ASTM B706-00(2011)

(Specification)Standard Specification for Seamless Copper Alloy (UNS No. C69100) Pipe and Tube

Standard Specification for Seamless Copper Alloy (UNS No. C69100) Pipe and Tube

ABSTRACT

This specification establishes the requirements for standard sized seamless pipes, both regular and extra strong, and seamless tubes in straight lengths produced from copper alloy UNS No. C69100 for general engineering purposes. The materials for manufacture shall be cast or extruded shells of such purity and soundness as to be suitable for processing by hot working, cold working, and annealing to produce a uniform wrought structure in the finished product. Products shall be produced in tempers TB00 (soft-annealed), TF00 (precipitation-hardened), and HR50 (drawn stress relieved). Products shall be sampled and prepared, then tested accordingly to examine their conformance to dimensional (mass, wall thickness, inside and outside diameters, cross-sectional area, nominal weight, length, squareness of cut, and density), mechanical (tensile and yield strengths, Rockwell hardness, and elongation), physical (electrical resistivity and coefficient of thermal expansion), and chemical composition requirements. Products shall also undergo nondestructive eddy-current and hydrostatic tests.

SCOPE

1.1 This specification establishes the requirements for copper alloy UNS No. C69100 seamless pipe in standard pipe sizes, both regular and extra strong, and seamless tube in straight lengths for general engineering purposes.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazard caveat pertains only to the test method portion, Section described in this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B706 −00 (Reapproved 2011)

Standard Specification for

1

Seamless Copper Alloy (UNS No. C69100) Pipe and Tube

This standard is issued under the fixed designation B706; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E478Test Methods for ChemicalAnalysis of CopperAlloys

1.1 This specification establishes the requirements for cop-

3. Terminology

per alloy UNS No. C69100 seamless pipe in standard pipe

sizes, both regular and extra strong, and seamless tube in

3.1 Definitions:

straight lengths for general engineering purposes.

3.1.1 For definitions of terms related to copper and copper

alloys, refer to Terminology B846, unless otherwise stated.

1.2 The values stated in inch-pound units are to be regarded

3.1.2 stock, n—straight lengths that are mill cut and stored

as standard. The values given in parentheses are mathematical

in advance of orders. They usually are 10, 12, or 20 ft (3.05,

conversions to SI units that are provided for information only

3.66, or 6.10 m) in length and subject to established length

and are not considered standard.

tolerances.

1.3 The following safety hazard caveat pertains only to the

testmethodportion,Sectiondescribedinthisspecification:This

4. Ordering Information

standard does not purport to address all of the safety concerns,

4.1 Ordersforproductsshallincludethefollowinginforma-

if any, associated with its use. It is the responsibility of the user

tion:

of this standard to establish appropriate safety and health

4.1.1 ASTM designation and year of issue, that is,

practices and determine the applicability of regulatory limita-

tions prior to use. B706–XX.

4.1.2 UNS designation, that is, C69100.

2. Referenced Documents

4.1.3 Temper (see Section 7).

2

4.1.4 Dimensions, diameter, and wall thickness.

2.1 ASTM Standards:

4.1.5 How furnished: straight lengths or coils.

B193Test Method for Resistivity of Electrical Conductor

Materials 4.1.6 Finish.

B846Terminology for Copper and Copper Alloys

4.1.7 Total length, or number of pieces, of each size.

E8Test Methods for Tension Testing of Metallic Materials

4.1.8 Total weight, each size.

E20Practice for Particle Size Analysis of Particulate Sub-

4.1.9 When product is purchased for agencies of the U.S.

stances in the Range of 0.2 to 75 Micrometres by Optical

government.

3

Microscopy (Withdrawn 1994)

4.2 The following options are available and shall be in-

E54Test Methods for ChemicalAnalysis of Special Brasses

cluded in the contract or purchase order when required.

3

and Bronzes (Withdrawn 2002)

4.2.1 Heat identification or traceability details.

E243PracticeforElectromagnetic(Eddy-Current)Examina-

4.2.2 Electromagnetic (eddy-current) examination.

tion of Copper and Copper-Alloy Tubes

4.2.3 Expansion test.

E255Practice for Sampling Copper and Copper Alloys for

4.2.4 Flattening test.

the Determination of Chemical Composition

4.2.5 Certification.

4.2.6 Mill test report.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

5. Materials and Manufacture

and Tube.

Current edition approved Oct. 1, 2011. Published February 2012. Originally

5.1 Material:

approved in 1982. Last previous edition approved in 2006 as B706–00 (2006).

5.1.1 The material of manufacture shall be cast or extruded

DOI: 10.1520/B0706-00R11.

