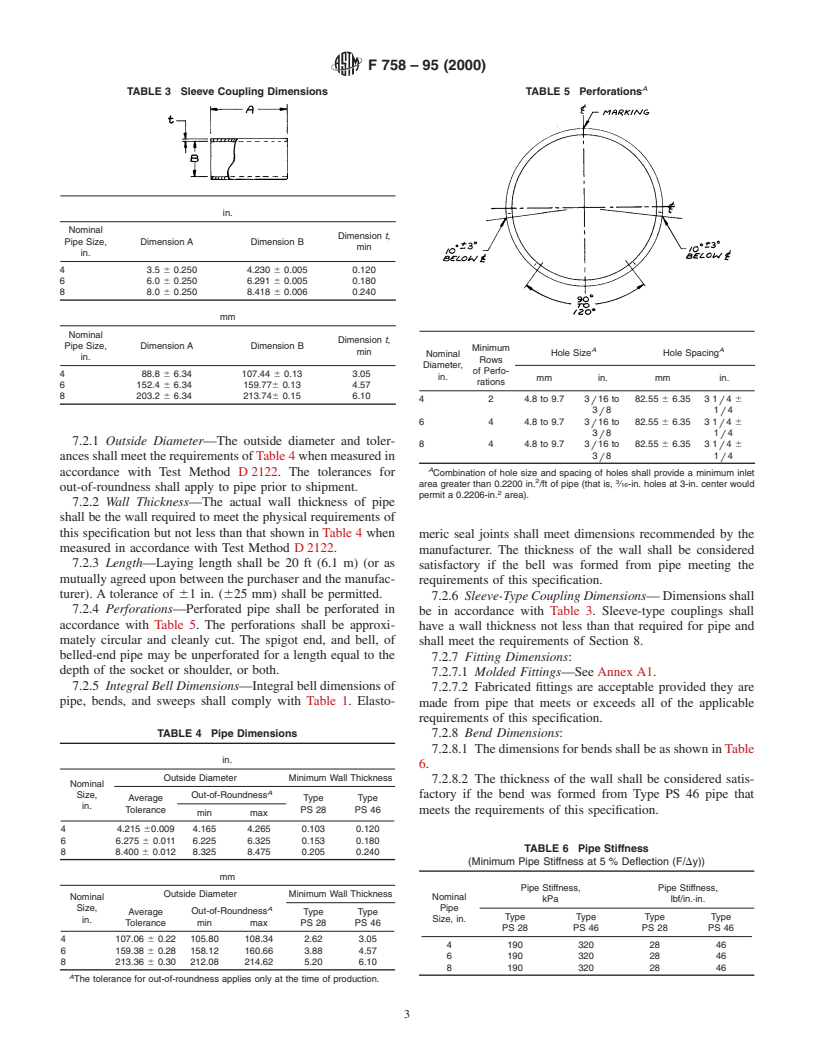

TABLE 3 Sleeve Coupling Dimensions TABLE 5 Perforations

in.

Nominal

Dimension t,

Pipe Size, Dimension A Dimension B

min

in.

43.5 6 0.250 4.230 6 0.005 0.120

66.0 6 0.250 6.291 6 0.005 0.180

88.0 6 0.250 8.418 6 0.006 0.240

mm

Nominal

Dimension t,

Pipe Size, Dimension A Dimension B

Minimum A A

min

Hole Size Hole Spacing

Nominal

in.

Rows

Diameter,

of Perfo-

4 88.8 6 6.34 107.44 6 0.13 3.05

in.

mm in. mm in.

rations

6 152.4 6 6.34 159.776 0.13 4.57

8 203.2 6 6.34 213.746 0.15 6.10

4 2 4.8to9.7 3 16 to 82.55 6 6.35 3 1 4 6

/ /

3 8 1 4

/ /

6 4 4.8to9.7 3 16 to 82.55 6 6.35 3 1 4 6

/ /

3 8 1 4

/ /

7.2.1 Outside Diameter—The outside diameter and toler-

8 4 4.8to9.7 3 16 to 82.55 6 6.35 3 1 4 6

/ /

3 8 1 4

ances shall meet the requirements ofTable 4 when measured in

/ /

A

accordance with Test Method D 2122. The tolerances for Combination of hole size and spacing of holes shall provide a minimum inlet

area greater than 0.2200 in. /ft of pipe (that is, ⁄16-in. holes at 3-in. center would

out-of-roundness shall apply to pipe prior to shipment.

permit a 0.2206-in. area).

7.2.2 Wall Thickness—The actual wall thickness of pipe

shall be the wall required to meet the physical requirements of

this specification but not less than that shown in Table 4 when

meric seal joints shall meet dimensions recommended by the

measured in accordance with Test Method D 2122.

manufacturer. The thickness of the wall shall be considered

7.2.3 Length—Laying length shall be 20 ft (6.1 m) (or as

satisfactory if the bell was formed from pipe meeting the

mutually agreed upon between the purchaser and the manufac-

requirements of this specification.

turer). A tolerance of 61 in. (625 mm) shall be permitted.

7.2.6 Sleeve-TypeCouplingDimensions—Dimensionsshall

7.2.4 Perforations—Perforated pipe shall be perforated in

be in accordance with Table 3. Sleeve-type couplings shall

accordance with Table 5. The perforations shall be approxi-

have a wall thickness not less than that required for pipe and

mately circular and cleanly cut. The spigot end, and bell, of

shall meet the requirements of Section 8.

belled-end pipe may be unperforated for a length equal to the

7.2.7 Fitting Dimensions:

depth of the socket or shoulder, or both.

7.2.7.1 Molded Fittings—See Annex A1.

7.2.5 IntegralBellDimensions—Integral bell dimensions of

7.2.7.2 Fabricated fittings are acceptable provided they are

pipe, bends, and sweeps shall comply with Table 1. Elasto-

made from pipe that meets or exceeds all of the applicable

requirements of this specification.

TABLE 4 Pipe Dimensions 7.2.8 Bend Dimensions:

7.2.8.1 The dimensions for bends shall be as shown inTable

in.

6.

Outside Diameter Minimum Wall Thickness

7.2.8.2 The thickness of the wall shall be considered satis-

Nominal

A

Size, Out-of-Roundness factory if the bend was formed from Type PS 46 pipe that

Average Type Type

in.

Tolerance PS 28 PS 46

meets the requirements of this specification.

min max

4 4.215 60.0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.