ASTM B394-03

(Specification)Standard Specification for Niobium and Niobium Alloy Seamless and Welded Tubes

Standard Specification for Niobium and Niobium Alloy Seamless and Welded Tubes

ABSTRACT

This specification covers wrought niobium and niobium alloy seamless and welded tubes. Material covered by this specification shall be made from ingots that are produced by vacuum or plasma arc melting, vacuum electron-beam melting, or a combination of these three methods. Seamless tubes may be made by any seamless method that will yield a product meeting the requirements of this specification. Welded tubing shall be made from flat-rolled products by an automatic or semiautomatic welding process with no addition of filler metal in the welding operation. The niobium and niobium alloy ingots and billets for conversion to finished products covered by this specification shall conform to the requirements for chemical composition of the following elements: carbon, nitrogen, oxygen, hydrogen, zirconium, tantalum, iron, silicon, tungsten, nickel, molybdenum, hafnium, titanium. When specified, the following elements shall be included in the chemical composition of the specimen: boron, aluminum, beryllium, chromium, and cobalt. The materials supplied under these specifications shall be in the fully annealed condition. Finished niobium and niobium alloy tubes shall be free of injurious internal and external imperfections of a nature that will interfere with the purpose for which it was intended. Hydrostatic and pneumatic tests are optional when the purchaser requires. A hydrostatic test shall be performed on each tube and shall withstand without showing bulges, leaks, or other defects.

SCOPE

1.1 This specification covers wrought niobium and niobium alloy seamless and welded tubes as follows:

Note 1—Committee B10 has adopted "niobium" as the designation for Element No. 41, formerly named "columbium."

1.1.1 R04200-Type 1 Reactor grade unalloyed niobium,

1.1.2 R04210-Type 2 Commercial grade unalloyed niobium,

1.1.3 R04251-Type 3 Reactor grade niobium alloy containing 1 % zirconium, and

1.1.4 R04261-Type 4 Commercial grade niobium alloy containing 1 % zirconium.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test methods portion of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B394 – 03

Standard Specification for

1

Niobium and Niobium Alloy Seamless and Welded Tubes

This standard is issued under the fixed designation B394; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 lot—a lot shall consist of all material produced from

the same ingot at one time, with the same cross section,

1.1 This specification covers wrought niobium and niobium

processed with the same nominal metallurgical parameters and

alloy seamless and welded tubes as follows:

heat treated at the same conditions.

NOTE 1—Committee B10 has adopted “niobium” as the designation for

Element No. 41, formerly named “columbium.”

4. Ordering Information

1.1.1 R04200-Type 1—Reactor grade unalloyed niobium,

4.1 Orders for materials under this specification shall in-

1.1.2 R04210-Type 2—Commercial grade unalloyed nio-

clude the following information as applicable:

bium,

4.1.1 Type and grade (Section 1),

1.1.3 R04251-Type 3—Reactor grade niobium alloy con-

4.1.2 ASTM designation and year of issue,

taining 1 % zirconium, and

4.1.3 Welding (Section 5),

1.1.4 R04261-Type 4—Commercial grade niobium alloy

4.1.4 Quantityinweight,numberofpieces,anddimensions,

containing 1 % zirconium.

4.1.5 Chemistry (6.3),

1.2 The values stated in inch-pound units are to be regarded

4.1.6 Temper designation (Section 8),

as the standard. The values given in parentheses are for

4.1.7 Permissiblevariationsinlengthandquantityorweight

B

information only.

(9.2, 9.4, and Table 1 ),

1.3 The following precautionary caveat pertains only to the

4.1.8 Quality and finish (10.4),

test methods portion of this specification. This standard does

4.1.9 Sampling (11.2),

not purport to address all of the safety concerns, if any,

4.1.10 Hydrostatic or pneumatic test (14.2),

associated with its use. It is the responsibility of the user of this

4.1.11 Inspection (Section 15),

standard to establish appropriate safety and health practices

4.1.12 Required reports (Section 17), and

and determine the applicability of regulatory limitations prior

4.1.13 Additions to the specification and supplementary

to use.

requirements, as required.