2

shells of Copper Alloy UNS No. C69100 of such purity and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

soundness as to be suitable for processing into the products

Standards volume information, refer to the standard’s Document Summary page on

prescribed herein.

the ASTM website.

3

5.1.2 In the event heat identification or traceability is

The last approved version of this historical standard is referenced on

www.astm.org. required, the purchaser shall specify the details desired.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

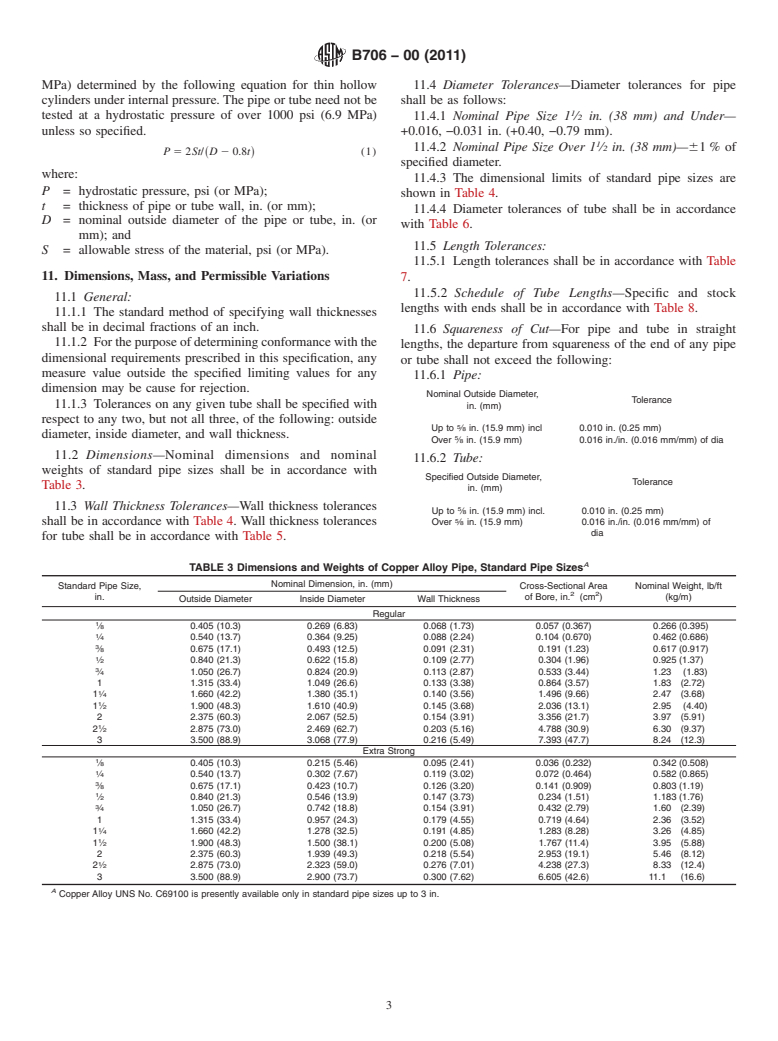

B706−00 (2011)

