ASTM D5275-92(1998)e1

(Test Method)Standard Test Method for Fuel Injector Shear Stability Test (FISST) for Polymer Containing Fluids

Standard Test Method for Fuel Injector Shear Stability Test (FISST) for Polymer Containing Fluids

SCOPE

1.1 This test method measures the percent viscosity loss at 100°C of polymer-containing fluids using fuel injector shear stability test (FISST) equipment. The viscosity loss reflects polymer degradation due to shear at the nozzle. Note 1-Test Method D2603 has been used for similar evaluation of this property. It has many of the same limitations as indicated in the significance statement. No detailed attempt has been undertaken to correlate the results by the sonic and the diesel injector methods. Equipment and replacement parts are no longer available for Test Method D2603 as it is currently written. The test method is currently under revision. Note 2-This test method was originally published as Procedure B of Test Methods D3945. The FISST method was made a separate test method after tests of a series of polymer-containing fluids showed that Procedures A and B of Test Methods D3945 often give different results.

1.2 The values given in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: D 5275 – 92 (Reapproved 1998)

Standard Test Method for

Fuel Injector Shear Stability Test (FISST) for Polymer

Containing Fluids

This standard is issued under the fixed designation D 5275; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial corrections were made in January 1998.

1. Scope 3. Summary of Test Method

1.1 This test method measures the percent viscosity loss at 3.1 The polymer-containing fluid is passed through a diesel

100°C of polymer-containing fluids using fuel injector shear injector nozzle at a shear rate that causes the less shear stable

stability test (FISST) equipment. The viscosity loss reflects polymer molecules to degrade. The resultant degradation

polymer degradation due to shear at the nozzle. reduces the kinematic viscosity of the fluid under test. The

reduction in kinematic viscosity, reported as percent loss of the

NOTE 1—Test Method D 2603 has been used for similar evaluation of

initial kinematic viscosity, is a measure of the shear stability of

this property. It has many of the same limitations as indicated in the

the polymer-containing fluid.

significance statement. No detailed attempt has been undertaken to

correlate the results by the sonic and the diesel injector methods.

4. Significance and Use

Equipment and replacement parts are no longer available for Test Method

D 2603 as it is currently written. The test method is currently under

4.1 This test method evaluates the percent viscosity loss for

revision.

polymer-containing fluids resulting from polymer degradation

NOTE 2—This test method was originally published as Procedure B of

in the high shear nozzle device. Minimum interference from

Test Methods D 3945. The FISST method was made a separate test

thermal or oxidative effects are anticipated.

method after tests of a series of polymer-containing fluids showed that

4.2 This test method is not intended to predict viscosity loss

Procedures A and B of Test Methods D 3945 often give different results.

in field service for different polymer classes or for different

1.2 The values given in SI units are to be regarded as the

field equipment. Some correlation for a specific polymer type

standard. The inch-pound units given in parentheses are for

in specific field equipment can be possible.

information only.