2. Referenced Documents

5. Materials and Manufacture

2

2.1 ASTM Standards:

5.1 Material covered by this specification shall be made

B391 Specification for Niobium and Niobium Alloy Ingots

from ingots that conform to Specification B391 and that are

3

produced by vacuum or plasma arc melting, vacuum electron-

E8 Test Methods for Tension Testing of Metallic Materials

beam melting, or a combination of these three methods.

4

5.2 Seamless tubes may be made by any seamless method

E29 Practice for Using Significant Digits in Test Data to

that will yield a product meeting the requirements of this

Determine Conformance with Specifications

specification, such as, but not limited to, extrusion of billets

with subsequent cold working by drawing, swaging, or rock-

3. Terminology

ing, with intermediate anneals, until the final dimensions are

3.1 Definitions of Terms Specific to This Standard:

reached.

5.3 Welded tubing shall be made from flat-rolled products

1

by an automatic or semiautomatic welding process with no

This specification is under the jurisdiction of ASTM Committee B10 on

Reactive and Refractory Metals and Alloys and is the direct responsibility of

additionoffillermetalintheweldingoperation.Othermethods

Subcommittee B10.03 on Niobium and Tantalum.

ofwelding,suchastheadditionoffillermetalorhandwelding,

Current edition approved Sept. 10, 2003. Published September 2003. Originally

may be employed if approved by the purchaser and tested by

approved in 1989. Last previous edition approved in 1999 as B394 - 99. DOI:

10.1520/B0394-03. methods agreed upon between the manufacturer and the

2

Annual Book of ASTM Standards, Vol 02.04.

purchaser. The manufacturer must use proper precautions to

3

Annual Book of ASTM Standards, Vol 03.01.

prevent contamination during welding.