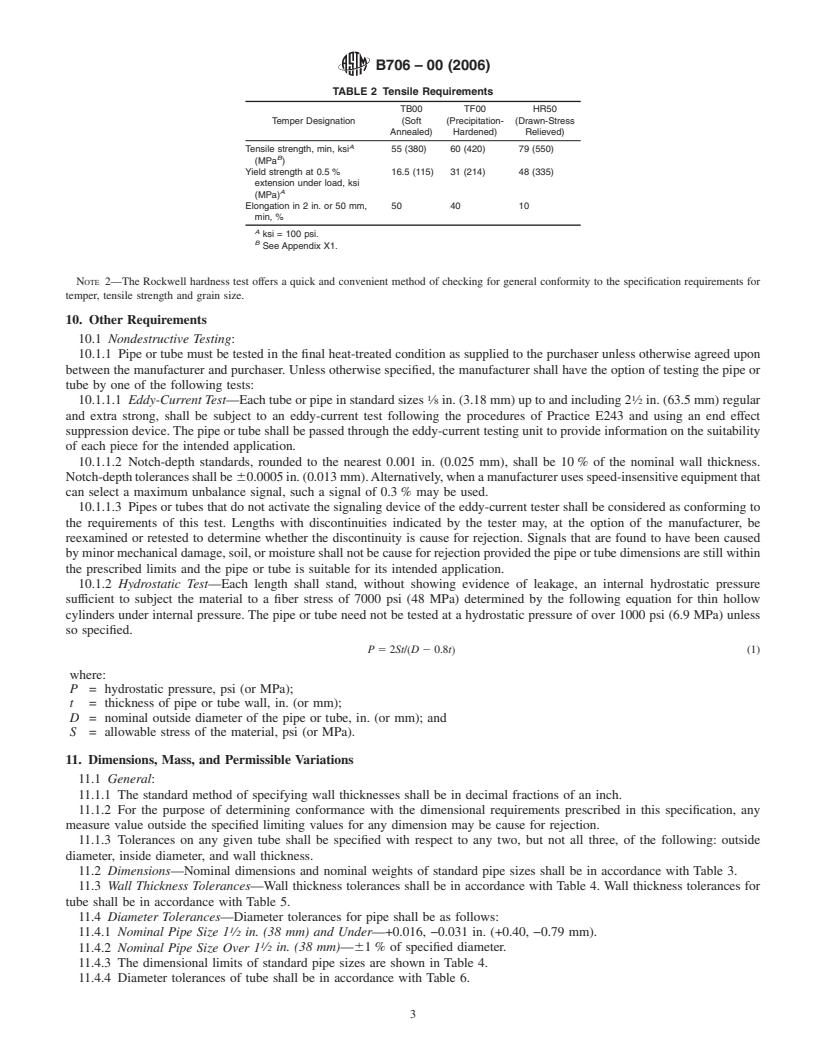

NOTE 1—Because of the discontinuous nature of the processing of TABLE 2 Tensile Requirements

castings into wrought products, it is not always practical to identify a

TB00 TF00 HR50

specific casting analysis with a specific quantity of finished material.

Temper Designation (Soft (Precipitation- (Drawn-Stress

Annealed) Hardened) Relieved)

5.2 Manufacture:

A

Tensile strength, min, ksi 55 (380) 60 (420) 79 (550)

B

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B706 – 00 (Reapproved 2006)

Standard Specification for

1

Seamless Copper Alloy (UNS No. C69100) Pipe and Tube

This standard is issued under the fixed designation B706; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 ThisspecificationestablishestherequirementsforcopperalloyUNSNo.C69100seamlesspipeinstandardpipesizes,both

regular and extra strong, and seamless tube in straight lengths for general engineering purposes.

1.2 Values stated in inch-pound units are the standard. SI values given in parenthesis are provided for information only.

1.3 The following safety hazard caveat pertains only to the test method portion, Section described in this specification: This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor Materials

B846 Terminology for Copper and Copper Alloys

E8 Test Methods for Tension Testing of Metallic Materials

E20 PracticeforParticleSizeAnalysisofParticulateSubstancesintheRangeof0.2to75MicrometresbyOpticalMicroscopy

3

E54 Test Methods for Chemical Analysis of Special Brasses and Bronzes

E243 Practice for Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E478 Test Methods for Chemical Analysis of Copper Alloys

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms related to copper and copper alloys, refer to Terminology B846, unless otherwise stated.

3.1.2 stock, n—straight lengths that are mill cut and stored in advance of orders. They usually are 10, 12, or 20 ft (3.05, 3.66,

or 6.10 m) in length and subject to established length tolerances.

4. Ordering Information

4.1 Orders for products shall include the following information:

4.1.1 ASTM designation and year of issue, that is, B706–XX.

4.1.2 UNS designation, that is, C69100.

4.1.3 Temper (see Section 7).

4.1.4 Dimensions, diameter, and wall thickness.

4.1.5 How furnished: straight lengths or coils.

4.1.6 Finish.

4.1.7 Total length, or number of pieces, of each size.

4.1.8 Total weight, each size.

4.1.9 When product is purchased for agencies of the U.S. government.

4.2 The following options are available and shall be included in the contract or purchase order when required.

4.2.1 Heat identification or traceability details.

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

CurrenteditionapprovedFeb.1,2006.PublishedFebruary2006.Originallyapprovedin1982.WithdrawnDec.15,1993.ReinstatedMarch10,2000.Lastpreviousedition

approved in 2000 as B706–00. DOI: 10.1520/B0706-00R06.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B706 – 00 (2006)

4.2.2 Electromagnetic (eddy-current) examination.

4.2.3 Expansion test.

4.2.4 Flattening test.

4.2.5 Certification.

4.2.6 Mill test report.

5. Materials and Manufacture

5.1 Material:

5.1.1 The material of manufacture shall be cast or extruded shells of Copper Alloy UNS No. C69100 of such purity and

soundness as to be suitable for processing into the products prescribed herein.

5.1.2 In the event heat identification or traceability is required, the purchaser shall specify the details desired.

NOTE 1—Becauseofthediscontinuousnatureoftheprocessingofcastingsintowroughtproducts,itisnotalwayspracticaltoidentifyaspecificcasting

analysis with a specific quantity of finished material.

5.2 Manufacture:

5.2.1 The product shall be manufactured by such hot-working, cold-working, and annealing processes as to produce a uniform

wrought structure in th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.