1.3 This standard does not purport to address all of the

5. Apparatus

safety concernss, if any, associated with its use. It is the

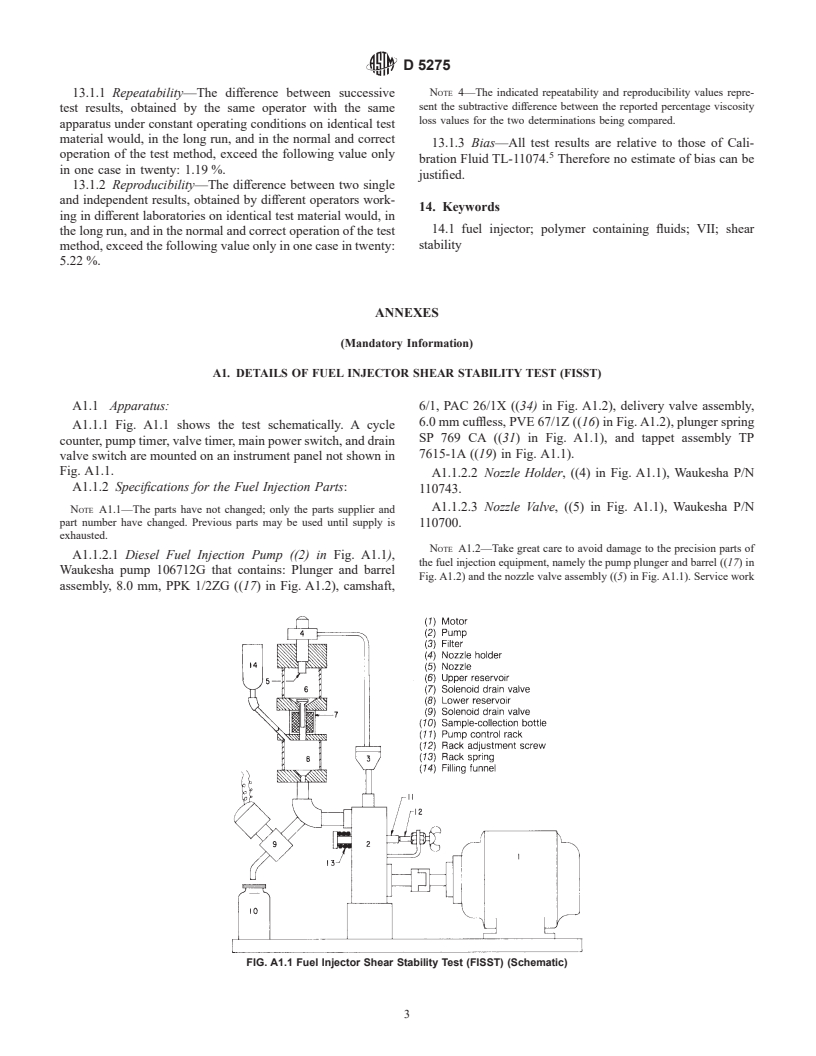

5.1 The apparatus consists of two fluid reservoirs, a single-

responsibility of the user of this standard to establish appro-

plunger diesel fuel injection pump with an electric motor drive,

priate safety and health practices and determine the applica-

a pintle-type fuel injection nozzle installed in a nozzle holder,

bility of regulatory limitations prior to use. Specific precau-

and instrumentation for automatic operation. Annex A1 con-

tionary statements are given in Section 7.

tains a more complete description of the apparatus.

2. Referenced Documents

6. Reference Fluids

2.1 ASTM Standards:

6.1 Diesel fuel is required for adjusting the nozzle valve

D 445 Test Method for Kinematic Viscosity of Transparent

assembly to the prescribed valve opening pressure.

and Opaque Liquids (and the Calculation of Dynamic

6.2 Calibration fluid TL-11074 is used to verify that the

Viscosity)

shearing severity of the apparatus is within the prescribed

D 2603 Test Method for Sonic Shear Stability of Polymer-

limits.

Containing Oils

D 3945 Test Methods for Shear Stability of Polymer-

7. Precautions

Containing Fluids Using a Diesel Injector Nozzle

7.1 During operation, the line between the pump and the

nozzle holder is under high pressure. The safety shield should

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee A suitable source of supply for the entire apparatus and spare parts (injectors)

D02.07.0B on High Temperature Rheology of Non-Newtonian Fluids. is Falex Corporation, 1020 Airpark Dr., Sugar Grove, IL 60554. Complete working

Current edition approved Aug. 15, 1992. Published October 1992. drawings and specifications may be obtained from ASTM Headquarters. Request

Annual Book of ASTM Standards, Vol 05.01. PCN 12-439450-12.

3 5

Annual Book of ASTM Standards, Vol 05.02. Available from Texaco Incorporated, P.O. Box 509, Beacon, NY 12508.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5275

be in place when the apparatus is running. Stop the apparatus 10.2 Flush the apparatus with three separate 100 cm

before tightening any fitting that is not properly sealed. portions of the test oil as described in 10.2.1 and drain. Do not

7.2 During operation and during the setting of the valve use solvent as part of the flush at any time because it could

opening pressure, the fluid is discharged from the nozzle at cause contamination.

high velocity and can inflict a serious wound if it strikes a part 10.2.1 Pour the first 100 cm charge of test oil into the lower

of the human body. Therefore, secure the nozzle assembly in reservoir, (8) in Fig. A1.1, through the funnel (14). Set the

position before the test apparatus is started. Similarly, take care cycle counter for three cycles of the fluid through the nozzle,

to shield the operator from the nozzle discharge during the the pump timer for 15 s and the valve time for 20 s.

pressure-setting step.

NOTE 3—These timer settings have been found satisfactory for all oils

normally tested. The pump time should be sufficient for all oil to be

8. Sampling

pumped through the nozzle and into the upper reservoir, (6) in Fig. A1.1.