4

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B394 – 03

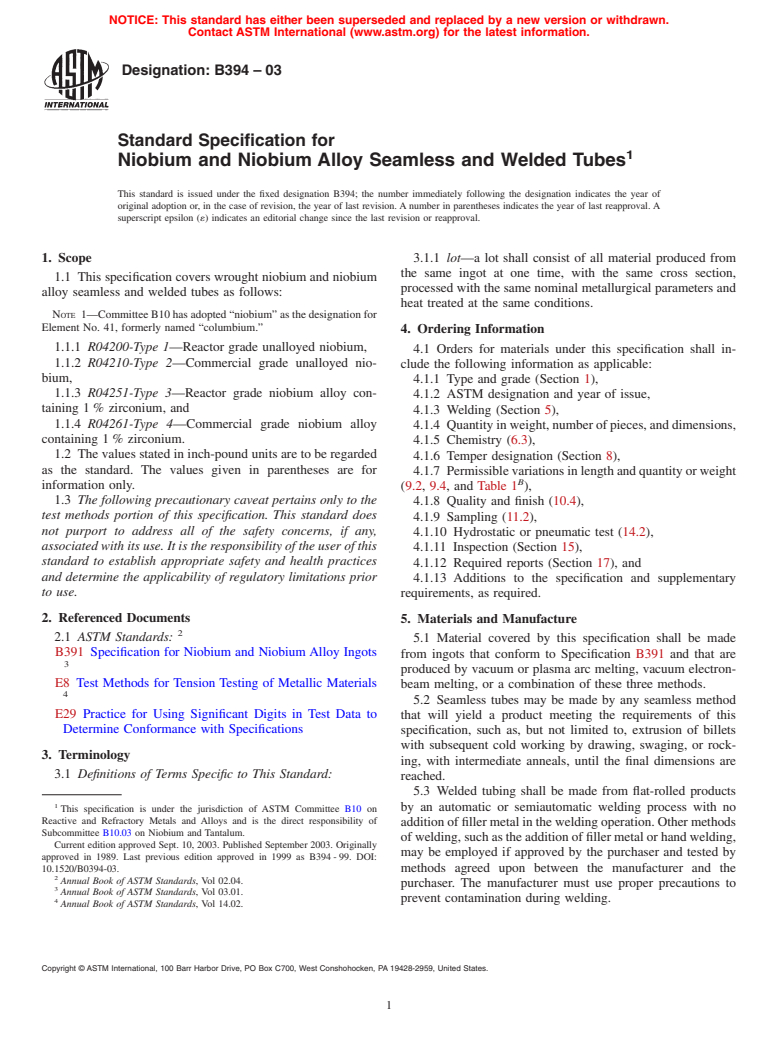

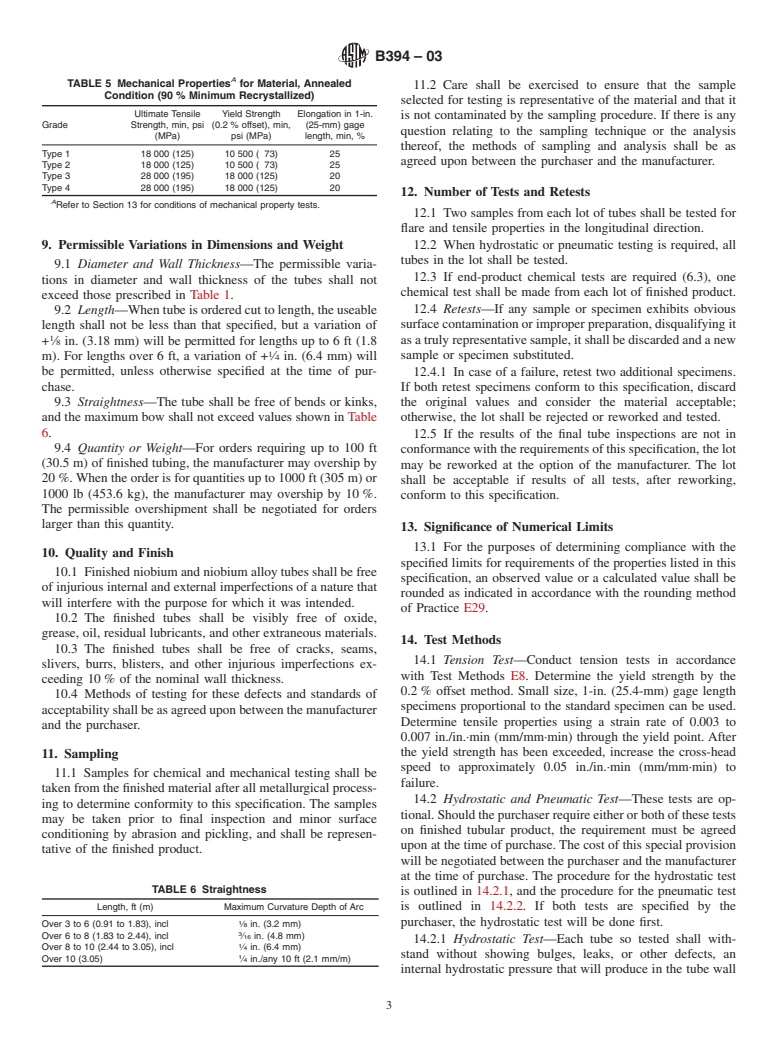

TABLE 1 Permissible Variations in Diameter and Wall Thickness

A

Measured at any Location

Variation in Variation in

Outside Inside Variation in

Nominal Outside Diameter, Diameter, Diameter, Wall Thickness,

B

in. (mm) Over and Over and Over and

C,D

Under, in. Under, in. Under, %

B C

(mm) (mm)

0.187 to 0.625 (4.7 to 15.9), excl 0.004 (0.010) 0.004 (0.010) 10

0.625 to 1.000 (15.9 to 25.4), excl 0.005 (0.13) 0.005 (0.13) 10

1.000 to 2.000 (25.4 to 50.8), e

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.