ASTM F1018-87a(2004)

(Specification)Standard Specification for Steel Emergency Gear Stowage Locker

Standard Specification for Steel Emergency Gear Stowage Locker

ABSTRACT

This specification establishes the material and design requirements, as well as the mandatory dimensional and construction details for four types of steel emergency gear stowage lockers used for the stowage of one or two complete fireman's outfit(s).

SCOPE

1.1 This specification covers the design, material, and manufacture of steel emergency gear stowage lockers.

1.2 Emergency gear lockers shall be of four types (see Section ).

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: F1018 – 87a (Reapproved 2004)

Standard Specification for

Steel Emergency Gear Stowage Locker

This standard is issued under the fixed designation F1018; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ABS Rules for Building and Classing Steel Vessels

SSPC Specification 6

1.1 This specification covers the design, material, and

AWS D1.1 Welding Code

manufacture of steel emergency gear stowage lockers.

1.2 Emergency gear lockers shall be of four types (see

3. Classification

Section 3).

3.1 Emergency gear lockers shall be classified in four types

1.3 The values stated in inch-pound units are to be regarded

as follows:

as the standard. The values given in parentheses are for

3.1.1 Type1—Forstowageofonecompletefireman’soutfit,

information only.

conforming to all requirements of all sections, figures, and

2. Referenced Documents details of this specification.

2 3.1.2 Type 2—For stowage of two complete firemen’s

2.1 ASTM Standards:

outfits, conforming to all requirements of all sections, figures,

A36/A36M Specification for Carbon Structural Steel

and details of this specification.

A276 Specification for Stainless Steel Bars and Shapes

3.1.3 Type3—Forstowageofonecompletefireman’soutfit,

A366/A366M Specification for Commercial Steel (CS)

with locker dimensions in accordance with Figs. 2, 3, and 4

Sheet, Carbon (0.15 Maximum Percent) Cold-Rolled

(dimensions only), and conforming to the requirements of 3.2,

A513 Specification for Electric-Resistance-Welded Carbon

3.3, 4.1, 5.2.4, and Sections 6 and 7 inclusive.

and Alloy Steel Mechanical Tubing

3.1.4 Type 4—For stowage of two complete firemen’s

A563 Specification for Carbon and Alloy Steel Nuts

outfits, with locker dimensions in accordance with Figs. 2, 3,

B36/B36M Specification for Brass Plate, Sheet, Strip, And

and 4 (dimensions only), and conforming to the requirements

Rolled Bar

of 3.2, 3.3, 4.1, 5.2.4, and Sections 6 and 7 inclusive.

B124/B124M Specification for Copper and Copper Alloy

3.2 One complete fireman’s outfit shall consist of the

Forging Rod, Bar, and Shapes

following emergency gear (not included in this specification):

B176 Specification for Copper-Alloy Die Castings

4 3.2.1 Self-contained breathing apparatus (24 by 14 by 11 in.

2.2 ANSI Standards:

(610 by 355 by 280 mm)).

B18.1.1 Small Solid Rivets

3.2.2 Recharge air tank (7-in. (180-mm) diameter by 22 in.

B18.6.3 Slotted and Recessed Head Machine Screws and

(560 mm) long).

Machine Screw Nuts

3.2.3 Set protective clothing, including helmet, gloves, and

B18.21.1 Lock Washers

boots.

B27.2 Plain Washers

3.2.4 Lifeline (150 ft (45 m), 18 by 18 by 10 in. (455 by 455

2.3 Other Documents:

by 255 mm)).

3.2.5 Three-cell, explosion-proof flashlight with spare cells.

3.2.6 Flame safety lamp.

This specification is under the jurisdiction of ASTM Committee F25 on Ships

3.2.7 Fire axe.

and Marine Technology and is the direct responsibility of Subcommittee F25.03 on

3.3 In addition to the equipment listed in 3.2, each locker

Outfitting and Deck Machinery.

shall contain space for the following (not part of this specifi-

Current edition approved Nov. 1, 2004. Published November 2004. Originally

´1

approved in 1986. Last previous edition approved in 1999 as F1018 – 87a (1999) .

cation):

DOI: 10.1520/F1018-87AR04.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Bureau of Shipping (ABS), ABS Plaza, 16855

Standards volume information, refer to the standard’s Document Summary page on Northchase Dr., Houston, TX 77060.

the ASTM website. Available from Society for Protective Coatings (SSPC), 40 24th St., 6th Floor,

Withdrawn. Pittsburgh, PA 15222-4656.