The valve time should be sufficient for the oil to drain completely from the

8.1 The test fluid shall be at room temperature, uniform in

upper reservoir to the lower reservoir.

appearance and free of any visible insoluble material prior to

placing in the test equipment. 10.2.2 Start the pump, (2) in Fig. A1.1, and run until three

8.2 After the test fluid has completed its twentieth cycle cycles have been completed. Drain and discard the sheared oil.

through the apparatus, drain it into a bottle for transfer to the 10.2.3 Similarly, run the second 100 cm for two cycles and

kinematic viscosity measurement. the third 100 cm flush for one cycle, draining and discarding

each flush.

9. Calibration 10.3 Pour 100 cm of the test oil into the lower reservoir

through the funnel. Set the cycle counter for 20 cycles. Set a

9.1 Set the valve opening pressure of the diesel injector

clean 120 cm (4 oz) bottle, (10) in Fig. A1.1, under the drain

nozzle assembly to 20.7 6 0.35 MPa (3000 6 50 psi) by means

tube of the lower reservoir to receive the sheared sample. Start

of a hand-actuated pump and diesel fuel.

the pump and run until the 20 cycles have been completed. At

9.2 Set the delivery rate of the pump to 534 6 12 cm /min

the end of the twentieth cycle, both drain valves, (7) and (9)in

by the procedure described in Annex A1.

Fig. A1.1, open automatically and the sample drains into the

9.3 Verify the shearing severity of the apparatus by running

collection bottle, (10).

the standard test procedure, described in 9.3.1, with reference

10.4 Measure the kinematic viscosity of the sheared oil and

oil. Make this check every twentieth run when the apparatus is

a sample of the unsheared oil at 100°C by Test Method D 445.

used frequently. Make this check before any other samples are

tested if the apparatus has been idle for a week or more. The

11. Calculation

kinematic viscosity at 100°C for the sheared reference oil is to

be within the limits prescribed for the specific batch of the 11.1 Calculate the percentage loss of viscosity of the

reference oil in use. For Batch BRL-72-2751 of TL-11074, the sheared oil as follows:

limits are 9.64 and 9.94 mm /s (cSt) at 100°C.

VL 5 100 3 ~V 2 V !/V (1)

u s u

9.3.1 If the viscosity of the sheared oil does not fall within

the above limits, make another shear test of the reference oil by where:

VL = viscosity loss, %,

the standard procedure. If the viscosity of the sheared oil still

V = kinematic viscosity of unsheared oil at 100°C, mm /s

does not fall within the limits, take steps to correct the rating u

(cSt), and

level of the test. Either mechanical difficulty or test technique

V = kinematic viscosity of sheared oil at 100°C, mm /s

is at fault. s

(cSt).

10. Procedure

12. Report

10.1 Shearing is accomplished by pumping the entire 100

12.1 Report the following information:

cm test oil charge through the nozzle in successive passes or

12.1.1 Percentage viscosity loss as calculated in 11.1,

cycles. One cycle consists of pumping the oil from the lower

12.1.2 Kinematic viscosity of the unsheared oil at 100°C,

reservoir (8) in Fig. A1.1, through the nozzle (5), and into the

12.1.3 Kinematic viscosity of the sheared oil at 100°C,

upper reservoir (6). At the end of each cycle, when the entire

12.1.4 Number of cycles,

test oil charge has been collected in the upper reservoir (6), the

12.1.5 For reference oil runs, the batch number of the

pump (2) stops and the solenoid-operated drain valve (7)

reference oil, and

opens, draining the oil into the lower reservoir (8). The pump

12.1.6 Specify this test method (ASTM D5275).

then restarts automatically for the next cycle. This process

repeats for the number of cycles that have been set on the cycle

13. Precision and Bias

counter. At the end of the last cycle, both solenoid-operated

drain valves, (7) and (9) in Fig. A1.1, open and the test oil 13.1 The following criteria should be used for judging the

acceptability of results:

drains into the sample collection bottle (10).

6 7

Suitable source of supply is Waukesha Engine Div., 1000 W. St .Paul Ave., Support data available from ASTM Headquarters. Request RR: D02-1131. This

Waukesha, WI 53188. Part No. G-818–7. test method was formerly Procedure B of Test Method D 3945.

D 5275

NOTE 4—The indicated repeatability and reproducibility values repre-

13.1.1 Repeatability—The difference between successive

sent the subtractive difference between the reported percentage viscosity

test results, obtained by the same operator with the same

loss values for the two determinations being compared.

apparatus under constant operating conditions on identical test

material would, in the long run, and in the normal and correct

13.1.3 Bias—All test results are relative to those of Cali-

operation of the test method, exceed

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.