4 7

Available from American National Standards Institute (ANSI), 25 W. 43rd St., Available from The American Welding Society (AWS), 550 NW LeJeune Rd.,

4th Floor, New York, NY 10036. Miami, FL 33126.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

F1018 – 87a (2004)

3.3.1 First-aidkit,(1),(10by10by7in.(255by255by180 5.2.4 Welded construction, in accordance with ABS Rules

mm)). for Building and Classing Steel Vessels or AWS D 1.1

Structural Welding Code shall be used throughout, unless

3.3.2 Spare air tanks, as space allows (see Figs. 2, 3, and 4).

otherwise specified.

4. Ordering Information

6. Dimensions and Tolerances

4.1 Order using this ASTM designation, year of issue, 6.1 Dimensions are as indicated.

6.2 Tolerance—6 ⁄16 in. (1.5 mm).

locker type, and finish.

7. Workmanship, Finish, and Appearance

5. Materials and Manufacture

7.1 Entire assembly shall be free of weld spatter, slag,

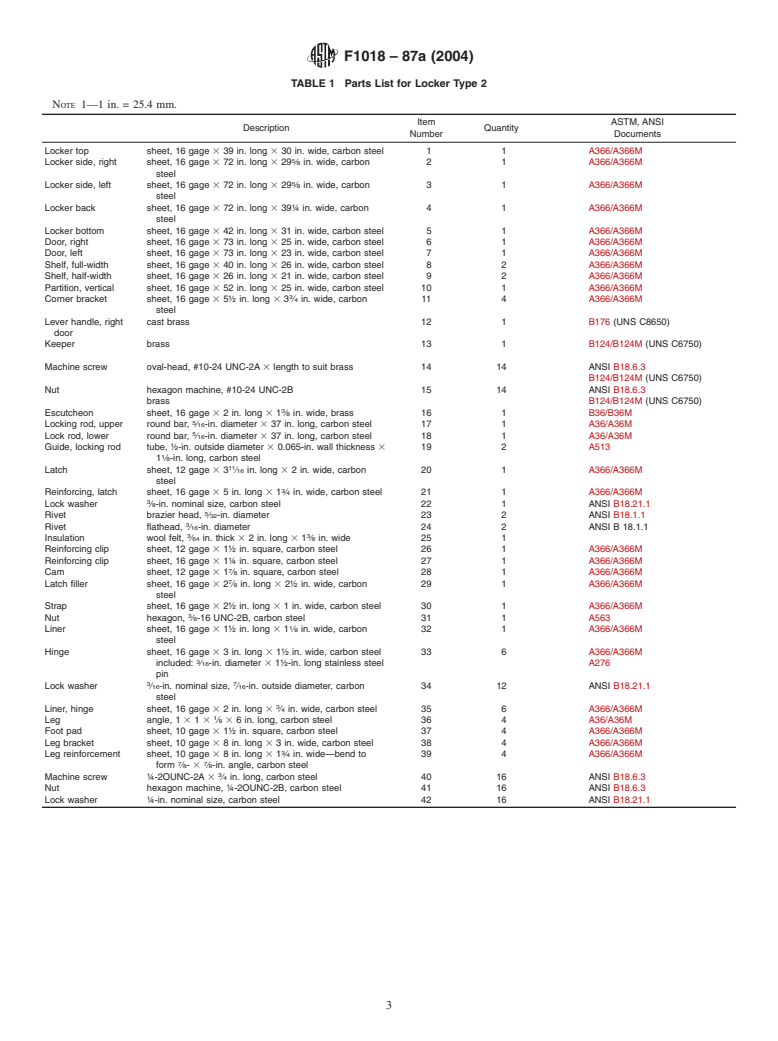

5.1 Materials—Materials shall be as specified in Table 1.

splinters, sharp edges, burrs, projections, and other defects that

5.2 Manufacture: may be hazardous to personnel.

7.2 The locker shall be cleaned after assembly to a com-

5.2.1 Mandatory dimensions and construction details for

mercial finish in accordance with SSPC-SP6.

Types 1 and 2 are as depicted in Figs. 1-9.

7.3 Unless otherwise required by the ordering documents,

5.2.2 Mandatory dimensions forTypes 3 and 4 are as shown

the unit shall have the manufacturer’s standard baked-on

in Fig. 2, Fig. 3, and Fig. 5, respectively, and applicable details

enamel finish.

ofSections“A-A’’and“B-B.’’Alternativeconstructiondetails

7.3.1 Thecolorshallbespecifiedintheorderingdocuments.

are permissible.

8. Keywords

5.2.3 Construction details depicted in Figs. 4-9, while spe-

cifically referring to locker Type 2, shall be adapted to suit

8.1 emergency gear; fireman’s locker; fireman’s outfit;

locker Type 1. locker; steel locker; stowage locker

F1018 – 87a (2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.